Physical properties of manual arc welding

Electrodes are used to perform manual arc welding. They are fed to the welding site gradually, as they melt, and move along the seam. At this time, the main physical property appears when an arc lights up between the electrode and the base metal. At this moment, the rod melts and the liquid metal in the form of drops flows into the so-called weld pool.

Simultaneously with the rod, the coating of the electrode melts, and then, turning into gas, protects the space near the arc and the bath itself on the molten surface, preventing contact of atmospheric air with the molten metal. Gradually, the arc moves, the weld pool becomes solid, the metal crystallizes, and in this place a connecting seam is formed, on the surface of which a hard crust of slag appears.

The welding arc is formed and maintained by alternating or direct current supplied to the electrode and the metal structure itself. So-called active spots form on the electrode itself and the surface of the bath. The distance between them is the arc length. The metal is melted to a certain depth, the size of which depends on several factors. First of all, this is the welding operating mode and its location in space. A significant influence is exerted by the speed of the arc, the design of the connection, the size and shape of the edges welded to each other.

general information

A wheeled welding unit (SAK, SAG, mobile/wheeled welding machine, etc.) is a hybrid of a welding machine and a portable power station-generator that generates electric current for welding and cutting. To generate electricity, a diesel internal combustion engine is used, which causes the welding generator to rotate. Afterwards, the generated welding current is supplied to the electrode, and full welding and cutting becomes available to you.

A striking example of SAC is the dy6500lxw electric generator with a welding function with mobile wheels from the Huter brand. Its technical characteristics allow the use of such a device in many areas: from repair to full-fledged production.

In what situations might you need a SAC? When access to electricity is either difficult or completely impossible. For example, during construction on a private country site. Often during the construction process it is possible to obtain only a couple of kW for domestic needs, which is not enough for full welding.

Also, SAC may be needed for on-site welding, when you do not know whether the customer will have access to electricity at the customer’s site. It may be able to provide you with the power you need, but you will never know for sure. And in such situations it is better to insure yourself in advance.

How do generator sets work?

The welding generator circuit is often used not only in production, but also at home when performing repair work. They are often used as autonomous sources of electricity and are indispensable equipment, especially in dachas and country houses during regular power outages.

In general, the actions of welding electric generators follow the same pattern.

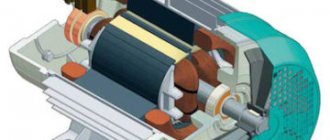

- A current with a variable value appears in the armature winding. It appears where these windings cross the magnetic lines of force located at the stator poles.

- The current is then supplied to the collectors and converted from alternating to direct.

- In the next stage, this direct current is applied to the carbon brushes, which are in very close contact with the commutators.

- At the end of the process, the current flows to the clamps connected to these brushes, and from them to the welding wires.

Wheeled welding machine (WAM)

When choosing a welding machine, we think about its power, dimensions, technical characteristics and additional functions. But we rarely think about the conditions in which our future welding machine should operate. But the choice of equipment largely depends on this.

If you expect that you will often work without an electrical outlet nearby, then you will need a mobile welding unit, also known as SAC (wheeled welding machine). The SAK welding machine is not just a welding machine. This is a full-fledged generator that can work even in an open field. In this article we will explain in detail what SAC is.

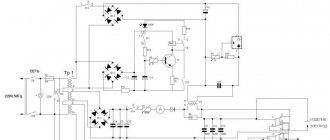

Collector circuit of generator sets

One of the leading schemes of such equipment are collector-type welding generators. The operation of these devices is carried out as follows.

When the welding circuit is open and there is no load, a so-called zero-load voltage appears at the device terminals. Its value is equivalent to the EMF arising in the armature winding. When in operating modes, this voltage is completely dependent on the magnetic induction flux appearing in the independent excitation winding. At the same time, the magnetic flux depends on the excitation current in the winding and is regulated by a special rheostat.

At the moment the arc is ignited, the current flow in the armature winding starts. Next, the current flows through the turns in the series field winding. A magnetic flux is created in it, directed against another magnetic flux, which is created in the magnetizing winding of the HVAC. In this regard, the welding current increases, and the total magnetic flux in the air gap of the generator decreases. Accordingly, the EMF induced in the armature winding decreases and the generated voltage at the terminals decreases.

What is SAC: general information + features

When a person chooses a laser machine, he first of all pays attention to the output power, dimensions and other technical characteristics. Very rarely does a buyer think about the conditions under which he will use the welding unit in the future.

I mean thinking ahead, and not a momentary impulse to acquire 1-2 things.

SAK (Wheel Welding Machine) is a hybrid design that combines welding and a mobile power station. In addition to the classic abbreviation, this equipment is often also called SAG or welding power station.

Please note: when building in hard-to-reach places or in new areas, the problem of connecting to a power source is extremely acute. Recharging without obtaining the appropriate permits will result in penalties.

