The best option for making concrete products is a concrete mold. Its creation at home requires accurate calculations, knowledge of the characteristics of the material used and the future sample, and control of the production process. The matrices are strong and stable, easy to use, designed for repeated use, and no additional construction equipment is needed during production.

For small-scale construction work, according to industry experts, self-production of concrete molds is very profitable, since savings reach 70%.

What are the tracks for?

Garden paths perform two important functions:

- Improve landscape design, give the garden a well-groomed appearance;

- After precipitation, it will be possible to cross the site along the paths, get to the gazebo, etc. The paths are easy to clear of snow. So improved trafficability, zoning, emphasizing the boundaries of flower beds - these are the functional tasks of the paths.

Properties and scope of cast concrete

Concrete floors laid on floor slabs are rarely level. Depressions, level differences, protruding reinforcement - all these defects can be corrected using the Cast Concrete technology. It allows you to achieve a surface slope not exceeding 2%.

Dry mixes “Cast concrete” are complex compositions consisting of:

- binder - cement;

- mineral fillers;

- polymer modifiers.

Modifying additives play a significant role in the construction mixture; their purpose is to ensure:

- high adhesion of the leveling layer to the concrete base;

- sufficient elasticity;

- mobility and good leveling properties of the mixture;

- resistance of the resulting coating to shrinkage.

The introduction of water-retaining additives allows you to increase the time for adjusting the solution and makes it possible to avoid cracking.

Depending on the desired end result, you can choose “Cast Concrete” mixtures, which not only level the surface, but also have additional advantages:

- good noise insulation properties;

- heat-insulating qualities;

- provide the possibility of installing floors with internal heating.

Look at the M300 cast concrete in our catalog. This brand of concrete is indispensable for screeding floors in apartments and larger premises.

What can garden paths be made from?

- Paving slabs. Paving stones have different shapes and colors. The durability and wear resistance will pleasantly surprise you.

- Concrete paths. Filling paths with concrete is a budget-friendly and effective option, but the aesthetics of such paths leave much to be desired.

- Large format porcelain tiles. Porcelain tiles are dense, highly durable and resistant to temperature changes. All this makes it a popular exterior cladding. Large tiles can be laid on a flat base as a path.

Types of different molds for filling garden paths

Stages of decorative coating manufacturing

If you want to create a colorful and high-quality coating in your yard, then decorative concrete is exactly what you need. But in order not to complicate your life, when making decorative concrete you should adhere to the established technology and take into account the advice of specialists.

Preparing the site and formwork

To make stamped concrete, choose a warm, dry day. The air temperature should not be lower than +5°C; minimal humidity will facilitate rapid drying of the workpieces. Using pegs and rope, they fence off the area chosen for covering.

The top layer of soil is removed from the selected area. If the covering is intended only for pedestrians, remove a layer of about 158 cm.

A mixture of crushed stone and sand is poured into the resulting formwork. The resulting pillow is carefully compacted. A polyethylene film is laid on top of the compacted pillow with an overlap of about 10 cm, and a reinforcing mesh is placed on top.

Kneading

For the production of printed concrete, Portland cement M400 or M500 with the addition of various plasticizers is best suited. For decorative coating, it is recommended to add polypropylene fiber to concrete.

For one cubic meter of concrete, 0.6 kg of this additive is sufficient. Polypropylene fiber significantly increases the service life of ready-made concrete and prevents the formation of chips and cracks on its surface. To make decorative concrete with your own hands, you need the following components:

- three parts sand;

- three parts of crushed stone fraction 5-20 mm;

- plasticizer C-3-0.5% on dry matter. It should be noted that the plasticizer is added to the mixture in the form of an aqueous solution;

- Portland cement M-400;

- polypropylene fiber 0.6 kg per 1 cubic meter.

The mixture prepared in this way is laid out in the formwork, distributed and compacted. A rule is used to ensure the smoothness and evenness of the surface layer. You can also roll the surface of the hardening mixture with a roller, this will ensure that small particles of hardening printed concrete are brought to the surface and large parts of the mixture are deposited.

Applying a decorative layer

Before applying the top decorative layer, the working surface is treated with a fixative. About 70% of the required amount of fixative is manually applied to the matte surface of the concrete and smoothed with an aluminum trowel. After this, the remaining part of the fixative is scattered and the surface is smoothed with a steel trowel.

The next step is applying the hardener. This component is a mixture of permanent pigments, filler and binder. Each layer of hardener is rubbed into the surface until the outer layer of stamped concrete is smooth and evenly colored.

