What is a hammer drill used for?

The tool is designed to perform percussion work in hard materials :

- stone;

- metal;

- brick;

- reinforced concrete.

A hammer drill is a universal tool.

It is used to drill holes of different diameters for dowels, sockets for sockets in concrete, chip tiles, break through floors, as well as concrete and brick walls, and make openings for laying communications.

The versatility of the hammer drill is explained by the ability to work in various modes :

- drilling;

- rotation with and without impact;

- hit without rotation.

Professional models can work like a jackhammer.

Tools

0 votes

+

Vote for!

—

Vote against!

Both in construction and in repairs, a hammer drill has become an indispensable assistant. This powerful electric tool, the very appearance of which already inspires respect, is designed for working on brick and concrete, but with no less success it can be used for working on wood or metal, like a regular drill.

How to work with a hammer drill so that the tool you choose lasts for many years? Proper operation of a hammer drill not only increases the service life of the tool, but also significantly reduces the risk of injury during its use. You should use certain working techniques that do not allow you to overload the tool, and also monitor its timely prevention.

Content

- Brief characteristics of rotary hammers

- How to prepare a hammer drill for work

- How to work with a hammer drill in different modes

- Drilling mode

- Impact drilling mode (drilling)

- Impact mode

- Techniques for working correctly with a hammer drill

- Care and operation of the rotary hammer

- When can you make noise with a hammer drill?

Brief characteristics of rotary hammers

To understand how to work with a hammer drill correctly, let’s look at its capabilities.

This powerful hand-held power tool is designed for impact work in hard structural materials such as reinforced concrete, metal and stone. Using a hammer drill, you can not only drill holes of different diameters, but also chip off old tiles, break through floors and walls, and make openings for utility lines.

The hammer drill is capable of operating in different modes, which makes it an almost universal tool. This is rotation with and without impact, drilling in concrete, stone, metal and wood, impact without rotation. A professional hammer drill can also replace a jackhammer.

Inside the hammer drill there is a striking mechanism - electropneumatic or electromechanical. To activate it, just press a button. The mechanism produces the blow itself, no additional effort is required.

The main disadvantage of this tool is its significant weight. By weight, rotary hammers are conventionally divided into 3 groups: up to 18 kilograms - light, from 18 to 25 - medium, more than 25 - heavy. The technical specifications indicate the impact force, which in most household hammer drills can range from 2 to 3 J, and in professional tools - from 2 to 10 and from 5 to 18 J, as well as the frequency of blows per minute, depending on the power, reaching 23 thousand blows per minute up to 44.5 thousand.

Rotary hammers use two systems for attaching replaceable tools. These are SDS+ and SDS-MAX. Their differences are in the diameter of the shank, respectively, 10 mm and 18 mm. Light hammer drills that weigh no more than 5 kilograms are equipped with an SDS+ chuck. Such tools can be both household and professional. The SDS-MAX chuck is designed for rotary hammers whose weight exceeds 5 kg. SDS-MAX tools are used professionally.

How to prepare a hammer drill for work

Before starting work, you need to understand the installation and removal of the replacement tool, the fastening system of which depends on the weight of the hammer drill.

Let's look at installing a replacement tool using the example of using a BOSCH GBH 2-26 rotary hammer. Drills with SDS+ type shanks with four splines are used here. Before installing the drill, you need to clean its shank and lubricate it with a special grease for drills. Lubrication helps the hammer operate more smoothly and increases its service life.

To install the tool, you must move the lubrication ring back. The cartridge is opened and installed. Then you need to turn it a little and lock it in the desired position. After this, the sliding ring should be released, which makes it possible to lock the tool. Make sure that the tool is properly secured in the desired position. Before installing or removing parts, be sure to make sure the hammer is turned off and unplugged.

For more convenient work with the hammer drill, you need to attach a soft additional handle to it, which reduces the level of vibration. Before starting work, make sure that it is fastened securely enough.

How to work with a hammer drill in different modes

Drilling mode

The tool should first be switched to drilling mode, avoiding impact. The toggle switch is installed opposite the mark, which looks like a drill. After this, you need to place the drill in the right place and turn on the tool using the button. When drilling, you do not need to press hard on the hammer; the pressure on it should not be more than five kilograms.

