A drilling machine for printed circuit boards belongs to the category of mini-equipment for special purposes. If desired, you can make such a machine yourself using available components. Any specialist will confirm that it is difficult to do without the use of such a device in the production of electrical products, the circuit elements of which are mounted on special printed circuit boards.

Simple mini PCB machine

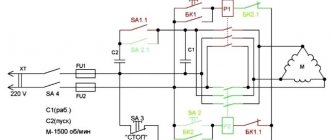

Motor speed controller

To control the rotation speed of the 12-volt DC motor, on which the miniature drilling machine is built, this PWM module was purchased. Its cost on Aliexpress was 108 rubles, excluding delivery costs in the fall of 2022.

Module characteristics:

- Operating voltage: DC6V-DC28V

- Power control: 0.01-80W

- Maximum current: 3A

- Quiescent current: 0.01A (standby)

- PWM duty cycle: 0%-100%

- PWM frequency: 15 kHz

- Board size: 32mm * 50mm * 15mm

During operation, a red SMD LED lights up on the module, which changes the brightness of the light in accordance with the selected power mode.

The module circuit is based on chips and microcircuits:

- LR8726 (IOR) - 30V, HEXFET Power MOSFET.

- S10 45 GKIKG412 (ST) - It is possible that this is a Schottky Barrier Rectifier (current rectifier) 45V 5A.

- NE555 is a universal timer - a chip for generating single and repeating pulses.

A small heatsink was installed on top of the elements with the TO252 housing, but there was no thermal interface in the form of thermal paste. In addition, the surface of the radiator was not smooth enough.

These shortcomings were easily eliminated - the radiator was sanded and KPT-8 thermal paste was applied. However, newer revisions of these modules do not have such a heatsink, and the descriptions on the sellers’ pages indicate that the device can safely operate like this.

December 15, 2022. Additions February 7, 2022.

GTXpert

| Shopping with ALME.RU is an easy way to get an additional discount (cashback) on Aliexpress and other stores. |

A simple machine for drilling printed circuit boards.

The easiest way to drill PCBs is by holding a motor with a drill chuck attached in your hands. At the same time, drills broke more than once, and every radio amateur scolded himself in his thoughts, and the next time when making a “signet” he definitely wanted to change something in this process. Everyone decides for themselves whether to make something from improvised means or purchase a ready-made one. It all depends on the place of residence of the radio amateur. For example, in rural areas far from large centers, the best way out of this situation is to make a machine yourself.

The main requirement for such a machine is that it cope with its task, and its manufacture does not require complex turning parts, since not everyone has the opportunity to have access to a lathe. I offer you a simple design of a drilling machine for a home workshop, which I saw on the Internet, and which will not be difficult to repeat at home. Unfortunately, I don’t know the author of this design, and if he turns up, I will be happy to indicate his name here and express my gratitude for the simple design. Machine dimensions; base 140x90 mm, height 150 mm. It copes with its task quite well and takes up very little space on the desktop. With such dimensions, it allows you to drill holes in boards up to 150-170 mm wide. (the length of the board is not limited), which is quite sufficient in amateur radio practice.

The base of the machine is made of any available material, with a thickness of at least 6-8 mm. Can be made from textolite, getinaks, metal, plywood. If you take plywood, it is better to have a thickness of at least 10 mm. The dimensions of the base are indicated above, but you can change these dimensions for your needs, both the base and other parts. In the future I will simply indicate my sizes. The entire structure is assembled on a U-shaped stand, for which it is necessary to take thick material so that the entire structure does not spring and has sufficient strength.

This design uses a metal strip 25 mm wide. and 4-5mm thick. Its total length is 140-150 mm. Bent in a U-shape, attachment to the base 30mm, height 40mm and the remaining length is 70-80mm. Three holes are drilled in the rack, one at the bottom for attaching it to the base, and two at the top for vertical pins. Long pin 100 mm long, diameter 5 mm.

A spring is placed on a long pin. The short pin is threaded on both sides, for attaching the pin to the stand and at the top for the locknut. The moving part with the motor attached to it moves on these two pins. The spring must be so rigid that it lifts the weight of the moving part with the engine.

