Since welding garage doors with your own hands is quite simple, if you have the skills to work with tools, you can save money by making them yourself. Next, we will understand the intricacies of making gates - we will look at what they generally are, what tools and materials are required, how to weld the frame and gates, install locks and latches, plus insulation of the finished gate.

Installation of garage doors Source ad-cd.net

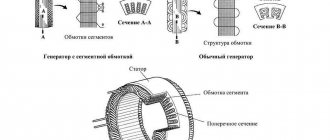

What are swing gates?

Swing gates can be either double-leaf or single-leaf.

Before you begin to implement the idea, you need to clearly understand what swing gates are, what elements they consist of and how they work. There are two types of this design:

- with one leaf;

- with two.

The first option is not suitable for a garage, since the dimensions of one door will be too large and it will be inconvenient to open it.

Double doors consist of several elements:

- frame made of metal corner, round or profiled pipe;

- valves;

- gates in one of the doors, if provided for by the project;

- loops;

- jib/beam/lintel;

- bolt and/or lock.

Assembly and installation of swing gates is simple. But those who do not have experience in manufacturing and installing such structures will need detailed instructions that take into account all the nuances of each stage of work.

Insulation of the garage

During the installation process, it is recommended to equip swing gates with a thermal insulation layer in order to maintain a higher temperature inside the room and extend the service life of the structure. Properly installed door skins reduce heat loss by up to 60%.

There are several different ways to finish a structure. The most common insulation material is extruded polystyrene foam sheets, which are suitable for internal and external cladding.

The material is evenly distributed inside the frame and covered with a plywood sheet or wooden paneling. It is not recommended to use budget cotton wool materials as insulation material, since they lose their original characteristics in a short period.

When covering the sashes, it is important to ensure that there are no air gaps left between the thermal insulation layer and the metal structure, as this will increase heat loss. For high-quality insulation, the layer of internal material must have a thickness of over 15 cm.

Having completed the procedure for insulating swing gates, you should give the finished structure an attractive appearance. To do this, it is enough to treat the coating with paint and varnish material. First, welding residues are removed from the gate, after which it is primed and painted.

Advantages and disadvantages

The main advantage of swing gates is reliability . But this is far from their only advantage. The simplicity of the design provides other advantages:

- there is no need to configure and maintain the automation;

- among the budget alternative options for sectional, overhead and sliding gates, there are no comparable in cost to swing gates - the latter are always more affordable;

- you can install automation: drives that open and close the doors;

- there is no need to strengthen the opening and the top floor, which is often required when installing sectional or overhead doors;

- the possibility of insulating the doors and frame;

- many door design options.

The main disadvantage is the need to get out of the car and close/open the gate under any, even the most unfavorable weather conditions. In addition, in winter it is necessary to clear the space in front of them from snow.

Design

The very first stage of welding garage sliding doors will be drawing up a detailed drawing and taking measurements of the opening. All necessary tools are also prepared, and the necessary materials and their quantities are selected. In order for the gate welding to be successful, it is important to take a responsible approach to the process from the first calculations of the height of the gates and their height.

Important! The permissible minimum distance on both sides from the car to the frame must be at least 30 cm. And the standard size of the sashes must be 5 meters.

It is also worth considering that the distance from the frame frame to the perpendicular to the wall should be 80 centimeters or more. It is recommended to make the frame, as the main element of the gate, from steel materials. As for the hinges, it is better to choose ones with reinforcement and external opening. When the project is ready, all the materials have been purchased and the tools have been collected, it’s time to think about welding.

What materials can it be made from?

If properly manufactured and used, swing gates made from profile pipes are guaranteed to have a long life.

Despite the wide selection of building materials, reliable swing gates can be made in several ways.

Option #1:

- Metal corner 50x5033 mm - for making the frame of the doors and the jibs or crossbars reinforcing it.

- Sheets of cold-rolled metal 2.5-3 mm thick. They are attached to the frame with a 3 cm outlet. Welding is used.

- 4 loops with a cross section of 25 mm, dimensions 30x160 mm. Welded onto metal sheets through additional metal plates.

