U13 - classification and application of the brand

Material classification: Carbon tool steel

Application: tools with increased wear resistance, operating at moderate and high pressures without heating the cutting edge

U13 - chemical composition of the material as a percentage

U13 - mechanical properties at a temperature of 20°

| Assortment | Size | Eg. | s in | s T | d 5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| The tape is annealed. | 0.08 — 3 | 900 |

U13 - foreign analogues

The table shows exact and similar analogues.

| USA | Germany | Japan | France | European Union | Italy | Spain | Bulgaria | Hungary | Poland | Czech | Austria |

| — | DIN,WNr | JIS | AFNOR | EN | UNI | UNE | BDS | MSZ | PN | CSN | ONORM |

| W112 |

| C125W |

| Y240 |

| |||||||||||||||||||||||||||||||||||||||||

Material U13A Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells U13A material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, U13A material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Classification of material and application of grade U13

Brand: U13 Material classification: Carbon tool steel Application: tools with increased wear resistance, operating at moderate and significant pressures without heating the cutting edge

Chemical composition of U13 material in percentage terms

Mechanical properties of U13 at a temperature of 20 o C

| Assortment | Size | Eg. | s in | s T | d 5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| The tape is annealed. | 0.08 — 3 | 900 |

Explanation of symbols, abbreviations, parameters

| Mechanical properties : | |

| s in | — Short-term strength limit, [MPa] |

| s T | — Proportional limit (yield strength for permanent deformation), [MPa] |

| d 5 | — Elongation at break, [%] |

| y | — Relative narrowing, [%] |

| KCU | — Impact strength, [kJ/m2] |

| HB | — Brinell hardness, [MPa] |

| Physical properties: | |

| T | — Temperature at which these properties were obtained, [Deg] |

| E | — Modulus of elasticity of the first kind, [MPa] |

| a | — Coefficient of thermal (linear) expansion (range 20 o - T), [1/degree] |

| l | — Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | — Material density, [kg/m3] |

| C | — Specific heat capacity of the material (range 20 o — T), [J/(kg deg)] |

| R | — Electrical resistivity, [Ohm m] |

Other brands in this category:

Please note that this information about the U13 brand is provided for informational purposes. The parameters, properties and composition of the actual U13 grade material may differ from the values given on this page. More detailed information about the U13 grade can be found on the information resource Brand of steel and alloys. You can check with our managers for information about the availability, delivery times and cost of materials. If you find inaccuracies in the description of materials or errors found, please inform the site administrators using the feedback form. Thanks in advance for your cooperation!

Marking of steels, how to understand it

Marking of steel grades

The presence of a wide range of steels and alloys produced in different countries has necessitated their identification; however, to date there is no unified system for marking steels and alloys, which creates certain difficulties for the metal trade.

In this regard, there are discrepancies that lead to errors in orders and, as a result, poor quality of products.

In Russia and the CIS countries, an alphanumeric system has been adopted, according to which numbers indicate the content of steel elements, and letters indicate the name of the elements. Letter designations are also used to indicate the method of steel deoxidation: “KP—boiling steel, PS—semi-quiet steel, SP—calm steel.” There are certain designation features for different groups of steels: structural, construction, tool, stainless steel, etc. The designations common to all are the letter designations of alloying elements: H - nickel, X - chromium, K - cobalt, M - molybdenum, B - tungsten, T - titanium, D - copper, G - manganese, C - silicon.

Structural steels of ordinary quality, unalloyed (GOST 380-94) are designated by the letters ST., for example ST. 3. The number after the letters conventionally indicates the percentage of carbon in the steel.

Structural unalloyed quality steels (GOST 1050-88) are designated by a two-digit number indicating the average carbon content (for example, ST. 10).

High-quality steels for the production of boilers and high-pressure vessels according to (GOST 5520-79) are designated as structural non-alloy steels, but with the addition of the letter K (for example, 20K).

Structural alloy steels, according to GOST 4543-71, are designated by letters and numbers. The numbers after each letter indicate the approximate content of the corresponding element, however, if the content of the alloying element is less than 1.5%, the number after the corresponding letter is not placed. Qualitative additional indicators, a reduced content of impurities such as sulfur and phosphate, are designated by the letter A or Ш, at the end of the designation, for example (12 X NZA, 18ХГ-Ш), etc.

Cast structural steels, according to GOST 977-88, are designated as high-quality and alloyed, but the letter L is placed at the end of the name.