When using drill chucks, do not use the “counterclockwise rotation” and “impact drilling” positions, as this may damage the chuck and cause it to separate from the power tool. To prevent this situation, the hammer drill has added an “impact blocking” function, designed for drilling various holes in wood or metal.

Before operating the tool directly, you need to check the mode in which it is located. The hammer drill should run at idle speed for approximately one minute. Pay attention to the operation of the gearbox. There should be no extraneous noise, vibration or knocking. Burning smells or the appearance of smoke should also alert you. They may appear if the power tool malfunctions.

Impact drilling mode (drilling)

First you need to switch the hammer drill to hammer drilling mode. The toggle switch is installed above the mark with the image of a drill and hammer. The drill must then be positioned where the hole needs to be made, and then turn on the tool.

When drilling, you should try to avoid skewing the drill, preventing it from sliding from the desired point. The hammer drill must be held firmly, but not pressed on it. Light pressure produces optimal results.

When filling a hole with crumbs and dust to clear it of debris, try to remove the drill empty. This will make further work easier.

When drilling in concrete, the drill may hit reinforcement. In order not to lose control of the tool, you need to take this possibility into account before starting work and immediately take a comfortable position, securely holding the hammer drill.

Impact mode

The impact mode is used for chipping and chiseling, as well as for gouging. The toggle switch is set to strike mode above the mark with the image of a hammer. The tool must be held with both hands and very firmly. Turn on the hammer drill. In order for it to be in the right place for impact, some effort should be applied. Greater force is also not needed here, since this will not improve the result.

Remember that while the hammer drill is operating, its position cannot be changed.

Techniques for working correctly with a hammer drill

1. When working, you must use protective equipment. These include safety glasses, gloves, and earplugs. You need to work in buttoned-up overalls, removing anything that could accidentally get wrapped around the drill while working.

2. Do not press hard on the hammer in the direction of impact or drilling. This is not necessary, since this will not affect the impact force and performance of the tool, but it may fail because of this.

3. The hammer drill should not run idle, because in this case the impact energy is absorbed by the mechanisms, and this leads to their additional wear.

4. When working with porous and loose material, it is better to use non-impact drilling to avoid its disintegration.

5. When working with materials of increased hardness, it is recommended to use a special lubricant. Machine oil can be used as a lubricant.

6. Working with solid materials also requires the use of liquid cooling. Cutting fluids can be special emulsions; grease or machine oil are also used.

7. If it is necessary to use long drills to save money, it is advisable to start drilling with shorter drills of the same diameter.

8. Regularly, every 180-200 holes, you need to lubricate the drill shanks with thick lubricant, after first cleaning them from dust and wiping them with a dry cloth. Solid oil or litos can be used as a lubricant.

9. To increase the resources of consumables, it is periodically necessary to allow the hammer drill to cool and cool the drills in water or machine oil.

10. It is necessary to monitor the heating of the tool body in the area where the gearbox is located. If it becomes very hot, you should take a break from working until the hammer has cooled down. It is not recommended to use water for cooling, as water entering the housing may damage the instrument.

11. It is necessary to alternate periods of working and resting the tool. For professional hammer drills, it is recommended to take a break of 10 minutes after every 30 minutes of work.

Care and operation of the rotary hammer

The length of its service life directly depends on how the basic rules for operating a rotary hammer are observed. First of all, you need to pay attention to the lubrication of the tool. There is no need to save money here, especially if there is concrete work to be done.

During work, a lot of construction dust is always generated. You can protect the hammer drill from it using a vacuum cleaner. Many models have special devices on the body to which the hose is attached. To protect yourself from concrete particles, you can put a shield on the drill, made, for example, from the bottom of a plastic bottle.

How to operate a hammer drill to avoid overheating? Please note that both when rotating quickly and when operating the tool at low speeds, it heats up very quickly. Therefore, it is important to strictly follow the work and rest schedule of the rotary hammer.

In order not to have to ask the question why the hammer drill does not work, you need to properly monitor the power tool and keep it in proper condition. After use, the disconnected tool should be cleaned with a soft cloth. If necessary, you can also use a damp cloth soaked in soapy water. It is necessary to clean the ventilation hole from dust and dirt.

