Every self-respecting man, in accordance with his duties as the “master of the house,” has a drill in order to hang a shelf, picture or cabinet at the request of his significant other. But the walls in houses and apartments differ in their structure, density and purpose. So, drilling a hole in a load-bearing wall is much more difficult than in an interior partition. Accordingly, drill bits for drills differ both in their purpose and in the material from which they are made. We will talk about how to choose the right drill bits for concrete, brick or stone in this short article.

Drilling holes in the wall correctly: general rules and recommendations for what to drill

In order to correctly drill a wall, you need to take into account the material from which it is made, based on this you need to select a tool.

- When working, hold the tool correctly. For example, a drill should be held straight in your hands and enter the surface in a vertical direction;

- for convenience, use an additional handle;

- Depending on the surface material, select the necessary drills.

- concrete, stone, brick wall - use a carbide drill, usually a Pobedit one;

- metal – metal drill;

- tiles, ceramic tiles - special drills for these materials, sometimes they can be replaced with a drill for concrete with Pobedit surfacing;

- Chipboard, wood - for holes smaller than 10-12 mm, a metal drill is suitable; for larger ones, special wood drills are used.

Drill for concrete, brick and stone

It should be noted that the person who invented the drill to make it easier to work with the material could not even imagine how many new engineering solutions would be produced based on the drill. An example of this would be a foundation on screw piles. This engineering solution made the construction of a safe and simple foundation much easier. A drill for concrete (as well as for stone, brick, etc.) is fundamentally different from a conventional drill. After all, if you drill concrete with an ordinary drill for working on wood or metal, it will instantly become dull and become completely unusable.

For this reason, special concrete drills are made using a special material called “win”. And the drill tip made from it is called “Pobedite”. On sale in hardware stores, you can see metal drills with pobedit tips on the ends. These are “pobedite” drills. We will talk about them in more detail later in this article.

In any case, these are very reliable, durable drills, because pobedit (a composite cermet material consisting of an alloy of cobalt and tungsten), which has no analogues, is close in strength to diamond. However, quality, as is known, directly depends on the manufacturer.

Pobedite drills can be used not only for concrete, but also for stone and brick. These are reliable drills. However, for stone it is best to use a diamond drill bit. It is more durable, but also expensive. For wood, it is best to use metal drills. We will look further at how to use them correctly and wisely in your work.

Tools for work

For work they use different tools, the main ones: drill, hammer drill, screwdriver. There are nuances to using each.

Drill

The tool is suitable when you need to make several holes. You can use a regular drill. When plunging a Pobedit drill into the body of the wall, sometimes you need to break the concrete with a punch that matches the diameter of the hole. This is necessary when the drill begins to get stuck in the surface, bumping into areas that are too dense. The process is quite labor-intensive.

For greater efficiency, you can use universal drills that have diamond coating. They are installed only on a conventional drill or on a tool where the vibration function is disabled.

For large-volume work, an impact drill and drills with pobedit tips are used. They are designed for holes up to 12 mm. The drill is suitable for working with metal and concrete.

Hammer

A hammer drill is a universal tool. It can be used to make a hole in a wall made of wood, tiles and concrete.

The tool has several functions - drilling, hammer drilling and impact mode. To make a hole, you need to select the desired drill depending on the surface and carry out the work by selecting the mode.

Screwdriver

A screwdriver is one of the most popular tools for repair and construction work. With its help you can tighten and unscrew screws, drill wood, metal, chipboard, plywood, tiles, plywood, lightweight concrete.

Which nozzles to choose

A specific nozzle is used for each material:

- concrete, brick, stone - drill with a carbide plate or pobedit;

- tiles, glass - cone-shaped drills with diamond coating;

- metal – spiral drill with a cylindrical cone;

- wood, drywall - for holes of different diameters, drills are used: feather, ballerina, screw, saw bits for wood;

- foam concrete - pobedit drills.

Is it possible to do without a drill and hammer drill?

Make a hole without a drill or hammer drill, but not in a concrete wall. To do this you will need a bolt or a punch.

The working end of the tool is applied to the place where the hole will be. On the opposite side of it, you need to strike hard, rotating the tool after each turn.

Into brick and concrete, like butter

For people living in an apartment (as opposed to owners of a private house), drilling brick and concrete is a frequent procedure, but not everyone knows and understands how drilling concrete differs from drilling brick. So we’ll try to figure out what can be used to drill into brick and what can be used into concrete; after all, there are differences and they are decent.

So, very often inexperienced craftsmen (and most often single women) confuse an impact drill and a hammer drill. For them, these 2 instruments are one and the same. So they try to drill through the concrete floor with a conventional 500-watt drill, although this operation is obviously doomed to failure. Concrete is very dense, brick is much softer than concrete. A lot can be said about the difference between a hammer drill and an impact drill, so it’s better to read my articles: How to choose a hammer drill for your home. Choosing a drill for the home.

After reading them, you will immediately understand the difference between a drill and a hammer drill; moreover, there are useful buying tips and what to look for. Definitely useful articles for beginners.

In this article, we'll take a quick look at the difference. The whole difference between an impact drill and a hammer drill is that the impact force of a hammer drill is tens of times greater and does not depend on the force of pressing the tool during drilling. The impact of a perfach is electric, while that of an impact drill is mechanical and depends on how hard you press the drill. However, even if you press with all your might, the impact force will still be low. Based on this, it turns out that brick can be drilled with an impact drill, but concrete is better with a hammer drill.

Tools for working with brickwork

Both options are suitable, and a hammer drill and impact drill will do the job. For a hammer drill you will need to buy a drill, for a drill - a pobedit drill bit. I also note that brick can be easily drilled without impact with an ordinary drill. Although most drills now come with impact. Many people do not know which drills are suitable for which dowel diameters. I’ll tell you what dowel, what kind of drill. That is, if the dowel is 6 mm, then take a drill with a diameter of 6 mm. The exception is when the wall is made of “shingles” - wooden planks criss-crossed; such walls are still found in old communal apartments. For such walls, you need to take a drill slightly smaller than a dowel.

