Before you find out which element from the periodic table is awarded the title of “the most ductile metal,” you need to clearly understand what ductility is. This is one of the physical properties associated with the structure of the metal.

Plasticity is the ability to take on a new shape without causing ionic bonds to break. In practice, the result of plasticity is good malleability, due to which metals can be used in industry, medicine, electrical engineering and households. Of the 126 elements in the periodic table, gold is recognized as the most ductile metal. Thanks to today's technologies, it can be pulled out into the thinnest thread, which will not be visible to the human eye.

The strongest metal alloy in the world

Platinum + gold - the world's hardest metal alloy

And straight to the heart of the scientific achievement - scientists from Sandia National Laboratory in the USA have developed a new metal alloy and called it the strongest alloy ever created by scientists in laboratories around the world. The newly developed material, made from a combination of platinum and gold, is estimated to be 100 times stronger than high-strength steel, making it the first metal alloy in the same class as diamond surfaces.

Application

Gold has long been used as an investment object; in addition, it has found active use in the jewelry industry.

In many countries, gold coins were used as money. Despite this, it was recognized as a world currency only in the 19th century. In 1922, bank notes with gold content, called “chervonets”, appeared in circulation in Russia. One bank note was equivalent to 10 gold rubles of the old coinage.

Gold is the most common material used in jewelry making. The higher the gold purity, the better resistance to corrosion the material will have; silver and copper give the product strength and different shades of color.

Source

How are metals produced?

Metals are extracted from ores. Various complex methods and calculation systems are used to determine their contributions. Metal production is carried out in several stages:

- Development of an ore deposit. It can be open or closed. Sometimes extraction methods are combined. The open incision method is less dangerous.

- Ore purification. This process is carried out to extract useful components (ore concentrate) that will be used in further production.

- Metal mining. It is carried out using electrolytic or chemical reduction methods.

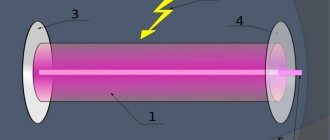

- Metal smelting. This is achieved in technological furnaces, where raw materials are heated to elevated temperatures. In addition, a reducing agent is used.

Development of an ore deposit (Photo: Instagram / polyus_official)

Golden thread

Gold's ability to withstand tensile stress without breaking has been known since its commercial use. The production of such wire for jewelry was established in ancient times - the ancient craftsmen already knew which metal was the most ductile. In the middle of the 20th century, a microwire with a gold core was produced, which, even with plastic insulation, was 7 times thinner than a human hair. From 1 gram of metal a continuous gold thread about 3.5 km long was drawn.

Today's technologies have brought the thickness of gold wire to several microns, and further development of the technological advantages of the metal continues.

Characteristics of metals

Metals are a group of more than 90 simple substances from the periodic table. They are rarely found in nature in their pure form, so they are most often extracted from ores. It is the name given to a type of mineral that is a combination of several chemical components such as minerals and the same metals. Metals are characterized by several properties that are used to classify them into groups:

- Hardness - resistance to penetration of another, harder body into the material;

- hardness - resistance to destruction when exposed to external load;

- elasticity - a change in the shape of a material under the influence of external forces and its restoration after the cessation of these forces;

- plasticity - a change in the shape of a material under the influence of external influences and its restoration after eliminating this influence

- Abrasion resistance - maintaining the appearance and physical properties of the material after severe friction

- Viscosity is the ability of a material to stretch under the influence of external forces;

- Fatigue is the ability of a material to withstand repeated loads;

- Heat resistance - resistance to oxidative processes when heated to high temperatures.

Scientists have recently created an improved aluminum alloy, 6063, that kills bacteria. It is believed that it can be used to make door handles in hospitals and other public places.

Physical properties

There are a number of parameters that unite all metals. Their general characteristics in terms of physical properties look like this.

The listed parameters are the general characteristics of metals, that is, everything that unites them into one large family. However, it should be understood that there are exceptions to every rule. Moreover, there are too many elements of this kind. Therefore, within the family itself there are also divisions into various groups, which we will consider below and for which we will indicate the characteristic features.

