Interesting Facts

- Using an anvil you can fire cannons.

- If an anvil in Minecraft falls on mobs or players, it will cause certain damage, the amount of which will depend on the height of the fall. If any player dies, a message will appear: “The player was crushed by a falling anvil.”

- An anvil cannot be destroyed by an explosion, although it does not prevent its spread.

- In a multiplayer game with an anvil, there is a bug where when repairing a tool or armor, or when exiting the anvil menu, the item and its components (or another similar artifact) fall out, after which experience is wasted. If you gain a little experience by any other method, the lost experience is returned, and things remain in the same state. In order to eliminate this bug, it is necessary to switch the interface language from Russian (or another language) to English during forging. You can also remove the name given to an item or change it using the Latin alphabet.

- It is impossible to suffocate in an anvil block.

- When an anvil falls due to falling on an incomplete block, there is a chance of damaging it, because the damage is calculated regardless of what it fell on.

- No matter from what height the anvil falls, it will not be damaged more than one level.

- If you rename an arrow, shoot it, and pick it up, the name given to it will disappear.

- If you rename a block and place it somewhere, then after mining that same block, the name will disappear.

Refinement of the anvil

Also check out these articles

- Maximum home protection

- The main advantages of modern automatic gates

- Advantages of modern water heaters for the home

- Features of hidden lighting

My grinding machine helped to bring the surfaces to a good condition, the power of which turned out to be not enough for such a task, but if you didn’t put too much pressure on it, it coped with this task quite well. There was only one problem - the rail got so hot that it burned my hands through the work gloves, and it took a long time to cool down - about half an hour, but I had enough other work to do, so I just left the rail to cool down and switched to other tasks - that’s how it was for me more interesting to work.

I did not bring the sole of the anvil to a perfectly straight state; it remained a little round in shape, because... Sanding it to a completely flat shape would take a lot of time; for myself, I decided that a little roundness of the sole would not hurt me.

After all the surfaces were level and the sharp corners were ground down a little, I drilled two holes for M8 bolts in the base of the rail to attach the anvil to the workbench (for larger anvils it is better to drill four holes for M10, for example).

Next, I covered the bottom of the anvil with masking tape and painted the entire anvil first with primer and then with two coats of spray paint.

Resources

If we are talking about an anvil, then the first steps in the world of Minecraft have already been completed, and nevertheless, we will describe step by step each stage of creating an anvil.

So, since the anvil requires iron ingots, the player will have to work hard in the mines to extract ore.

Since caves in Minecraft are by no means deserted, stock up on food and torches, put on armor, pick up a pickaxe and go underground.

Iron ore looks like a block of stone with orange flecks, it can be found almost anywhere and can be mined with any pickaxe except a wooden one. A stone one will also do, but using an iron and other pickaxes the player will be able to cope much faster. Dig everything you see in caves

Thirty-one ingots are enough for an anvil, but iron is very important in the game and is never superfluous

Anvil support

There are several options for making a strong base.

1. If the support is stationary, then take a large massive stump of hard wood and dig it into the ground. To make it last longer, you need to take it and cover it with metal hoops. In order for the anvil to hold firmly on the stump and not fall on the blacksmith’s foot at the first blow, you need to weld pieces of reinforcement bent at right angles, like the letter G, to the bottom of the rail. The resulting paws are placed on the stump and driven into it, but not tight.

2. The next option for support is made from a metal barrel dug into the ground. A stump or metal welded frame is filled with sand, filling the entire volume of the barrel. This is an outdoor option for an anvil base. Blacksmiths set the height of a stump or metal barrel taking into account their height. At the moment of striking the workpiece, the master’s hand should be at the level of the horizontal plane.

Read also: Checking the wire for a break with a multimeter

3. If the anvil is portable, then it needs a welded metal base with stiffeners so that it can withstand impacts of varying power. You can decorate it and upholster it with a wooden box with pockets for different pliers and hammers.

How to make a reliable anvil for your forge - device and tips

These two concepts are inseparable. There is no point in explaining that without an anvil it is impossible to process metals using the forging method. It is an indispensable attribute of any, even the smallest, forge.

The design of this device is so simple that you will not need any special knowledge or equipment (tools) to make it yourself. In essence, it is an iron “monolith” of a special shape, with planes that must meet certain requirements.

But is there any point in making an anvil if it is not a scarce commodity and is easy to buy? (The only problem is the delivery if it is massive). The price of the simplest mini-device starts at approximately 2,250 rubles. It is clear that it is clearly not suitable for blacksmithing. But more massive models are, accordingly, more expensive.

For example, weighing 35 kg - about 22,000, 75 kg - 43,000, 125 kg - 70,000 (in rubles).

So it turns out that if you need an anvil for home crafts, then it still makes sense to make it yourself (like a blacksmith’s hammer). Even if the business is put into production, the fact that the anvil is of its own production is unlikely to affect the quality of the work.

It is worth making this argument in favor of self-production. High demands are placed on the working surface of the anvil. This is especially true for its edges, which should not be deformed (uneven), which is often observed during intensive use.

It turns out that from time to time the anvil will have to be replaced (or reanimated). And although a lot depends on how often it is used and what metals the master works with, it is still more advisable to make an anvil than to spend money on purchasing it again.

If only because if you made it yourself, it won’t be difficult to repair it.

Now we can move on to the issue of its manufacture. We will not give examples of any specific standard sizes, since there can be any number of options - each master prepares an anvil “for himself.” The main thing is to understand the technology and the main nuances, and everything else will be prompted by your own ingenuity. How it works, what options there may be, is easy to understand from the photographs.

Support

First you need to decide on the installation of the anvil. If it is stationary, then you can use a massive stump or a heavy metal frame dug into the ground as a base. For a portable type of device, a frame is selected that is welded from corners. It should be taken into account that the “stand” will have to withstand serious shock loads, so stiffening ribs must be installed. Although there are other ways to strengthen the structure.

By the way, about the stump. Firstly, it must be securely fastened with metal hoops. Secondly, if you just dig it into the ground, then such an anvil will not last long. Even after treatment with antiseptics, taking into account the loads during the work, the wood will begin to deteriorate.

Therefore, it is advisable to place the stump inside a metal barrel installed in a hole, into which sand is first poured. How much of it is needed, the level of “backfilling” is at the discretion of the master. Naturally, the tree must be a “strong” species. (But this is only suitable for outdoor use).

The most important blacksmith tool

Anvils are the most important tool that allows you to perform various forging works associated with cold and hot forging of metal. This element of the workshop is quite specific, but it is simply irreplaceable in the case of professional production of forged products.

Such a tool may vary depending on the type of problem being solved. It can have a variety of structural elements, sizes and shapes. There are mainly two types of forging anvils: one-horned and two-horned.

The first version of the device is in greatest demand. The horn is used in shaping the bends of metal products in figured forging.

What does the anvil consist of?

The sides allow you to make bends at right angles. The surface of the device itself is smooth and even, and also ground and hardened. This is the working part.

