Welding rail joints is a difficult process that requires maximum concentration and care. Since the web material contains a lot of carbon, it is considered a difficult-to-weld metal. By making mistakes in creating a rail weld, you can get cracks in the joint. We will discuss the essence of this type of welding in this article.

What is aluminothermic welding?

The method is as follows: a special powder is placed in a special metal structure, which is located above the junction of two sections of the fabric being welded, and then this powder melts. The purpose of the powder is that it reliably and firmly connects the base material and thus the microstructure of the seam becomes very viscous. Such joints are made very quickly and over time they do not sag, which indicates their high quality.

The powder, which acts as a binder in thermite welding of rails, consists of 23% aluminum chips and 77% iron oxide. The powder structure is finely dispersed, granule size is 0.5 mm. The technology is based on the ability of the metal to be reduced in aluminum oxides. However, as already noted, this can only happen at high temperatures, which is why an igniter is used, through which the mixture is ignited. It is this process that turns iron oxide into pure metal.

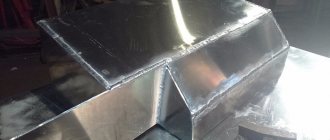

A casting mold is used at the site, thanks to which the alloy is directed to the joint.

Note! It is very important that a sealed structure be formed, which is why special different shapes have been created for different rail configurations.

If, after completing the work, you find some gaps and cracks, then you need to get rid of them; for this, heat-resistant coating is used. Due to its liquid consistency, it flows into the butt joint area and fills the free space. As a result, slag forms on the surface.

The process of creating a rail weld must be carried out with the obligatory sealing of the joint when it is still hot. To do this you need to get presses. Upon completion of the work, the slag must be beaten off with a hammer, and the seam itself must be sanded with a special machine and grinder.

How to weld rails

When carrying out installation and repair work on sections of the railway track, as well as in similar conditions associated with laying rail lines, special welding technologies are used.

Features of rail welding technologies are expressed in increased requirements for the operational reliability of connections, as well as their resistance to mechanical loads.

Basic methods

Welding of rail joints belongs to the category of particularly important activities, the organization and implementation of which is impossible without the use of equipment and modern welding mechanisms.

The main types of welding technologies used in the installation and repair of rails are:

- electric contact welding;

- electric arc method;

- thermite treatment (aluminothermic welding of rails);

- modern gas-press welding.

Each of these methods has certain advantages and disadvantages. To become more fully acquainted with them, we will consider each of the listed welding methods in more detail.

Electric contact method

The electric contact approach to connecting rail joints is based on their strong heating and subsequent melting through an electric arc, which is formed by a significant low-voltage current.

To implement the method, special machine complexes are used that operate in automatic mode (MSGR-500, MS-5002 or K-190, for example).

Before welding, the rails to be processed are laid either directly on the tracks, or with a slight offset inside the branch or outside the track (at a distance of about 260 centimeters from its axis).

In this case, the welding mechanism itself moves along the restored thread, that is, it is a self-propelled rail welding station.

During its operation, replaceable contact heads of various types are used, providing the necessary welding modes (continuous reflow or intermittent heating of contacts).

Electric arc method

Non-contact arc welding is one of the most common methods used for mating rail joints.

According to this approach, the rails are first laid with a small gap, after which their ends are welded with metal electrodes melted through an arc discharge. This type of non-contact welding does not require the application of excess sedimentary pressure and is implemented using alternating or direct currents supplied from a mobile welding station.

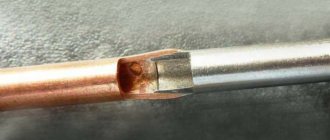

The most effective way to perform arc welding of rails is the so-called “bathtub” method, according to which pre-cut rails across the longitudinal axis are laid strictly along the track line with a slight elevation and a gap of approximately 14-16 millimeters.

A working electrode is inserted between the ends of the rail blanks laid in this way, followed by passing a current of about 300-350 amperes through it.

As a result of this effect, the molten mass spreads evenly over the gap and completely fills it. To prevent it from flowing out, the gap between the rails is closed with special blocking barriers. Upon completion of welding, the resulting seams are ground over the entire joint area.

Thermite treatment

Aluminothermic technology has been tested by time. The use of thermite welding of rails is based on a reducing reaction that occurs when the base (aluminum) comes into contact with another component - iron oxide.