Table of tensile strength of metals

| Metal | Purpose | Strength, MPa |

| News | Pb | 18 |

| Tin | Sn | 20 |

| Cadmium | Cd | 62 |

| Aluminum | Al | 80 |

| Beryllium | Be | 140 |

| Magnesium | Mg | 170 |

| Copper | Cu | 220 |

| Cobalt | Co | 240 |

| Iron | Fe | 250 |

| Niobium | Nb | 340 |

| Nickel | Ni | 400 |

| Titanium | Ti | 600 |

| Molybdenum | Mo | 700 |

| Zirconium | Zr | 950 |

| Tungsten | W | 1200 |

Soft, viscous and durable

On the Mohs hardness scale, gold scores 2.5–3.7. In its pure form, this metal is much softer than many widely used materials and can be scratched with a knife or even a fingernail. Therefore, in order to avoid rapid wear of gold products, special strengthening alloy elements, usually silver or copper, are added to the metal for their production. Gold also has harmful impurities. The most ductile metal on the periodic table becomes brittle in the presence of lead, platinum, cadmium or sulfur.

The softness of gold is of a special nature; it is complemented by its viscosity and malleability. The convenience of molding and technological processing of parts is complemented by high tensile strength - 3300 kg/cm2. This unique combination of physical and mechanical characteristics of gold has been used since ancient times. An example is gold leaf.

Rating of the strongest elements in the world

There are a large number of well-known metals and alloys. Among the strongest are 10 elements.

Tantalum

A metal called tantalum, which was discovered in 1802, ranks third on our list. It was discovered by the Swedish chemist A. G. Ekeberg. For a long time it was believed that tantalum is identical to niobium. However, the German chemist Heinrich Rose managed to prove that these are two different elements. Scientist Werner Bolton from Germany was able to isolate pure tantalum in 1922. This is a very rare metal. The largest deposits of tantalum ore were discovered in Western Australia.

Due to its unique properties, tantalum is a highly sought-after metal. It finds a variety of uses:

- In medicine, tantalum is used in the production of wires and other components that can bind tissue and even act as a bone substitute;

- Alloys containing tantalum are resistant to aggressive environments and are therefore used in the aerospace and electronics industries;

- Tantalum is also used to produce energy in nuclear reactors;

- It is also widely used in the chemical industry.

Titanium

The last place in the top ten hardest metals is titanium. The first pure form of this element was obtained by the chemist J. J. Berzelius of Sweden in 1825. Titanium is a lightweight, silver-white titanium metal that is very hard and resistant to corrosion and mechanical stress. Titanium alloys are used in many branches of mechanical engineering, medicine and the chemical industry.

Iridium

Iridium is at the top of the list of the hardest metals. It was discovered at the beginning of the 19th century by the English chemist Smithson Tennant. Iridium has the following physical properties:

- It has a silvery-white color;

- Its melting point is 2466 oC;

- Its boiling point is 4,428 °C;

- Its resistivity is 5.3-10-8 Ohm-m.

Because iridium is the hardest metal on the planet, it is difficult to work with. However, it is still used in various industrial applications. For example, it is used to make small balls that are used in pens. Iridium is also used in the production of components for space rockets and some automotive parts.

Very little iridium occurs in nature. Findings of this metal are a kind of proof that meteorites fell where it was found. These cosmic bodies contain significant amounts of this metal. Scientists believe that our planet is also rich in iridium, but its deposits are closer to the Earth's core.

Tungsten

The hardest metal found in nature. This rare chemical element is also the most refractory of the metals (3422 °C).

It was first discovered as an acid (tungsten trioxide) in 1781 by Swedish chemist Carl Scheele. Further research led two Spanish scientists, Juan José and Fausto d'Elhujar, to the discovery of acid from the mineral tungramite, from which tungsten was then isolated using charcoal.