It contains two square and round holes, which are used when performing additional operations with products and when supporting the tool.

Based on weight, anvils are divided into small, medium and large. The best option is the heaviest models weighing 95 kg or more. Such devices allow you to work with large workpieces.

At home, such a tool is not one of the most necessary. However, its presence allows you to easily align various products, such as nails, wire or sheet metal.

Naturally, use for domestic purposes does not require the mandatory purchase of such a tool. However, if necessary, a homemade anvil can be made. It will easily allow you to perform all the simplest functions that are required of it.

Of course, it is extremely difficult to make a high-quality figured product using a homemade version.

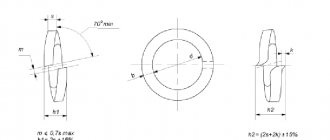

Construction of a blacksmith's anvil

A two-horned anvil is considered an ideal and universal option. On strong metal paws there is a so-called “face” or the main flat surface on which the blacksmith performs all flat forging procedures. To ensure that this part is perfectly flat and smooth, a ground plate made of 35L steel, that is, alloyed, is installed on it.

A cone-shaped horn is welded on one side. It is used for rolling and bending parts. Sometimes they are installed on both sides, depending on the type of work. On the other side, a square shank is often welded. With its help, products are bent at an angle of 90 degrees. For convenience when working with workpieces, craftsmen can add additional functionality to their anvils. For example, weld or cut a square hole for a backing tool or shperak. You can also make a round hole to fix, for example, a metal rod when bending.

Shperak is inserted if it is necessary to have a small working surface (mini-anvil). It consists of an all-metal stamping with tips on both sides and a special inflow. It is convenient to do artistic and decorative forging of products on the shperak.

2 comments

Watchmakers who work on miniature metal products have very small anvils. They have their own name - shperak. Their characteristic feature is a long handle, by which the anvil can be clamped in a vice.

It is worth noting that in blacksmith terminology, a special type of anvil is called a shperak. But let the experts talk about this.

And I have a steel prism at home, which I use instead of an anvil. I straighten the metal rods, chop off the necessary pieces of metal with a chisel. Yes, and I perform many other plumbing tasks. And I call this prism “Gitelmacher”, since I got it from a German with that name.

Do-it-yourself small blacksmith anvil and attachments for it

Hello, dear readers and DIYers! In this article, the author of the YouTube channel “Pask Makes” will tell you how to make a small blacksmith anvil.

His previous anvil was too small and had limited functionality.

Materials. — Rail connector — Steel square — Steel sheet, rod — Railway spike — Block — Oil, paint. Tools used by the author. — Grinder — Cutting and sharpening and cleaning discs — Welding machine — Drilling machine — Belt grinder — Screwdriver — Gas forge — Vise — Scraper — Chisel, clamps, core, chisel, pliers.

Manufacturing process. The craftsman will use an old rail connector as the material for the slab.

He removes the rust with a grinder and saws the connector in half.

To mark the central hole, he uses a steel square, from which various nozzles will be made.

The craftsman makes multiple cuts and then saws the steel off at different angles. Then it is leveled with a sharpening disc. But the master considered this method too complicated.

He processes the second half slightly differently: he drills several small holes on a drill press, makes two side cuts, and then chips off the material with a chisel. All that remains is to grind off the drill marks. This method turned out to be much easier and faster than the previous one.

The square fits perfectly.

Next, he welds both workpieces together. The seam has to be boiled and cleaned several times.

Then the excess material at the ends is cut off, and all surfaces are ground.

All that remains is to clean the central hole with a file, precisely adjusting it to the dimensions of the steel square.

Four segments of the same width are marked on a separate steel plate, and the center for the hole is marked in the middle of each. These are future anvil mounts.

Then the workpieces are drilled first with a thin and then with a thick drill. Low speed and lubrication are important here.

Then the blanks are sawn, and their edges are ground on a grinding machine.

Now the legs are welded to the steel plate of the anvil, one on each side.

Four more plates are cut from the steel strip.

The author covers the square with them, fixes them with clamps, and welds them together without affecting the square itself.

All that remains is to finally weld the seams, clean them, and sand all structural elements. The main part of the anvil is ready.

Afterwards, the master cuts out a block of suitable diameter. Aligns the top and bottom surfaces so that they are parallel and the log does not wobble.

He paints the top cut, tries the anvil on the block, and marks the places for the notch.

A hole is drilled in the center of the log, then the remaining wood is removed with a chisel.

Since the seams protrude slightly and interfere with the tight fit of the anvil, the upper edges have to be beveled a little.

The steel platform is installed in a block of wood and secured with wood bolts. For each bolt, a hole is pre-drilled in the wood so that it does not tear.

The bark is cleared off with an ax, and the edges of the log are somewhat smoothed with a scraper. How to make this tool, I wrote earlier in this article.

The lower cut is also covered with paint.

The author begins to manufacture auxiliary forging attachments for the anvil. He cuts off an old railroad spike and heats it in a forge.

After forging and grinding, the result is a cutter like this. It's time to test it in action.

Now the author is making a primitive bending fork. Welds the rods to a metal plate, and on its other side - a steel square.

It turned out to be a very convenient attachment for bending even very small radii.

You can make many different attachments for this anvil. Thanks to the author for a useful tool for a blacksmith!

Good mood, good luck, and interesting ideas to everyone! Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

How to install fittings on jeans: master class

- Description

- Comments 2

How to install rivets and metal buttons on jeans with your own hands using available tools - a step-by-step master class.

Rivets and a metal button are a traditional set of metal fittings for jeans. If you sew jeans yourself, here is a master class on how to install rivets and buttons with your own hands.

For example, rivets and a button can be useful for these models:

- 1

- 2

- 3

- 4

- 1

- 2

- 3

- 4

- Best-seller

- 1

- 2

- 3

- 4

- 1

- 2

- 3

- 4

- 1

- 2

- 3

- 4

We sew jeans and trousers in denim style: a selection of patterns

You will need:

— a set of accessories (rivets and buttons);

- an anvil or something that will perform its function (you need something solid, ideally metal, but a thick board made of dense, strong wood will also do);

- narrow masking tape;

How to sew stretch denim: life hacks and tips

Step 1

Let's look at the fittings first. As a rule, for jeans you need:

— a button (available in different diameters) and the included nail (it can be smooth all-metal, smooth tubular or, as in our case, with a circular notch; it holds better when installed at home);

- rivets, they are also solid (consist of a head, a part located on the outside, and a leg, this is a part that secures the head and is located inside).

Step 2

Decide where you will place the rivets. A simple option: refer to a purchased pair of jeans that you like in this regard for an example. Experienced seamstresses convince us: if you want to put rivets not only on the front, but also on the back pockets, you should think twice about it. The fact is that the rivets on the back can scratch or damage the furniture when sitting.

Step 3

Place the rivets in the desired places and press them into the fabric with your finger. Small circles will remain: place a dot in the middle of each with a thin marker or pen.

