Everyone had to observe spark discharges, including people who were far from knowledge of electrical engineering. Thunderstorms are accompanied by giant spark discharges. The release of enormous energy concentrated in the electrical discharge of lightning (see Fig. 1) is accompanied by a blinding flash of a hot barrel. One of the types of spark discharges created by humanity is an arc discharge, or simply, an electric arc.

Rice. 1. Lightning discharge

To date, the reasons for the occurrence and properties of an electric arc have been studied in detail by science. Physicists have found that in the area of its combustion there is a huge concentration of charges that form the plasma of the barrel. The temperature of the column reaches several thousand degrees.

Causes and places of occurrence

Electrical arcing is one of the deadliest and least understood electrical hazards and is prevalent in most industries. It is widely accepted that the higher the electrical system voltage, the greater the risk to people working on or near live wires and equipment.

The thermal energy from an arc flash, however, can actually be greater and occur more frequently at lower voltages with the same destructive consequences.

An electric arc usually occurs when there is accidental contact between a live conductor, such as a trolleybus or tram line contact wire with another conductor, or a grounded surface.

When this happens, the resulting short circuit current melts the wires, ionizes the air and creates a fiery channel of conducting plasma with a characteristic arc-shaped shape (hence the name), and the temperature of the electric arc at its core can reach over 20,000 ° C.

What is an electric arc?

In fact, this is the common name for an arc discharge, well known in physics and electrical engineering - a type of independent electric discharge in a gas. What are the physical properties of an electric arc? It burns in a wide range of gas pressure, at constant or alternating (up to 1000 Hz) voltage between the electrodes in the range from several volts (welding arc) to tens of kilovolts. The maximum arc current density is observed at the cathode (102-108 A/cm2), where it is contracted into a cathode spot, very bright and small in size. It moves randomly and continuously over the entire area of the electrode. Its temperature is such that the cathode material boils in it. Therefore, ideal conditions arise for thermionic emission of electrons into the near-cathode space. A small layer is formed above it, charged positively and providing acceleration of emitted electrons to speeds at which they impact ionize atoms and molecules of the medium in the interelectrode gap.

The same spot, but somewhat larger and less mobile, forms on the anode. The temperature in it is close to the cathode spot.

If the arc current is of the order of several tens of amperes, then plasma jets or torches flow out of both electrodes at high speed, normal to their surfaces (see photo below).

At high currents (100-300 A), additional plasma jets appear, and the arc becomes similar to a bundle of plasma filaments (see photo below).

Combustion conditions

The essence of the welding process is the conversion of electrical energy into thermal energy.

To maintain the welding column, it is necessary to create conditions for rapid ionization of the gas: the parts are heated so that the air around them is warm, or a gas capable of ionization is supplied to the working area. Particles of alkali and alkaline earth metals are most easily ionized. When current is passed through the rod, their particles become active.

To prevent the arc column from extinguishing, it is important to maintain a constant temperature in the cathode region. It directly depends on the chemical composition of the cathode and its area. The required temperature is maintained by a current source; in industrial conditions it reaches 7 thousand degrees.

How does an arc manifest itself in electrical equipment?

As mentioned above, the catalyst for its occurrence is strong heat generation in the cathode spot. The temperature of the electric arc, as already mentioned, can reach 20,000 ° C, about four times higher than on the surface of the sun. This heat can quickly melt or even vaporize the copper of the conductors, which has a melting point of about 1084 ° C, much lower than in an arc. Therefore, copper vapors and splashes of molten metal often form in it. When copper changes from solid to vapor, it expands to several tens of thousands of times its original volume. This is equivalent to a one cubic centimeter piece of copper changing to a size of 0.1 cubic meters in a fraction of a second. This will create high-intensity pressure and sound waves propagating around at high speed (which can be over 1100 km per hour).

Exposure to electric arc

If it occurs, serious injuries, and even death, can occur not only to persons working on electrical equipment, but also to people nearby. Arc injuries can include external skin burns, internal burns from inhaling hot gases and vaporized metal, hearing damage, vision damage such as blindness from ultraviolet flash light, and many other devastating injuries.

A particularly powerful arc may also cause it to explode, creating a pressure of more than 100 kilopascals (kPa) and releasing shrapnel-like debris at speeds of up to 300 meters per second.