The moving part is made of a metal strip, at least 1.5-2.0 mm thick and 20 mm wide. The total length of the strip is 100 mm, the fold dimensions are 20x40x40 mm. A through hole is drilled for the thick pin and a hole for the thin pin. By the way, the pins can be made of the same diameter, the main thing is that the material is sufficiently rigid, for example, shafts from dot matrix printers. The clamp for mounting the engine is made according to the diameter of the existing engine and is made of sheet aluminum. I have an engine used for the DPM-30 machine.

To power such an engine, a 12-volt source is sufficient, and most importantly, it is necessary to make a motor control circuit for it. This is so that without load the motor rotates slowly and when the drill touches the board, it starts working at full power. There are as many such schemes as you like, for example you can choose from here. In my opinion, it is better to collect the latter. Although, to be honest, I still use it myself without such a circuit, I have an adjustable power supply and during pauses I simply remove the voltage.

Dual spindle machine

A two-spindle machine is used to bore holes on both sides and turn the ends of parts. But there are several nuances in this equipment that are worth getting acquainted with:

- The OS-402A vertical double-spindle deep drilling machine has a stepped and automatic drilling cycle.

- To increase its own productivity, a double-spindle rotary milling unit has been developed.

- The design of a two-spindle machine for lapping reinforcement was designed and manufactured at the Lenenergo enterprise.

- To screw two threaded parts simultaneously from both ends of the roller, a two-spindle unit with a mechanical drive with a horizontal spindle was manufactured at another production facility.

- The three-spindle unit type C - 13 and the unit type C - 12 are similar in technical characteristics and design. But there is also a difference between the machines, where the table of a two-spindle machine has a shorter length.

- There are rotary table surface grinders with one or two spindles. The difference is that with a dual-spindle machine, one spindle is used for preliminary grinding and the other is used for final grinding.

- Devices for rolling rods and fillets on shafts are in great demand among the population. Only in some cases can one count on the simultaneous rolling of two shafts on their side for a two-spindle machine; the installation of a special valve is also present on the machine.

- The specialized machine has manual control and, thanks to the 4723D model, a mechanical drive. The machine is also used for multi-position processing of many parts. Its kit includes the following: a machine tool, a machine generator of unipolar pulses, a high-frequency electronic semiconductor generator. In contrast to this model, the double-spindle machine is reinforced with an L-shaped traverse.

It is worth noting that each dual-spindle unit represents the most powerful equipment for any workshop, which any master should use.

Homemade plywood machine

A drilling machine made of metal is durable and reliable. However, not every craftsman has a welding machine.

Therefore, we offer an alternative option - to make the frame and main parts of the drilling machine from plywood.

Please note: to assemble a homemade drilling machine, the author uses MDF, but it is better to use plywood.

Necessary materials:

- plywood;

- furniture guides;

- edged board;

- plastic legs;

- fastening clamp;

- metal plate.

First of all, we take two furniture guides, and after removing the internal movable slats, we screw them to the plywood blocks. The bars themselves will need to be secured to a wide piece, as shown in the photo.

Next, we take another pair of furniture rails - we screw them to the plywood platform between the side rails (we also remove the internal movable strips).

We make a mount for a drill. You must first cut off a metal plate and weld a clamp to it. Additionally, we make reinforcement using round or square rods (this is the only operation where welding is used).

Now you will need to make a movable platform. We saw off a piece of plywood of the required size and screw the internal strips of the furniture rails to it. We connect both parts of the structure together.

Another plywood board must be screwed to the movable platform, to which a metal plate with a clamp is attached.

After this, we cut out the base of the drilling machine and screw plastic legs to its lower part.

Next, we install a stand made of edged boards. The previously assembled structure must be attached to the rack.

Install the return spring. We fix the electric drill or screwdriver in the clamp.

Do-it-yourself mini electric drill - very simple and fast

And again, good day to all, dear enthusiasts of homemade devices, tools and other mechanisms.