Step 4

Make holes in the designated places with an awl. Pierce all layers of fabric, trying not to tear, but to push its fibers apart.

Step 5

From the inside out, insert the parts of the rivet legs into the holes.

Step 6

Using nippers, bite off the excess part of the leg, leaving 1-1.5 mm above the surface of the fabric.

Step 7

If the leg, as in our case, is hollow, then when biting it off it may flatten somewhat (see photo). However, an all-metal leg can also become flattened. One way or another, the leg needs to be trimmed. Do this using pliers or needle-nose pliers, being careful not to overdo it and flatten the leg in a perpendicular direction. Ideally, the leg should return to its original round shape.

If it turns out that the leg was bitten off a little at an angle, it is better to straighten it by lightly tapping it with a hammer from above.

All these manipulations will help to place the rivet more firmly and beautifully, plus they increase its chances of remaining in place for a long time.

Step 8

Place the rubber mat on the anvil, with a sheet of paper on top. Place jeans on top. Place the rivet head on the leg. Hit the head with a hammer quite firmly and with a firm hand. Check whether there is a gap between the cap and the fabric and whether the cap can rotate. if so, hit again. The final result should be the same as in the photo: the cap fits tightly to the fabric (and does not rotate), but the fibers of the fabric are not damaged. Repeat with the remaining rivets.

Step 9

Let's move on to installing the button. Mark the point where the button will be installed.

Step 10

Punch a hole in the intended location.

Step 11

Place the mat on an anvil or board. Place the button bottom side up on the mat (see photo) and secure with two strips of masking tape. Make sure you do not tape the hole in the button shank.

Step 12

Insert the nail from the inside into the hole in the belt. Make sure the stem of the nail is fully inserted into the hole.

Step 13

Place the tip of the stem of the nail in the center of the hole in the button.

Step 14

Holding the belt with your hand (watch your fingers!), hit the head of the stud quite hard with a hammer. Check if the button rotates. If yes, repeat.

Both the button and the head of the stud should fit snugly against the fabric without damaging it. Ready!

The main stage of work

A grinder cuts off the top layer of the rail and creates the most even surface possible. It is advisable to install an alloy steel plate on it and polish it thoroughly. Use a triangle to check the evenness of the anvil corners. This is an important point. Next, the horn is welded on one side and the square shank on the other side.

To check the smoothness and quality of grinding of the working part of the anvil, you need to test it. To do this, you need to hit its surface with a hammer or mallet. If everything is done correctly, the hammer should bounce off it like a ball. At the same time, a characteristic ringing is heard that lasts for a long time. If the anvil has passed the test successfully, then you can proceed to the next stage of work, namely, correctly and securely fasten the anvil from the rail to the base.

How to drill hardened metal

There are drills with carbide tipped (TK, VK, etc.) on the working part and entirely made of carbide, of different diameters. I usually make do with homemade drills from similar soldered bits, pressed into a tube and ground on a diamond cup to the diameter I need. if you need it for one-time drilling, buy a drill bit for concrete or tiles and resharpen it.

| vityuxa |

| max12312 |

| leoleo1972 |

| Barkay |

Wow! While I was composing, leoleo1972 had already written about Hamlet. I recommended these videos to you. And Max’s advice about VC rods is on the same topic.

A couple of tips after that. First. If you have a choice, do not take a VK lower than VK6. For example, VK2 is much better than VK6 in terms of cutting properties, but there is little cobalt binder (only 2%), so the drills are as fragile as glass. They are not suitable for everyday use; they break at the first contact with steel. Second. When sharpening a VK on a diamond, the rod/drill/solder quickly heats up. Do not cool it in water under any circumstances - you will ruin it. The heat resistance of the VC is enormous, so just clamp it in a collet or chuck or in a hand jewelry vise and don’t worry about overheating. Cooling is only in air.

Mastering the "blacksmith's craft"

But, of course, it’s not enough to just craft this piece of metal. You still need to learn how to use it. Repairing a tool involves placing two objects in the anvil interface area. At the end of the day, the repaired tool will be about seven percent stronger than the original two combined. Starting from a certain version, you can make repairs in Minecraft using the materials from which the broken item was crafted. With this approach, it is necessary to place the tool itself in the left cell, and the material in the right cell.

In Minecraft, as you know, you can put enchantments on objects. So, to be able to use an anvil means to be able to change the effects of these enchantments cast on certain categories of objects. These include armor, enchanted books, tools, and weapons. To make changes, you need to place two enchanted items of the same type plus two books (also enchanted) and any item. As a result, the item received will be one level higher than those listed.

As already mentioned, this block in Minecraft makes it possible to rename items. This can be done by sacrificing five levels of experience. But subsequent renaming will be more expensive.

How to make

Initially, you need to select the appropriate material. In the factory, for the manufacture of such a forging device, grade 35L steel is used. This is one of the alloyed types of metal. But for a home workshop, you can use a piece of railroad rail.

A channel will also work as a temporary option, but such a device will not last long; it will inevitably become deformed.

How to make an anvil from a rail with your own hands? The entire manufacturing algorithm can be seen in the video provided:

- For manufacturing, you will need a piece of rail 200-300 millimeters long or more if you need a larger device.

- Initially, the workpiece is marked. On the surface they indicate where the horn and rim will be.

- Using a grinder, excess metal is cut off from the edge along the markings, forming a triangular shape for the future horn. After trimming, it is advisable to round it, for which a grinding machine is again used.

- You need to cut a notch under the triangle of the horn.

- On the opposite side, mark the location of the rim or heel. Excess metal is cut off exactly at right angles.

- The front part of the rail anvil must be smooth, so all protrusions on the upper part are carefully leveled with a file and ground.

- To securely fasten the device, you need to make holes in the base of the rail.

- Non-working side surfaces are cleaned of traces of corrosion and contamination, and then painted.

- The homemade anvil is ready, after which it needs to be securely fixed. You can watch the video on how to do this:

However, when making such an anvil, the result can be a narrow front part. To fix this, you can apply the same technology, but turning the rail the other way around, thus obtaining a wide base of the workpiece as a working surface.

Having made such a device from a rail with your own hands, we proceed to its installation, for which you can use additional channels as fasteners.

Rail anvil

Alternatively, a piece of a powerful I-beam can serve as the starting material for the anvil.

But, having thinner metal on its shelves, it is suitable for small forgings and will warp over time.

Such homemade products can temporarily replace a full-fledged factory product. However, over time, for normal and convenient work, it is better to purchase a real device, which is much more convenient and allows you to process metal using various techniques.

When tested with a blow, a high-quality anvil with a hardened surface rings at high tones, and the hammer bounces.

If you have experience in making homemade anvils, share it in the comments section for this material. What did you make such equipment from and how does it perform during use?

How to make a forge with your own hands: forge structure

The word “forge” is usually associated with a dark room with anvils, forges, hammers and blacksmith’s tongs. However, creating a forge with your own hands is much simpler than it seems at first glance. In addition, the forge can be made quite compact without adapting special premises for it.