Construction steels, according to GOST 27772-88, are designated by the letter C and numbers corresponding to the minimum yield strength of the steel. Additionally, the following designations are used: T - heat-strengthened rolled steel, K - increased corrosion resistance (for example, C 345 T, C 390 K, etc.). Similarly, the letter D denotes high copper content.

Bearing steels, according to GOST 801-78, are designated in the same way as alloy steels, but with the letter Ш at the end of the name. It should be noted that for electroslag remelted steels, the letter Ш is denoted by a dash (for example, ШХ 15, ШХ4-Ш).

Unalloyed tool steels, according to GOST 1435-90, are divided into high-quality, denoted by the letter U and a number indicating the average carbon content (for example, U7, U8, U10) and high-quality, denoted by an additional letter A at the end of the name (for example, U8A) or an additional letter G, indicating an additional increase in manganese content (for example, U8GA).

Alloyed tool steels, according to GOST 5950-73, are designated in the same way as structural alloyed steels (for example, 4Х2В5МФ, etc.)

High-speed steels have the letter P in their designation (the designation of steel begins with this), followed by a number indicating the average tungsten content, and then letters and numbers determining the mass content of elements. They do not indicate the chromium content, since it is consistently about 4% in all high-speed steels, and carbon, since the latter is always proportional to the vanadium content. It should be noted that if the vanadium content exceeds 2.5%, the letter F and number are indicated (for example, steel R6M5 and R6 M5F3).

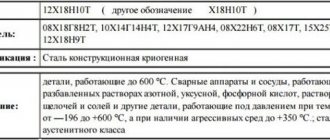

Standard stainless steels, according to GOST 5632-72, are marked with letters and numbers according to the principle adopted for structural alloy steels (for example, 08Х18Н10Т or 16Х18Н12С4ТУЛ).

Stainless steel, non-standard experimental batches were designated by letters - indices of the manufacturer's plant and serial numbers. The letters EI, EP, or EK are assigned to steels smelted for the first time, ChS - to steels smelted in Chelyabinsk, for example, EI-435, ChS-43, etc.

To indicate the finishing smelting method, the names of a number of steels are supplemented with letters (for example, 13Х18Н10-VI), which means vacuum induction smelting.

The European steel designation system is regulated by the EN 100 27 standard. The first part of this standard determines the order in which steels are named, and the second part regulates the assignment of serial numbers to steels.

In Japan, the names of steel grades usually consist of several letters and numbers. The letter designation determines the group to which the steel belongs, and the numbers indicate its serial number in the group and its property.

In the United States, there are several systems for naming metals and their alloys. This is due to the presence of several standardization organizations, these include AMS, ASME, ASTM, AWS, SAE, ACJ, ANSI, AJS. It is quite clear that such marking requires additional clarification and knowledge when trading metal, placing orders, etc.

Classification of material and application of grade U13A

Brand: U13A Material classification: Carbon tool steel Application: tools with increased wear resistance, operating at moderate and significant pressures without heating the cutting edge

Chemical composition of U13A material in percentage terms

Mechanical properties of U13A at a temperature of 20 o C

| Assortment | Size | Eg. | s in | s T | d 5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| The tape is annealed. | 0.08 — 3 | 900 |

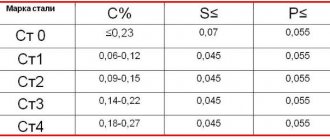

Marking and decoding of carbon steels of ordinary quality

Steels contain increased amounts of sulfur and phosphorus. Marked St.2kp., BSt.3kp, VSt.3ps, VSt.4sp. They are deciphered as follows: St is the index of a given steel group, numbers from 0 to 6 are the conditional number of the steel grade. As the grade number increases, the strength of the steel increases and the ductility decreases. An example of such steels containing carbon, sulfur and phosphorus is shown in the table below.

According to guarantees upon delivery, there are three groups of steels: A, B and C. For steels of group A, mechanical properties are guaranteed upon delivery; the index of group A is not indicated in the designation. For steels of group B, the chemical composition is guaranteed. For group B steels, both mechanical properties and chemical composition are guaranteed upon delivery. The indices kp, ps, sp indicate the degree of deoxidation of the steel: kp - boiling, ps - semi-calm, sp - calm.