In addition to its widespread use in incandescent lamps, tungsten's ability to perform under extreme thermal conditions makes it one of the most attractive elements for the weapons industry. During World War II, metal played an important role in establishing economic and political relations between European countries.

Tungsten is also used to produce carbide and in the aerospace industry to produce rocket nozzles.

Beryllium

Now it’s better not to protect this metallic beauty. Because beryllium is very toxic and also carcinogenic and causes allergies. If you breathe air containing beryllium dust or beryllium fumes, you may develop beryllium, a disease that affects the lungs.

However, beryllium is not only harmful, but also useful. For example, add just 0.5% beryllium to steel, and you will get springs that will be elastic even when brought to red heat. They can withstand billions of load cycles.

Beryllium is used in the aerospace industry to create heat shields and guidance systems, and to create fire-resistant materials. Even the vacuum tube of the Large Hadron Collider is made of beryllium.

Uranus

This naturally occurring radioactive substance is very widespread in the earth's crust, but is concentrated in certain hard rocks.

One of the hardest metals in the world, it has two important commercial uses - nuclear weapons and nuclear reactors. Therefore, the end products of the uranium industry are bombs and radioactive waste.

Rhenium

Rhenium is a very rare and expensive metal that, although found naturally in its pure form, is usually added to molybdenite.

If Iron Man's suit were made of rhenium, it could withstand temperatures of 2000°C without losing strength. What will happen to Iron Man inside the suit after such a “fire show” is kept silent.

The metal is used in the petrochemical and chemical industries. This metal is used in the petrochemical industry, electronics and electrical engineering, and in aircraft and rocket engines.

Osmium

Silvery, bluish metal of light color.

It belongs to the platinum group and is considered one of the densest elements. It is characterized by hardness. Os is a brittle metal, but it is resistant to mechanical stress and acid-resistant. Scientists have recorded the presence of osmium in metal meteorites. Forming an ideal composition with other elements, it is widely used in medicine, electronics, chemistry and petrochemistry, rocket science, and is widely used in the production of pens.

Chromium

Chrome is a blue-white metal. It has high strength and hardness, as well as strong magnetic properties. It does not become brittle and is resistant to acids and alkalis.

It is used in the production of various alloys that are used in medical equipment. Cr is also used in the synthesis of artificial rubies, and chromium salts are used for wood preservation and leather tanning.

Ruthenium

The name of the second most powerful metal in the ancient language, ruthenium, means Russia. This metal has a silvery color, belongs to the platinum group and is found in the muscle tissue of all living creatures on earth.

It is a high-strength, hard, refractory metal, resistant to chemicals and capable of forming complex compounds. Ruthenium is used in the aerospace, medical and electronics industries, and as an additive to give gold its black color.

Graphene

Molecular lattice of graphene. The first item on our list is a material that is widely used in the aerospace and automotive industries. When safety comes first and launching rockets into space seems very dangerous, the use of graphene is simply necessary. It is 200 times stronger than steel. Graphene consists of a single layer of carbon atoms arranged in a triangular lattice.

Iron and steel

As a pure substance, iron is not as hard compared to other participants in the rating. However, due to the minimal cost of extracting it, it is often used in combination with other elements to produce steel.

Steel is a very hard alloy made from iron and other elements such as carbon. It is the most commonly used material in construction, mechanical engineering and other industries. And even if you have nothing to do with them, you still use steel every time you cut food with a knife (unless it's ceramic, of course).

Artificial metal

In 2015, Californian scientists created microplates. It is currently the lightest metal on Earth, consisting of 99.99% air. However, due to its special design, the element has high strength. It is an interweaving of tubes, each of which is the size of 0.001 human hair. The amazing properties of microfiber are just beginning to be fully exploited in industry.

Carbon fiber

Black carbon fiber composite. The characteristics of carbon fiber that make it an excellent choice for military vehicles, missiles, and sports car parts are its high stiffness and very low weight. Carbon fiber can also withstand very high temperatures and is highly resistant to a variety of abrasive chemicals. Essentially, carbon fiber is super-dense, aligned carbon atoms that are 5 to 10 micrometers in diameter.