Equipment for working on concrete

Of course, if you need to drill just a couple of holes in concrete (for dowels to hang a curtain in a room), then an impact drill can help, but you should immediately warn that you will be drilling for a long time and will spend more than one drill bit)) And of course your own You will also spend a lot of energy. To do this, you will need a regular Victory drill, the cost is low, from 15 to 40 rubles, depending on the diameter and length. When drilling with an impact drill, do not press too hard, but do not hold the drill in the hole for too long, let it cool, otherwise it may even melt (there was one such case). The temperature when drilling concrete is very high.

A hammer drill is the best tool for drilling concrete; you insert the drill and drill without experiencing any problems. One not very expensive drill (diameter 6 mm, price 40 rubles) is enough for about 40-50 holes. Take, for example, inexpensive and quite good drills from the Enkor company.

Drilling large diameter holes.

Sometimes you need to drill large holes in the wall. How to do this? For a hammer drill, you can buy a concrete bit, which can be used to drill without impact. The size range is wide, crowns come in different sizes, ranging from 30 mm to very large 120 mm. The most common size is 68 mm, for drilling holes for a socket. Don’t forget to switch the hammer drill to drilling mode without impact, otherwise your bit will squeak very quickly.

For drills, you can find special tungsten carbide bits on sale. I will only note that such drills can be used to drill not only brick and concrete, but also tiles, paving stones, and porcelain tiles. This is such a universal thing and the most important thing is that the holes made with such a crown turn out very neat and even.

In the video below, they are working with a “practice” crown on a brick. You can also work on concrete.

That's probably all, good luck with your drilling and repairs in general.

Another note: How I polished marble with “turtles” - polishing marble with a grinder

How to drill without dust: options, the better

Construction work is always accompanied by dust and debris, but using some recommendations and tips, it can be significantly reduced:

- During operation, the hammer drill leaves a slight dust, so that it does not fly around the room, use a construction vacuum cleaner at the same time. Some brands of tools have a built-in vacuum cleaner, which makes the task easier;

- using a drill, it is best to either make a jig on the end or a bag, or make an envelope under the hole so that the debris falls into it.

How to drill holes in a brick wall: choosing tools and attachments

To make a hole in a brick wall, a hammer drill with a drill or an impact drill are suitable; the latter is most often used. Its power must be at least 600 watts, the minimum number of revolutions is from 2500 per minute. It is best to use a drill with continuously adjustable power and a quick clamp function.

Using the hammer drilling function, the drill becomes identical to a hammer drill. Increases speed and ease of operation. To make a hole in a brick wall you need to use the dynamic impact method. Without this, the drill will not be able to engage the inside of the brick.

How to drill a load-bearing wall with a hammer drill in a panel house

In most panel houses, the walls are made of concrete; in order to make a hole with a hammer drill, you need to use pobedit drills.

In addition to them, you can use special crowns. They have soldering around the circumference. When using them, you need to disable the hammer drill's impact function.

Specialists use diamond drilling, which requires powerful equipment and skills.

How to properly drill a reinforced concrete pipe with a hammer drill

When using an impact drill for reinforced concrete, you need to use the “perforator” mode and pobedit drills. First, the hole is made smaller, then larger. The drill needs to be cooled periodically.

Important! When working with concrete, you need to avoid hitting the reinforcement, otherwise the drill will break. Using a special device you can check where it is located.

How to make a hole in a concrete wall with a drill

It is difficult to drill into a concrete wall with a conventional drill. You need to install victory drills and select low speeds. A dowel is inserted into the desired location to help the tool pierce the surface. Next, drilling should be alternated with striking the dowel.

If the drill does not have a speed control, then it will not be possible to make a hole.

How to make a hole in a concrete wall in an apartment with a drill

For a small hole, you can use a punch. Most conveniently, it can be made from a drill, 8 mm in diameter. The end is sharpened sharply. The drill is placed in the desired place, rotated, while simultaneously hitting it with a hammer. Wet the drill periodically to make it work longer.

Features of working with a drill

In order to drill a hole in a very solid (load-bearing) wall, an ordinary drill (no matter what kind of drill we put there) will clearly not be enough. For this purpose, special drills are used - with a hammer drill. And also special drills for concrete sds. Usually, they are marked or “sds-max”. Their distinctive feature is also their cylindrical tail. A drill bit for a hammer drill for concrete is used, as the name implies, in a drill with a hammer drill, when it is necessary to drill a hole in a load-bearing wall or in another surface of increased hardness. That is, in situations where a regular drill (as well as an impact drill) will not help. An impact drill (a special drill for concrete) comes in several types. Thus, concrete drills, called shallow drills, make it possible to drill small holes, while auger drills make deeper and wider ones. Spiral-shaped impact drills help cope with a more difficult task - making larger holes (even up to three centimeters).

If you need to drill a very large hole (for example, for a socket or switch), up to 12 cm in size, use a concrete core drill. It allows you to obtain recesses of up to 12 cm in particularly durable materials. You can see two types of core drills on sale: pobedit and diamond. A Pobedit drill for concrete has Pobedit teeth on the working part, while a diamond drill has diamond sputtering.

Concrete drills come in different diameters - from 4 to 12 mm. A drill bit for a large-diameter concrete hammer drill is rarely used in everyday life. As a rule, it is most often needed by professionals who are constantly renovating premises.

However, there is still a certain feature in the size of drills that should be taken into account when using them - the larger the diameter of the drill, the longer it is, and vice versa, the shorter the drill, the thinner it is. And this is not surprising, because a thin long drill will simply break during operation, unable to withstand the shock load on it.

Work rules: tips

When working with tools, you must follow safety rules and general recommendations:

- 1) When performing work, protect your respiratory system, dust is harmful.