Creating a relief or imitation on the surface

If your task was to make the surface of stamped concrete relief, imitating stone, boards or brick, after applying the hardener, the wet surface should be treated with special presses that will give the concrete the required shapes.

This operation should be carried out with concrete that has not yet hardened, until its surface easily yields to finger pressure.

Laying

The prepared matrices are laid on the concrete surface. The first row is usually placed along the outer edge of the formwork. To achieve perfectly straight lines, the matrices should be pressed closely together. For final hardening of decorative concrete it will take about two days. After this, the concrete surface is cleaned, excess material is removed with hard brushes with long bristles. The surface is washed and dried.

Applying an acrylic layer

For the final finishing of decorative concrete, a protective acrylic layer is applied to its surface. This protective measure will reduce the harmful effects of the environment and significantly increase the service life of printed concrete.

SUBSCRIBE to OUR YouTube channel Ekonet.ru, which allows you to watch online, download free videos from YouTube about human health and rejuvenation. Love for others and for yourself, as a feeling of high vibrations, is an important factor in healing – econet.ru.

Please LIKE and share with your FRIENDS!

https://www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Making printed concrete with your own hands will require special attention, careful selection of components and strict adherence to technology. But such a coating will wonderfully decorate the interior of your home or cottage and give the architectural ensemble of your home its own unique flavor. published econet.ru

Paths made using special molds

What's the point? Cement-sand mortar is poured into the molds under the tiles. As a result, the path turns out to be blocks that imitate a path paved with stones. The result is a beautiful and neat pattern that can be diversified and enlivened with unexpected color schemes and variations.

What are the advantages of molds for pouring a garden path?

- Beautiful and neat appearance.

- The filling process is accelerated.

- Unlike a solid concrete path, which will take a long time to dry, a fragmented path will dry faster.

- If you make your own molds, you have the opportunity to come up with an individual design.

The finished concrete path will be durable, resistant to constant walking and friction, and you can even drive a car along it. Additional painting and spraying will improve the strength characteristics and improve the appearance. Purchased form for a garden path - video

Craft ideas for beginners

It’s worth starting with the simplest figures and sculptures. These can be mushrooms, gnomes, animals, various characters from fairy tales. Moreover, when it comes to bright figures, it is worth considering not so much the complexity of making the sculpture itself, but rather giving it brightness and compliance with the sketch. So, an ordinary mushroom is a stalk and a semicircle, but the correct coloring gives it a similarity with the idea.

The same applies to animals and characters from fairy tales - the shapes themselves are simple, but not everyone knows how to beautifully paint the figures they make. Below are many options for simple crafts with which you can start creating sculptures and concrete products.

We use purchased forms

Store-bought products are a great option. They are durable and suitable for refilling. Their cost is low, and time for independent production is saved. Plastic matrices are most often used. How to fill a path with their help?

Let's consider two options:

- pouring all fragments of the path and their subsequent laying;

- pouring a concrete path in place on a prepared base.

First option: laying ready-made elements

- You need to prepare the foundation. Do not pour paths onto turf or unprepared soil. Next spring the grass will sprout, the soil will shrink due to rain and the concrete will crack.

- Remove a layer of soil 5-10 cm thick.

- Cover it with crushed stone and compact it well.

- The boundaries of the path are marked by concrete curbs. For them, trenches of the required depth are dug, after which the curbs are installed on a concrete solution. Their position is checked with a level; they must be in the same plane.

- Sprinkle sand on top of the crushed stone, which is wetted with water. Level the sand so that it is in one plane. Use two pipes or two channels as beacons along which you can pull the sand with a building level.

- The finished fragments are laid on the prepared base. Their position is adjusted with a rubber hammer. You can tap the protruding part a little or add sand where the path has settled.

At the end, to ensure the integrity and density of the concrete elements, the path is sprinkled with dry sand. It gets into the cracks and gaps between the tiles.

Do not forget to make a slight slope; if there is no slope, there will be constant water on the path. The slope will allow water to drain.

Drying concrete tiles

Drying concrete tiles must be properly arranged. Do not dry the tiles in the sun: the moisture will evaporate too quickly and the material will become cracked.

Set up a drying area in a well-ventilated area where the paving stones are not exposed to direct sunlight. Cover the tiles with plastic tiles to help the moisture evaporate more slowly.

Do not stack the tile molds one on top of the other, they may bend and you will end up with a bowed and deformed material.

