From the author: Hello friends! To carry out repair and construction work, it is often necessary to drill into concrete and brick walls. Drills for metal surfaces are not suitable; they quickly begin to become dull and differ in the cutting part, quality and other features. Therefore, you need to know which drill bits for concrete are best, because there are quite a large number of their manufacturers.

Main types of concrete drills

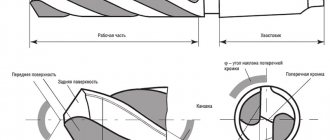

A distinctive feature of a concrete drill from others is soldering. It is created from a strong alloy, due to which a hardness similar to diamond stones is achieved. Craftsmen call these types pobedit; these products differ in strength from other types that are created for metal or wood.

There are 2 main types by which concrete drills are classified:

- for a drill - consist of a shank for a nozzle, which is made in a cylindrical or multifaceted shape. The dimensions are small, the product is suitable for creating holes in many hard materials, for example, brick, foam block. It is recommended to use a high-power drill, which will allow you to drill into concrete,

- for a hammer drill - the drill is cylindrical in shape, has a shank, designations SDS PLUS or SDS MAX. The goods themselves are quite large and long, suitable for reinforced concrete structures.

If you need to create holes in a reinforced concrete structure using a simple drill, then it is not always possible to solve the problem with just a drill. You need to use a hammer drill, and for this tool, drills are divided into the following types:

- screw - used to create deep holes,

- spiral - suitable for large holes,

- flat - used for drilling passages of different sizes and depths.

For proper operation, you will need to not just insert the drill into the chuck, but snap it into place. To make this task easier, the products have a slight thickening at the very end. It should also be noted that the products are considered professional tools, since they can be used to create holes from 4 mm to 3 cm in diameter.

If you need a larger hole, then the crown type will come to the rescue. Such products make it possible to make a recess of 12 cm in diameter. The products are very durable and are produced in several versions:

- diamond - visually made in the form of a pipe or crown, mounted on a rod, the edges are coated with diamond, which ensures high strength,

- pobedit - similar to an attachment, the main difference from diamond is the absence of sputtering; it is replaced by special teeth made from pobedit.

It is recommended to use crown products for holes for sockets, switches or wiring, and other communications. To select a suitable concrete product for a drill, you will need to take into account not only the parameters of the element, but also the dimensions of the future hole. Based on this, the length of the drill is selected, which depends on the diameter:

- diameter 4 mm - length 5 cm,

- 5 mm - 10 cm,

- 6 mm - 15 cm,

- 8 mm - 25 cm,

- 10 mm - 54 cm,

- 12 mm or more - up to 100 cm.

It turns out that for large holes a long concrete drill is used. If you use thin instruments, there is a risk of damage due to increased load.

Features of drills

In order to choose the right drill for concrete structures, without making mistakes, you will need to know the features that distinguish them from products for metal and other materials.

The shape of the working area will be quite blunt; this area is made of a Pobedit plate. This type is suitable for concrete as woodworking products will include sharp tips. Due to this, at the beginning of the work, the wood is stuck inside, and only then a hole is made. The working area of a metal product is similar to a cone with no sharp points.

The color of concrete products is often metallic white. Products for wood will be strictly metal, and for metal, black colors are used.

Drilling Tips

There are a few simple rules to follow when drilling into concrete. Due to this, the work is performed more efficiently, and the service life of the product increases:

- When you first experience drilling concrete with a drill, you need to prepare several types of drills, you can even reserve them for metal. This is due to the fact that each type has its own purpose - for example, some are suitable for brick, while others are suitable for concrete and ceramics. When creating holes in the wall, there is a possibility that metal reinforcement will appear along the way, in which case the drill is changed and work continues,

- Some people specifically sharpen a concrete drill bit, so they can drill into metal during the job. This decision is wrong, since for the versatility of the product you will need to know many sharpening rules and have a lot of experience,

- It is forbidden to work without breaks; if the drill overheats, it may be damaged. It is recommended to drill for 15 seconds and then leave the drill to cool down. Do not use water or other mixtures for rapid cooling,