One of the types of rolled metal products, in the production of which ordinary quality steel is used, is a channel - https://metalloprokat.navigator-beton.ru/prajjs_list/shveller.html

Decoding steels in materials science

Belongs to the class: structural carbon quality. Chemical composition: carbon - 0.17−0.24%; silicon - 0.17−0.37%; manganese - 0.35−0.65%; sulfur - up to 0.04%; phosphorus - up to 0.04%. Widely used in boiler making, for pipes and heating pipelines for various purposes; in addition, the industry produces rods and sheets.

HVG transcript

Belongs to the class: alloyed instrumental. Used for the manufacture of measuring and cutting tools, taps, broaches.

https://youtube.com/watch?v=L4ERh9njqQ8

Russian labeling standards

According to Russian standards, steel is marked with a marking that indicates the metal composition and type (partially).

If the carbon content does not exceed one percent, then its presence is not included in the labeling. The marking includes designations of additives to impart alloying properties to the alloy. They are designated by tenths and hundredths of a percent. If any component is less than one and a half percent, then its presence is indicated only with a letter. But not only the chemical composition is present in the labeling. There are symbols here that indicate the characteristics of the steel alloy for the application and the quality level. So the letter “A” indicates the high quality of the product.

Types of steel and markings

Some products require high wear resistance, others require corrosion resistance, and others require magnetic properties.

But most of the alloys are required for the manufacture of structural steel, which is divided by type and marked with letters:

- "C" is for construction. With a low content of alloying components, characterized by good weldability.

- For springs (spring). These alloys have excellent elasticity, resistance to destructive processes, and fatigue strength. For the manufacture of springs and springs.

- "Ш" for bearings. From the name it is clear that these alloys are needed for the manufacture of bearing elements for various components and mechanisms. The main properties are wear resistance, excellent strength, and low fluidity.

- Corrosion resistant steel or stainless steel. This type is distinguished by a high content of alloying components and increased resistance to aggressive environments and substances.

- Heat-resistant steel grades are alloys that can be used in products that can function under load at high temperatures. Scope of application: elements of various engines.

- "U" for tools or tool steel has found its application in the manufacture of measuring instruments in the metalworking and woodworking industries.

- “P” high-speed steel is in demand for the production of tools in metalworking equipment.

- Cementitious – an alloy used for components and mechanisms that operate under significant surface loads.

For other steels (spring, tool) they do not have designations. Only the chemical composition is indicated.

In addition to types, steel is classified according to its chemical composition, quality, melting method, structure, and purpose.

Metal marking with paint: OST 1 00413-86: Color marking of metal materials

Home > Articles > Marking of rolled metal products

Marking of rolled metal products is regulated by GOST 7566-94. However, during the construction process, not everyone wants to understand GOST standards. In addition, all markings, for example, of rebar or steel angles, are listed in the price list. And then you saw strange abbreviations there. To understand which rolled metal product is suitable in each specific case, it is enough to know the rules for reading labeling symbols.

For example, to fence an area with a fence made of corrugated sheets, you must purchase a metal profile of a certain marking. This type of rolled metal product is marked in the form of a set of numbers and letters: for example, 0.7x2000x3000 C9. This combination of characters carries the following information:

- 0.7 mm – thickness;

- 2000 mm – width;

- 3000 mm – length.

Now we can conclude that the profile sheet will have a size of 2 * 3 m and a thickness of 7 mm. The letter indicates the application: C – wall, N – roofing, and NS – mixed type, which is used for various purposes. Any metal warehouse is required to advise you on this matter.

However, you must figure it out yourself so that when purchasing products in the future, you can check whether the appropriate rolled metal alloy was delivered and whether it is marked according to accepted standards. Rolled metal is marked depending on its supply to the market: internal or external.

Chemical composition

The main additives for alloying are metals. The variability of the quantitative composition and mass fraction makes it possible to obtain different grades. It’s just that iron, in its technical properties, is a low quality final product: low strength and high corrosion require the addition of components that will improve the quality. However, in practice it has been proven that by increasing one property, others decrease. Thus, high-alloy stainless steel has low mechanical strength, and high-quality carbon steels, while gaining strength, become corrosive.

The main components of the chemical composition of steel are carbon and iron, and carbon should be no more than 2.14%, iron no less than 50%. The amount of carbon in the composition determines its classification: low-carbon, medium-carbon, high-carbon.

If the percentage of carbon content is high enough, then the alloy is obtained with high hardness, but the strength is reduced.