Filling in place

Filling in place requires the same preparation of the base: you need to remove a layer of soil and make a backfill. Here's what to do:

- Place the matrix on a flat base. Make sure that it stands without distortions and has the required slope.

- Prepare the mortar for concreting. Cement 400 grade, sand and water are used. Crushed stone grade 5-10 can be used as a filler, which will provide greater strength to the material.

- The finished solution should not be liquid, it should not flow beyond the tile form.

- The solution is poured into the matrix, and then the reinforcement is thrown there. The solution is distributed over the entire area using a trowel.

After the solution has set, the mold for making tracks can be removed. To make this easier to do, it is pre-lubricated with mining or something greasy. You can remove the plastic matrix after 30-40 minutes. Basic steps for filling a track.

They practice ironing of set tiles: a layer of cement is sprinkled on top of the paving stones and immediately leveled over the entire area.

If a new form needs to be installed, the previous one will serve as a beacon. You need to make sure that the new fragment is in the same plane as the previous ones.

The main thing in the process of pouring in place is to protect the path from direct sunlight or atmospheric conditions. You can cover the path with a layer of wet sawdust. Under them, within two days the path will gain maximum strength.

You should also protect the flooding area from strong winds and rain by covering the paths with plastic film or making a canopy.

Preparation of building materials: selection and calculation

In order for the path covering to serve for a long time, you need to determine the appropriate formulation of the finished solution. To make it, the classic concrete recipe is suitable:

- cement – 1 part;

- sand – 2 parts;

- crushed stone - 3 parts.

Composition of mortar for paving slabs

Water is taken in an amount sufficient to obtain a moderately thick mass: not liquid, but not too dense. In order not to prepare the cement mortar with a reserve, you can determine the dimensions of the tile (and therefore the shape) and its volume. This will allow you to find out the amount of concrete. Often paving stones are made 30x30 cm, and a thickness of 4 cm is sufficient. Then the volume will be equal to: 4x30x30 = 3600 cm3 or 0.0036 m3.

At the next stage, the number of such products is calculated, for example, 100 pieces. The total volume of all paving stones will be 0.36 m3. To prepare the solution you will need 6 parts of building materials (the list is given above). Respectively:

INTERESTING: Installing a shower drain

0.36/6 = 0.06 m3.

One part is cement. To determine the amount of sand, you need to multiply the value of 1 fraction by 2 (0.12 m3). Accordingly, take 3 parts of crushed stone or 0.18 m3. To understand how much you need to take (in the equivalent of buckets), you need to know the volume of the container - 0.01 m3. But you should not prepare a limited amount of materials. An additional volume of sand, water, crushed stone, etc. may be required. For this reason, a little more materials are prepared - the volume obtained in the calculations is multiplied by 10%.

Wire is used as reinforcement, but in this case you will have to create the frame yourself. You can do it simpler - prepare a chain-link mesh. A suitable option is a cell size of 5x5 cm. An alternative option is a reinforcing mesh for plaster. You can determine the area of the metal layer by knowing the dimensions of the tile:

30x30 = 900 cm2 or 0.09 m2.

In order for the mesh to retain its properties longer and not rust, it must be galvanized. At the next stage, the forms are prepared. You will have to do them yourself. Determine dimensions and configuration. It is easiest to make square or rectangular tiles at home.

DIY forms

Homemade forms for garden paths can be made from wood, metal, plastic or polyurethane. Let's consider the simplest option - wooden molds for pouring. Wooden molds for tiles are divided into:

- into square matrices;

- rectangular options;

- hexagons - reminiscent of a honeycomb. This filling option looks original and unobtrusive.

How to make square shapes

- To make a square matrix, use 5x5 bars. The bars form the formwork - the frame of our form.

- The bars are secured together with wood screws.

- To make the structure rigid, metal corners are attached. Now the matrix can be used many times.

- Options with a bottom are preferable. Use laminated plywood, which must be screwed to the frame.

You can make a mold without a bottom, but then you need to fill it locally. This is not always convenient: it may rain unexpectedly outside. The solution must be protected from direct sunlight, otherwise the moisture will quickly evaporate and there will be cracks in the finished fragment.

Use of wooden matrices

- Pour the prepared solution into them. To increase strength, throw pieces of reinforcement or wire into the solution.

- To make a design on the front side, place a piece of tile or stone on the bottom of the mold. When the solution hardens and you remove the tile, there will be additional decor on the front side.