- Concrete always contains solid fractions in the form of stones, which can stop the drill during operation. It is easy to crush such inclusions with a chipper, and then continue to create a hole,

- if a hole needs to be made in a concrete wall, which is a load-bearing wall, or in ceilings, then it is better to use a hammer drill. Thanks to it, work is performed more efficiently and quickly,

- It is necessary to drill ceramics on walls or floors without the impact mode of the drill, otherwise the materials will be destroyed. Ceramic surfaces should only be worked with concrete drills,

- Cheap concrete drills are made from low-quality alloy, so they are not hard and need to be sharpened from time to time. To do this, you can use an angle grinder and a diamond disc,

- While drilling, it is not recommended to put pressure on the drill; this causes loss of balance, and drilling becomes more difficult. In addition, there is a possibility of the drill breaking, it simply bursts,

- To make holes for plastic dowels, it is recommended to make the depth a little larger. Dust and other dirt will not allow you to place the element correctly, a reserve is simply necessary,

- You need to start drilling concrete with low drill speeds so that the drill does not jump and the hole is smooth. After reaching a certain depth, the speed increases or the tool switches to impact mode,

- If the drill is used very often and for a long time, then you need to replace the chuck. Over the years, the fixation weakens, so the quality of work decreases, there is a risk of injury,

- When drilling, experts recommend soaking the drill in cold water, but not cooling it using this method. This rule protects the product from damage,

- To maintain cleanliness while working, it is recommended to put a plastic cup on the drill. This protects against flying concrete dust,

- Do not hold or hold the chuck with your hands while the drill is operating. You can only hold on to the body,

- When using gloves and protective clothing, it is important to use the correct size to avoid getting caught in the cartridge. Additionally, it is recommended to wear glasses to protect your eyes from dust.

When working according to the rules and using these tips, drilling concrete will be a simple and safe task, and the drills will last a long time.

Useful tips for working with a concrete drill

1. Before starting work on concrete, it is best to stock up on different drills, including those for metal. The fact is that concrete drills are allowed to be used only for their intended purpose - for drilling concrete, ceramics, stone and other hard materials. But it happens that, having entered the concrete, the drill rests against metal reinforcement. In this case, you will need a metal drill, which temporarily replaces the concrete drill, drills through the reinforcement, and then inserts the drill back. Some craftsmen manage to sharpen a drill so that it becomes suitable for working on both metal and concrete, but this is very difficult to achieve and requires a lot of experience and special skills.

2. When working with concrete, you must constantly ensure that the drill does not overheat. After 15 seconds of continuous drilling, pause. Cooling is allowed only naturally, in no case using water or other liquid.

3. Sometimes, when entering concrete, the drill encounters a hard stone and cannot overcome it. In this case, it is better to use a chipper, crush the stone and then use a concrete drill again.

4. If during the repair process it is necessary to make holes in a load-bearing wall or ceiling, it is better to put aside the impact drill and use a hammer drill. Otherwise there will be no sense, only fatigue and wasted time.

5. If there is a need to drill into ceramics, use a drill for concrete, just turn off the impact drill mode, otherwise the tile will crack.

6. Blunt drills are sharpened with a grinder using a diamond disc. But if you initially purchase a high-quality, expensive instrument, then such a need will not arise.

Sharpening

When drilling concrete surfaces, sooner or later there is a need to sharpen the working part, even if it is made of diamond or coated with diamond. For the procedure you will need to use a sharpener or a special machine. In addition, at home you can use a regular universal machine or sharpen attachments with a grinder.

It is important to inspect the drill tip before doing any work. It should have 2 “shelves” that are the same length. Otherwise, damage will occur during drilling, and the holes themselves will be of poor quality. The whole sharpening process is not complicated, the main thing is to ensure the evenness of the shelves:

- for concrete and other hard materials, the alpha angle is 200–300,

- the cutting edges must not touch the grinding wheel, otherwise there is a risk of breakage,

- When sharpening, it is forbidden to bring the drills to heat; from time to time you need to pause and cool the material; the use of water is allowed. If the working part is hot, then it must be left to cool in the usual way, since contact with water risks cracking the drill.

