Those who want to learn how to make a jig blank with a thin-rolled metal crown using a punch and a matrix have come to the right page.

A few words about the procedure, methods and devices necessary for making crown blanks for homemade jigs of various shapes, which you wouldn’t be ashamed to show to your friends while fishing.

First, you should make punches designed to form recesses of the required shape in a piece of thick metal (matrix). The same devices are used to press out a concave cavity in the crown blank of a homemade jig.

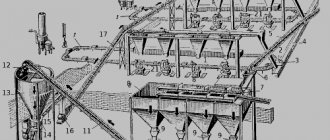

A matrix in the form of an aluminum plate with impressions of the working ends of the punches - vertical drifts - are shown at the top in the photo. Any of the cavities can be used to make an impression in the crown of the jig.

Impressions of jig crowns

On the aluminum plate - the matrix - there are imprints of crowns - blanks for relatively small jigs of various shapes, which on my fishing trips I often use to search for live bait for winter baits.

I catch large fish of the carp family for the family table on the current with heavy lead jigs, for the manufacture of which, if there are no crowns on the baits, neither a punch nor a matrix is required.

Therefore, to use large jigs with shiny surfaces for fishing, you can make (stamp) crowns of either a different shape, or simply deepen the impressions of the crowns in the matrix. To the right of the punches the photo shows a homemade core used for punching holes in jig crown blanks.

Below the knockouts lies a block of the first aluminum I came across in the trash, on which I renewed the impressions with all the punches. Based on the prints, you can select the shapes of the blanks - the crowns of homemade jigs (see photo), which you may need on your next winter or summer fishing trip.

If problems arise with the availability of aluminum of the required thickness, then the matrix for home-made embossing of thin crowns for homemade jigs can be made from solid (with impurities) lead, melting it in a tin can.

To catch fish on winter fishing trips, I advise you to immediately make a batch of jigs of different weights with impressions of the crowns of the most popular shapes. Moreover, some of the bait is distributed to friends and acquaintances. It happens that you have to help out unfamiliar fishermen.

Updating the matrix for jig crowns

Over time, the crown impressions in the aluminum block of the matrix wear out - either they become too large or lose their clear outline. It is clear that then the prints of jig blanks in the matrix can and should be updated.

Typically, updating is required after the production of a very large batch of identical jig crowns. But, as a rule, fishermen make jigs with different popular shapes for fishing trips.

Updating the matrix will also be required if, in some finished recess on an aluminum block, we decided to get an impression of the crown blank of a new jig using a punch that is not the “native” one.

If there is no other aluminum bar in the household, and the reverse plane of the working matrix is also already broken, then the surface of the working matrix will need to be updated.

Regarding updating the crown impressions of homemade jigs, detailed material is given at the bottom of the page, and the hardened ends of the punches do not require updating at all.

Next, we’ll figure out how to make a jig blank from a crown impression into which you can pour solder or lead.

Types of dies and punches

Today there are different types of punches and dies, some of which are used more often, others less often. Among the most common and frequently used are:

- forming (used to give a sheet of metal three-dimensional shapes);

- cutting or punching (used when processing the contour of a metal);

- bending (used in cases where it is necessary to bend a sheet of metal along a line).

It is worth noting that bending punches are in quite high demand among consumers. Therefore, our company is engaged in the manufacture of punches and dies and offers its customers a large selection of such punches, which differ in type, shape and other indicators.

If bending punches are intended for cold processes, then high-strength steel with increased hardenability is used, and if for hot processes, then steel with high wear resistance is used. Our company’s specialists discuss all these points with the client when placing an order for the production of dies or punches.

How to make a jig crown blank

Blanks for most homemade jigs with crowns can be made using the method suggested below.

Blanks - the crowns of future jigs in the shape of a droplet and a pellet in a cut form, but unprocessed along the contour, are shown in the right position of the photograph. On the left in the picture are jigs that can be made by pouring solder into the contour-processed workpieces.

For those fishermen who have decided to make their own jigs from metal at home from scratch, the technical process for making a jig blank with a shiny crown surface in a short interpretation will be as follows:

We place the jig blank in the form of a strip cut from a metal sheet onto the cavity in the matrix and, using a hammer and a pair of punches, punch a recess in the blank. To do this, the shapes of the punch surfaces must be tied strictly to their recess in the matrix.