The forge itself is a room with equipment for blacksmithing. In the forge, metal blanks are heated and processed using hammers and other forging tools. Less commonly, melting metals and alloys for casting some elements.

In fact, the forge does not necessarily have to be located indoors. In our case, the forge is an open space (or a space under a canopy).

The forge contains a forge - a source of open fire. Small particles of coal are often blown out of it. In addition, the metal is processed hot at about 800-900ºС. Therefore, the floor in the forge should not be made of flammable materials and there should be no electrical wires in the vicinity of the forge and anvil, since hot workpieces often drop onto the floor.

Blacksmith anvil

It can be almost any one that can be found. The main thing is that the edges and working surface of the anvil are not knocked down (the edges must be smooth). When you hit a real blacksmith's anvil with a hammer, it should bounce off it, and the anvil itself should ring loudly.

The anvil can be installed either on a large wooden stump or on a frame welded from a corner. The second option is more functional; in addition, it allows you to turn the anvil and install it anywhere in the yard or room without any problems.

Installation on a stump, as a rule, secures the anvil in one place “forever”.

The height of installation of the anvil is determined by the level of extension of the blacksmith’s arm: so that when struck with a hammer, its surface is approximately parallel to the ground.

Forge

The furnace can be welded from sheet metal with a refractory brick inserted inside. In order not to cook the forge, you can use a cut old cylinder for this. The forge, like the anvil, is also installed on a frame welded from reinforcement at approximately the height of the blacksmith’s belt. The frame of the forge is less massive than that of the anvil, consisting of 12-14 reinforcements.

You can also weld a grate (a grate on which burning coal or firewood is located) from fittings at the bottom of the hearth.

But the spaces between the grate rods should be as thin as possible (no more than 1-2 mm), since flaming forge coal, when burned, breaks up into very small particles and will spill out through large holes.

The air stream should be supplied from the side, slightly at an angle downwards, and not from below, like in stoves. This is due to the fact that the jet is strong and, when fed from below, will blow small particles of coal from the forge, which will scatter quite far.

Old vacuum cleaner

Necessary for blowing air into the forge during blowing work.

Hammer

This is an ordinary hammer. But not like a locksmith's, which has one end that is thinner. A hammer is a hammer that has both ends equally flat. Unlike a sledgehammer, the hammer has a lighter weight (from 800 grams to 2 kg) and a short handle for working with one hand.

You should choose a hammer based on your own physical capabilities in order to work with it for a long time and not get tired. It is very important that the hammer is made of good steel; it is better to use an old Soviet one.

Chinese hammers can crack after several blows, and some develop grooves on the working surface during use, which indicates the low quality of the metal.

Chair forging vice

The main difference between a blacksmith's vice and a metalworker's vice is the metal from which they are made. The forging vise is made of tool steel and can be struck without fear of splitting the vise.

Blacksmith pliers with long handles

Long handles are necessary for working with small workpieces. A plus will be a locking ring that fastens the handles into a lock, which allows you to avoid squeezing them with force when working with a workpiece.

Other tools are non-specialized or ordinary plumbing tools.

Recommendations for setting up a forge

This equipment for a full-fledged forge can be placed in a corner, in an area of less than 1 square meter, since the anvil and forge can be moved. If you plan to work indoors, then an additional hood should also be made at the place where the forge is installed. If the forge is located in the yard or under a canopy, then an exhaust hood is not needed; during active combustion, the forge emits little smoke.

Coal for forging needs “fiery” coal. You can distinguish it by its weight. Pieces of this coal, even very large, are very light. It flares up strongly, burns quickly and gives the high temperature necessary to heat the workpieces to forging temperature. You should choose large and medium pieces. Small ones burn out quickly and do not give the desired temperature.

Source: https://www.diy.ru/post/2446/

Typical design

For extended functionality, this blacksmith tool must consist of the following parts:

- Faces. It is a flat surface in the center where you can process flat, wide workpieces. Often a blind hole is made in the left or right side of the face to make cavities and holes, as well as to fix a part of the workpiece, the opposite end of which must be bent.

- The horn is a cone-shaped process that is adjacent to one of the ends of the anvil. Designed for plastic rolling or rolling of strip metal into a body of rotation. Ideally, the anvil is equipped with two horns, then the second (sometimes called the tail) is made in the shape of a pyramid, and is used to obtain spatial bodies of more complex shapes.

- Paws - four supporting protrusions in the lower part of the body, with which the tool rests on the workbench. If the anvil is assumed to be stationary, then through holes are made in the paws for fastening.

- Rim - a rectangular or square area of the face, which is located closer to the horn, and is used for crimping sheet metal products.

Anvil device

In the simplest version of the anvil, the rim and/or tail, as well as holes in the paws, may be absent.

Methods for attaching anvils

What is better to make it from?

First of all, you need to decide on the location of the anvil. If a reliable workbench is not available, then you can use a strong, wide stump as a support (oak is the ideal solution: this wood is strong in compression and ideally dampens the vibrations that arise during the forging process). In this case, the diameter of the stump, freed from bark and surface defects, will determine the size of the anvil, in particular its length. It should not be less than 200 mm.

If there is no stump, you can use a high (not lower than 100 mm) wooden shoe, which is rigidly mounted on the end of a barrel filled with sand. The barrel must be buried halfway into the ground.

As a blank for the anvil, it is most advisable to take a suitable piece of a decommissioned crane rail KR-120 or (which is better) KR-140. Unlike railway rails, this option provides the following advantages:

- For the production of crane rails, a stronger metal is used in accordance with GOST 4121. This is high-carbon steel grade “steel 63”, which is characterized by a high manganese content and has a standard strength of at least 730 MPa, with a head hardness of 212 HB;

- The neck of the crane rails is wider, which will increase the stability of the anvil during forging work;

- The profile of the crane rails provides a smoother transition from the neck to the head, which prevents the occurrence of stress concentrators in the tool.

Fixed anvil

The only drawback of crane rails is that there are no mounting holes, and you will have to do them yourself.

How to build a forge yourself?

Independent production of decorative forged products will require a special room for forging and welding. Traditionally, this room is called a forge or blacksmith's workshop.

Placement of equipment in the forge: 1—emery machine; 2 - forging machine; 3. pipe bender; 4 — cabinets for tools; 6 — vice; 6 - workbench; 7 - fan; 8 - water tank; 9 - forge; 10 — hangers for tools; 11- table for tools; 12—anvil; 13 - boxes with coal.

Work in a forge involves working metal parts, usually while they are hot. Welding using an electric or gas machine also involves working with an open flame and metal heated to a high temperature. This places special demands on setting up a forge at home.

How to build a blacksmith shop with your own hands?

It is best to build a forge from materials that are not susceptible to easy fire:

Layout of equipment in a rural forge.

- bricks;

- cinder block;

- asbestos cement sheets.