- Drying is not carried out in the open sun. Place the molds in the shade to air or in a ventilated area.

Production technology

There are different reasons for making tiles yourself: quality control (you can be confident in the result), reducing the final cost of paving stones. For this we prepare:

- concrete mixer, alternatively - a container for mixing the solution;

- shovel;

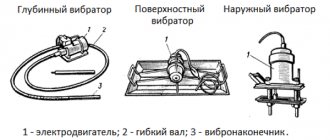

- vibrating table;

Vibrating table for making paving slabs

- molds for filling products;

- trowel.

Work should be carried out wearing personal protective equipment (gloves, mask, goggles, headscarf). Further stages of manufacturing paving slabs:

- Calculation and purchase of building materials: cement, sand, water, fillers (crushed stone, plasticizers, etc.), reinforcing elements (mesh, rods, wire), their thickness should be 4-6 mm, which will increase the strength of the coating.

- Creating a sketch of forms: scrap materials and unnecessary parts of structures are used for production. The configuration should be determined: rectangle, polygon.

- Mixing components to prepare cement mortar.

- Preparation and pouring of molds followed by pressing to increase the density and strength of products.

- Drying.

- Removing tiles from molds.

- Repeated drying - done naturally (in the open air), it is recommended to prepare a canopy.

A suitable location on the site is selected. To be able to work comfortably, you should pay attention to several parameters. The quality of the surface - it must be flat so that the concrete hardens correctly (without sagging or unevenness). The dimensions of the site are sufficient to accommodate equipment, tools, and materials. It must be remembered that concrete sets quite quickly, so it is not recommended to place it in several areas. In addition, you need to provide a place where the tiles will dry in the molds.

Professional additives for sculptured concrete

If you search on the Internet, you can find many offers for the sale of both imported and domestic additives to concrete mixtures. All of them, to one degree or another, contain the previously listed components. There are substitutes for construction quartz sand to lighten the weight of the mixture (marble or dolomite flour). In higher quality and more expensive mixtures, starch ether is added. It allows you to further reduce the sliding of the solution from vertical surfaces. For the same purpose, polypropylene fiber is added to the mixture in small quantities.

It can also be noted that in the literature, instead of the name RPP, the names of various latexes are often given (usually acrylic latex). In addition to SSS, latexes are used in many other industries, including the production of paints. Which paints to choose and how best to paint concrete is a topic for a separate article. Good luck to everyone in your work and see you again on .

Composition of cast concrete and its features

Even despite the invention of various floor leveling technologies, conventional concrete screed still remains the most popular. But increasingly, experienced craftsmen began to use cast concrete systems instead. Just like a regular cement-sand composition, it is capable of correcting all unevenness on a concrete floor, masking protruding bushes of reinforcement, and even working with a sloped base. But there is one significant difference in such concrete solutions - ready-made mixtures have a unique composition that allows you to achieve a smooth surface without the use of vibration devices.

Cast concrete mixtures are complex compositions of:

- cement binder;

- mineral filler. In most cases, sifted, clean sand of small fractions is used;

- modifying additives.

The latter components make such compositions special and give them many advantages over conventional concrete mortar such as:

- high elasticity, mobility and self-leveling ability. Due to these qualities, when working with ready-made stretching mixtures, the use of vibration installations is not required;

- not susceptible to shrinkage of the finished coating;

- high level of adhesion to the base;

- resistant to cracking;

- significant setting time, allowing you to adjust the poured layer. This quality appears in those formulations where water-retaining additives are added;

- both the poured surface and the dry mixture are resistant to temperature changes.

If there is a need or technical need to increase noise and heat insulation, then you can select dry mixtures with a special composition, for example, “Real” or “Petrolit” cast concrete. There are many compositions “Cast concrete M300” used in the construction of a “warm floor” system.

All these properties of ready-made mixtures only speak of the significant advantages of using a leveler instead of using a conventional cement screed. But to achieve such quality, a significant number of different modifiers must be added to the composition. And such components are quite expensive, which is reflected in the final cost, which is several times higher than classic cement mortar.

Not only good plasticizing additives make levelers ideal solutions for filling floors, but also competent selection of the composition and the correct combination of aggregate granulometry. If you approach this issue wisely, then instead of expensive sand you can use fly ash, stone flour or microsilica.

List of sources

- stankiexpert.ru

- zamesbetona.ru

- wiki.sc

- kamsaddeco.com

- ExpertFasada.ru

- 1beton.info