Hi all! This creative post was born after an incident that Master Sergei spoke about. True, it was not a board, but a connector, and not after soldering, but after debris got into the connector %-). Damn, how does my brain work?! But this does not change our topic. Here are my Top 3 best ways to clean the board after soldering. The same methods are, in principle, applicable for cleaning all kinds of connectors from micro-debris and dust. The above division is quite arbitrary and is a personal opinion, which you can challenge in the comments at the end of the text.

Why do Ballerinas need rosin?

To dance in both soft and hard shoes, dancers use rosin (which, by the way, musicians use to play the bow). ... The rosin is knocked out of such a package by turning it upside down, it crumbles and falls out.

Interesting materials:

What are the similarities between proverbs and sayings? What is the meaning of the White Guard? What is the point of the book 1984? What's the point of wearing a bodysuit? What does glucose contain? What does chlorophyll contain? What are the consequences of unemployment at the societal level? What is the main idea of Descartes' method of radical doubt? How to create a GIF? What is the essence of the philosophy of existentialism?

SMD soldering in 1206, 0805, MELF, MINIMELF, etc.

These packages produce resistors, capacitors, diodes and LEDs. Such elements are supplied in paper or plastic tapes adapted for automatic assembly. Such tapes are wound on reels and usually contain 5,000 pieces of elements, although maybe even 20,000 in one reel.

Such coils are installed in assembly machines, thanks to which the entire production process can be fully automated. The role of a person in such production is only the installation of new coils and quality control of the finished product.

The enclosure name encodes the dimensions of the SMD component. For example, 1206 means the element is 120 mils long and 60 mils wide. Mils is 1/1000 of an inch or 0.0254 mm.

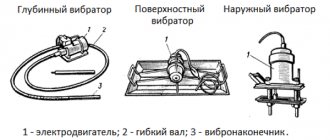

In practice, the most commonly used cases are 1206, 0805, 0603, 0402, 0201, 01005. For manual installation, the 1206 case is ideal, but even 0402 can be soldered by hand, although this is quite tedious. MELF elements are cylindrical in shape and are most often diodes or resistors. Let's get down to business now!

Solder the diode into the MELF package

First of all, we must irradiate one of the contact pads. We treat the pad with flux and touch it with the tip of the soldering iron, and after a while we apply solder. The solder should melt immediately and cover the entire pad evenly. All you need is a thin layer of solder - it's better to have too little than too much.

Soldering iron YIHUA 8858

Updated version, power: 600 W, air flow: 240 l/h...

More details

Next, we take the SMD component by its sides and place it in the soldering area. After this, you should heat the previously tinned pad and press the SMD component into it. The solder should evenly cover the component lead.

The last stage is soldering the second contact. There is nothing complicated here - we touch the contact and the pad with the tip of the soldering iron, then apply solder to it, which quickly melts, enveloping the soldering area in an even layer.

The following pictures show how to solder a capacitor in a 1206 package. The sequence of operations is identical to the one above.

Preparing for work

Before cleaning microcircuits, it is worth understanding whether it is worth doing at all. Many people have encountered oxidation of an electronic board. This process can be called inevitable. There may be several reasons for the appearance of contamination: the fan pulled debris and dust inside, water penetrated, or excess was not removed after soldering.

Any contamination to a certain extent affects the boards:

- The layer of debris or dust on the device is an additional thermal insulation layer. The heat that an electric current produces is not dissipated, but remains at a specific point. Because of this, some parts of the board may fail.

- Moisture or dirt stuck to the top can cause current to pass through. This can lead to a short circuit and damage to the board.

Preparation for cleaning begins by turning off the device and de-energizing it. Then you need to disassemble the device, but only if you can later put it back together. Otherwise, it is better to contact specialists. It is better to work in dry clothes away from moisture.