If the hammer drill still stops working, keep in mind that it should be repaired by specialists. By the way, you should contact the service center even after intensive use of the tool, even if it is in good condition. A preventive inspection will help you avoid problems that could lead to injury. This recommendation should not be neglected, especially if you are using tools with high power and strong impact.

When can you make noise with a hammer drill?

A separate conversation about the noise created by the tool during operation. It's no secret that few people are delighted with the sound of a working hammer drill in the mornings and weekends. What to do if you need to do repairs, but you don’t want to quarrel with your neighbors? When can you work as a hammer drill without also getting into trouble with the law? It should be taken into account that according to the law, the “period of silence” in the country is considered to be the time period between 23.00 pm and 07.00 am.

Not all people wake up by seven in the morning, so it’s still better to postpone any noisy repair work until at least nine o’clock. Each region, as a rule, sets its own time frame. In some, repair work is allowed only on weekdays from 09.00 am to 19.00 pm. Therefore, the question of how many hours and until what time you can work as a hammer drill is best decided based on the Code of Administrative Offenses of your region. It would not be superfluous to refer to local laws and regulations because they may also consider other issues regarding the regulation of repair work or other information that will be relevant specifically in your area.

Preparing the hammer drill for work

Before drilling with a hammer drill, you need to prepare for work, study the instruction manual and strictly follow the requirements described in it. If the rules are violated, the instrument may break and it is not always possible to repair it. The required load must not be exceeded. Long and continuous operation leads to overheating of the gearbox and drive elements, which fail. Parts are lubricated only with high-quality compounds . It is prohibited to perform work that is not provided for in the instructions. Before drilling into a wall with a hammer drill, it is inspected.

Check integrity:

- housings;

- cartridge;

- electrical insulating layer of the connection cable.

It is necessary to make sure that there are no chips or cracks on the crowns, drills and drills. The cutting edges must be sharpened.

Before drilling a hole with a hammer drill, perform a trial run and operate in idle mode . Check whether the buttons and toggle switches responsible for the speed and direction of rotation of the cartridge work.

On an unfamiliar object, make sure that the wiring is of sufficient size to power a powerful tool. Otherwise, the cable will overheat, which will lead to melting of the insulation and short circuit.

Features of drilling different surfaces

There are as many varieties of materials as there are drilling features. High-quality results can only be expected if they are strictly followed.

Metal

This material is difficult to handle mechanically. You need to work with metal with very strong, high-quality drills , otherwise the workpiece can be damaged. It is extremely difficult to drill into thin metal sheets. They move all the time. A special device is used to fix them.

For metal use especially strong drills

Tree

Wood is easy to drill and chisel, but when working with it, certain requirements must be observed. Logs must be secured. When working with small wood, use simple sandpaper. Wrap the blanks in felt. It will help remove burrs that appear after drilling. When working with wood, do not put too much pressure on the tool. There are several types of wood flooring, each treated differently. For example, when drilling plywood, to prevent it from splitting, use an attachment resembling a potato peeler. To make one, a steel tube . They use it to make holes in the plywood.

Wood of different species varies significantly in hardness . As a result, the load on the equipment when working with pine is less than with oak. It must be borne in mind that the resulting chips clog the drill, which can cause it to overheat.

The store sells a large number of different products. Don't buy the cheapest ones. They are not reliable. They can be purchased to perform one-time work. It is better to opt for products made from metal alloys . They are more durable and wear-resistant when working with a wooden base.

Concrete

A drill with a Pobedit tip is best suited for working with this material . First, mark the drilling point. A small recess is made in it with an ordinary drill. A drill of the required size is installed in the hammer drill chuck and a hole is drilled with it. During the process, the nozzle is dipped into water from time to time, so it penetrates the concrete better. If you have to hammer reinforced concrete slabs, there is a chance that the hammer drill will bump into the reinforcement. You can drill slightly to the side or diagonally. If it is necessary to make a hole at a specific point, use a special nozzle and a regular drill. Pobedit nozzles are not intended for punching reinforcement.