Sharpening a drill for concrete is a complex process that requires certain skills, so without knowledge it is better to turn to the experts.

The use of concrete drills for other materials

There is an opinion among many ordinary people that drills, regardless of their purpose, are a universal tool that can cope with any material, it’s only a matter of time. This, of course, is a misconception: anyone who has tried to drill through a brick wall or metal with a wood drill will confirm this. A wood drill is designed for drilling wood by removing chips at an angle close to a straight line; for metal, the drill also removes chips, but at an angle of about 45 degrees, gradually penetrating into it, the Pobedit drill crumbles and pierces concrete.

If you apply a concrete drill to wood, it will simply crumble the wood and the hole will look disgusting, and if you try to drill into metal, the bit will not last long, its edges will simply wear off.

Review of manufacturers

Drills that are used for concrete are produced by both domestic and foreign companies. The cost largely depends on the country of origin. The high price of the product is justified, since all types of concrete products are characterized by a long service life and improved quality. It is very difficult to say exactly which is the best concrete drill bit for a drill. Among the leaders from foreign brands are:

- Makita - precision drills with unusual brazing. While working, it is easy to create smooth and clear holes of different sizes, but more often they are shallow,

- Bosch is the most popular company producing equipment and materials for repairs and construction. The drills have a four-spiral working surface. This ensures maximum performance and minimum friction. Often used for drilling concrete of any density and creating deep holes,

- Diager Twister is a company that is distinguished by its high reliability and high-quality product. Drills are used for both concrete, brick, and other stones. The assortment is very large, there are drills for drills, hammer drills and other tools,

- Metabo and Staver .

The companies described produce high-quality products, but they are expensive. Among domestic companies and manufacturers from the CIS and China, it is necessary to highlight:

- Bison are the most common drills from domestic manufacturers. The company offers a large assortment at an affordable price with good quality,

- Interskol,

- Anchor,

- Hurricane.

Chinese drills can be quite good and reliable, but they cost more than usual. It is worth understanding that high-quality goods cannot be cheap, since only the best raw materials and new technologies are used for their production. To make the right choice, it is recommended to watch the video:

Products with low cost may be made from a poor alloy, or made in violation of the technological process. There are many fakes that are almost no different from the original. Craftsmen claim that a fake is always darker in color, since some of the stages during casting are skipped or disrupted. To save money, it is better to buy drills in a set rather than individually.

Features and types of concrete drills

Different types and sizes of drills

A high-quality reinforced concrete drill should be so hard and durable that it can make a good installation hole the first time and not break. The production of such elements is made from especially strong steels, with diamond coating or pobedite surfacing. It is this additional processing that distinguishes concrete drills from all others by their extreme strength and hardness.

In appearance they are quite similar. A diamond drill resembles a crown on a base rod with a fine diamond coating. The Pobedit one is quite similar in design to the diamond one, but it is made in the form of an attachment and instead of sputtering there is Pobedit overlay at the very tip. It is she who crumbles the concrete.

Concrete drill set

The first sign by which all available drills can be divided is their purpose. There are breakout attachments that do not make a neat hole, but simply remove concrete for installation of other structures. Through-hole drills are used specifically to create holes of various diameters and depths.

- In addition to the main classification of drills, they can also be divided into two large groups according to the tool: for drills and hammer drills.

- They differ slightly in design, namely in the shape of the shank. Thus, the drill attachment is equipped with a cylindrical shank, while the hammer drill attachment has a hexagonal shank. Less often a cylinder.

- Also, the latter must be marked SDS PLUS or SDS MAX. A concrete drill bit for a hammer drill, or also called a drill, is shown in the photo below.

Drill bit for concrete

If you have no experience, which drill to use in concrete in a specific situation, you can decide after the first drilling test. Roughly speaking, if the drill does not take concrete, then you need to take out a hammer drill and use it, since just such a drill is capable of making a hole even in the densest material.

Concrete drills can be divided into three large groups, intended for specific work:

- Flat drills provide the opportunity to make holes of small diameter and length. But such drills require more effort to operate.

- Spiral drills allow you to create large diameter mounting holes. They are large in size and have an elongated shape.