If the forge is forced to be located in a building with wooden walls, they must be plastered. The floor in the forge is paved with brick, poured with concrete, or made from a mixture of clay and sand, wetting it and thoroughly compacting it. A garage, shed or utility room in the house is suitable for a locksmith workshop. Cold forging machines can also be placed there, since this method of metal processing does not require the use of open fire.

The area of the room for forging decorative elements can be relatively small and dictated only by the convenience and freedom of movement of the blacksmith.

For the production of small-sized products, the optimal forge area can be considered 16 sq.m.

Tools in the forge: hammers, vices, tongs, sharpening.

Such a workshop makes it possible to place all the necessary equipment under one roof. Welding work should only be carried out outdoors.

When carrying out forging work indoors, it is necessary to ensure sufficient ventilation. A supply and exhaust type forced ventilation device would be ideal. In this case, exhaust equipment is placed above the furnace. The height of the ceilings should not be less than 2.5 m. A forge under a canopy does not need ventilation, but working in it in winter will be quite uncomfortable.

Internal arrangement of the forge, main fixtures

The specifics of a blacksmith’s work involve the placement of characteristic devices in the workshop:

Construction of a blacksmith's forge.

- blacksmith's forge;

- anvils and speraks;

- correct slab;

- bending plate;

- vice;

- hammers, handbrake, sledgehammer;

- tools for cutting, sharpening, drilling, chopping;

- locksmith's workbench.

In addition, it is imperative to equip the forge with a container of water to cool the forging, which will always be at hand, and a fuel box with a poker and scoop. Ensuring fire safety dictates the placement of a fire extinguisher in an accessible place.

The most necessary tools

Heating metal blanks to a high temperature before processing requires the presence of a forge in the workshop. This is a type of open-type furnace, on the hearth of which high-temperature fuel is burned - charcoal or coal. The forge is usually located on the wall farthest from the entrance so that the blacksmith can have access to it from 3 sides. This allows you to heat both long workpieces and small parts for the manufacture of decorative metal elements.

Anvil with a device for clamping workpieces.

For a small workshop or for making small parts, a portable forge is well suited, which can be made from sheet metal or from a cut-off gas cylinder. Processing larger workpieces (parts of railings, fences, etc.) will require the installation of stationary equipment.

Traditionally, such a furnace is made of brick: the base is laid out from brick or cinder block, leaving space in the center for an ash pan and air flow to the grates. You can also weld the base from a steel corner by making an ash pan from sheet metal. For forced blasting in order to increase the combustion temperature of the fuel, a pipe is laid. You can use a vacuum cleaner to pump air.

A grate is installed on top of the ash pit, and the walls around it are laid out from refractory bricks, forming a furnace nest where the burning fuel is located.

The hot workpiece is processed on an anvil. For this purpose, you can adapt a piece of rail, one end of which is ground into the shape of a cone. If possible, it is better to purchase a professional anvil, but a piece of thick (2-3 cm) steel plate with a smooth surface is also suitable for making decorative parts.

You can install the anvil:

- on a wooden block (“chair”);

- on a monolithic concrete base;

- in a barrel of sand.

With any installation method, the height above the floor of the working surface of the anvil (platband) is determined individually and should approximately correspond to the level of the thumb on the hand of the blacksmith standing next to it.

Accessories (bending and leveling plates, vices, clamps) are used to secure and process workpieces.

The bending plate has holes into which, if necessary, pieces of rod are inserted according to the pattern; between them, identical elements are bent in large numbers (curls, snails, etc.). On the right plate, long workpieces can be bent at right angles or straightened.

Shperaks are mini-anvils for small elements. In a vice, the ends of the part are clamped when twisting, bending, or some tools (shperaks, lowers) for processing workpieces.

Impact tools should be represented by a set of hammers and sledgehammers of various weights (4-16 kg) for striking when forging large products. For final processing of the workpiece, handbrake tools weighing 800-2000 g with a handle length of about 35 cm are used. The handbrake is used to deliver precise blows and correct the shape of the product. Hammers with shaped strikers are used for forgings of a special configuration. These hammers are usually purchased or made for a specific task.

Various power tools for metal working must have cables with a cross-section appropriate for the load.

A mechanic's workbench is a table at a convenient height for the owner, on which you can install power tools, lay out blanks and finished parts, and perform cold operations on processing products: sharpening, grinding, cutting, etc.

All forge equipment must be placed taking into account the individual requirements of the master for ease of work and unhindered access to the main workplaces: forge, anvil, workbench. Making a forge at home is quite affordable, and working in it will bring pleasure and allow you to independently make various things from metal.

Source: https://moyakovka.ru/instrumenty/kak-postroit-kuznicu.html

Tools we will need

- Standard 16 oz hammer

- Measuring tape - your boards will already be cut, but you will need to offset them for this design

- Wood glue

- Nails - I used 21/4" (7D) decking nails to secure 2 x 12's

- Ear Protection - I've had tinnitus for many years, so I wear protection even when I'm just working with knocking.

- Eye Protection - We've all heard horror stories about how a bad hammer sends nails back into your eyes. Be sure to protect your eyes

- Shims - if you want to play it safe

- 2 10' 2 x 12 pine boards - No need to get fancy here with luxury hardwoods as you will be applying pressure to the bottom of the board which ends during nailing

You may notice that I did not include a circular saw for cutting wood in the list. I did this in order to accommodate guys who do not have this equipment. My method relies on the cutting services of your local hardware store, as well as being able to load sawdust into the trunk of your car

Experience

Experience helps you repair objects and combine spells. The experience level must be increased in order to use more powerful magic when forging. Forging can be done with a wide variety of materials. You will not be able to combine items if it requires 40 levels or more. But this does not apply to creative mode.

When you transfer an enchantment to another item, you can spend less resources on it. But this is only if you need to create a more powerful item in the first slot, and not so powerful in the second. Let's look at this with an example...

The first slot takes the sword that needs to be repaired and is combined with sharpness one. In the second slot, the sword is combined with sharpness four. The severity of four is transferred in this case. Basically, you can create anything by combining items with different enchantments.

Do-it-yourself mini-forge: a budget option

Sometimes in the lives of people living “on earth” there are moments when you want to do something with your own hands, without putting it off. Someone is thinking about carpentry, someone is engaged in the manufacture of decorative products, and someone is literally passionate about forging. Moreover, real, i.e. - “hot.”

So, in this article:

- What is the minimum set of tools and equipment needed for forging.

- How to make an anvil from an old rail.

- What can you use to construct a portable forge?

A basic set of tools needed for metal forging

The method of imparting plastic properties to metal by heating has been known to mankind since time immemorial. Unlike the so-called “cold forging”, in which the metal is not heated, during “hot” (and, as is considered, “real”) forging, the metal is heated in a forge.

Due to its plasticity, heated metal can be given a wide variety of shapes, which is what masters of artistic forging use.

In addition to experience, which is accumulated over the years, forging requires the appropriate tool. These can be special pliers, mandrels, bending templates, etc., but the hammer and anvil remain the most important “assistants” of a blacksmith for many centuries.