Ceramic tile

Tiles are often used to decorate bathroom walls. This is a very fragile material. It is impossible to make holes in it with ordinary drills. You need special ones with carbide tips . Soldering reduces the load on the surface, making drilling into ceramic coating much easier.

The best tools for drilling holes in ceramics are those with a diamond coating . Such products are expensive, there is no point in buying them for a one-time job. They are usually used by craftsmen whose work involves constant drilling of ceramic tiles.

If you have to drill glued tiles, take glass drills . Some people recommend using a mounting grid. It is placed between the tile and the drill, then the mesh will not crack. After the drill passes the tile, a drill is inserted into the chuck, which performs impact movements.

To drill tiles, use special drills with carbide tips.

Tool overview

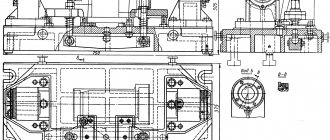

To process surfaces made of concrete, an electrically driven tool is used.

There is equipment with additional impact action, which makes it possible to obtain holes of the correct geometric shape in solid materials. Diamond drilling rigs are characterized by increased weight and dimensions; the equipment is used by construction or repair teams.

If the user needs to make single channels, and there is no electric tool available, then he needs to know how to make a hole in a concrete wall without a hammer drill. For drilling, a steel rod or a piece of pipe of suitable diameter with teeth at the end is used.

The rod is struck with a hammer, and then the improvised tool is turned 1/3 of a turn. The procedure takes a long time, the quality of the hole edges is poor.

Hammer

Drilling a hole in concrete is done with an impact drill or hammer drill; the tool allows you to drill channels up to 500 mm deep. The disadvantages of using the equipment are increased noise during operation and the risk of wall destruction due to vibration loads.

An additional disadvantage is the formation of a large amount of dust; a professional tool requires the installation of a bushing for the vacuum cleaner hose.

Regular drill or screwdriver

It is almost impossible to make a hole in a concrete wall with a hand or standard power tool. The equipment allows you to make channels of small diameter in soft material; when you try to drill into a concrete base, the drill becomes dull or breaks.

To facilitate the drilling process, a chisel or punch is used to break up solid inclusions in concrete. It will not be possible to drill concrete floors or walls without a hammer drill.

Diamond drilling

To cut holes in concrete reinforced with metal reinforcement, a diamond bit installed in special equipment is used. The tool supplies water to the working area, which cools the crown and washes away the resulting dust. The installation allows you to make a hole of large diameter; there is no damage or chips on the edge of the channel.

Safety precautions at work

To protect yourself from injury and the tool from damage, you must follow safety rules. Work with a rotary hammer in overalls, transparent glasses, gloves, closed shoes, earplugs or headphones , as the tool is dusty, noisy, and particles of solid material fly away when chiseling. A working rotary hammer will not slow down or make any extraneous noise.

If it is necessary to make a long hole, first drill with a short drill and gradually move on to a long one. If it is not given rest, it will overheat. The technical manual indicates recommended operating times under load and at idle.

You should not touch the nozzle with your bare hands immediately after it has stopped, as you may get burned. timely cooling , otherwise it will lose its hardness and elasticity. To cool the holes and nozzles, a special liquid system is used, the operation of which is based on the supply of cooled water or emulsion to the desired location using tubes or a water coupling.

The tail section of all drills requires periodic lubrication. It is recommended to carry out this procedure before installing the nozzle. Although lubrication is allowed every 150-200 operations . The instructions indicate the frequency of maintenance that must be observed.

What to do if a drill or auger gets stuck in the wall

Even knowing how to drill correctly with a hammer drill, you may encounter a problem when the drill gets stuck in the wall. Most often, the cause is the nozzle getting caught between the stone and the iron reinforcement . This happens if the drill penetrates very deeply into the wall. There is no need to press the trigger further and loosen the tool. The nozzle can break, and getting it out quickly and easily is not always possible. The worst thing is that the hammer drill will burn out. If the drill is stuck in the wall, the cartridge is freed from it. A thin drill is inserted into the tool and a piece of concrete is carefully drilled out near the stuck nozzle. There is no need to get there. Gradually, slowly, you will be able to hollow out pieces of concrete and pebbles around the stuck nozzle. After this, the drill can be removed from the wall.

To reduce dust during work, you can use tape and a bag.