Individuals who have suffered electrical arc injuries may require extensive medical treatment and rehabilitation, and the cost of their injuries can be extreme—physically, emotionally, and financially. Although businesses are required by law to carry out risk assessments for all work activities, the risk of arc hazards is often overlooked because most people do not know how to assess and effectively manage the hazard. Protection against the effects of an electric arc involves the use of a whole range of means, including the use when working with energized electrical equipment, special electrical protective equipment, special clothing, as well as the equipment itself, primarily high-low voltage switching electrical devices designed using arc extinguishing means.

Recommendations

- A. Anders (2003). “Tracing the Origins of Arc Plasma Science-II. Early continuous discharges" (PDF). IEEE Transactions on Plasma Science

.

31

(5):1060–9. doi:10.1109/TPS.2003.815477. - Ayrton, Herta (2015). Electric arc (CLASSIC REPINT)

. S.L.: FORGOTTEN BOOKS. paragraph 94. ISBN 978-1330187593. - The Electric Arc

, Hertha Ayrton, p.20 - Lakiesh, Matthew (1920). "Artificial light, its influence on civilization." Nature

.

107

(2694): 112. Bibcode:1921Natura.107..486.. Doi:10.1038 / 107486b0. HDL:2027/chi.14153449. OCLC 1446711. S2CID 4135392. - "Arc". Columbia Encyclopedia

(3rd ed.). New York: Columbia University Press. 1963. LCCN 63020205. - Davy, Humphrey (1812). Elements of Chemical Philosophy

.

paragraph 85. ISBN 978-0-217-88947-6. This is the probable origin of the term " arc

". - ^ a b

“Elucidation of the origin of arc plasma Nauka-II.

Early continuous discharges." Author: André ANDERS. IEEE. Xplore

, ieee.org.

IEEE Transactions on Plasma Science

. Volume 31, Issue 5, October 2003 - Kartsev, V. (1983). Shea, William R. (ed.). Mathematical nature

. Boston, MA: Kluwer Academic. p. 279. ISBN 978-90-277-1402-2. - Mason, Joan. "Sarah Ayrton." Oxford Dictionary of National Biography

(online ed.). Oxford University Press. Doi:10.1093 / link: odnb / 37136. (Subscription or UK Public Library Membership required.) - ^ a b c d

Howatson, A. (1965).

"Introduction to Gas Discharges". Science and Technology of Plasma Sources

.

9

(4): 47–101. Bibcode:2000PSST…. 9..517B. Doi:10.1088/0963-0252/9/4/307. ISBN 978-0-08-020575-5. S2CID 37226480. - Mehta, V. (2005). Principles of Electronics: For Diploma, AMIE, Degree and other Engineering Examinations

(9th, Colourful, Illustrative Ed.). New Delhi: S. Chand. pp. 101–107. ISBN 978-81-219-2450-4. - "Laser beams create tunnels for lightning." Retrieved 2015-06-20.

- Clerici, Matteo; Hu, Yi; Lassonde, Philip; Milian, Carles; Quiron, Arnaud; Christodoulides, Demetrios N.; Chen, Zhigang; Razzari, Luca; Vidal, Francois (06/01/2015). "Laser guidance of electrical discharges around objects." Science achievements

.

1

(5): e1400111. Bibcode:2015SciA…. 1E0111C. Doi:10.1126/sciadv.1400111. ISSN 2375-2548. PMC 4640611. PMID 26601188. - "Arc Suppression" Retrieved December 6, 2013.

- Harper, Charles A.; Petrie, Edward M. (2003). Plastics Materials and Processes: A Concise Encyclopedia

. John Wiley and Sons. item 565. ISBN 9780471456032. - Harper and Petrie 2003, p. ???[ page needed

] - “Laboratory note No. 106 Impact of arc extinguishing on the environment

.” Arc extinguishing technologies. April 2011. Retrieved October 10, 2011.

Arc in electrical apparatus

In this class of electrical devices (circuit breakers, contactors, magnetic starters), the fight against this phenomenon is of particular importance. When the contacts of a switch that is not equipped with special devices to prevent an arc are opened, it is sure to ignite between them.