Option #2:

- Rectangular pipe 40x40x2.5 mm or 50-50-2.5 mm for the frame of the doors and reinforcing elements.

- Sheets of metal 1.5-2 mm thick are fixed to the frame with rivets.

- 4-6 loops.

- 4 metal plates for hinges.

For the installation of gate posts, pipes of 80x80x3 mm are used. The upper beam, which reinforces the opening, is made of channel No. 16 (shelf height 160 mm) or No. 18, depending on the width of the gate. The threshold can be made from the same materials: a profile pipe or a metal corner.

The most reliable way to install swing gates in a garage is to mount a frame from channel No. 24 under them and install it during the construction of walls and ceilings . If this is not possible, elements reinforcing the opening are installed: an upper beam, a threshold and racks for the sashes.

Reference! The proposed material options for installing swing gates in the garage are universal and suitable for any buildings: brick, concrete, wood, foam and gas blocks. The only exception is a garage made of metal profiles. Such buildings require lightweight structures.

For garages, “flexible” gates are made from metal profiles, so that each leaf can be pressed against the opening with minimal effort. The frame of such structures consists of a bent profile with an open section (l- or u-shaped). The sashes are installed on 4-6 hinges.

Gates with a rigid frame are designed and manufactured in such a way that the leaves fit the opening with a minimum gap and immediately close with the provided locks, without applying additional effort. Accurate data on the required materials in a particular case can be obtained through calculations.

Why do you need a drawing?

In order not to redo finished work later, it is better to calculate and find out the important points in advance:

- calculate the optimal size of the doors, make sure once again that nothing in front of the garage or on the side interferes with the free opening and closing;

- it is important that the distance from the side pillar to the driving car is more than thirty centimeters. Even if you currently have a Lada, still calculate the dimensions of the jeep, maybe buy your dream in a few years, don’t overthink the gate later;

- standard height is two meters;

- the optimal opening for a garage box is 2.4 by 2.1 or 5.4 by 2.4;

- the material for the sashes must be reliable, strong and durable - the best option is galvanized steel, five millimeters thick. You can also take a thickness of two millimeters for a lightweight frame garage design;

- consider a locking mechanism. The simplest option is locking on external pads; the more difficult option is armored linings.

On the drawing it is easy to mark the location of all the elements and calculate what sheet size is needed and how much fasteners are needed.

Calculation

You can make the calculation manually, using formulas, or using a special calculator

Professional calculation of the strength characteristics and geometric parameters of materials for the manufacture of garage doors is carried out using a set of complex mathematical formulas. The following factors are taken into account:

- opening rigidity;

- deplaning deformations for given dimensions of the valves and the use of a certain material;

- bending strength;

- twisting forces (from wind pressure, weight load, mechanical influences).

Specialized calculators have been developed to perform accurate calculations. If necessary, you can use them.

Installation of supports

Installation of support posts is the most important step in hanging a gate. The reliability of the gate itself in the future depends on how well it is produced.

One-hundred-millimeter steel pipes can serve as support pillars. Channels or I-beams with a flange width of 100 mm or more are sometimes used as supports.

Factors affecting foundation depth:

soil type; weight of gate leaves.

In any case, the depth of the foundation should not be less than 1.5 m. It is mandatory to take into account the geological characteristics of the soil!

It is necessary to take into account that the foundation will have to withstand dynamic loads from the movement of the valves and the effects of wind. A properly laid foundation must be able to withstand changes in soil properties at different times of the year (freezing and thawing).

It is a very good option if a specialist checks the accuracy of your calculations. The procedure for installing support pillars is as follows.

Pits of calculated depth are prepared. What should be taken into account when preparing holes is stated above. The diameter of the pit must exceed the diameter of the pipe prepared as a support by no less than 10 cm. The bottom of the pit is filled with small stones, gravel or broken bricks. Pillars are installed in the pits. Checking the vertical installation of pillars should be done by level.

Which is better: heated floors or radiators?