But this is the case if we already have all the necessary devices and thin-rolled metal for making jig blanks. Ready-made uncircumcised jig crown blanks are shown in the photo at the very beginning of the page.

Cost of manufacturing punches and dies

In modern RuNet, where it would seem that absolutely everything can be found, it is very difficult to find an accurate, transparent and 100% reliable price list for the production of punches and dies. The reason is that these products are usually not standard, but individual in nature, and the enterprise can calculate their cost only taking into account all the features of the future part. The defining criteria are:

- sizes,

- complexity of form,

- type of raw material,

- purpose of the punch or matrix.

Indirect pricing factors include the need for additional services (for example, development of drawings), urgency of the order, transportation costs and other conditions.

How to make a jig from a crown blank

If we intend to make our own jigs for fishing at great depths or good currents, then we increase the weight of the homemade products by increasing the size of the cavities in the jig blanks. To do this, we break the matrix metal under the punch to the required depth.

Next comes stamping and trimming the blanks along the contour, piercing holes in the crowns for winding the fishing line.

In order to independently make the jig you need for fishing, fill the selected shape of the workpiece with solder, solder the hook, and perform mechanical processing of the surface of the crown of the finished jig.

In this way, you can make jigs with polished shiny or matte surfaces from thin-walled crown blanks. The technology for making jigs for summer and winter fishing is described in detail on the next page of the topic.

A little explanatory material about the choice of shapes for a batch of homemade jigs with shiny crowns.

What materials are punches and dies made of?

The purpose of punches and dies is largely determined by the materials from which they are made.

If the production of punches with unsurpassed strength indicators is required, steel alloys of grades 6ХВФ, Х12Ф1 and Х12М are chosen. They are able to cope even with particularly “impregnable” workpieces - for example, from electrical steel grades. If the main purpose of the die is not to cut or punch, but to separate, the optimal materials for its production will be 8ХФ, У8 and У8А steels. For stamping materials that are not metals or made from soft non-ferrous metals, alloys of grades 40 and 50 are suitable.

Shapes of jig crowns

Popular crown shapes for homemade jigs are shown in the drawing. Based on the selected outlines of the upper surfaces of the baits, we make punches, with the help of which the crowns of the jigs are stamped into the matrix.

Blue outlines the contours of the blanks - the crowns of homemade jigs for winter or summer fishing.

The orange color corresponds to the shape of the solder poured into the crown after machining the homemade product.

The shapes of the working ends of the drifts make it possible to increase the volume in the cavity of any crown by increasing the depth of the cavity punched in the aluminum. With the help of such a simple operation, you can increase, along with the volume and weight of the finished homemade jig, while keeping the shape of the homemade jig unchanged.

Black paste shows the direction of the hook forearm soldered into a homemade jig.

In the third hexagon-shaped jig from the left, the hook shank can be soldered into the corner between the side edges or in the middle of one of the side ribs of the future homemade jig.

Compare and make sure that the outlines of the homemade jig blanks shown in the picture correspond to the shapes of the working surfaces of my punches.

For summer fishing, homemade jigs with a flattened shape and gliding properties are more suitable. To control the jigs, I use a side nod when hooking a telescopic fishing rod.

But I repeat once again, the shapes of homemade jigs for your fishing trips can be completely different. It’s just that the working ends of the punches should be sharpened differently for them.

Just in case (for an amateur), I depicted the various shapes of the crowns of a dozen more popular homemade jigs for summer and winter fishing. For some homemade products, making punches at home will require a lot of time. But, believe me, your work will be compensated by fish catches.

Punch for preparing a jig crown

The punches for stamping blanks—the crowns of homemade jigs—are shown in the photograph. Next, we will talk about selecting a suitable profile for channels and rods and methods for making punches.

In order to reduce the amount of grinding work when making punches yourself, you should look for metals with the appropriate profile sizes and shapes. That is, those that will require less time for mechanical processing of the working surfaces of the punches.

For example: for punches that serve as stamps for jig blanks, “pellets”, profiles of round rods of different diameters are better suited. And to make a punch for a jig in the shape of a droplet, it is advisable to look for a rod of rectangular cross-section.

Since the aluminum bar I took as a matrix is relatively soft in its physical properties, it is not difficult to find harder metals to make punches.

But the best results, in my opinion, are obtained when making punches from carbon steel grade 40 or 45. The metal is well processed in an unhardened state and is durable; various broken steel crafts sometimes lie literally under our feet.