At the moment when the contacts begin to separate, the area of the latter decreases rapidly, which leads to an increase in current density and, consequently, to an increase in temperature. The heat generated in the gap between the contacts (the usual medium is oil or air) is sufficient to ionize the air or evaporate and ionize the oil. The ionized air or steam acts as a conductor for the arc current between the contacts. The potential difference between them is very small, but it is enough to maintain the arc. Consequently, the current in the circuit remains continuous until the arc is eliminated. Not only does it delay the interruption process, but it also generates a huge amount of heat that can damage the breaker itself. Thus, the main problem in a switch (primarily a high-voltage switch) is extinguishing the electric arc in the shortest possible time so that the heat generated in it cannot reach a dangerous value.

Discharge duration

In practical applications, continuous discharge mode is more often used. However, pulse mode is also common. It is used for contact welding.

Welding of workpieces is not carried out in a continuous seam, but at several points. Such a connection does not provide tightness, but is strong enough to make thin-walled structures, such as housings for household appliances, various devices and installations, and car bodies.

The process is carried out by a non-consumable massive electrode, which is pressed against the workpiece with great force. A short-term current of very high strength is passed through the electrode - up to several thousand amperes. At the point of contact, the metal of both workpieces melts, and at the end of the pulse it cools and crystallizes as a single whole.

Next, the electrode (or workpiece) moves along the seam line to a new point, is pressed against it and a new impulse is applied.

Roller electrodes for resistance welding

There is a variation of this method that allows you to obtain tight connections. In this case, the electrode is made in the form of a roller rolling along the surface of the workpiece. The pulses are supplied at short intervals; the guiding zones along the rolling line partially overlap and form a continuous weld material. This technology is used for automatic welding of pipelines.

Factors for maintaining an arc between switch contacts

These include:

1. Electric arc voltage equal to the potential difference between the contacts.

2. Ionized particles between them.

Accepting this, we note additionally:

- When there is a small gap between the contacts, even a small potential difference is enough to maintain the arc. One way to extinguish it is to separate the contacts at such a distance that the potential difference becomes insufficient to maintain the arc. However, this method is not practical in high voltage applications where separation over many meters may be required.

- Ionized particles between the contacts tend to support the arc. If its path is deionized, then the quenching process will be facilitated. This can be achieved by cooling the arc or removing ionized particles from the space between the contacts.

- There are two ways by which arc protection is provided in circuit breakers:

— high resistance method;

— zero current method.

Varieties

There are several classifications of the element in question, which have different current supply schemes and the environment where it appears.

Welding

- With direct action. In this case, the equipment is installed parallel to the metal product that needs to be welded. The arc, in turn, becomes at right angles towards the electrodes and the metal surface.

- With indirect action. Appears when using two electrodes that are located at an angle of 50 degrees from the work being welded. An arc appears between the electrode and the material being welded.

The appearance of a welding arc.

In addition, it can be divided according to the principle of the atmosphere where the welding arc appears:

- Open sphere. The arc can burn in an open space with the formation of a gas phase, which contains vapor of the metal, electrode and surfaces after processing with a welding tool.

- Closed sphere. The arc burns under flux. In the gas phase near the arc, vapor from the material, electrodes and the flux layer itself enters.

- With supply of gas mixture. The arc may contain compressed gas such as helium, carbon dioxide, hydrogen, argon and other gaseous impurities. They are necessary so that the welded surface of the product is not subject to oxidation. Thanks to their supply, the environment is restored or becomes neutral to external factors. The gas supplied for operation, steam from the product being welded and the electrodes enter the arc.

In addition to the listed classifications, we can also distinguish types by duration of action:

- classic is used for constant use;

- pulse – for one-time use.

One of the most popular parts is steel, i.e. consumable electrode. However, today most professionals prefer non-melting, from which we can conclude that the types of elements under consideration are quite different from each other.

Extinguishing the arc by increasing its resistance

In this method, the resistance along the arc path increases over time so that the current decreases to a value insufficient to support it. Consequently, it is interrupted and the electric arc goes out. The main disadvantage of this method is that the extinction time is quite long, and enormous energy has time to dissipate in the arc.

Arc resistance can be increased by:

- Arc elongation - the resistance of the arc is directly proportional to its length. The arc length can be increased by changing the gap between the contacts.

- Cooling the arc, or more precisely the medium between the contacts. Effective fan cooling must be directed along the arc.

- By placing the contacts in a difficult-to-ionize gas environment (gas switches) or in a vacuum chamber (vacuum switches).

- Reducing the cross-section of the arc by passing it through a narrow hole, or reducing the contact area.