- 2) If you work outside, you need to install fences at 2.5 meters.

- 3) When performing work at a height of more than 1.5 meters, use a strong base - scaffolding or a goat.

- 4) When working with a tool, the speed must be turned on smoothly, and in no case should it be turned off when it is in the body of the wall.

- 5) When drilling through plaster, you must carefully study the communication plan so as not to hit anything.

- 6) It is strictly forbidden to drill through the decorative coating.

- 7) Choose the right drill bits for each surface.

- Wet the drill with water to prevent it from overheating.

How can I repair a large drilled wall?

You can seal unnecessary holes in the wall using a special building mixture. It provides strength and durability. The composition must be selected depending on the area and type of defect.

Using putty, you can level the surface, including concrete. There are several types of putty:

- cement – used in exterior and interior decoration, suitable for concrete. Durable and moisture resistant. It dries for a long time and often in a mesh pattern, which requires re-application;

- gypsum - used in dry rooms, is not resistant to water and is afraid of temperature changes. Does not crack when applied, so you can immediately apply a thick layer;

- acrylic – finishing. It needs to be applied in a thin layer, so it is suitable for small defects.

Read also: Cold welding universal instructions for use

None of the mixtures are used for sealing through holes.

Polyurethane foam is a universal material. There is one-component (used without preparation) and two-component (when used, a construction gun or mixer is used).

When applied, the foam increases in volume and fills the required space. It hardens and gives high-quality density. Deep holes can be sealed.

The repair mixture is suitable for eliminating large defects. It has good adhesion, is frost-resistant, strong and durable.

When you decide to make a hole, carefully read the rules and recommendations. Choose a tool, depending on the composition of the surface, and a drill. If you are not confident in your own skills, then entrust the work to specialists.

Advice from an experienced master

A good owner always has several drills of different types for working with a drill - drills for wood, metal, brick and concrete. To work with a drill on concrete, it is best to stock up on different drills, including Pobedit drills and metal drills. This is necessary so that, during the drilling process, when faced with the fact that the drill rests on the metal (this happens when there is metal reinforcement under a concrete slab), it would be possible to easily and quickly rearrange the drills - replace the concrete drill with a metal drill - and continue work without delay or delay. And when the metal runs out, you can put back the sds concrete drill. Those experienced craftsmen who have been working with a drill for many years know how to sharpen the drill in such a way that it can be used to work both on concrete and on metal, but for a person who has never encountered this before, this is an elusive task, and even better don't start and don't try.

It is also very important that when working with a drill, the drill does not overheat. To do this, it must be periodically cooled regularly (approximately every 15-20 seconds of operation). To do this, pause and lower the metal drill into a small container of cold water. Hold the drill there for a while, and then, when it cools down, continue the drilling process. There is no need to dry it. However, this rule only applies when drilling metal. When drilling wood, there is no need to cool it - it does not overheat. And when working with a Pobedit drill, it is not cooled in water - only in a natural way. We worked, drilled for half a minute, turned off the drill. We waited until the drill cooled down, and only then we continued working. You cannot use any cooling liquid during the operation of the Pobedit drill.

There is also a situation when, during the drilling process, we come across a stone under a concrete base. For stone, a regular sds concrete drill will not work - we take a chipper in our hands. After completing the work with the stone, we return to the concrete drill.

If in the process of work you have a need to drill one or several holes, no matter what diameter, not in an ordinary wall (interior partition), but in a load-bearing one, then it is best to use a hammer drill for this, and not an ordinary drill. You should not try to do this with a household drill, it is useless. And, of course, in this case we will need a drill bit for a concrete hammer drill.

But when working with ceramic or tiles, a hammer drill is not needed. It will only crack the tiles. You don't need an impact drill either - it will also crack and ruin your entire tile. Forget about a concrete drill bit. Only a household drill with a regular, small-diameter metal drill will help here.

You can use a Pobedit drill bit for drilling ceramic or tiles (not including the hammer drill mode).

Those drills that become dull during work can be easily re-sharpened - metal ones with regular sandpaper, and pobedit ones with a diamond disc. However, if you choose expensive, high-quality drills from well-known manufacturers in the store, you are unlikely to ever need to sharpen them - they simply do not get dull.

Further, upon completion of this review of drills, we offer you to watch a short video on the topic we discussed.

Useful video

Drilling a brick wall includes the practical implementation of certain skills, as well as preparatory processes regarding the tool used and the surface we process, in fact, the brick wall.

The quality of the final result depends on the type of drill used. The latter must have a strength exceeding the strength of the brick used at the time of laying. Typically, pobedit drills with a diameter of 4, 6, 8 and 12 mm are used, respectively.

Tools and equipment

The list presented below is optimal regarding the drilling process, or more precisely, the implementation of the task without interrupting the process itself.

So, the list consists of the following names:

- impact drill;

- dowels;

- drill (pobedit / 4 – 12 mm);

- curly screwdriver;

- metal detector with limited range;

- cold water poured into any convenient container;

- metal core;

- eye protection element.

Tool preparation

The tool used in the process of drilling a brick wall is an impact drill. Such a drill must be powerful, which means it must have at least 600 W and 2500 thousand revolutions per minute. The main feature that is worth paying attention to is the ability to smoothly adjust the speed to maximum.

If buying a drill is still an upcoming event, then the emphasis should be on a drill with reverse rotation, as well as a self-clamping chuck. The latter eliminates the need to constantly use a key to clamp drills, although one is included in the kit.

The presence of a shock function is a prerequisite, since its absence will undoubtedly lead to:

- overheating of the drill, and in particular surfacing from pobedite (sudden wear of the cutting part);

- normal drill pressure without engaging the cutting edge, since only the static load increases.

Preparatory work: positioning relative to the brick wall

Preparatory work regarding the brick wall itself immediately before drilling is more of an informational nature than a “strategic” - design one. From the point of view of safely performing such work, it is necessary to use the metal detector that was indicated in the list above.