Any person who is thinking about taking up blacksmithing is faced with the need to purchase the appropriate tools. A high-quality and heavy anvil weighing under 100 kg is not a cheap pleasure.

I bought my anvil by weight at a secondary metal shop. From work experience, I can say: what I couldn’t flatten on a rail, I managed to do on a real anvil.

Vtorchermet may be a “gold mine,” but a lot depends on luck. Our price for a used anvil is approaching the cost of a new one. Although I managed to acquire a powerful vice and anvil weighing about 30 kg in this way. Her “face” is, however, dented, but it can be fixed.

So, what to do if you want to forge, but the family budget does not allow such expenses? Moreover, if it is unknown whether the business will be to your liking, or in a few months all the expensive equipment will begin to gather dust in the garage.

In this case, you should take advantage of the experience of FORUMHOUSE participants and acquire a mini-forge made from materials that are at hand. Moreover, even with this “dacha” option, you can make a lot of different things that are needed on the farm, and which you cannot buy in a store or on the construction market.

Step-by-step instructions for making an anvil from a rail

Prepare the work site. Place a piece of rail on the table, mark it with a marker and ruler as follows:

- Measure 40% of the total length of the rails, draw a line;

- Measure half the width of the rail, make a mark;

- Connect the lines and the mark so that you form a triangle or the so-called “anvil horn” on the rail site.

If you still have questions about the correct marking of the workpiece, look at the photos and videos on our website.

Secure the future forging anvil in a metal vice. Turn on the grinder and cut the horn according to the marking lines.

Important! When working with power tools, be extremely careful. The metal vice must be securely fastened to the table surface. The desktop should not be loose

To protect your own health, wear a welding mask, protective apron and gloves.

The work table should not be loose. To protect your own health, wear a welding mask, protective apron and gloves.

After making deep cuts with a grinder, take a hammer. It will help you speed up the process: use it to beat off the left and right edges of the metal triangle. Be prepared for the edges to be uneven - there is nothing wrong with that, we will process them later.

Take the rail out of the vice, turn it on its side so that the broken triangle is “looking” at you. Use a marker to mark lines leading from the edge of the rail to the inner hole (closest to you). Beat them off with a hammer.

Stepping back an inch from each raw “back” end, draw lines with a marker. Your task is to mark the “tail” of the anvil. Use a grinder to make cuts on the metal, then beat the metal into pieces with a hammer. The "tail" is the functional part of the tool. But since we are creating a home, and not a professional, anvil, whether to carry it out or not is only your desire.

Stapler

A stapler

is a mechanical device that joins pages of paper or similar material by guiding a thin metal staple through the sheets and folding ends. Staplers are widely used in government, business, offices, work places, homes and schools.

The word "stapler" can refer to a number of different devices with different purposes. In addition to joining sheets of paper, staplers can also be used in a surgical setting to join tissue together with surgical staples to close a surgical wound (much in the same way as suturing).

Most staplers are used to join multiple sheets of paper. Paper staplers come in two different types: manual and electric. Manual staplers are usually carried by hand, although models that are used on a table or other surface are not uncommon. Electric staplers come in many different designs and models. Their main operating function is to quickly connect large numbers of sheets of paper in series. Some electric staplers can staple up to 20 sheets at a time. Typical staplers are a third class lever.

Content

- 1 History 1.1 Modern stapler

Story

The increasing use of paper in the 19th century created a demand for an efficient paper fastener.

In 1866, George McGill was awarded U.S. Patent 56,587 for a small bendable brass paper fastener, which was the forerunner of the modern paper clip. In 1867, he received U.S. Patent 67,665 for a press for inserting a fastener into paper. He showed his invention at the 1876 Centennial Exposition in Philadelphia, Pennsylvania, and continued to work on these and various other paper fasteners throughout the 1880s. In 1868, an English patent for a stapler was issued to CH Gould, and in the United States, Albert Kletzker of St. Louis, Missouri, also patented the device.

In 1877, Henry R. Hale filed Patent No. 195,603 for the first machines to simultaneously insert and clamp a staple, and for this reason he is considered by some to be the inventor of the modern stapler. In 1876 and 1877, Hale also filed patents for the Novelty Paper Box Manufacturing Co. from Philadelphia, Pennsylvania. However, the inventions of NPB Manufacturing Co. were to be used for stitching boxes and books.

The first machine to accommodate a magazine of many pre-formed staples appeared in 1878.

On February 18, 1879, George McGill was issued patent 212,316 for the McGill one-way stapler, the first commercially successful stapler. This device weighed over two and a half pounds and loaded one 1/2-inch wide wire staple, which it could pass through several sheets of paper.

The word "stapler" was first used to refer to a machine for fastening paper with thin metal wire in a magazine

American

Munsey's Magazine

in 1901.

In the early 1900s, several devices were developed and patented that punched and folded paper to attach them to each other without a metal clamp. Clipless Stand Machines

(made in North Berwick) sold from 1909 to 1920s.

He cut a tab in the paper, which he folded and tucked. The paper fastener of the new Bump model

used similar cutting and weaving technology.

Modern stapler

In 1941, the type of paper stapler that is most common today was developed: the four-way paper stapler

.

In the four methods, the operator could either use a stapler to staple paper to wood or cardboard, or use it to staple like bag pliers, or in the conventional manner with the head positioned a short distance above the staple plate. The stitching plate is known as the anvil. The anvil often has two settings: the first and most common is the reflective

setting, also known as the "primary" or "permanent" setting.

In this position, the legs of the bracket are bent towards the center of the crossbar. It is used to staple papers that do not require separating. If rotated 180° or slid to the second position, the anvil will be set to the deflection

, also known as "secondary", "temporary", or "straight". In this position, the shackle legs are bent outward, away from the crossbar, causing the legs and crossbar to form a more or less straight line. Stapling with this setting will result in a looser paper hold, but the staple will be much easier to remove. However, the use of the second setting is almost never used due to the prevalence of staple removal devices and the general lack of knowledge about their use. Some simple modern staplers have a fixed anvil that is not vertical.

Modern staplers continue to evolve and adapt to changing user habits. Stapling devices with less force or ease of squeezing/use, for example, use different lever efficiencies to reduce the force required by the user. As a result, these staplers are typically used in work environments where repetitive, large staple operations are routine.

Some modern desktop staplers use Flat Clinch technology. With Flat Clinch staplers, the staple legs first pierce the paper and are then folded and pressed absolutely flat against the paper, eliminating the commonly used two-stage anvil and using a recessed staple base in which the legs fold. Consequently, staples do not have sharper edges and do not cause paper to lay flat, saving space for folders and binders.

Industry

In 2012, $80 million worth of staplers were sold in the United States. The dominant manufacturer in the US is Swingline.

Methods

Permanent mount

binds objects by pushing the staple through the material into

an anvil

, a small metal plate that bends the ends, usually inward.