Warm floorBatteries

The pillars are supported using special crossbars or supports. The pillars are concreted (we constantly monitor the verticality of their installation). If the mass of the gate leaves is large enough, it makes sense to use reinforced concrete. Before hanging the sashes, you must wait until the concrete foundation is completely cured (28 days). While the hardening process is underway, the foundation is watered and protected from exposure to sunlight.

Required materials and tools

To manufacture swing gates (with a wicket) with dimensions of 2200x3000 mm, you will need not only materials and tools. Adaptations will also be needed, since swing garage doors are manufactured/welded only in a horizontal position.

Materials

The profile pipe is ready for use

- Metal corner 50x50x2 mm, length 2.2 m - 2 pieces (a total of 4.4 m of corner will be required).

- Profile pipe 50x25x2 mm, length 3 m – 2 pcs.

- Sheets of cold-rolled metal (can be replaced with hot-rolled) 1250x2500 mm, 2 or 3 mm thick - 3 pcs.

- Profile pipe 40x25 mm (or 40x20 mm) 2.2 m long - 9 pcs (necessary for the manufacture of horizontal strips of sashes and gates).

- Profile pipe 40x20 mm, 3 m long – 3 pcs (for the manufacture of vertical slats for the frame of the sashes).

- Profile pipe 40x40 mm, 3 m long – 1 piece (for mounting a vertical strip at the junction of the working doors, holes for the lock and bolts are also formed in it)

- Additional elements: steel plates for hinges and to strengthen the joints of the frame, steel rods.

- Level lock.

- Garage bolts: vertical and horizontal.

- Primer for metal.

- Solvent No. 646.

- Dye.

- Chalk.

- Insulating tape.

- Coarse to medium grit sandpaper.

Reference! Using a profile pipe to construct a threshold is a reasonable solution. With this design, the gate frames are raised above the level of the parking area by 20-25 mm. In this regard, rainwater will not flow into the room.

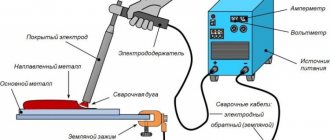

Tools

- Welding machine.

- Electrodes.

- Sledgehammer, hammers.

- Grinder, metal wheels.

- Drill, drill bits.

- Hammer.

- Screwdriver Set.

- Bolts with nuts, self-tapping screws.

- Clamps.

- Level (preferably laser).

- Tape measure or rangefinder.

Important! Before you start working with the welding machine, you need to make sure that the garage wiring can withstand this load.

When calculating and purchasing materials, take into account the need for framing (a double frame with horizontal crosspieces) of the garage opening. For its manufacture and installation you will need the same materials and tools. You can use a metal corner, channel, profile pipes. The strapping is an optional element of the gate design; it is necessary to strengthen the opening and the structure as a whole.

Adaptations

To perform cutting and assembly work, you will need two tables: the main and auxiliary. The dimensions of the main one should be such that both doors and frames fit on it. The table surface must be level. Otherwise, there is a high risk of distortion. The table must be durable, able to withstand the weight of metal, tools and blows with a sledgehammer.

Types of structures

Before purchasing building materials and designing, the owner selects the appropriate type of garage door. There are only 3 types of products:

- swing;

- lifting;

- sliding

You can make garage doors yourself.

In the first case, the doors open outward, and in the second they move to the sides due to rollers. To properly weld the gate, you need to pay attention to the following points:

- take into account the weight of the gate;

- if there is no free space for swing models, then it is preferable to install sectional lifting models;

- decide on painting the canvas, because the color should be combined with the general appearance of the fence and the house;

- select the thickness of sheet metal and corners;

- choose strong hinges, since weak ones can become deformed.

Country property owners often decorate their gates with forged elements. This pleasure is not cheap, but the overall appearance is significantly improved. Even a beginner can bend the armature and create beautiful shapes from it, but a lot of time will be spent on the work. In addition, you will need a special machine for bending rods and a torch. It’s easier to order these products online from craftsmen.

In this video you will learn how to make a garage door:

You cannot buy corrugated sheeting as a canvas. Such thin-walled metal can be easily cut with a regular opener. The attacker takes a tool, cuts out the part of the product on which the lock is located, removes it and gets inside the garage. There won't be a car there in the morning. Therefore, to reliably protect the machine, only thick-walled sheet metal is used.