In addition, carbon steel heats up well. If you make punches from carbon steel to form cavities in homemade jig blanks, then the devices will last forever after hardening. (By the way, many fishermen have knives for ice screws made of steel of these exact grades.)

The main stages of manufacturing punches and dies

The production of punches and dies begins with the processing of the so-called base surfaces - that is, the initial blanks, which still bear little resemblance to the final product.

At the same time, primary grinding of the material is carried out. Then the working contours of future products are marked and working processing is carried out using this marking. During this process, the punch and stamp acquire their basic features. Next, specialists pre-assemble the stamp, note existing defects, eliminate them and finally polish the surface. When the die components are completely ready, the production process ends with assembly and adjustment.

Making a jig crown punch

To make a punch, we cut off a piece of metal 7-8 cm long from a rod of a suitable profile. The profiles of the punch blanks that are closest to the outlines of some jigs are shown in the drawing.

Using a file (needles), we give the cuts (ends) of the punch blanks the shape of the upper surfaces of the jigs we like. Roughing can be done on an electric sanding wheel.

Then the working surfaces of the manufactured punches should be sanded with sandpaper. (By the way, in metallurgy there are quite hard grades of bronze, they are also worth taking a closer look at.)

Punches with jig surface profiles can be made from welding electrodes of various diameters. The flux layer must be removed from them. To make your own jigs of an oblong oval shape, the working end of the electrode rod should be heated as much as possible and flattened with a hammer.

It is advisable to harden completely manufactured steel punches with ready-made jig profiles. To do this, we clamp the drift between the jaws of the pliers, heat the working end of the punch to the maximum temperature above the burner of the gas stove and immediately lower it into the water.

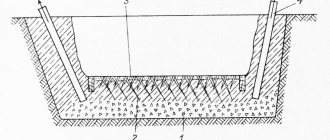

DIY jig matrix

The matrix for stamping jig blanks is shown in the bottom position of the photograph. Making your own device from scratch will only take a few minutes if you select the appropriate metal.

It is clear that the metal for the matrix should be malleable and not too hard. Only in this case, on the surface of a metal bar, we can easily knock out impressions of the working surfaces of the punches with the profiles of the upper surfaces of the jigs.

But the material for making a matrix with your own hands should not be too soft, otherwise we will break the prepared recesses already when stamping the first jig blanks. In addition, the thickness of the matrix should be quite sufficient so that it does not begin to warp (bend) when struck with a hammer.

For making matrices with my own hands, I use aluminum bars with a thickness of 12-15 mm. They fully satisfy all the requirements presented above. And the prints of jig blanks, as they are broken, can be periodically corrected and updated until they are significantly reduced in size.

Let's figure out how you can stamp jig blanks of different profiles in a matrix.

Impression of a jig in a punch with a matrix

Using a hammer and punches with profiles of different shapes, we alternately punch indentations in the matrix - impressions that repeat the configuration of the working surfaces of the manufactured punches.

Then, using a file, we remove the excess metal that has come out near the imprints of future jigs, using this operation to level the surface of the aluminum bar. Our matrix with impressions for making do-it-yourself crowns for jigs of various shapes is ready for use.

As the punch prints wear out in the matrix, you can hammer the corresponding recess with a hammer and renew it again with your punch. Therefore, the matrix for making jig blanks lasts a long time.

And a few more words about the matrix material for making stamped jig blanks with your own hands.

Making homemade spinners using the stamping method.

Once you have made the stamping dies, making the spinners themselves is not difficult. First, a template is made from which the spinner blank is cut. The workpiece is inserted into the matrix, covered with a punch, and one blow of a heavy hammer is enough to make a spinner.

Spoons are stamped from copper and brass with a thickness of up to 2.5-3.0 mm. Double-sided bimetallic spoons can also be produced in this way. The blanks are stamped separately, then drilled and fastened with two rivets. The shape of the finished spoon is corrected by final stamping.

Based on materials from the book “DIY Fishing Tackle and Hunting Equipment. Manufacturing and repair." Storozhev Konstantin.

Alternative metal for the matrix for jigs

One day, on occasion, I chopped up a lot of lead from the battery terminals of a ZIL-131, then melted it in a frying pan. The result was a pancake of very hard lead, apparently with some solid impurities. This kind of metal is also suitable as a matrix for making jig crowns.

From this metal you can make some simple lead jigs with your own hands.

The next page provides tips that will not hurt when making and soldering tin-lead jigs yourself.