Domes in Russia are covered with pure gold...

Despite the centuries-old history of gold mining, this metal has always been considered rare and precious. This is the most ductile metal. This quality makes the use of gold foil for decorative finishing of interior elements or even for covering church domes cost-effective. To cover a large area, very little precious metal is required: 1 gram of plate can be forged into a sheet with an area of 1 m2.

Even the manual method of producing sheets for gilding makes it possible to achieve a thickness of a thousandth of a millimeter. This thickness allows the gold plates to adhere to the surface due to molecular attraction. The technology for producing tinsel has improved significantly. Now robotic lines are used to flatten gold sheets, but the process is based on the high plasticity of the source material.

Rating of the lightest metals on earth

In this chapter, we'll focus on the world's lightest metals: what properties they have, what they're used for, and why they're interesting.

Lithium

Lithium is in group 1 of the periodic table of elements. It has the lowest atomic mass of all metals - only 3, after hydrogen and helium. A simple substance, lithium, under normal conditions has a silvery-white color.

It is the lightest alkali metal, its density is 0.534 g/cm³. Thanks to this, it floats not only in water, but also in paraffin. For its storage, paraffin, gasoline, mineral oils or petroleum ether are usually used. Lithium is very soft and pliable and can be easily cut with a knife. To melt this metal, it must be heated to 180.54 °C. It will only boil at 1340°C.

In nature, there are only two stable isotopes of this metal: lithium-6 and lithium-7. In addition to them, there are 7 artificial isotopes and 2 nuclear isomers. Lithium is an intermediate product in the reaction of converting hydrogen into helium, thereby participating in the formation of stellar energy.

Which metal is the lightest on earth

Lithium is known as the lightest metal and is widely used in alloys.

Lithium is used in:

- in the production of chemical anodes for energy sources;

- in optical work and experiments;

- High performance lasers.

For example, lithium hydroxide is used to produce the electrolyte in alkaline batteries. Lithium silicate and aluminate are also used in the production of ceramics as a base. This ceramic hardens at room temperature.

This property of lithium is used

- in metallurgy;

- in military affairs (in the development of advanced technologies);

- in the production of thermonuclear energy.

Lithium is also widely used in industry, as some compounds of this metal help whiten fabrics.

Interestingly, the use of lithium has expanded into medicine and pharmaceuticals. In psychiatry, lithium compounds are used to stabilize the emotional state of patients.

Magnesium (Mg)

Magnesium is a malleable metal with an atomic mass of 24.307 °u and a density of 1.7 g/cm^3, which ranks 12th in the periodic table. It was first obtained in its pure form in 1808. It is malleable and easy to press and cut.

It has a high melting point (650 °C) and corrosion resistance. When creating magnesium-based alloys, the mechanical properties of the metal are significantly improved, which significantly expands the range of applications of this type of material.

One of the most abundant elements on Earth, it is found in both the Earth's crust and seawater, usually in salts and minerals. Natural deposits of native magnesium are extremely rare; only a few deposits have been found in Russia, Eastern Siberia and Tajikistan. It is believed that in 2020 the United States will become the largest producer of magnesium in the world.

Its main application is the production of various alloys, both light and ultra-light, which can be used in aircraft and automobiles. Due to its flammable properties, it is also used in pyrotechnics and in the production of incendiary and illumination projectiles for the defense industry.

In the past, photography would not have been possible without magnesium powder with oxidizers - although magnesium flashes are used much less frequently than before, they are still in great demand. Magnesium is also important for the proper functioning of the body and metabolic processes, therefore magnesium-based preparations are used in medicine, cardiology, neurology and gastroenterological diseases.

Potassium

Potassium is the second most abundant element on the periodic table and ranks 19th in molecular weight. Like lithium, it is not found in lump form due to its increased activity, so potassium is extracted from minerals.