On most modern staplers, the anvil rotates or slides to switch between folding the ends of the staples inward for permanent stapling or outward for securing

(see below). Clips can be standard, curved, flat or rounded, completely flush with the paper to make document stacking easier.

Consolidation

temporarily binds documents or other items. To secure, the anvil slides or rotates so that the staple bends outward rather than inward. Some staplers secure by bending one leg of the staple inward and the other outward. The clamp securely binds the object, but is easily removed.

Gluing

Attaches objects to surfaces such as bulletin boards or walls. A stapler that can glue has a base that swings out of the way so the staples go straight into the object rather than folding against the anvil. In this position, the staple is driven in a similar way to how a stapler operates, but with less force driving the staple.

Stapling devices

have an inverted V-shaped staple for stapling pre-folded sheets for booklet making.

Staplers without staples

, invented in 1910, are a stapler that cuts out a small piece of paper and threads it through a slit. A more recent alternative method avoids holes by crimping the pages together with jagged metal teeth.

Processing the metal surface of the anvil

Use a sanding wheel to remove any traces of rust from the metal pad. After processing, the metal surface of the future metal anvil should be smooth and even.

After using a power tool, use a hand metal file. The surface should be treated with compounds that protect the metal from rust. You can purchase them at any specialized store.

Perform final grinding of the workpiece surface. Sand the metal with a fine grit wheel again. Perform the grinding process as many times as necessary to obtain a perfectly smooth, horizontal surface of the anvil.

Important! To ensure the evenness of the workpiece surface, use a level. Remember that if the surface of the anvil is uneven, the parts processed on it in the future will also have defects. lantern

If there are no glimpses of light and there are no gaps between the level and the surface of the workpiece, the work is successfully completed

In order to make sure, using a level, that the surface is really perfectly smooth and even, look at it from the side “into the light” using a lamp or a regular flashlight. If there are no glimpses of light and there are no gaps between the level and the surface of the workpiece, the work has been successfully completed.

Place the rail on a vise. Using a grinding machine, process all other surfaces of the anvil working platform, giving the workpiece an aesthetic appearance. The result should be a shiny arrowhead.

Cover the lower part of the rail, which is covered with rust and has not been treated, with protective black paint for metal. It will protect the material from corrosion and additionally give the anvil an attractive appearance.

Your homemade anvil is ready to use. As a support for it, you can use, for example, an ordinary strong stump. Remove surface defects and bark from it, firmly secure the “craft” created with our help.

Anvil base

The base of the anvil can be a heavy wooden block (called a “chair”) dug into the ground. The depth to which the chair needs to be dug is at least 0.5 m. The anvil itself is attached to the base either with clamps or crutches. The chair in its upper part must be fastened with a steel hoop. The diameter of the log is recommended to be at least 600 millimeters. The ground around the chair must be thoroughly compacted. The top of the chair must be perfectly level, otherwise the anvil will bounce from the impacts.

If you don’t have a suitable block of wood, you can make it a composite one.

Stacked bases for anvils

It is also permissible to make the anvil base in the form of a cast iron or steel rack for mobility.

Single-horned anvil on a steel base

Sometimes they just use oak, maple or birch stump.

Photo of an anvil on a stump from the blacksmith festival

You can also use a wooden or metal barrel filled with sand, clay or earth, and place a wooden pillow on top.

Scheme of installing an anvil in a barrel

It is practical to cover the upper part of the chair with roofing iron, so that the chair does not burn from hot stumps and other things.

The height of the base is determined individually. It is recommended to make it at such a height that the blacksmith could touch the face of the anvil with the fingers of his lowered hand. Then he will not spend extra effort when forging, leaning forward and lifting the hammer too high. In other words, he will not get unnecessarily tired while working.

If a one-horned anvil is used (most often this is the case), then the horn should be to the left of the smith.

Due to the enormous load on the anvil during the forging process, it must be very firmly attached to the chair. The base should be strictly vertical, and the face of the anvil, accordingly, strictly horizontal. During forging, neither the anvil nor the chair should vibrate.

The anvil is placed at a distance of 1.5-2 meters from the forge and at approximately the same height; this makes it easier to transfer the hot workpiece from the forge to the working surface of the anvil.

Enough free space should be left around for hammer hammers and other auxiliary workers.

Even from this metal you can make a base for an anvil, watch a short video here https://kovka-svarka.net/kuznitca/kak-sdelat/. And on this page there is a photo of the assembly of that base step by step.

Almost anyone can make cold forging equipment and operate it.

To carry out work, the best inverter-type welding machines must have an output current of at least 160 A. The ssva-160-2 inverter is exactly such a machine. Using a forge, you can obtain a wide variety of workpieces for welding work. There are many examples of products made by welding and forging, photos of which can be viewed on Internet sites.

Anvil elements

A blacksmith's anvil is a mandatory attribute of his workshop. With its help, a number of technological operations with metal are performed. This tool is used for forging, giving metal the required shape, hardening, etc.

This item is made of durable alloy steel, and its weight can exceed 300 kilograms, especially if we are talking about a stationary forging anvil.

It must be stable and durable, as it bears significant loads. Hitting the anvil with a hammer produces a smooth, clear sound. A dull ringing indicates the presence of cracks or voids in the instrument.

As noted earlier, there are one-horned and two-horned models. Why does the anvil have this shape? The point is this: the horn allows you to make bends with the necessary curvature, and the flat surface serves to do the main work.

Anvil mounting diagram.

The main elements of the device include:

- horn;

- shank;

- recess for forming holes;

- holes for installing tools and other forging equipment on the anvil;

- face;

- shoe;

- platform for cutting metal.

The protrusion on the side of the instrument is called a horn. Its shape varies depending on its purpose. In one-horned models it is cone-shaped. Used in forming metal bends and rolling out rounded parts.

The second horn is used in bending products at angles less than normal and is made in the shape of a truncated cone.

A face is a flat surface. It is on it that the main operations are performed.

The anvil should absorb the impulse from a blow to the front part. For these purposes, the device is installed on a durable wooden or sand cushion.

It is important that the face is positioned strictly horizontally. This will allow you to do the work with the highest quality. Many people are interested in the question of how to install an anvil in height

The height of the anvil from the floor is correct if the hammer strikes the casing horizontally

Many people are interested in the question of how to set the anvil in height. The height of the anvil from the floor is correct if the hammer strikes the casing horizontally

In addition, it is important that the blacksmith does not have to make additional efforts to adjust the blow, bend down or lift the tool too high

Forging anvils: types, designs, manufacturing

Blacksmith's anvil. The productivity of forging and the accuracy of the finished forging depend on the correct design of this, at first glance, very simple object. Meanwhile, it is not at all necessary to order a tool from a specialized workshop: if you have a certain set of working equipment, a home craftsman can make it with his own hands.