To achieve the desired performance properties, chemical alloying elements are introduced, which divide the steel into three classes:

- with a low content of alloying components (up to 2.5%);

- medium alloyed – up to 10%;

- highly alloyed – up to 50%.

This is indicated in the labeling by the percentage number for each element. If there is no number, it means there are less than 1.5% additives. Carbon indicators are not displayed, since it is present in all compositions. Carbon content is at the beginning of the labeling. The same marking indicates the purpose of the alloy. There are also letters that are arranged in a certain order: beginning, middle, end.

Decoding steels and cast irons

For cast irons, called gray, the characteristic form of graphite is lamellar. They are marked with the letters SC, the numbers after the letter designation indicate the minimum value of the tensile strength.

Example 1: ChS20 – gray cast iron, has a tensile strength of up to 200 MPa. Gray cast iron is characterized by high casting properties. It can be easily processed by cutting and has anti-friction characteristics. Products made of gray cast iron can dampen vibrations well.

At the same time, they are not sufficiently resistant to tensile loads and do not have impact resistance.

Example 2: HF50 – high-strength cast iron with tensile strength up to 500 MPa. Possessing a structure in the form of spheroidal graphite, it has higher strength characteristics compared to gray cast iron. They have a certain plasticity and higher impact strength. Along with gray cast iron, high-strength cast iron has good casting characteristics, antifriction and damping properties.

These cast irons are used in the production of heavy parts, such as press equipment frames or rolling rolls, internal combustion engine crankshafts, etc.

Example 3: KCh35-10 – malleable cast iron, having a tensile strength of up to 350 MPa and allowing elongation of up to 10%.

Malleable cast irons, in comparison with gray ones, have greater strength and ductility. They are used for the production of thin-walled parts that experience shock and vibration loads: hubs, flanges, engine and machine crankcases, driveshaft forks, and so on.

Methods for determining steel grade

- Attach the cutting edge of the tool to the surface. Our task is to cut off the top thin layer of medium length. Now let's analyze the chips. If it breaks quickly, you can’t get it at all, only short fragments, then most likely you have high-carbon steel in your hands. It is because of the carbon content that plasticity is lost, hardness appears, and strength suffers. A low-carbon composition, on the contrary, will give long curls of a uniform structure. And the process of knocking down the top layer will be easier.

- More energy-consuming method. Suitable for those who have a stove - the most ordinary wood stove will do. But for the purity of the experiment, the higher the temperature maintained inside (before hardening), the better. Take a metal rod and a file. We make an incision and remember what efforts were made. Now we subject the sample to hardening and re-cut. If, after heating, ease of manipulation remains, then you are dealing with low-carbon steel. A large amount of carbon in the composition makes the metal difficult to process after hardening.

- For the third method we will need a grinding wheel. First, prepare your workplace - good lighting, put a dark, uniform background behind it so that the sparks are better visible. These are the ones that will be used to check the steel. If they are large, splash in a large volume, and are bright, then you are dealing with high hardness of the material. Otherwise, with a small sheaf and small particles of sparks, the metal is not solid. To correctly interpret the result, take another workpiece for comparison, the brand of which you know. Be sure to press both samples with the same force and at the same angle.

- Using a grinding wheel, you can determine the material by other characteristics, for example, the color of the sparks. Of course, a number of indicators are quite subjective; it is much better to test in comparison with other samples. If you have a lot of small stars scattering in different directions, but they fly close, and they have a red tint, then you are dealing with a high-carbon sample. A sheaf that is lighter and has fewer sparks will indicate an average carbon content, while a very small part of it in the composition will give long straw-colored stripes without stars at the ends - this is how iron is turned.

- Is it difficult with these methods? Then use the color table, we will attach one of them below.

If you are dealing with steel that has been alloyed, then some of its characteristics can suggest what alloying elements were added. For example:

- The presence of phosphorus in large quantities (this is a harmful impurity) will lead to increased cold brittleness, that is, at negative temperatures, a metal sheet or rod will simply break and cracks will form on it.

- Chrome makes the workpiece very resistant to corrosion, so if you have a clean, rust-free sample that has been sitting outside for a long time, it is most likely chrome steel.

- The same chromium, like nickel, if a large amount is added, removes the magnetic properties of the sample.

Some other characteristics and special properties are not easy to check at home. But if you can determine the features of metalworking, hardening, and heat resistance, then you can find out the presence of other additives.