Preparatory work

Preparing the opening

Preparing the opening involves performing several steps:

- Make sure that the walls on both sides of the opening do not have cracks or deformations.

- Dismantle the old structure, if any.

- Align the opening (if necessary).

- Clean surfaces from dirt, cement and plaster deposits.

Creating a Project

Initially, the owner needs to decide whether the product will be swinging or sliding. Swing gates are easier and faster to make. Sliding models are more difficult to build: the work is complicated by rollers that must be correctly installed in the profile.

The product cannot be installed blindly; for this purpose, a competent drawing must be created. There are several options: ask for help from a familiar specialist who will quickly deal with the matter, use a sheet of paper and draw diagrams, or make them using a graphics editor. If the owner does not have the skills to use the program, then it is not worth doing the project on a computer, because this will take a lot of time.

Step-by-step design:

- If a car enthusiast has no desire to engage in drawing, then he can use ready-made diagrams on the Internet. It is enough to adjust the dimensions of the opening to the option of interest.

- In addition to the drawing, a design sketch is made. No artistic skills are needed here, just a simple image is enough.

- After drawing, the owner creates a list of materials, dimensions, dimensions of the opening, and parameters of the sashes on a separate sheet of paper. For example, 4 profile pipes with a wall thickness of 3 mm, of which the first two are 200 cm long, the others are 300 cm long.

- Experts advise making an estimate that indicates the financial costs for certain types of parts. This also includes the price for delivery of building materials.

In order not to walk around the market for a long time in order to find out the prices for this or that material, the owner just needs to ask his neighbors or friends who installed welded garage doors about the amount spent on purchasing metal.

Step-by-step instructions for making metal swing gates

Installation of metal swing gates for a garage can be done in two ways.

Option #1:

The Bulgarian went into action

Step 1. Cutting materials: use a grinder to cut corners and pipes of the required sizes corresponding to the drawing or project.

Step 2. Assembling the double frame.

- Two vertical strips, the length of which corresponds to the height of the gate, are connected by welding to each other with horizontal jumpers (steel strips).

- Holes are drilled in the wall of the opening for fasteners, for which pins from reinforcement can be used. The minimum depth of holes is 200 mm.

- Dust the holes.

- They are filled with cement-sand mortar.

- Use a sledgehammer to hammer in the pins.

- On the protruding part of the pins, measure 50 mm and cut off the excess with a grinder. There is another option for performing this task: cut the pins flush with the frame and scald them after installing it.

- Install the frame.

- The protruding parts of the reinforcement are bent with a sledgehammer.

Installation work is performed using a plumb line and level. The second vertical pillar of the frame is installed in the same way.

Step 3. Marking the horizontal line for installing the top beam and threshold. When performing work, use a laser level.

Step 4. According to the instructions given in step No. 2, install the horizontal frame beams.

Step 5. The frame of both doors is assembled on the table. Do not forget about the need for reinforcing crossbars, which can be arranged in an x-shape, t-shape or according to the principle of horizontal jumpers. If a gate is provided, its frame is welded from the appropriate elements.

Step 6. Weld the hinges.

Step 7. Hang the sashes.

Step 8. Weld the metal sheets (sew up the sashes).

- Sheets for sash cladding must have an outlet at the top and bottom of at least 20 mm.

- The center should be covered by the overlap of one of the sashes.

Step 9. Clean the metal from the effects of welding.

Step 10. Cover with anti-corrosion primer.

Step 11. Install locks and latches.

Step 12. Paint the gate.

If necessary, insulate the doors and openings.

Option #2:

The second option for manufacturing swing gates is suitable if there are no conditions for construction perfectionism

This method of manufacturing a sash frame is optimal in situations where it is not possible to build a perfectly flat horizontal surface for assembling the frame.

Step 1. Making scarves. 4 identical strips 50 cm long are cut from a metal corner. They are grabbed at several points to the frame of the opening. The scarf is an auxiliary element that will subsequently be cut off with a grinder. Therefore, continuous welding is not required.