It is very soft, silver in color and produces a purple flame when burned. Potassium interacts with oxygen, acids and water. Explosions are not uncommon, so working with this dangerous metal requires extreme caution and the use of protective equipment. If potassium particles come into contact with the skin, they will cause severe chemical burns. It should be stored in airtight containers with added substances that prevent the penetration of oxygen. This could be silicone or mineral oil.

Potassium obtained from rocks in its pure form is used:

- For the production of electrodes;

- In lamps, photovoltaic cells.

Potassium is used in the form of alloys:

- In peroxide synthesis;

- In work to determine the age of rocks;

- As an indicator in biology and medicine;

- As a coolant in reactors.

Potassium is most in demand in medicine for the production of various types of alloys. A significant portion of drugs are synthesized on the basis of this metal. In addition, it is the basis of vitamin complexes, the purpose of which is to support the cardiovascular system and acid-base balance in the body.

Sodium

Sodium is an inorganic compound that is also an alkali and does not occur in nature in its pure form. It is found in minerals such as borax, thenardite, halite and others. Sodium is obtained in the laboratory by melting table salt. This industrial process also synthesizes chlorine.

Like lithium and potassium, this metal reacts violently with oxygen, acids, carbon dioxide and alcohols. It may spontaneously ignite when mixed with fluorine or chlorine. When water is added, a small explosion occurs and caustic soda is formed.

Externally, it is very similar to potassium. Its color is silver, although it quickly darkens in open air. Useful characteristics for industry are its excellent conductivity of electricity and heat.

Sodium has the greatest temperature difference between its boiling and melting points. Thus, the first process occurs at a temperature of +883 °C, and the second at +98 °C. This is the reason why sodium is used in nuclear reactors because it can withstand critical temperatures.

In the human body, Na is necessary for normal metabolism. The lack of this useful element leads to neuralgia and problems with the gastrointestinal tract. However, too much of it can lead to high blood pressure and swelling.

Aluminum

The hardest metal among light and non-ferrous metals is aluminum. This element is identified with the golden mean, when you need a material that is not only weightless, but also resistant to any impact.

The baby rattle was the first product made of aluminum.

It is one of the few chemical elements that is directly involved in the production of everything that forms the basis of a modern household. The world's most popular metal has won the title of most useful in the 20th century. However, in the 21st century, little has changed. Aluminum alloys (harder than pure metal) are used in construction, cutlery, tools, furniture and more.

Which is better titanium or tungsten?

Titanium is very strong and hard and has a much lower density. Tungsten is slightly magnetic and slightly electrically conductive. Titanium is non-magnetic and less electrically conductive. Tungsten is not corrosion resistant in seawater like titanium and is not a photocatalyst like titanium.

Interesting materials:

How to leave a complaint to the post office bank? How is the mechanism of muscle contraction carried out? How is the list sorted? How to lighten denim? How to free up space in cloud storage? How to free up memory on Samsung j5? How was Stalingrad liberated? How to bleach yellow soles from white soles? How to bleach plastic dishes? How to thank a person in your own words?

The lightest non-ferrous metals

The most common way of classifying non-ferrous metals according to their physical and chemical properties is into seven groups, among which the so-called heavy and light non-ferrous metals are distinguished. This traditional definition is based on the density of the material.

The main list includes aluminum, magnesium, titanium, lithium, tin and beryllium. This group also includes cadmium, thallium, gallium, bismuth, indium and other elements.

The production of light alloys is extremely energy-intensive, so enterprises specializing in this area of metallurgy are located near sources of cheap energy.

Types of Metal Casting Processes

Metal casting involves filling a mold with raw materials, which are in a liquid aggregate state. After a certain time, the material in the container hardens and is then removed.

Sand casting is considered the cheapest and most widespread. The model is filled with sand mixture, which fills the free space between it and 2 open boxes. Cavities and holes in the part are created using sand cores placed in the mold. The mixture poured into the boxes is shaken, resulting in compaction. The cavities that have formed are filled with molten metal through special sprues. The casting is removed after breaking the mold following the solidification of the liquid metal.