Its practical application immediately before drilling will eliminate the possibility of damage to wiring, internal heating systems, as well as various reinforcing components.

Marking sockets, switches and lamps is the final stage of preparation. Taking into account the features of laying electrical wires from the above-mentioned “points” to the distribution box, and this is usually a vertical laying, but not excluding the possibility of a diagonal one, we determine the drilling location.

Despite the expected accuracy in choosing the drilling location, the first 10-20 mm deepening must be done with a screwdriver. Using this will allow you to timely identify communications recessed in the plaster, as well as avoid their critical damage.

Direct drilling into a brick wall

The answer to the question of how to drill a brick wall with a drill can be obtained solely through independent practical experience. So let's get started!

The drilling process itself, regardless of the finish of the brick wall or its complete absence, begins with making a mark. The hole in the wall is marked with a core. Why do you need a mark? After using the core, a slight depression remains, which reliably fixes the cutting part of the drill at the initial stage of work.

The drill must be kept level throughout the entire drilling process, otherwise the cutting element (Pobedit drill bit) will break.

The human factor affecting the drill and the static load on the drill are interrelated quantities. The first, namely “pressure” on the drill, should be smooth and soft, despite the need for significant loads in order to achieve the final result.

If significant static loads can be dealt with by regularly cooling the drill (returning the tungsten and cobalt alloy to its original state), then uniform drilling is the result of a uniform and smooth impact on the tool itself.

Using coolant (water) during drilling may damage the tool. The working cutting Pobedite drill is lowered into the water only 70% of the working length, that is, the one that remains after fixing the latter into the chuck.

The drilling process is monotonous and does not require special skills, but it does require considerable attention. So, for example, the latter will help to identify and, of course, overcome a burnt brick, if, of course, one came across the drilling path. You can identify a burnt brick by the color of the dust. Usually it is black.

Passing such sections must be carried out at low speeds, which, in turn, must be combined with the activation of the shock function. Observing these two conditions, as well as making efforts towards the tool itself, it is necessary to carefully control the heating of the Pobedit drill.

Drilling holes measuring 12 mm requires a slightly different approach, namely the consistent use of all of the above sizes of Pobedit drills. To start drilling a brick wall for a 12 mm hole, you need to start with a 4 or 6 mm drill.

One of these drills reaches the planned depth, then the width of the hole is expanded with a 10 mm drill. After the depth in relation to the previous drill size has been achieved, a similar action should be repeated with a 12 mm drill.

Taking into account this technology to achieve the required hole diameter, namely a diameter of 12 mm, the final result will be achieved much faster, and, at the same time, without unnecessary effort. Regarding how to quickly and efficiently drill any brick wall with a drill in order to obtain a diameter of, for example, 30 mm, you should pay attention to diamond drilling.

When improving an apartment, it becomes necessary to mount all kinds of objects on the walls and ceiling - photographs, paintings, lamps, mirrors, curtains, shelves, TV, baseboards and much more.

In order to hang a photograph or a small painting, of course, you should not drill into the wall. It is enough to hammer in a small nail. Not every carnation is suitable for this task. It is best to use dowels - nails from fastening brackets that secure computer network cables to walls. These cloves are of sufficient length, thick and hardened. It turns out that it can even be driven into a concrete wall.

Performing the operation of drilling holes in walls with modern equipment with power tools will not present any greater difficulty if you know how to drill correctly. It will save you from unnecessary cleaning and keep your property intact if you use a jig for dust-free drilling.

Design features of drill bits for a concrete drill

Initially, you need to find out what a concrete drill looks like on a drill in order to make a hole in the wall. To realize the idea, you will need a drill with an impact function. It is for the impact drill that you need to select a special drill for drilling concrete. In normal drilling mode, the tool will not be able to cope with the task without impact.

Everyone can imagine what an ordinary drill for wood and metal looks like. For drilling concrete, nozzles of a similar design are used, with only a slight difference - the presence of soldering made of carbide materials on the tip, head or working part. These brazes are designed to penetrate the wall while increasing the life of the cutting tool.

Drills for concrete on a drill are coated with pobedit surfacing, which combines a tungsten alloy with cobalt. This carbide material is applied only to the head of the nozzle, which is directly involved in contact with concrete and other similar materials. The alloy of tungsten and cobalt makes the cutting attachment strong, reliable and resistant to abrasion of the cutting edges.

In addition to Pobedit, manufacturers also produce concrete equipment for drills with soldering, or more precisely, coating with diamond dust. Such attachments are even more reliable when working with durable materials. They can even be used for drilling reinforced concrete, as they have high cutting properties.

The distinctive features of concrete drills lie not only in the design of the head, but also in the shank. The shank is the part that is recessed into the drill chuck and is clamped by the claws of the mechanism.

This is interesting!

The head of a drill for concrete consists of a cutting plate, which has a projection larger than the spiral itself by 1-2 mm. It is this cutting plate with a special sharpening at an angle of 75 degrees that is covered with Pobedit soldering.

It is by the design of the head that you can distinguish a concrete drill device from other attachments for drilling metal and wood. Before choosing a drill bit for a drill, you need to understand their types and design parameters.

How to drill a wall

A better tool than a hammer drill for drilling holes in brick and concrete walls has not yet been invented. But rarely does anyone have the luxury of having such an expensive tool on their household. Usually buy an electric impact drill.

Drill selection

When purchasing an electric drill, you need to be guided by the following technical characteristics.

The power of the drill must be at least 600 W. Revolutions up to 2500 per minute and the ability to smoothly adjust them from zero to maximum. The presence of reverse rotation (switch for the direction of rotation of the drill clockwise or counterclockwise). The best chuck is a quick-release chuck; you won’t have to waste time clamping drills and constantly searching for a lost key. The diameter of drills clamped in the chuck is up to 12 mm.