Today I am pleased to share with you a simple method for making a simple, budget-friendly option for making a mini electric drill. Then we will consider with you the identified pros and cons of the resulting product. The mini drill has become widespread and is used to perform an incredibly large number of tasks at home, in the garage, in the country or for repairs. A mini drill is used for a wide variety of small jobs. In particular, it is used for drilling electrical printed circuit boards; a conventional electric drill is completely unsuitable for such work. A mini drill equipped with special attachments can be used as an engraver, a grinder or a router. To use it in this capacity, special nozzles with a rough working surface are used. During operation, the nozzle processes the part or applies the required pattern to the product being processed. Of course, a mini drill will not be able to handle thick iron, but a hole in a metal sheet up to one millimeter thick will be enough to drill. There are an unimaginable variety of options for making a mini-drill with your own hands. Everything fits into your flight of imagination, fantasy and is limited solely by the components available to you for making a drill. So your imagination is limited only by your spare parts bins. The heart of any mini drill is a small but quite powerful electric motor. Also, for the manufacture of our mini drill, you will need a collet chuck (a collet chuck is a type of drill chuck. They hold the drill in the drill during the drilling process. The quality of the work performed by the electric drill depends on the quality of the collet chuck and, accordingly, the fastening of the drill to the electric motor. Therefore, the choice of collet cartridge should be approached with all responsibility), it is quite problematic to make a high-quality collet cartridge on your own at home, so it is better to purchase it in a store. Standard chucks (with collets for drills with a diameter of 0.5 to 3.2 millimeters) can be found in any online store at an affordable price, the price varies from 100 to 150 Russian rubles

An important part of the mini drill, where all the components are placed and attached, is the body. There are many options, in our case we use a pipe from a fan pipe, the inner diameter of which perfectly matches the outer diameter of the electric motor

When fixed in the housing, the engine stood up with virtually no gaps. Connecting electrical wires are selected based on the power of the drill, but due to the fact that we are using an electric motor with low power consumption, we select insulated electrical wires of small cross-section. For high-quality soldering of an electrical circuit, we will need soldering acid and tin rods, a soldering iron or connectors. Almost any novice DIY enthusiast can assemble a mini drill on their own. It's a matter of desire and perseverance. As always, about observing safety precautions when working with high-risk tools. Work carefully. Following all safety regulations. Do not taste electricity with your tongue, do not stick your fingers where the dog does not stick its tail. Before any action, turn on your brain. And then, take my word for it, each member of your friendly family, including the dog, will have their own mini drill.

The procedure for assembling a homemade device

As practice shows, it is most convenient to assemble a homemade machine for drilling holes in printed circuit boards in a certain sequence. You must act in accordance with the following algorithm.

- The frame is installed, and legs are attached to its underside, if they are provided for in the design.

- A movement bar and a holder frame on which the drilling head will be mounted are attached to the assembled frame.

- The holder frame is connected to a shock absorber, which is also fixed to the equipment frame.

- A handle for controlling the movement of the drilling head is installed, connected to a shock absorber or holder frame.

- An electric motor is mounted, the position of which is carefully adjusted.

- A collet or a universal drill chuck is attached to the shaft of the drive motor using adapters.

- A power supply connected to the electric motor via electrical wires is being installed.

- A drill is installed in the chuck and securely fixed in it.

- The assembled homemade machine is tested by trying to drill a hole in a dielectric sheet with its help.

To ensure that your homemade mini-drilling machine can always be disassembled and modified, it is best to use bolts and nuts to connect its structural elements.

If you want to make your own mini-equipment for making holes in printed circuit boards, you can always use the drawings and advice of those who already own such a machine and are actively working on it in their home workshop.

Parts for assembly

- Engine with chuck and collet. On the one hand, a jaw chuck is very convenient, but on the other hand, it is much more massive than a collet clamp, that is, it is often subject to beats and very often they have to be additionally balanced.

- Plywood parts. A link to files for laser cutting in dwg format (prepared in NanoCAD) can be downloaded at the end of the article. You just need to find a company that deals with laser cutting of materials and give them the downloaded file. I would like to note separately that the thickness of the plywood may vary from case to case. I come across sheets that are a little thinner than 5mm, so I made the grooves 4.8mm each.

- 3D printed parts. A link to files for printing parts in stl format can also be found at the end of the article

- Polished shafts with a diameter of 8mm and a length of 75mm - 2 pcs. Here is a link to the seller with the lowest price for 1m that I saw

- Linear bearings 8mm LM8UU - 2 pcs.

- Microswitch KMSW-14

- Screw M2x16 - 2 pcs.