Is it possible to drill tiles, wood, tiles and metal with a hammer drill?

A rotary hammer is a screwdriver, drill, jackhammer and construction mixer in one tool. How to use a hammer drill in different modes, what materials can it work with, and how to properly care for this tool?

A hammer drill is a versatile electric tool that can perform many tasks. With its help, you can drill holes in hard surfaces, tap walls, and also work in chipper mode.

At the same time, the safety of the work carried out corresponds to a high level, and even a person far from the construction industry can learn how to use a hammer drill.

From this article you will learn how to drill various materials with a hammer drill, prepare it for work, and also care for it.

What materials is the hammer used for?

Can a hammer drill drill into wood, metal or tile? Is this tool used as a concrete mixer? Many people have similar questions before buying a hammer drill. After all, you want to get the most out of an impact drill. Therefore, below are all the functions of the rotary hammer with brief explanations for each of them.

Rotary hammer functions

Drilling tiles. The drilling site is marked, and a hole is drilled at low speeds using a special drill for tiles without impact mode. Having reached the wall, the drill changes.

Drilling wood. In drilling mode without impact, at maximum speed, when using wood drills.

Drilling metal. Not recommended. It is possible to drill only thin sheet steel using special metal drills.

Stir the solution. Not recommended. You can burn out the engine due to too much load. Used only for mixing small quantities of solution with low viscosity.

Tighten screws and self-tapping screws. Not recommended. Firstly, it is extremely inconvenient due to the significant dimensions of the hammer drill. Secondly, due to the high power of the tool, there is a high risk of overtightening.

Thus, you can perform many operations with a hammer drill, but this will not always be advisable. Still, the main purpose of this tool is drilling and chiselling concrete surfaces. Therefore, it will last as long as possible when used as intended.

Rotary hammer operating modes

Each rotary hammer has three operating modes: drilling, hammer drilling and impact mode. Depending on what material is being worked with, one or another mode is selected.

The drilling mode is used to make holes in hard materials - tiles, wood, plastic, metal, etc. The hammer drill in this mode performs the function of an ordinary drill. To activate it, switch the toggle switch to the position opposite the drill icon.

Drilling with a hammer drill

How to drill metal with a hammer drill? Select a drill of the required diameter for metal. If the diameter of the hole or the thickness of the metal is too large, it makes sense to start with small drills, gradually widening the hole formed. Hammer in drilling mode. The surface must be marked so that the drill does not “walk.” Let's get to work, controlling the heating of the motor.

How to drill tiles with a hammer drill? This operation is also performed in drilling mode. Use special drills for glass and ceramic tiles with a tungsten carbide tip or pobedit drills.

The location of the hole is marked, adhesive tape is placed on top (so that the drill does not move), or the drilling points are marked. When the tile is drilled through, the drill and mode are changed to hammer drilling (in the case of a concrete wall).

The drilling mode with impact on the switching switch is indicated by the image of a drill and a hammer. It is used for drilling holes in fragile materials - concrete, plaster, brick, etc. In this mode, the drill simultaneously rotates and strikes, due to which the material is destroyed, and dust and fragments are thrown out.

The impact mode is turned on to perform chipping, chiseling and gating. On the toggle switch this mode is indicated in the form of a hammer. Depending on the functions performed and the characteristics of the material, various attachments can be used: blades, peaks, chisels, etc. In this mode, the tool does not rotate, only chiseling.

Many modern rotary hammers also have a reverse mode. It will be very useful if the drill gets stuck. When this mode is turned on, the motor rotates in the opposite direction.

When can you work with a hammer drill?

Carrying out repair work using a hammer drill in an apartment building is inextricably linked to causing inconvenience to neighbors. To avoid conflict situations or even fines, you need to know your rights and responsibilities.

In accordance with the rules for the use of residential premises, it is prohibited to create noise and vibration during the period from 23:00 to 7:00.

This means that at this time, not only can you not work with a puncher, but you can’t even talk loudly, sing or play musical instruments.

Working with a hammer drill during the reconstruction or redevelopment of premises in apartment buildings is prohibited on weekends and holidays, because this action results in noise and/or vibration. It is also not allowed to perform such work on weekdays between 9:00 and 19:00.