Read also: DIY wood sawing machine drawings

The presence of a switchable hammer drilling function. Of course, when this function is enabled, the drill will not become a full-fledged hammer drill, but drilling walls will be much easier and faster, and here’s why. Brick, cement and concrete withstand static load - pressure very well. But they are easily destroyed by dynamic influences - impact. Karatekas, with a strong blow, easily break a brick in two with the edge of their palm. When drilling with a drill without a hammer function, there is simply pressure from the drill and it is difficult for the cutting edge to catch on to the material, so drilling is slow and the drill becomes very hot due to friction. Drilling with impact is completely different. Upon impact, the drill punctures a part of the material with its cutting edge, and, falling with an impact into the formed recess, breaks off a portion of particles of the material. Something similar to chiseling is happening.

Drill selection

Walls made of wood, plasterboard, and foam concrete can be successfully drilled with an ordinary drill. For walls made of brick, stone or concrete, you need a carbide drill. It differs from steel by cutting edges made of carbide material welded onto a regular drill, usually Pobeda. Less commonly, artificial diamond.

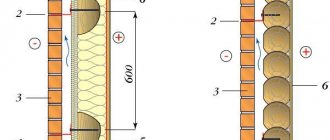

The pobedite insert is clearly visible at the end of the top drill. It is enough to have 2 Pobedit drills with a diameter of 6 and 8 mm on the farm.

Using drills with pobedite surfacing, you can drill a hole no more than 10-15 cm deep. For drilling to greater depths, for example, to drill through a wall, use a drill. Drills for drilling brick and concrete walls are up to one meter long and are designed for drilling holes only with a hammer drill. Even the cutting edges of the drill are made not sharp, but rounded to increase their wear resistance. A drill with a hammer function can also be successfully drilled with a drill.

Drills come with a shank diameter of 10 and 18 mm, with special grooves of the SDS+ or SDS-max standard for fastening, but they also clamp well in a regular jaw chuck. The standard and diameter of the drill are stamped on its shank.

If you need to drill through a thick wall, for example half a meter, then the passage is carried out in several stages with drills of the same diameter, but of different lengths. This is necessary for safety and faster drilling. First, drill the wall with a 20 cm long drill to a depth of 10-15 cm, then with a longer drill to a depth of 30-35 cm and finish drilling with a 50 cm long drill. The drill for such work must be powerful enough. Of course, the drill is not designed for such a load and its use is permissible only in exceptional cases. To perform this type of work, it is better to rent a real hammer drill.

Nowadays, many different devices and tools are used to carry out the necessary construction work. One of the very first was a drill. Holes for various purposes remain in demand today: to hang a picture, lay a wire, assemble and attach furniture, secure a baseboard and much more. For each material in which you need to make a hole, you need to use a drill bit suitable for that material. So what types of drills are there?

Content

- Classification of drills video

- Design of the working part

- Shank design video

- Materials for making drills

- Drill Coatings

- Different materials - different drills

- We work with metal

- We drill wood, plywood, chipboard and plastic

- Drilling concrete and brick

- Other materials

Drill classification

The drill has been used by people for more than two thousand years. During this time, it has come a long way from a simple wooden stick to a high-tech product.

Conventionally, each drill is divided into three parts:

- working part;

- neck;

- shank.

Drills are classified according to several criteria:

- design of the working part;

- shank design;

- by manufacturing method;

- by appointment;

- according to the material being processed;

- by drill coating.

Design of the working part

The working part of the drill is selected depending on the material in which the hole needs to be drilled:

Spiral or screw drills are the most popular and common, familiar to every average person. The working part of the drill consists of two cutting edges, which are formed by the intersection of two helical surfaces. At the tip of the drill, the edges form an angle - depending on the material being processed, its value changes. For soft metals and wood it is 80-90°, for steel and cast iron - 116-118°, for stone, concrete, brick - 130-140°. One of the varieties of twist drills is deep drill bits. Technological holes are soldered or drilled into the tool to supply coolant to the working area.

Flat (feather) drills - used for drilling holes in wood and plastic. The cutting part, made in the shape of a blade, allows you to drill holes of large diameter and depth.

Annular drills - made in the form of a hollow cup, the material is selected only along the perimeter of the drill.

Centering - used when drilling center holes. They are divided into four types: A, B, C, R. The type of drill depends on the sharpening angle of the drill and the presence of a safety cone. They are used for drilling shallow holes for further processing.

Single-cut drills – designed for drilling precise holes in metal. Often used in weapons production. The drill is made hollow. The chips, along with the coolant, are discharged through a technological hole in the drill, which ensures high drilling accuracy. Used for drilling long and short holes. Provides low surface roughness. When working with this drill, it is recommended to rotate the tool quickly and slowly rotate the part in the opposite direction.

Conical drills – designed for drilling in sheet metal up to 4 mm thick, various plastics, glass. The drills do not require preliminary centering and have a smooth cutting part.

Step drills - used for processing sheet metal, plastic, glass, marble. They have increased wear resistance of the cutting part and an extended service life. With their help, centering, drilling and deburring are performed in one go.

Forstner drill - used for drilling holes in wood, plastic, and drywall. As a result of using this tool, accurate holes with the correct geometry and clean, scratch-free holes are obtained. These drills are equipped with four cutting surfaces: two main cutters and two scoring ones. Ideal for drilling blind holes with a flat bottom.

Multi-sided hole drills - used for drilling three-, four-, five- and hexagonal holes. The number of teeth in these drills is always one less than the number of edges of the hole.

Shank design

Drill shanks also have differences; let’s look at the shank designs.

Cylindrical shank - used on all types of drills. In most cases, the diameter of the shank is equal to the diameter of the drill. Transmits little torque due to possible slippage in the chuck.

Conical shank (Morse taper) - used in industrial tools for securing in machine tool chucks.