Step 2. Cut 4 strips to make the sash frame.

Step 3. The corners prepared at the previous stage are welded to the gussets so that a “frame within a frame” design is obtained. Continuous welding is needed only in the inner corners (for sashes).

Step 4. Installation of stiffeners. If one of the doors has a gate, its frame is welded.

Step 5. Installation of canopies/hinges. Use products with a male-female connection. The “father” is fixed to the frame of the opening, the “mother” is fixed to the gate wings.

Step 6. Using a grinder, cut the frame of the doors in the middle vertically.

Step 7. Cut off the scarves.

Step 8. The doors are sheathed with sheets of metal or other material chosen at the design stage.

Video: DIY swing garage doors

Coloring

Before the last stage (installation), you should start painting the garage door. The paint protects the metal from corrosion and gives it a pleasant appearance. The coating increases the durability of the gate.

How to paint a garage door? First of all, you need to choose the right paint. You should pay attention to the level of adhesion . It must match the metal from which the gate is made.

In addition, the paint must not contain chemicals that interact with the metal surface. Otherwise, oxidative processes . The paint must also have good water-repellent properties, as this is its primary task.

best suited for painting metal gates - acrylic, organic silicon, alkyd. Acrylic paint is the most modern solution. It meets all requirements, is durable, but the downside is the high price. The silicone coating will be durable and very resistant to sunlight.

The paint is well compatible with most metals. Alkyd paint is characterized by increased elasticity and resistance to physical impact (for example, scratches).

What color should I paint my garage door? the paint color so that it more or less matches the surrounding color scheme. But there are no special regulations in this regard.

The most common colors are shades of green, blue, and gray.

The tools you will need are a solvent, a roller/brush, sandpaper, a stiff brush, a primer and the paint itself. After purchasing paint and the missing tools, you can begin preparatory work.

How to paint garage doors?

At the first stage, you should clean the surface from rust and traces of old paint (if any). The procedure can be performed using a stiff, metal brush. Then the surface is sanded with sandpaper. The surface becomes rougher and can better accept primer.

After this, they begin to apply the primer . This will serve as a base for the paint. The primer is applied in two or three layers. It is imperative to wait until one layer has completely dried, only then can the next one be applied.

The last step is painting . For application, a regular roller is often used. The paint is applied starting from the top edge. This technique will help prevent the appearance of smudges. The stripes should overlap. It is recommended to paint with a margin , drawing along the border of the previous stripe again.

It is best to paint in vertical lines , applying paint in two or three layers. Multi-layer painting will make the color rich and prevent the appearance of missing areas.

Please note that painting work should be carried out at a mild temperature - from +10 to +25 degrees.

Features of care and operation

Properly manufactured and installed swing gates have a large margin of safety. To ensure that their service life is not exhausted prematurely, it is necessary to follow several simple maintenance rules.

- Keep metal structures clean.

- Renew the protective paint coating in a timely manner.

- Avoid mechanical damage to the skin: dents and paint chips.

- Do not clean painted structural elements using scrapers, stiff bristle brushes, washes or solvents.

- Before opening/closing the doors, make sure that there are no obstacles in the way of their movement.

- Do not allow weight loads on the gate leaves.

- The hinges are periodically lubricated with Litol or something similar.

The process of making swing gates in a garage is not as complicated as it might seem at first glance. All stages of this task, from design to painting the finished structure, can be done with your own hands. This will significantly reduce the cost of the garage improvement estimate.

Hanging gate leaves on supports

It is possible to correctly install the sashes into the opening in the “white” version only after the concrete has completely hardened.

To lubricate the joints of the hinges, use Litol or Tsiatim. The shutters are installed between the supports. The gap between them should be about 10 mm.

You can tighten the sashes using a clamp.

The lower part of the hinge hinge is then inserted into the upper part. Then the loop is tacked to the support. The second sash is installed in the same way. After checking the geometric parameters of the structure, the final welding of the seams is carried out.

The doors can be moved only after the welding seams have completely cooled. Then the welding areas are ground.