- Auger drills are the professionals for drilling deep holes. For example, to create a long hole, but no more than 1 meter, you need to take a 12 meter drill. There are grooves for removing construction dust.

Large-size drill in a hammer drill

Attention! But there are also special attachments - for example, a drill for aerated concrete. It differs in shape and parameters from pobeditovy and diamond, which do not drill, but simply destroy cellular concrete. It has a hexagonal rod shape, and at the end there is a special design that carefully makes the necessary installation holes in the aerated concrete.

Drill for aerated concrete

But, knowing this information, it is impossible to select the right drill with complete confidence. You also need to take into account its parameters, which directly determine the size of the future mounting hole.

The video in this article will tell you more clearly how to distinguish drills from each other.

Basic criteria for choosing a drill for concrete

Drills of various diameters and lengths

Before you buy drills, you need to decide on the volume and type of work to be performed. And accordingly, purchase the necessary tool. After all, their price is not the lowest among the entire range of similar drilling devices.

For small home repairs, a diamond drill with a small diameter ranging from 6 mm to 10 mm will be sufficient. If you just need to hang a picture, then take a closer look at thinner drills with a diameter of 3 mm, 5 mm, and 5.5 mm.

Depending on the diameter of the drill, mounting holes of varying depths are obtained:

- d=4 mm – L=50 mm;

- d=5 mm – L=100 mm;

- d=5, 5– L=100 mm;

- d=6 mm – L=150 mm;

- d=8 mm – L=250 mm;

- d=10 mm – L=540 mm;

- d=12 mm, 16 mm, 18 mm, 20 mm, 250 mm and other sizes - L up to 1000 mm.

Multi-format drill bits for concrete

According to the main GOSTs, drills have modern markings, which indicate their sizes, and not just the diameter. Below are the most common drill length parameters for performing various tasks.

They will help you decide which drill to choose for concrete in a particular situation:

- Drill 6x110 - indispensable when carrying out repairs in apartments and houses for various purposes. This type of drill is the most common. For this reason, it cannot always be found on the shelves of specialized stores.

- The 8x600 drill bit is also suitable for making deep holes. If you do the sharpening correctly, you will completely answer your question: “Is it possible to drill wood with a concrete drill?” Of course, it won’t be very convenient to drill into wood with a heavy-duty drill bit into concrete, but if you get the hang of it and acquire a certain skill, it will work out well.

- Drills 12x200 and 12x460 are intended for installation of various furniture and installation of electrical cables of any complexity.

- Drill 24x460 is a large-sized drill, actively used in the construction of heating and water supply systems.

Gradation checked by length

These are the main criteria when choosing drills. But they differ in quality and have their own characteristics. Therefore, special attention should be paid to the manufacturer. It is he who will tell you how to choose a drill or drill of the required size and configuration.

Which drill brand do you prefer?

Bosch drill set

Let's go over the main, all well-known brands that produce drills.

These are the ones you can see on the shelves of almost all specialized departments and stores:

- B osch is the most popular brand, under whose logo you can find drills on the shelves. They are distinguished by a four-spiral shape of the working rod, which helps to apply a minimum of force and remove dust and crumbs along with the drill from the hole. They are also distinguished by increased performance and minimal friction. Drills are most suitable for making deep holes in concrete of any density.

- Diager Twister is a reliable manufacturer that has proven itself in the market with high-quality and reliable products. Drills are applicable not only for concrete, but also for brick and natural stone of any hardness. From the wide range of this brand you can choose an impact drill of any size.

- Makita has focused its attention on producing highly accurate drill bits with unique brazing. Such devices can be used with concrete to make shallow and ultra-precise holes.

- BISON is the most famous domestic brand, under which various types of drills are produced. They are no less reliable than the above products, but are more affordable.

The set was verified by Bison

If we look at Chinese manufacturers, then among them you can also find decent examples of drills. But the price for them will not differ much from the cost of Bosch or Makita. More budget options may be fake, which you will immediately find out when drilling.

It is quite difficult to determine by eye what a factory original looks like and how it differs from a fake. Therefore, in the question of which drill to choose is best and not to make a mistake, consult the seller.