Triangular shank - drills are easily clamped with a three-jaw chuck, eliminating rotation of the drill in the chuck.

Square shank - a drill with such a shank is inserted into a hole of the appropriate shape. Nowadays it is practically not used due to poor fastening in the three-jaw chuck.

Hexagonal shank - easily secured in the chuck and prevents tool slipping. Based on it, a special ¼-inch holder has been developed for quick tool change. The disadvantage of the shank is that it reduces drilling accuracy when the tool is installed in a ¼-inch holder rather than in a chuck.

SDS (Special Direct System) - shank developed by Bosch. This is a specially designed spline system for quick tool changes. Tools with SDS shanks are called drills. The company has developed 5 types of shank:

- SDS – shank with two grooves, fully compatible with SDS-plus.;

- SDS-plus is the most common SDS type shank. It has four grooves with which it is fixed in the cartridge. Shank diameter 10mm. Suitable for use in all light construction hammer drills. The maximum drilling depth of drills is up to 1 m, diameter – up to 26 mm;

- SDS-top - designed to solve the problems of failure of drills of the SDS-plus system when drilling holes of 16-26 mm. The shank is made with a diameter of 14 mm, which increases the reliability of the drill. To install an SDS-top system drill, you need to change the hammer drill chuck.

- SDS-max – shank diameter 18mm. Used in heavy hammer drills when drilling holes with a diameter of 20mm or more.

- SDS-quick – introduced in 2008. Instead of grooves, protrusions are used in the shank. Used for Bosch Uneo rotary hammer. Compatible with ¼" holder.

Materials for making drills

Drills are made solid or welded. For small diameters up to 8mm, drills are made in one piece. Drills of larger diameter are welded. The drill shank is made from carbon steel, and the cutting part is made from:

Carbon steel (U8, U9, U10, U12) – for drilling wood, plastic, soft metals.

Low-alloy steel (X, B1, 9ХС, 9ХВГ) – used for the same materials, but has increased heat resistance (up to 250°C) and the ability to increase cutting speed.

High speed steel (HSS) – used for drilling unhardened steels. They have high wear resistance and heat resistance (up to 650°C).

Drills with hard alloy (T15K6, T5K10, VK3, VK8) – drills with soldered hard alloy plates. They have great heat resistance (up to 950°C) and wear resistance. Used for drilling concrete, stone, tiles, non-ferrous metals, non-hardened steels.

Carbide drills (VK6, VK8, VK10M, VK15M, T5K12V) are made from steels containing tungsten carbide, titanium and cobalt. Used for drilling high-strength and hardened metals, non-ferrous metals, cast iron, stone, concrete. Drilling is carried out at low speeds.

Drill Coatings

To improve the mechanical properties of drills, they are coated with various materials that help increase their strength and wear resistance.

The following are used as coatings or soldering for the cutting part:

Black oxide film – provides the drill with protection against corrosion and increases the heat resistance of the drill.

Titanium nitride (TiN) is a ceramic material with a golden or yellow-brown color. The coating is obtained by vacuum plasma melting. Increases the service life of the drill by 3-4 times. Drills with this coating cannot be sharpened.

Titanium-aluminum nitride (TiAlN) is a violet-black coating that has heat resistance up to 950°C and high hardness.

Titanium carbonitride (TiCN) is a bronze-violet coating, the shade depends on the amount of carbon in the coating. One of the best coatings for cutting tools.

Borazon is a soldered tool based on boron carbide, which is inferior in hardness to diamond, but has greater heat resistance than diamond. This allows you to increase the cutting speed and processing of the material.

Drills (drills) equipped with diamond – diamond-tipped drills are used for drilling tiles, glass, crystal, ceramic tiles, and stone. When working with a diamond-tipped drill, you should remember that there is increased heat generation in the cutting area, which can lead to damage to the tool or the workpiece. To remove heat, it is necessary to use coolant (cutting fluid). Diamond-tipped drills are highly productive and require almost no sharpening.

Different materials - different drills

This principle has become fundamental in materials processing. Let's consider where, what and how to use it.

We work with metal

In most cases, screw drills are used for drilling metal. They do an excellent job of this task. The drill is selected taking into account the metal in which the hole needs to be drilled. This could be a drill made from low-alloy steel, or maybe from a carbide material. For thin sheet workpieces, step drills can be used.

We drill wood, plywood, chipboard and plastic

Metal drills are also suitable for drilling holes in wood. True, this does not guarantee the accuracy of the task. For precise and high-quality processing of wooden surfaces, screw drills with a special centering tip and feather drills are used. The Forsner Drill has also been developed for blind holes.

Drilling concrete and brick

The construction industry uses drills with an SDS shank - the so-called drills. Since concrete holds compressive loads well, drills for concrete and brick work with shock-rotational movements, thus chipping the material and increasing the speed of work.

Other materials

Glass, tiles, ceramic tiles, and crystal are fragile materials; drilling into them should only be done by rotating the tool. Diamond-tipped drill bits are used for drilling.

To drill large-diameter holes, use a ballerina - a special drill for tiles.

The industry also produces universal twist drills that can be used for various materials. Of course, no one will work with them professionally, but minor repairs in the apartment can be carried out.

Author: Sergey and Svetlana Khudentsov

0

How to drill a wall

Before you start drilling into a wall or ceiling, you need to make sure that there are no electrical wires or other cables running under the intended location in the plaster. Otherwise, you can damage the electrical wiring and get under voltage yourself.

How to avoid getting caught in a wire

It is necessary to inspect the wall for the presence of a switch or socket. Usually, wires extend upward from them in a vertical direction to the junction box. But verticality is the ideal case. This rule is rarely observed in practice by electricians; to save wire, hidden wiring is often laid diagonally. Here's an example of this. When I made repairs and moved the counter to another place, after removing the old wallpaper the following picture opened. You can clearly see how the wire leading to the meter was laid.

But still, the wire will run from the switch to the nearest box. The wire will also go from the chandelier to the nearest box.