Precision casting is an improved Italian method of wax molding. As it progresses, a plaster model and mold are created, the product and sprues are modeled from wax, and a molding container is created. The model and sprue wax are then melted out, the molten metal is poured into the mold and knocked out. Finally, the casting is finished.

Mechanical properties of metals and alloys

The mechanical properties of metallic materials are as follows:

- Force. It lies in the ability of a material to resist cracking under the influence of external forces. The type of force depends on how the external forces act. It is divided into: compression, tension, torsion, bending, creep, fatigue.

- Plastic. This is the ability of metals and their alloys to change shape under load without destruction and to maintain this shape after applying a load. The ductility of a metal material is determined by its elongation. The greater the elongation that occurs as the cross-sectional area decreases, the more ductile the metal is. Materials with good ductility are well suited for work under pressure: forging, pressing. Plasticity is characterized by two quantities: relative shrinkage and elongation.

- Hardness. This quality of a metal lies in its ability to resist the penetration of a foreign body of greater hardness without causing irreversible deformation. Abrasion resistance and strength are the main characteristics of metals and alloys, which are closely related to hardness. Materials with such properties are used in the manufacture of tools used for metalworking: cutters, files, drills, taps. Often the hardness of a material is used to determine its wear resistance. For example, harder grades of steel wear less than softer grades.

- Impact resistance. The ability of alloys and metals to withstand shock loads. One of the properties of a material that can be used to absorb shock loads during machine operation, such as a wheel axle or crankshaft.

- Fatigue. This is the state of a metal that is constantly under tension. Fatigue of the metal material develops gradually and can lead to destruction of the product. The ability of metals to resist damage from fatigue is called strength. This property is a function of the nature of the alloy or metal, surface condition, nature of processing and operating conditions.

Plasticity test

The ductility characteristics of metals are usually determined by static tests. The most revealing is the tensile test. To find out which metal is the most ductile, it is necessary to subject samples of the same size to this effect under similar temperature conditions. The amount of deformation that a metal sample can withstand before failure is an objective indicator of ductility.

The numerical expression of the tensile test result is two main coefficients. Relative elongation is the percentage ratio of the increased length of the sample after rupture caused by deformation to the original one. The most ductile metal - gold - has an indicator of 65%. For comparison: for iron – 40-50, for aluminum – 30-40.

The second indicator of plasticity is the relative narrowing of the cross section of the sample. For gold, the initial cross-section of the sample is 90% larger than what it had before breaking. For aluminum this figure is 80%, for copper – 75%.

How to increase the strength of metal

There are several ways to increase the strength of metals and alloys:

- Creation of alloys and metals with a defect-free structure. Work is underway to produce fibrous crystals (whiskers) that are several tens of times stronger than conventional metals.

- Obtaining an increase in volume and surface pressure artificially. Metal processing under pressure (forging, drawing, rolling, pressing) produces volumetric riveting, while rolling and shot blasting produces surface riveting.

- Formation of metal alloys using elements from the periodic table.

- Cleaning metal from impurities it contains. As a result, the mechanical properties of the metal are improved, and the propagation of cracks is significantly reduced.

- Elimination of metal surface roughness.

What you need to know about artistic forging when making forged products

According to technical terminology, artistic forging is a method of metal processing in which the required shapes and sizes are achieved through deformation. This definition hides one of the most ancient technologies, which allowed man to take a huge step in history and has not lost its significance today. Forging is actively used in metallurgy and mechanical engineering.

Handmade rose

What is artistic forging

The main sign of artistic metal forging is the presence of a creative or artistic component in the product produced by the master.

This product can be made for practical use or have only aesthetic value.

Artistic forging has long been established as an independent type of blacksmithing, and another specialization has been added to the blacksmith’s profession - metal artist.

History of artistic forging

The history of practical application and processing of metal goes back several thousand years. The history of artistic forging goes back just as many millennia, as evidenced by ancient archaeological finds.