- Screw M3x40 h/w – 5 pcs.

- Screw M3x35 slot - 1 pc.

- Screw M3x30 h/w – 8 pcs.

- Screw M3x30 h/w with countersunk head - 1 pc.

- Screw M3x20 h/w - 2 pcs.

- Screw M3x14 h/w - 11pcs

- Screw M4x60 slot - 1 pc.

- Bolt M8x80 - 1 piece

- Nut M2 - 2 pcs.

- M3 square nut – 11pcs

- Nut M3 – 13pcs

- M3 nut with nylon ring - 1 pc.

- Nut M4 - 2 pcs.

- M4 square nut – 1 piece

- M8 nut – 1 piece

- Washer M2 - 4 pcs

- Washer M3 – 10pcs

- M3 washer enlarged - 26 pcs.

- M3 locking washer – 17 pcs.

- M4 washer - 2 pcs.

- M8 washer - 2 pcs.

- M8 locking washer – 1 piece

- Set of installation wires

- Heat shrink tube set

- Clamps 2.5 x 50mm - 6 pcs

Add-ons

Other people who have already assembled such a machine made many suggestions. If you allow me, I will list the main ones, leaving them in their original form:

- By the way, it would be good to remind those who have never worked with such parts before that plastic from 3D printers is afraid of heat. Therefore, you should be careful here - you should not go through holes in such parts with a high-speed drill or Dremel. Handles, hands...

- I would also recommend installing the microswitch at a very early stage of assembly, since you still need to be able to screw it to an already assembled frame - there is very little free space. It would also not hurt to advise craftsmen to at least tin the microswitch contacts in advance (or even better, solder the wires to them in advance and protect the soldering points with pieces of heat-shrink tubing), so that later during soldering they do not damage the plywood parts of the product.

- Apparently I was lucky and the chuck on the shaft was not centered, which led to serious vibration and hum of the entire machine. I managed to fix it, but it's not a good option. Since the rotor axis bends, and it is no longer possible to remove the cartridge, there are fears that I will pull out this very axis entirely.

- Tighten the screws with locking washers as follows. Tighten the screw until the lock washer closes (straightens). After this, turn the screwdriver 90 degrees and stop.

- Many people advise attaching a speed regulator to it according to Savov’s scheme. It turns the engine slowly when there is no load, and increases speed when load appears.

DIY drilling machine

What to do if you don’t have a drilling machine for printed circuit boards at home? Of course, it’s expensive to buy, and it happens that the machine is not needed for frequent use.

I offer you 2 simple ideas for making your own drilling machine with your own hands. The first option is very simple; to make it we will need an electric motor from cassette recorders.

Remember these? Such motors can be removed from any Chinese or Soviet-made tape recorder.

They look something like this:

So, we have an electric motor, we also need a drill of the required diameter, usually 0.7-1 mm, we need to take thin paste from a ballpoint pen, a thin thread of 10 centimeters, scissors and instant glue.

Is everything ready? Let's start collecting.

We take the scribbled paste from a ballpoint pen (you can use a new one) and cut off 15 mm, then we need to put it on the motor shaft a little less than half (6-7 mm). Then remove it with a screwdriver or tweezers and put it aside (although you don’t have to remove it).

We take a drill, wind a thread on it turn to turn in 2 layers, below is the photo:

Holding the end of the thread (so as not to unwind), apply a drop of second glue and quickly push the drill into the tube. If you hesitate, the glue will harden.

Here's what we got:

If the drill rotates crookedly, you simply bend the paste in the desired direction until the drill is centered, and you can start drilling your board

Second version of the drilling machine

Now I’ll tell you about the second version of the drilling machine, the one I use. Making it will be a little more difficult. I will not give detailed drawings with dimensions, because...

the machine was assembled from what we have, let the article be for informational purposes only, but I will still describe the machine in photographs and schematically.

You can try to assemble a similar machine for yourself using my drawings. This machine looks like this:

- It is built on a lever mechanism, when pressed, the motor and the drill are lowered, and if the lever is released, the motor rises up again.

- Here is a photo of the mechanism itself:

The lifting and lowering part is made of sheet metal, the sheet is cut to the desired shape, bent and holes are drilled. Instead of the bent rod shown in the photo, you can use something similar, for example, replace it with two long M4 screws with a thread at the end.