Typically the wires are recessed to a depth of no more than 10 mm. To check, use a blunt instrument, such as a screwdriver, to dig into the wall to this depth. If no wires are found, then you can start drilling. And yet, just in case, up to a depth of 20 mm, you should not press too hard on the drill and after deepening every couple of millimeters, visually check whether the wire is caught.

There are special devices that allow you to determine the location of wires in the wall. Here are some of them that are not expensive, made in China, but nevertheless work well. It also has a metal detector function, which allows you to identify the location of metal reinforcement in concrete walls. The device allows you to find copper electrical wiring at a recessing depth of up to 10 mm. Electrical wiring made of aluminum wires can only be detected in metal detector mode.

Wiring detection is indicated by a flashing LED and an intermittent beep. In metal detector mode, when detected, the diode lights up constantly and the sound produced is continuous. There is a sensitivity regulator, the finder is powered by a Krohn-type element. Such a device is especially necessary when installing suspended and suspended ceilings, since the load-bearing structures are attached with self-tapping screws near the ceiling, exactly where electricians usually lay the wiring.

If you happen to break the electrical wiring, then the website article “Connecting broken wires in the wall” will help you to repair it yourself.

Drilling holes in reinforced concrete

Brick walls can be drilled with a Pobedit drill without much difficulty. We decided on the location, attached the jig and, pressing hard on the drill, drilled a hole. It happens that you come across burnt bricks in the wall, which drills more slowly, the dust is not red, but black. The main thing is to drill at low speeds (200 - 400) with the impact mode turned on, pressing harder on the drill handle, and make sure that the drill does not overheat.

I bring to your attention a great video where you can see how a brick wall is drilled using an ordinary drill with a hammer drill function and a drill with pobeditovy surfacing. A hole was made in the brick wall for a box to install an internal electrical outlet.

As you can see, drilling a brick is not at all difficult. Be careful,

When drilling for a long time, the drill heats up to a high temperature and

if you touch it, you can get a severe burn.

It is necessary to periodically stop drilling and dip the drill in water.

Unless the concrete wall or ceiling is made of 600 or 500 grade cement, it drills just as well as brick. In domestic construction, only grade 400 cement is used. In old houses, sometimes there are columns and ceilings made of high-strength concrete. They are very difficult to drill and take a long time.

When making concrete blocks and wall panels, for strength, they install iron reinforcement welded together mutually perpendicularly, which is corrugated rods with a diameter of 8-15 mm, and add granite crushed stone. A pobedite drill is not able to overcome such an obstacle. But there is a simple solution. When, while drilling, the drill suddenly stops going deeper, it means it has encountered reinforcement or granite. The reinforcement can be successfully drilled with an ordinary drill. If you don’t have a simple drill on hand and it is permissible to move the location of the hole, then you can move it diagonally up or down. Granite pebbles in concrete crumble when struck with a drill or narrow chisel inserted into a hole with a hammer. After each blow, to prevent the tool from jamming in the concrete and to make the work go faster, it is necessary to turn it a quarter turn. After removing the obstacle, drilling continues with a Pobedit drill. For a drill with a hammer drill, granite stones are not an obstacle and can be drilled successfully.

Drilling tiles

To drill into tiles with a carbide-tipped drill not specifically designed for tiles, it is necessary to first remove the glaze after marking the drilling point.

This is done very simply, with a core, and if it is absent, you can use an ordinary self-tapping screw or even a thick nail with a sharp end to chip off the glaze in the place of the future hole with very light blows and then drill like a brick wall at low speeds.

Drilling large diameter holes in the wall

When installing ventilation ducts and hoods, it becomes necessary to make a large diameter hole in the wall, for example 18 cm. Sometimes you want to hide an electric meter in the wall, and then you need to make a niche in the wall.

Read also: Homemade band sawmills with a gasoline engine video

At home, this problem can be solved using a carbide drill. The outline of the future hole is drawn on the wall with a pencil. On the outside of the marking line, holes are drilled with a carbide drill with a diameter of 8-12 mm with a distance between the edges of the holes of about 10 mm. For a hole in the wall with a diameter of 18 cm, you will need to perform about 30 drillings with a drill diameter of 10 mm. Next, a sample of the wall material is made using a chisel and hammer. With a smaller drill diameter, the edges of the hole will be neater, but you will have to drill more holes.

If the wall is thick and the length of the drill is not enough to achieve through drilling, then you can drill in two stages.

If it is possible to drill a wall on both sides, then first drill as described above on one side of the wall, then in the geometric center of the resulting sample, a hole is drilled in the wall to reach out, that is, through. Relative to the resulting hole, markings are made on the opposite side of the wall and the operation is repeated.

If it is not possible to drill a thick wall on both sides, then you will have to do drilling and sampling in two stages. From the marking line on the outside, another line is drawn at a distance sufficient so that after the first sampling in the wall and further drilling, the drill can go deeper into the made niche without touching the edges of the wall.

To reduce the labor intensity of the work, it is better to immediately purchase a drill of sufficient length.

Drilling depth limiter

To control the depth of the resulting hole during the drilling process, you can put a piece of cambric (tube) of the required length on the drill bit until it stops in the chuck.

If you don’t have a suitable cambric on hand and you need to drill a small number of holes, then you can use ordinary PVC insulating tape, winding several turns of it. This simple device will speed up your work and save you from having to stop drilling to measure the depth of the hole.