Primitive tips for spears and hoes show signs of creative processing. Previously, forging had a mainly practical orientation, but among the blacksmiths there were always craftsmen who knew how to combine practicality with artistry.

Examples include samples of weapons and armor, horse harness, and household utensils.

The beginning of the development of artistic forging as an independent craft can be considered the Renaissance and the associated flowering of arts and science. Medieval palaces and temples in the Renaissance or Baroque style contain forged elements in their decoration, reflecting the spiritual, heraldic or simply aesthetic needs of the owners.

Today, these requests are defined by the concept of “interior design,” in which elements of artistic forging continue to occupy their rightful place.

Tools for artistic forging

For many centuries, the standard set of blacksmith equipment and tools has not changed.

A forge with coals, bellows for fanning them, a hammer and anvil, tongs and a barrel of water were the main tools of the blacksmith.

The development of medieval production introduced elements of mechanization into this set, and the industrial revolution turned blacksmithing into an industry aimed at mass production of products.

Hammer and anvil

This direction received at its disposal a whole range of special equipment for artistic forging, machines and devices that made the work of a blacksmith easier and made it possible to produce complex products.

The classic coal forge still remains in the blacksmith's arsenal, but muffle furnaces and induction heaters have also come to its aid. Many forging machines retained their historical names, corresponding to their purpose - benders, snails, waves, twisters and torsion bars - but received a powerful electric drive or turned into universal multifunctional machines.

Types of blacksmithing

Forging technology includes several types of operations that differ in the tool used, execution modes and purpose.

These operations are fully used in the technique of artistic forging, and the manufacture of any product can include any set and sequence of them.

The main feature for classification is the processing temperature - hot and cold forging. Other criteria can also classify the operation into different types and subtypes.

Hot artistic forging

During hot forging, the product is subjected to preliminary and, if necessary, accompanying heating to increase softness and ductility. There are two types of hot forging of metal:

- Free or hand forging, in which the workpiece is freely placed on an anvil, and the required shape and size are achieved by blows of a hand or mechanical hammer. This type also includes forge welding - the connection of parts heated to the melting temperature using a forging tool.

- Stamping, in which the workpiece is placed in a die with an internal cavity, the shape and size corresponding to the finished product. During the forging process, the workpiece is deformed and fills the empty die area.

Cold artistic forging

In cold forging, the product is processed without preheating. It takes a lot of force to deform cold metal, so this method is used for processing small-section workpieces. For cold artistic forging, a variety of machines are used, including cold stamping.

Basic artistic forging techniques

Each type of forging of metals and alloys has its own technologies and processing methods. Artistic forging, taking into account its specifics, uses in its arsenal almost all the basic techniques of blacksmithing, with the help of which any creative idea can be expressed in metal.

Disembarkation

The purpose of the operation is to reduce the length of the workpiece while simultaneously increasing the cross-section. In hot hand forging, the heated part is placed vertically on an anvil and hammered at the upper end. By heating individual places and holding the part with tongs, thickened nodes, bends, volumetric or flat elements of the intended decoration can be made on it.

Broach

Broaching is the opposite operation to upsetting and is used to lengthen the workpiece. The direction of impact when broaching is across the axis of the part with its rotation or advancement along its length.

Depending on the shape of the workpiece (flat, round, hollow, ring) and the equipment used, the broaching technique includes many techniques. Individual broaching techniques can be called by their own terms - spreading, flattening or rolling.

Blacksmith working

Rounding

The operation is used in hot forging methods and consists of rounding the edges of profile blanks. Initially, the corners of the workpiece are forged, bringing it to an octagonal cross-section. The final rounding is performed using special crimps or cutout hammers.

Threading

Threading various elements through each other is a common technique actively used in artistic forging. Threading is carried out in two ways - by assembling according to the principle of chain links or by flashing a hole in one of the elements. In this case, chisels of the required shape and size are used for the operation.