- Mechanism drawings:

- Drawing of the lifting mechanism.

- To avoid confusion, I drew the lifting and lever mechanisms separately

- This is what you get if you combine the two top pictures

- I think the essence is clear and now, using my sketches, if you wish, you can put together something similar, I gave you the idea, so go for it!

I also want to give a little advice about drills, drills become dull very quickly and begin to drill poorly, if you don’t have a sharpening machine, then why not throw them away? I found the following way out of this situation: we take a drill and carefully break off the end of the drill with pliers (a millimeter or a little more), and we don’t need to break it off haphazardly, as correctly shown in the pictures below.

Materials and tools for making the machine

Before starting work, you need to think through the sequence of all technological operations in the manufacture of a homemade machine, plan the manufacturing technology, decide on future materials and tools that will be needed during the work process.

To make a machine with your own hands, you will need the following materials and components:

- Plywood 15 mm.

- Pine board, solid;

- Furniture drawer guides;

- Sleeve;

- Furniture footwear;

- Wing nut;

- Fastening: M6 bolt, self-tapping screws of various lengths.

To make a machine from a drill or screwdriver, you will need the following tool:

- Circular saw or sawing machine.

- Jigsaw.

- Angle grinder (angle grinder or simply “grinder”).

- Drill or screwdriver.

- Grinding machine.

- Various hand tools: hammer, screwdriver, clamps, wood core drill (or simply “crown”), square, marking pencil, etc.

Design

At first glance, the scheme seems complicated, however, it is not. In fact, the mini machine is not very different from the classic one; it is smaller in size with some nuances in the design layout.

Since this equipment is not large in size, it should be considered as desktop equipment. The homemade version of the equipment is usually slightly larger than the purchased one, due to the fact that when assembling it yourself, it is not always possible to optimize the design by selecting small-sized components. But even in this case, the homemade machine will have small dimensions and weight no more than 5 kg.

Assembly video

Elements of a drilling machine

To assemble a mini device with your own hands, you will need the following:

- Bed;

- Transitional stabilizing frame;

- Bar for moving;

- Shock absorber;

- Height adjuster handle;

- Engine mount;

- Engine;

- Collet (or cartridge);

- Adapters.

It is worth noting that we are describing a homemade mini drilling machine, assembled from improvised materials with your own hands. The factory design is distinguished by the use of specialized components that are almost impossible to make with your own hands. The basis of a mini drilling unit, like any other, is the frame. It serves as the base on which all the nodes will be held. The frame can be a handy device, for example: the skeleton of a microscope; stand for linear measurements with a digital indicator.

Or you can make it yourself, for example, a light wooden frame - by connecting the boards with self-tapping screws, or a heavy and stable one - by welding a steel profile to a metal sheet. It is better when the weight of the frame is higher than the main weight of the other components, this increases the stability of the unit and reduces its vibration during operation.

Motors for PCB Drilling Machines

Another interesting scheme based on spare parts from a CD-ROM and a hair dryer with automatic adjustment of the engine speed depending on the load.

Homemade bed

When making a steel frame with your own hands, you can screw the legs under it to fix its position. The stabilizing frame can be made, for example, from a slats or corners, but it is better to use steel. The type of bar for moving can be chosen in any way, the most convenient, and at the same time better combine it with the shock absorber. In some cases, the shock absorber itself may be such a bar. The functions of these parts are to vertically displace the equipment during operation. You can make the shock absorber yourself or remove sliding slats from office furniture, or buy them in a store. The height adjuster handle is installed on the body, stabilizing rail or shock absorber. The motor mount is installed on the stabilizing frame, it could be, for example, a simple wooden block. It is needed to bring the motor to the required distance and securely fix it. Then the motor is installed directly on the mount. A chuck or collets are directly attached to the motor, to which adapters used for installing drills are attached. Adapters are selected individually, depending on the motor shaft, its power, type of drills, etc. In conclusion, we can say that the assembled mini drilling machine can be constantly modified during operation. For example, you can stick an LED strip on the chuck to illuminate the samples being drilled.