- By dividing the arc - its resistance can be increased by dividing it into a number of small arcs connected in series. Each of them experiences the action of elongation and cooling. The arc can be divided by introducing some conductive plates between the contacts.

Arc extinction using zero current method

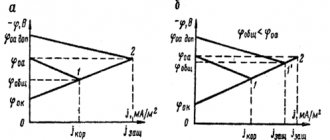

This method is used only on AC circuits. It keeps the arc resistance low until the current drops to zero, where it extinguishes naturally. Its re-ignition is prevented despite the increased voltage at the contacts. All modern high-alternating current circuit breakers use this arc extinguishing method.

In an alternating current system, the latter drops to zero after each half cycle. At each such reset, the arc goes out for a short time. In this case, the medium between the contacts contains ions and electrons, so its dielectric strength is low and can be easily destroyed by increasing voltage at the contacts.

If this happens, the electric arc will burn for the next half cycle of the current. If immediately after it is reset to zero, the dielectric strength of the medium between the contacts increases faster than the voltage across them, then the arc will not ignite and the current will be interrupted. A rapid increase in the dielectric strength of the medium near zero current can be achieved by:

- recombination of ionized particles in the space between contacts into neutral molecules;

- by removing ionized particles away and replacing them with neutral particles.

Thus, the real problem in interrupting AC arc current is the rapid deionization of the medium between the contacts as soon as the current becomes zero.

Methods for deionization of the medium between contacts

1. Gap lengthening: The dielectric strength of the medium is proportional to the length of the gap between the contacts. Thus, by quickly opening the contacts, a higher dielectric strength of the medium can be achieved.

2. High blood pressure. If it increases in the immediate vicinity of the arc, the density of particles making up the arc discharge channel also increases. The increased density of particles leads to a high level of their deionization and, consequently, the dielectric strength of the medium between the contacts increases.

3. Cooling. The natural recombination of ionized particles occurs faster as they cool. Thus, the dielectric strength of the medium between the contacts can be increased by cooling the arc.

4. Explosion effect. If the ionized particles between the contacts are swept away and replaced by non-ionized ones, the dielectric strength of the medium can be increased. This can be achieved using a gas explosion directed into the discharge zone, or by injecting oil into the intercontact space.

These switches use sulfur hexafluoride (SF6) gas as the arc extinguishing medium. It has a strong tendency to absorb free electrons. The switch contacts open with a high pressure flow of SF6) between them (see picture below).

The gas captures free electrons in the arc and forms an excess of low-mobility negative ions. The number of electrons in the arc quickly decreases and it goes out.

Uses

An electric arc can melt calcium oxide.

In industry, electric arcs are used for welding, plasma cutting, EDM, as arc lamps in movie projectors, and observation points in stage lighting. Electric arc furnaces are used to produce steel and other substances. Calcium carbide is produced in this way because it requires a large amount of energy to promote the endothermic reaction (at a temperature of 2500 ° C).

Carbon arc lamps were the first electric lights. They were used for street lamps in the 19th century and for specialized applications such as floodlights before World War II. Today, low pressure electric arcs are used in many areas. For example, fluorescent tubes, mercury, sodium and metal halide lamps are used for lighting; Xenon arc lamps are used for film projectors.

Formation of an intense electric arc, similar to a shallow one. arc flash is the basis of explosive detonators.

The main remaining application is high voltage switchgear for high voltage transmission networks. Modern devices use sulfur hexafluoride under high pressure in a nozzle flow between individual electrodes within a pressure vessel. The alternating short circuit current is interrupted at zero current by highly electronegative SF6 ions absorbing free electrons from the decaying plasma. Similar overhead technology was largely replaced because it required many noisy units connected in series to prevent current re-ignition under similar supergrid conditions.

Electric arcs have been studied for the electrical propulsion of a spacecraft.

They are used in the laboratory for spectroscopy to create spectral radiation by intensely heating a sample to matter.

Guiding the arc

Scientists have discovered a method of controlling the arc path between two electrodes by directing laser beams at the gas between the electrodes. The gas turns into plasma and directs the arc. By creating a plasma path between the electrodes using different laser beams, the arc can be formed in curved and S-shaped paths. The arc can also hit an obstacle and reform on the other side of the obstacle. Laser-guided arc technology can be useful in applications to deliver an electrical spark to a specific location.[12][13]