Blacksmith anvil

Classification of anvils

The types of anvils and their shapes are different. They are classified:

- by weight: for example, a 10 kg anvil can only be used for hot forging with a hammer weighing no more than 1 kg (this is the ratio of weights that is considered optimal);

- by the presence of a blacksmith's horn: the anvil is two-horned or one-horned. in the simplest cases, an anvil of a simple configuration is used, but much cannot be done with it;

- according to the shape of the supporting part - with or without paws, on a solid base;

- according to the presence of a hole and its shape - steel anvils with a round and/or square blind hole;

- with or without a tail.

Connection with experience

To repair items or combine enchantments, you need experience. The more powerful the magic involved in forging, the higher the level of experience you must have. The materials used in forging do not matter. It should be noted that merging may not be available if the crafted items require over 40 levels (this limit does not exist in Creative mode). Another consequence of "carrying" enchantments is that if you create a more powerful item in the first slot and a less powerful one in the second, you will spend much less. For example, if you combine a damaged sword with Sharpness I in the 1st slot and the exact same weapon with Sharpness IV in the 2nd slot, a Sharpness IV transfer will be made. If on the contrary, then only repairs will be made. This feature persists when combining items with different types of enchantments.

A “naked” forge - without a forge - is the height of indecency

To put it pompously, we can say that the forge is the heart of the forge, only there “the steel submits obediently,” turning almost into plasticine. The device is simple: coal burns in the furnace of such a furnace, and a metal billet is placed there, which is heated to the required temperature. The smallest forge can even be built from a tin can. And he will allow you to make forged things as successfully as his respectable “colleague” in the craft. True, their sizes will be appropriate.

The main task assigned to the operation of this equipment is to provide a fairly high temperature for heating the steel. The best option would be a solid fuel fireplace that uses coal. He also has a competitor - the Kuznetsk gas forge.

Types and types of anvils

Types of anvils, their shape and weight can vary significantly.

They are divided into several categories according to the above criteria, namely:

- hornless – massive instruments with a large weight, the value of which is in the range of 96 – 210 kg;

- one-horned - have only one cone-shaped horn, their weight varies from 70 to 210 kg;

- two-horned anvil - a device weighing from 100 to 270 kg;

- single-horned cantilever;

- shperaks are mini anvils weighing up to thirty kilograms.

The choice of anvil for hand forging is made based on the work that is planned to be performed. Heavier models are perfect for working with large and massive workpieces. Simple, lighter options with one horn are a good choice when working with small-sized structures.

Lightweight models are suitable for small jobs at home. If you need to make any homemade product, there is no better option.

An important criterion is the type of work performed. Here you should decide which option is better: a two-horned or one-horned model. In addition, anvils may have additional elements, for example, a vice, which allows you to perform work alone.

It is worth paying attention to the presence of holes used to place hammers and sledgehammers. Shperaks, small in size and weight, are widely used in jewelry. In this area, products do not require serious impact processing, so they need an appropriate tool

In this area, products do not require serious impact processing, so they need an appropriate tool

Shperaks, small in size and weight, are widely used in jewelry. In this area, products do not require serious impact processing, so they need an appropriate tool.

Drawing of an anvil for making it yourself.Quite often, devices for performing jewelry work are made to order. They have various functional elements necessary to solve certain problems.

Sometimes one anvil may not be enough. In large workshops, it is advisable to have two options for devices: one stationary and the other portable.

Don't forget about proper installation. The quality of work directly depends on this

Despite everything, this device is quite heavy, its installation should be given due attention

Falling and tipping over are common problems caused by improper installation. In addition, the stand must fulfill its direct functions: in addition to securely fixing the device, it must be able to absorb hammer blows.

A wooden block is the most commonly used type of stand. Its diameter usually ranges from 500 to 600 mm. Hard woods are used. These include oak, birch, ash, etc.

The installation height is determined by the height of the master. To prevent the wooden stand from creating additional unnecessary vibrations, it is buried in a hole more than half a meter deep. The bottom of the pit is compacted with a sand lining.

It is important that the chair is installed horizontally. This parameter can be easily checked using a level. If buying an anvil is not affordable, then it can be replaced with a homemade device

It can be made, for example, from a rail, channel or I-beam

If buying an anvil is not affordable, then you can replace it with a homemade device. It can be made, for example, from a rail, channel or I-beam.

Such devices, made with your own hands, will last for decades. However, you should not think that they can fully replace a real, professional instrument. Hand anvils will not produce the same quality work as production models.

In this case, it is important to understand: the factory version, produced using casting technology, will be significantly better than homemade ones. Its design contains all the necessary components with a hardened surface. In addition, in this model the horn has the correct shape, necessary, for example, in skillful figured forging

The factory model will last quite a long time

In addition, in this model the horn has the correct shape, necessary, for example, in skillful figured forging. The factory model will last quite a long time.

Requirements for a blacksmith's anvil

- Dimensions and weight. For small-sized forgings, you can get by with relatively small anvils that can be installed on a table or workbench. However, serious forging work will require a massive, securely fastened device. Factory devices have standard weights of 5, 10, 30, 50 and 100 kg.

- Parameter matches. Simple forging can be done even on an ordinary piece of channel. But, if the work includes forging operations such as piercing, bending, and reaming, the parameters and dimensions must be observed. In this case, the edges of the anvil should be kept at right angles, and the holes should be located at convenient points. The horns should be appropriately evenly rounded, the rim should be an exact rectangle.

At home, it will be difficult to make an exact copy of a factory-made product, but some conditions can be met. So, how and from what is a homemade anvil made?

An anvil is a massive metal support on which workpieces are forged. According to the design of the anvil, there are the following types:

- Hornless: GOST 11396-75, weight 96-200 kg

- One-horned: GOST 11397-75, weight 70-210 kg

- Double-horned: GOST 11398-75, weight 100-270 kg

- Single-horned console: GOST 11399-75, weight up to 95 kg

- Shperaks: GOST 11400-75, weight up to 30 kg

It is recommended to make anvils of all types from steel 45L with subsequent heat treatment of the platbands and horns to a hardness of HB 340-477, and shperaks to a hardness of 41.5-46.5 HRC.

- The anvil can be used as a kind of percussion musical instrument (Amon Düül)

Purpose of the anvil

This type of working tool is used in many areas of production. There are anvils for blacksmithing, metalworking, jewelry, even for medical purposes. Dental technicians use them, but naturally in a much smaller size. In the forge, all manual operations are performed on it: forging and hardening of parts after the forge, giving the workpiece the desired shape.

Craftsmen need a metalworking anvil for straightening work and for bending metal surfaces. Jewelry workshops use small steel anvils on which rings, earrings, bracelets are bent and straightened, holes are punched when decorating products, etc. In dentistry, craftsmen also use it when making crowns. In general, in every household and private home it is necessary to have an anvil, at least a small one, so that you can simply straighten a nail or bend a corner.

How to attach an anvil to a metal chair?

But, in principle, you can place it in any other place in the workshop, provided that free access to it is provided from all four sides.But placing a blacksmith's anvil somewhere in the corner is not the best solution, since it will be inconvenient to work.

We also advise you to read the article: how to make a spacious tool box from an old metal canister.