General information about drilling machines

Any drilling machine is necessary in order to ensure the ability to efficiently and accurately process parts made from various materials. Where high precision processing is required (and this also applies to the process of drilling holes), manual labor must be eliminated as much as possible from the technological process. Similar problems are solved by any drilling machine, including homemade ones. It is practically impossible to do without machine equipment when processing hard materials, for drilling holes in which the efforts of the operator himself may not be enough.

Design of a benchtop belt driven drill press (click to enlarge)

Any drilling machine is a structure assembled from many components that are securely and accurately fixed relative to each other on a supporting element. Some of these nodes are rigidly fixed to the supporting structure, and some can move and be fixed in one or more spatial positions.

An example of motors used in the manufacture of a homemade mini drilling machine

The basic functions of any drilling machine, through which the processing process is ensured, is the rotation and movement in the vertical direction of the cutting tool - the drill. On many modern models of such machines, the working head with the cutting tool can also move in a horizontal plane, which allows this equipment to be used for drilling several holes without moving the part. In addition, automation systems are being actively introduced into modern drilling machines, which significantly increases their productivity and improves processing accuracy.

Below, as an example, are presented several design options for homemade drilling machines for circuit boards. Any of these diagrams can serve as a model for your machine.

List of components

Here is a complete list of everything needed for assembly:

- Printed circuit board (link to manufacturing files at the end of the article)

- U1 - MC34063AD, switching regulator, SOIC-8

- U2 - LM358, operational amplifier, SOIC-8

- U3 - L78L09, stabilizer, SOT-89

- D1,D3 - SS14, Schottky diode, SMA - 2 pcs

- D2 - LL4148, rectifier diode, MiniMELF

- C1 - capacitor, 10uF, 50V, 1210

- C2 - capacitor, 3.3nF, 1206

- C3, C4 - capacitor, 4.7 µF, 1206 - 2 pcs

- C5 - capacitor, 22uF, 1206

- R1-R3,R7,R9,R11 - 1 Ohm resistor, 1206 - 6 pcs.

- R4, R10 - resistor 22 kOhm, 1206 - 2 pcs.

- R5 - 1kOhm resistor, 1206

- R6 - resistor 10-27 kOhm, 1206. The resistance depends on the rated voltage of the motor used. 12V - 10kOhm, 24V - 18kOhm, 27V - 22kOhm, 36V - 27kOhm

- R8 - resistor 390 Ohm, 1206

- RV1, RV2 - subscript resistor, 15 kOhm, type 3224W-1-153 - 2 pcs.

- XS1 - terminal, 2 pins, pitch 3.81mm

We also made a limiter ring on a 3D printer for easy installation on the engine. The download link for the STL file is at the end of the article.

What to make it from

On the Internet you can find a lot of video materials on making homemade models of mini devices. The most popular designs of mini drills are represented by the following list:

- MD from an electric cartridge.

- A complete analogue of the factory “Dremel”.

- Drill made from a toothbrush.

- MD from the printer drive.

- Economical option without housing.

- Second life for an old tape recorder.

- Antiperspirant idea.

MD from an electric cartridge

Every home has an electric light bulb socket. The body can be made from it. There are standard sockets and housings for minion bulbs. Both of them are suitable for homemade products. It all depends on the outer diameter of the electric motor.

Manufacturing proceeds as follows:

- The core of the fittings is removed.

- Unscrew the back cover.

- A motor is inserted inside the housing, the side surface of which is covered with hot glue or cold welding.

- Adjust the shaft thickness to the size of the collet clamp hole.

- A polymer lid from a plastic container is glued to the front of the case. A hole is first cut in the cover to allow the motor rod to pass through.

- The cartridge is secured to the shaft with a transverse locking screw.

- The motor wires are threaded through a hole in the screwed cover, which are then connected to the output terminals of the rectifier.

- If you can place a microswitch in the back cover of the electric chuck, then using the drill will be convenient.

Note! The rectifier regulator changes the current and voltage, thereby increasing or decreasing the rotation speed of the functional attachment. At the same time, we must not forget that if the permissible current is exceeded, there is a risk of “burning” the motor

Complete analogue of the factory “Dremel”

A mini drill is often called a Dremel by name - the leading manufacturer of this type of power tool. It is almost impossible to make a homemade product completely similar to the Dremel model.