Decoration of ledges

Ledges of various shapes in the artistic forging technique are made for both decorative and technological purposes in order to secure the parts together. The ledges are made using sharp anvil ribs or special backing equipment.

Bending

Bending is a common technology actively used in artistic forging. Special machines and devices have been developed for bending, allowing craftsmen to work according to their own templates.

DIY forged elements and parts

Today there are shops or workshops offering artistic forging products of their own production. The demand for these products is stable, despite the inflated cost of forged products.

If you wish and have some experience working with metal, much of the range of artistic forging professionals can be done with your own hands. It is not at all necessary to arm yourself with a forge and a sledgehammer or purchase a special machine.

Even for the manufacture of complex elements or products, a workbench, a vice, a welding machine and a hammer are sufficient.

The material for amateur creativity will be a round rod, a profile pipe with a small cross-section, a narrow strip of steel or sheet metal.

Furniture

As furniture for self-production, you can consider garden or country tables and chairs, decorative shelves for walls. Forged elements can decorate the interior of a kitchen, bedroom, hallway or garden gazebo, and an old stool or floor lamp intended for scrapping can be reinforced with forged strips and presented as an antique.

Alcove

A gazebo, the cherished dream of summer residents and owners of their own plots, does not have to be made of wood or brick. You can also make a metal structure from a profile.

It is easy to turn it into a light and elegant composition with the help of hand-made forged parts - an openwork arch twisted from a steel circle at the entrance, curlicues around the perimeter of the gazebo or an intricate pendant for a lamp.

Gates

Forged gates and entrance gates are perhaps the most popular products from the range of artistic forging today, in which practicality is combined with artistic taste. Meanwhile, many owners of private houses, for economic reasons, make do with an entrance unit purchased or independently made from standard rolled metal and metal profiles.

Any metal structure can be classified as non-standard or made initially using the simplest self-made forged elements. The already mentioned steel rods, profiles or strips are used as a workpiece. From them you can make various twisted patterns and monograms, leaves and buds, strict or arbitrary geometric shapes.

Subscribe to the channel, like, repost, and we will post useful information about metals for you!

You can also visit our information site all about metals.

Interesting Facts

- Titanium alloys, whose specific gravity exceeds the specific gravity of aluminum by approximately 70%, are 4 times stronger than aluminum. Therefore, from the point of view of specific strength, alloys containing titanium are more viable for use in aircraft construction.

- Many aluminum alloys exceed the specific strength of steels containing carbon. Aluminum alloys are very ductile, resistant to corrosion and can be easily processed by pressure and cutting.

- Plastics have higher specific strength than metals. However, due to insufficient rigidity, mechanical strength, aging, increased fragility and low heat resistance, laminates, textolite and sandwich plastics have limited use, especially in large-sized structures.

- It was found that ferrous and non-ferrous metals and many of their alloys are inferior to fiberglass in terms of corrosion resistance and specific strength.

The mechanical properties of metals are an important factor influencing their practical use. When designing any structure, part or machine and choosing a material, it is necessary to take into account all the mechanical properties that it possesses.

Side subgroups of the periodic table

The general characteristics of metals of side subgroups completely coincide with those of transition metals. And this is not surprising, because, in essence, they are exactly the same thing. It’s just that the side subgroups of the system are formed precisely by representatives of the d- and f-families, that is, transition metals. Therefore, we can say that these concepts are synonyms.

The most active and important of them are the first row of 10 representatives from scandium to zinc. All of them have important industrial significance and are often used by humans, especially for smelting.

Application

Gold has long been used as an investment object; in addition, it has found active use in the jewelry industry.

In many countries, gold coins were used as money. Despite this, it was recognized as a world currency only in the 19th century. In 1922, bank notes with gold content, called “chervonets”, appeared in circulation in Russia. One bank note was equivalent to 10 gold rubles of the old coinage.

Gold is the most common material used in jewelry making. The higher the gold purity, the better resistance to corrosion the material will have; silver and copper give the product strength and different shades of color.