The key design feature of welding wheel units is the presence of an internal combustion engine. It is according to this that equipment is classified within our state. I will describe the detailed distribution by motor type for power supplies below in the table.

| Type | Subspecies | Description | |

| Petrol | Inverter portable | These are small generators with a power of up to 1 kW. Manufactured in a “suitcase” form factor. They are purchased for home use, because the intensity of the supplied electrical energy is not enough for industrial purposes. | |

| Inverter up to 6 kW. | Increased power also entails increased weight of the unit. Such models are supplied in the form factor of a chest on wheels. To prevent equipment parts from suffering mechanical damage, a frame of pipes is usually made around the engine. | ||

| Gasoline up to 10 kW | Designed for use at high intensity over long periods of time. Form factor like a barrel on wheels. | ||

| Diesel (DGS) | Design execution | Classical | Linear type rotation generator |

| Open | Used in buildings. | ||

| Soundproof | If a “quiet” operating mode is required. | ||

| Van | For difficult climates. | ||

| Mobile | In mobile structures. | ||

| Type of current | Low voltage | up to 1 kW. | |

| High voltage | from 1 kW to 10 kW. | ||

| Generator type | Parallel | Generation of current at standard frequency. | |

| Asynchronous | Generation of current of non-standard frequencies. | ||

| Welder | Constant | DC generation. | |

| Removable | AC current generation. | ||

Among gasoline power plants, container-type power plants can also be distinguished. For constant outdoor use, modification of the external casing is required (noise-absorbing casings are used) + fine adjustment to the form factor. Typically, such equipment is made to order. Peak power can be up to 200,000 watts.

Among diesel equipment, three concepts should not be confused - “power plant”, “unit” and “generator”. Each of the objects has its own design + differs in the scale of assembly.

Design features of SACs:

- Built-in cooling system that protects sensitive parts from overheating. With high-quality cooling, the operation of the welding unit will not be suspended at the most inopportune moment;

- the part of the equipment that is responsible for the welding operation itself is manufactured as an induction generator;

- The engine is usually covered with a special fireproof casing to prevent external negative influences of weather. The second function is to protect the welder from potential injury;

- the lower part of the frame is equipped with a chassis. The wheel size may vary and depends on the operating conditions of the equipment. For indoor use, these are small ones, but if we are talking about transporting the SAC over long distances (like a trailer), the diameter of the wheels increases significantly. All these points are discussed individually with the supplier of the units.

When referring to the technical characteristics of SACs, it is important to pay attention to the type of welding current and its peak power. Usually this is up to 120 A. The second, no less important selection rule is the ability to connect other electrical equipment to the unit. It is irrational to drag such a colossus behind you just for the sake of welding. It is necessary to select units that are capable of producing an output voltage suitable for most classic power tools. Such SACs can be useful during construction or installation work, and even in everyday life as a temporary power source for housing.

Valve type generator circuit

Gasoline generators of this type are made in the form of an inductor three-phase alternating current generator. It has a higher frequency, and the circuit has a built-in rectifier unit. A three-phase AC armature winding is installed on the stator. It is connected according to the “star” or “triangle” scheme. Between the two rotor packages, the excitation winding is also located on the stator.

The rotor itself is made in the form of two packages consisting of gear elements made of electrical steel. It has no windings and rotates around its axis. Each rotor package has eight teeth, offset from each other by 180 degrees.

When a direct current passes through the field winding, an alternating magnetic flux occurs in it. Its distribution is carried out in such a way that the first package creates only the north poles, and the second - the south. When the rotor and stator teeth are aligned, the maximum value of the magnetic flux is achieved, and the amount of resistance along the path of this flux will be minimal. The magnetic flux becomes minimum when the stator tooth coincides with the rotor slot.

Thus, it is clearly seen that the excitation winding is directly involved in the creation of a pulsating or alternating magnetic flux. Penetrating the three-phase stator winding, this flow causes the induction of an alternating emf with an increased frequency in it. In turn, the alternating EMF is converted into a constant voltage of the valve generator using a rectifier unit.

The name of the device is associated with the rectifier unit, which uses silicon valves assembled according to a three-phase circuit in the form of a bridge. The excitation winding is powered through a three-phase generator power circuit. For this, there is a special unit, which includes current and voltage transformers, as well as rectifiers. After starting, the generator is initially self-excited due to the residual magnetic flux.

Peculiarities

The SAC welding machine has a number of features that you need to consider.

Let's start with fuel. As you already understand, SAC is a fuel-powered device. And diesel fuel is often used. It is inexpensive and economical, and its characteristics are sufficient to generate electricity. You can rarely find devices running on gasoline fuel. This is the exception rather than the rule.

Make sure that the SAC model you choose has a built-in cooling system. Thanks to it, the device will work stably and will not let you down at the most inopportune moment. If you buy a SAC without cooling, you will significantly complicate your welding. You will have to constantly monitor the temperature of the device, do not use it longer than indicated in the instructions and worry about the duration of operation. Such a unit needs to constantly cool down, and this is a waste of time.

The components of the device themselves are attached to the frame and covered with a metal casing. Check before purchasing how strong and reliable this frame is and what metal the casing is made of. Do not buy a low-quality device, even if it is offered at a tempting price. Due to a low-quality housing, such a unit simply will not be able to perform all the tasks that you assign to it.

The device you choose must have wheels. Pay attention to them too. They should be durable and have a thick rubber tire. After all, you will not have to move it on asphalt.