It should be understood that the noise level coming to neighbors from the operation of a hammer drill directly depends on the quality of the sound insulation performed and the thickness of the floors in the house.

A rotary hammer is one of the most popular electric tools, which is widely used not only in the construction industry, but also in home life.

With its help, you can perform a wide variety of tasks - drilling materials such as concrete, wood, metal, ceramics, brick; stirring liquid solutions; chiseling and chipping. In order for the impact drill to serve for a long time and without breakdowns, it is necessary to use attachments in accordance with the type of surface and operating mode of the hammer drill.

Proper care of your electronic instrument will also significantly increase its service life.

How to drill without dust

To prevent dust when drilling the wall, take a plastic bag and tape , preferably masking tape. In the right places on the wall, mark the holes to be made. Under the mark on the wall, glue an open plastic bag with tape so that the dust falls inside. When you increase the speed, some of the dust will be blown away by the engine fan, so you need to drill carefully at low speeds, then the waste will pour out exactly into the bag. It is important to stick the tape to the wall very tightly. If the fit is not tight, dust will spill between it and the wall, and the wallpaper will become dirty.

Basic parameters to consider when choosing drills

Soldering determines the speed of hole punching, drill wear resistance, and drilling quality. If you plan to work with masonry or marble tiles, it is better not to use a concrete drill. For heavy and reinforced concrete, a diamond tip attachment is suitable. If you have no experience in choosing products, you should familiarize yourself with simple recommendations.

An essential criterion is the choice of drill according to the chuck . Depending on its type, a drill is selected; another type will not work. Then select the desired size. You need to choose a drill of such a size that it is slightly smaller than the required hole, because when the drill enters the surface, it crushes the concrete around the circumference. When purchasing, you need to pay attention to other equally important parameters.

Drill diameter

To work with different materials, drills of the appropriate diameter . Due to the narrow nozzle, it is difficult to enlarge the hole smaller than the required size. The work will be performed poorly, and it will not be possible to securely install the product.

Length of the product

This is an important indicator. Often you have to work with thick surfaces. If necessary, drill holes of about 0.5 m; the equipment must be strong and durable. When choosing a specific nozzle, you need to determine the length of the product .

Hole type

When you need to drill a workpiece to a certain depth, and not right through, use products with a conical tip . This is necessary when making holes for furniture hinges. It is important here not to spoil the material, because it is thin.

Before purchasing, you need to evaluate the appearance of the drill . There should be no unevenness or cracks on the surface. The presence of such defects will negatively affect the final result. The holes for the hinges are drilled using a Forstner drill . It has a special limiter, which is adjusted depending on the thickness of the material being processed.

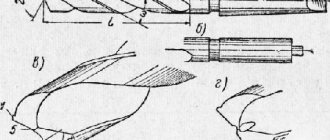

Drills and drill bits for rotary hammers

Color

In addition to these indicators, the color of the drill is of great importance:

- Gray . The cheapest and most durable products.

- Black . Much more durable than previous ones.

- Yellow . They have high hardness.

- Golden . Very strong.

No less important indicators are wear resistance and performance. A good drill or high quality drill will be enough to make a large number of holes. When choosing equipment for working with concrete or other materials, you should pay attention to the shank of the hammer drill . This recommendation is due to the fact that the drill shank and tool chuck design do not always match each other.

Tips for using rotary hammers

There are several rules for using rotary hammers that must be followed.

- During operation, do not press too hard on the tool to prevent damage to the drill. In any case, this will not increase power and performance.

- A common mistake is the desire to complete the entire operation in one go. The drill needs to be cleaned periodically.

- The choice of equipment is determined by the type of work performed and the specific features of the tool itself. For example, when using one type of hammer drill, you will need an adapter to replace the nozzle, while the second has a quick-release design.

- Mechanical damage or systematic overheating of the equipment is not allowed. When choosing, you should pay attention to models with an aluminum case, which, due to the characteristics of the material, always cool better.

- When working with a hammer drill, it is recommended to wear rubber gloves, which will help dampen vibration, despite the fact that the tool itself is equipped with special inserts for this purpose.

It is important to find out: “TOP 5 drill manufacturers: which company is better”