Wooden gate for a summer residence

Fences at dachas rarely represent an impregnable barrier. Usually these are not too high wooden fences. For such a fence it makes sense to make a gate made of wood. There is a very simple one, no fuss. Only dry boards will be needed (provided that there are already pillars).

If you don’t have woodworking machines (thicknesser, router), it’s easier to buy an edged board with the required parameters. The width/thickness of the boards is arbitrary, as are the distances between the planks. Most often they use a pine board 6-10 cm wide and about 2 cm thick, the distance between the planks is 2-6 cm. More or less is possible - it depends on the desired degree of “transparency”.

One of the most common options

It is advisable to have dry boards. It’s unlikely that anyone will use a drying chamber, but aged for a couple of years or at least six months or a year (humidity about 25%) is already excellent. To prevent wood from deteriorating longer, it must be treated with protective impregnations. Now there are compounds that protect even wood that lies on the ground (protective impregnations for wood in direct contact with the ground). But some of them give the wood an extraneous tint (most often greenish, olive). If you are going to paint the gate, it’s not a big deal

If you are planning to use a light varnish, pay attention to this point

Simple garden gate

This is the simplest gate that an ordinary person, not a carpenter, can make. If you know how to saw, hold a hammer, and hammer nails, everything will work out. You don't have to do anything more complicated.

Take two planks or two beams (parameters depend on the weight of the gate). They are equal in length to the width of the future gate. These bars are laid across. The distance between them is slightly less than the height of the gate. It makes sense to place them at the same distance as the bowstrings on the adjacent fence (as in the photo above). Then the gate will look like part of the ensemble.

Wooden gate device

Treated and dried picket boards are laid out at a given distance on the crossbars. To make it easier to maintain distances, you can use scraps of the same length, laying them between the boards (you can also use a matchbox if you are satisfied with its size). We take nails (two per plank at the top and two at the bottom) and attach the boards to each cross member.

After all the planks are nailed, we turn the gate canvas over, try on the jib, and draw the lines along which the jib should be cut. We saw off the excess with a hacksaw, put it in place, fasten it - two or three nails on both sides. Now we attach each board to the slope. This gives the wicket additional rigidity.

How to make a simple wooden gate for a summer house

We choose metal hinges, or barn hinges. They are small in size, just for country gates. If desired, they are attached to the front part of the gate - they add some zest. You can just as easily secure them from the back.

How to make a gate from boards: the correct design

A simple garden and dacha option is described above, but there is a more complex and reliable design. This requires minimal carpentry skills: it is assembled using a tongue/groove connection. This wooden gate consists of two thicker strapping slats, two crossbars (top and bottom) and a strut. The thickness of the upper crossbars and pickets (vertical slats) is the same, but the thickness of the strapping slats is three times greater (thicker is possible, thinner is not). For example, pickets, crossbars and miters have a thickness of 20 mm, strapping slats - 60 mm.

How to make a wooden gate with a frame

A groove is cut in the strapping slats, and a tenon is cut at the ends of the crossbars. The joint is coated with wood glue and clamped in a vice. The bevel can also be installed - on a tenon and groove, but it turns out to be of a complex shape and falls on the joint. Therefore, more often it is simply attached to nails - it’s easier. After the frame is assembled, pickets are nailed. They can be nailed from the yard side or from the street side. Instead of nails, you can use bolted connections; in this case, the fasteners also serve as decoration. It makes sense to install stainless or bronze rivets.

How to weld a gate frame from pipes with your own hands: drawing, video

- Selection of material

- What materials need to be purchased?

- Initial stage

- The welding process is the next step

- Rolling gates

Owners of houses in the vicinity of the city or private plots are always thinking about how to build large gates with their own hands without losing quality and attractiveness.

There are many components of gates and materials for their manufacture. How not to make a mistake in choosing? This question is always relevant for vigilant owners.

Swing gates - diagram

To save time and get rid of unnecessary hassle, it is recommended to call experienced specialists for help. If you want to create something unique, you can master the basics of such work and make a unique, reliable gate with your own hands.