Recommendations and tips on how to drill concrete with a drill

Many people wonder what the best drill bits should be used for the job. Everything depends not only on the attachment and the power tool itself, but also on the correctness of the corresponding manipulations. Features of using the devices in question are to comply with the following recommendations:

- Choosing the right nozzle. This determines not just the ability to drill a hole with a drill, but also the ability to secure a dowel in it. To do this, it is necessary to take into account the diameter as well as the length of the corresponding nozzle. You need to pay attention to the dimensions right away, but it is better to buy a set of drill bits for a drill in a package

- Drilling reinforced concrete - to make a hole in a wall made of reinforced concrete, it is not necessary to buy a special device with diamond coating. An ordinary pobedit drill is also not able to cope with this task, since it will heat up and quickly become unusable. However, there is a way out of this situation - when the equipment reaches the metal reinforcement, it is necessary to install a metal drill in the drill chuck and drill through the metal. Once the metal is drilled out, you can continue to use pobedit-tipped tooling

- If pobedite-tipped equipment has become dull, it can be restored using a grinder with a diamond-coated wheel

- Avoid overheating of the equipment - if the concrete is very strong, the drilling process can take 10 minutes or more. During this time you need to pause, otherwise the metal of the equipment will quickly heat up and begin to melt. Each subsequent minute of work should be alternated with pauses of 10-15 seconds. It is best to use water cooling by feeding water into the hole being drilled.

- Difficulties with drilling stones - if during the work the nozzle bumps into a stone, then there is a high probability that the drill will not be able to cope with it. To crush stone you will need a more powerful tool - a hammer drill. With its help you can quickly break through a wall and achieve your goal.

- Frequent use of an impact drill for processing concrete surfaces is not recommended. First of all, the tool is not designed for such loads, so if you plan to frequently use the tool with attachments made of pobedite tipped, then it is better to use a hammer drill

- When drilling holes in ceramics, only diamond drills should be used, and the work should be performed in a non-impact mode. This will prevent the destruction of the integrity of the tile, since, despite its high strength, it is a fragile material.

If you take all these recommendations into account, the process of processing concrete using drill equipment will be carried out effectively. Below is a table with recommendations for using concrete drill bits for drills.

| Popular questions | Answers |

| How to drill a concrete wall in an apartment | To do this, it is better to use a hammer drill with a drill. If you don’t have a hammer drill, a drill with a high-quality Pobedit drill bit will do. |

| How to drill through concrete with rebar | Equipment for concrete and metal is used simultaneously. As soon as the device hits the reinforcement, you need to use metal equipment |

| How to choose drills | It is necessary to select according to such basic parameters as nozzle length, thickness or diameter, type of soldering, as well as the design of the tail part |

| Is it possible to drill concrete with a screwdriver? | If a drill can be fixed in a screwdriver chuck, this does not mean that this tool is suitable for processing concrete. Firstly, it does not have a shock function, and secondly, its electric motor is too weak |

| Is it possible to drill through concrete using metal equipment? | This is not possible, since the device will stand in place without making holes. In addition, the equipment will quickly become dull |

The type of equipment under consideration is intended for use not only in the design of impact drills, but also in a hammer drill. To do this, a special collet chuck or adapter for drills is installed in the hammer drill. However, you need to take into account the fact that the drill equipment is not designed for heavy loads, so it is possible that during prolonged use in a hammer drill, it can quickly fail. And it is not recommended to use a screwdriver to drill holes in the wall, as this method quickly leads to failure of the tool.

Jig for drilling holes without dust

Due to the heterogeneity of the walls, especially those made of brick, the drill often “leads” away from the intended place and if there is more than one hole, then the suspended shelf does not hang horizontally or, even worse, it is impossible to hang it, since the installed dowels do not coincide with the mounting ones loops. You can use a jig in the form of a sheet of plywood with a pre-drilled hole, but when drilling due to vibration it can also move and again the result will not be what was expected. But there is a simple technology that allows you to drill two or more holes strictly in specified locations.

Precise hole drilling

It turns out that the problem can be solved very simply by gluing a sheet of any sandpaper with glue or double-sided tape to the entire area of the side of the conductor that is attached to the wall. At the same time, the adhesion of the jig to the wall surface increases many times over, and during drilling, the specified accuracy of positioning of the jig is ensured. The hole will appear exactly at the marking location.

Depending on the weight of the product and the density of the wall, you have to drill holes for dowels of different diameters, usually 6 or 8 mm. For the versatility of the jig, it is necessary to drill several holes of the desired diameters with an ordinary drill.

To top it off, attach a plate to the end of the base of the conductor at a right angle. Thanks to this modification, most of the drilling products will remain on this shelf, which will prevent contamination of the wallpaper and reduce the scattering of dust in all directions.

The proposed device is also indispensable when drilling holes for attaching skirting boards. Drill a hole in the jig at a given height from the shelf. When drilling, place the shelf on the floor and all the holes will be exactly at the required height from the floor, which will guarantee a tight fit of the plinth to the floor surface.

Sometimes you have to hang a product on the wall, for which you need to drill several holes in the wall and maintain the distance between them with greater accuracy. If the wall is brick and plastered, then it is impossible to perform accurate drilling without a jig.

To make a jig for precision drilling, a board, sheet of plywood or metal is suitable. After marking, the required number of holes is drilled in the sheet using an ordinary drill. Consider the case for fastening the product with two screws. One hole is drilled with a diameter equal to the diameter of the drill that will be used to drill the wall, the second with a diameter equal to the diameter of the self-tapping screw. After the jig is made, the first hole is drilled in the wall using the jig for the precision drilling described earlier, and a dowel is driven into the hole.

The jig is screwed to the wall using a self-tapping screw into the hammered dowel and leveled using a water level so that the drilled holes are on the same horizontal plane.

Thanks to the use of a simple jig, which can be made in a few minutes from any available material, the holes were created exactly at a given distance from each other.

Using the same technology, you can drill a whole series of holes at a greater distance from each other. In this case, first the outer holes are drilled using the technology described above, the jig is screwed with two outer self-tapping screws, and then all other holes are drilled.

The proposed options for conductors are convenient when renovating an apartment, when dirt is common everywhere. However, when the renovation is completed and cleaned up, drilling becomes stressful. You don’t want to stain your carpets and furniture with concrete or brick chips and dust.