It all depends on the master in terms of selecting spare parts. Making homemade products in a home workshop can never compare with professional MD production. Although, with some effort, you can achieve some success in this direction.

Advice. There is no need to blindly copy an industrial production model. It is better to purchase a ready-made tool.

Drill made from a toothbrush

Those who have used electric toothbrushes know how quickly the cleaning heads become unusable, and new brushes are impossible to find on sale. If you have one lying around the household, then this is a suitable option to make a mini drill.

The difficulty of manufacturing is to remove the vibrator and install the cartridge on the engine shaft. The device is powered by a battery or an 18650 battery. Such a device will not have a large number of motor shaft revolutions. But the MD will serve well as an engraving tool.

Dynamo from printer drive

An old printer is an excellent “supplier” of parts for making a mini drill. The electric motor and power supply are removed from the device. If the electric motor shaft is too thick, it is ground on a grinder. The engine is turned on and brought to the abrasive. Regularly measuring the diameter, the turned rod is adjusted to fit the opening of the collet chuck. After completing all the work on installing the housing, attaching the cartridge, and installing the limit switch, the device is connected to the power supply. After this, all that remains is to install the desired functional attachment and get to work.

Engine from an old printer

Economical option without housing

In order not to search for a suitable product for the drill body, the motor is wrapped in 2 layers of shrink film. The heated coating tightly covers the side surface of the motor, thereby creating reliable insulation of the power tool.

Mini drill without housing

Second life for an old tape recorder

A thrifty owner can find an old tape recorder or player. If the sound reproducing device is made in a stationary form, then use a power supply, as in the previous case.

The engine from the player is also adapted to rotate the cartridge with the nozzle. The device will be mobile, since powerful AA batteries are placed in the power supply instead of batteries.

Electric motor from a tape recorder

Antiperspirant idea

The body of a used roll-on deodorant is quite suitable for making a mini drill. The advantage of this option is the shape of the plastic bottle. It is made so that it is comfortable and firmly held in your hand.

Roll-on deodorant body

Additional Information. When manufacturing the MD case, you should try to install the power button within the reach of the worker’s thumb. This will create an additional comfortable option for controlling the device.

Clamping mechanism

The next important component of the device is the chuck used to hold the drill. To make a clamping device, you must purchase a collet chuck in advance. It is a clamping device capable of firmly holding cylindrical objects. Having secured the drill in the collet chuck and firmly clamped it on the motor axis, you just need to connect the power supply or batteries to the motor.

This simplified version of a mini-drill is already capable of drilling holes.

If you do not want to burden yourself further, and you will not use the tool very often, you can leave it as is.

However, holding the “naked” motor in your hands is uncomfortable, and the mini-drill looks unattractive. To bring what you started to the finish line, you will need a shell and separate control components.

Method No. 2 – Use the reel!

Another original way to make a mini drill at home is using a fishing rod reel. In this case, the assembly technology is quite simple, but the principle of operation itself will be based on mechanical rotation, you will get a mini-hand drill

To make a device with your own hands you will need:

- spinning reel;

- a chuck from an old drill or a collet clamp of a suitable size;

- hot glue or cold welding;

- drill.

The assembly process is quite simple and consists of only two steps. The first step is to dismantle the spool with fishing line and cut off the remaining extra axis.

After this, the cartridge is glued to the remaining rod. You can do without a chuck and install a collet instead.

When the glue has hardened, you can check the finished mini drill. You can see all the assembly details in this video example:

How to make your own micro drill from a coil

From a ballpoint pen

To make a drilling device from a ballpoint pen, no electrical elements are needed, and no skills in working with power tools are required.

You will need a ballpoint pen with an automatic mechanism, hot-melt adhesive, a stick with jumpers at the end that rotates the drill, and a drill of the required size. The main load falls on the body, so you need to choose samples made of metal or thick plastic.

Build process

The ballpoint pen is completely disassembled. A drill is inserted into the lower part of the body, from which the rod usually comes out. The shank is fixed into the hole on the stick. To ensure that the entire working structure of the tool becomes a single mechanism, the parts are fixed to the inner walls of the body with hot-melt adhesive. The drilling process will be performed through mechanical action on the stick, which serves as the handle of the device.