The resulting metal (reduced iron) at operating temperatures of about 2000 degrees is poured into a special fire-resistant form that matches the geometry of the rails being welded.

This reaction is accompanied by the release of a significant amount of thermal energy.

Welding rails using the thermite method began a very long time ago (from the mid-19th century), but since then this type of welding, due to the use of aluminum, began to be called aluminothermic.

It is important to note that the described chemical reaction after igniting a special high-temperature fuel (thermite) lasts only a few seconds.

In addition to the two components considered (iron and aluminum oxide), alloying additives and small steel particles are introduced into the working welded mixture, which slightly slow down or dampen the ongoing process. Additives are necessary to ensure that the steel in the welding zone acquires the required qualities and parameters characteristic of most rail products.

When considering the features of this type of welding process, it should be noted that upon completion of the reaction, the total chemical mass is divided into two fractions: liquid metal and light slag, which floats to the top of the mold.

Termitan technology allows the following types of track products to be connected to each other:

- surface-hardened rail blanks;

- volumetrically hardened joining parts of rails,

- rails that have not undergone special heat treatment in any combinations.

This type of welding ensures compliance with the requirements of the basic standards for high-speed rail lines, in terms of compliance with welding technology standards.

Gas press method

This welding technology is based on joining metal rail joints at relatively low temperatures (notably below the melting point), but at a sufficiently high pressure.

The main advantages of the gas pressing method include the homogeneity of the material structure in the welding zone, as well as the high strength of the resulting joint.

Thanks to the listed advantages, this method can effectively “cook” even very heavy and large railway products. Before welding, the ends of such rails are tightly joined to one another, after which they are cut simultaneously using a special tool (a rail cutting machine with a circular saw or a mechanical hacksaw).

As a result of preparatory operations, the required tightness of the end parts of the rails with high purity of the metal interface is ensured.

In addition, immediately before welding, the ends are treated with dichloroethane or carbon tetrachloride. At the stage of preparing the rails for welding, their ends are heated to the required temperature using special combination burners that ensure sufficient temperature is obtained.

After thorough heating, the ends of the rails are clamped using a specially designed hydraulic press and continue to heat up to 1200 degrees.

During the welding process, the torch bodies are slightly displaced relative to the joint being processed (they make small oscillatory movements). The frequency of such periodic movements, as a rule, does not exceed 50 vibrations per minute.

Simultaneously with these movements of the gas burner, the rails are compressed by a hydraulic press with a force of 10 to 13 tons, the exact value of which is determined by special calculations. As a result of this treatment, the welded metal at the joint is deposited by approximately 20 millimeters.

To implement the described technological chain, special gas pressing equipment (universal machines) is used.

Upon completion of the entire complex of gas welding operations, the finished joint is thoroughly cleaned of slag, and then returned to its normal appearance (they say that it is “normalized”).

So, the considered key methods for welding rail joints are applied in accordance with the technical requirements and conditions for carrying out repair and restoration activities.

Of all the approaches, aluminothermic welding stands out, as it best meets modern requirements for non-contact restoration of rails or laying railway lines. It is the thermite method that is most often used in the construction and repair of modern transport highways.

Advantages and disadvantages

Aluminothermic welding of rails is very often used in practice; its wide popularity is due to a number of advantages that stand out when using this method:

- The process is carried out very quickly (no more than 30 minutes). Several experienced welders can create 10-12 seams in 1 hour.

- Welding work may not require connection to stationary sources of electricity.

- All necessary parts and tools can be purchased at any hardware store.

- To weld a rail well, in principle, you do not need any special education; it is enough to practice several times to make the connection strong and reliable.

- If you strictly follow the rules for performing the technology for creating a seam, you will ultimately get a connection that will withstand heavy loads.

- Provided that good technique is used, the process is considered completely safe for the people doing the work.

- Thermite welding of rails does not require strict connection to a populated area; it can also be carried out in the field.

Despite the large number of advantages, like any other technology, welding work based on the use of aluminothermy has its disadvantages, which cannot be ignored:

- Since the powder used is flammable, extreme care should be taken when handling it.

- In order to ultimately get a high-quality seam, you need to pay special attention to preparation and complete it in detail.

- Make sure the equipment is in good working order.

- You need to be very careful, because if water gets into the burning container, the metal will splash.

Aluminothermy

To weld rails using the aluminothermic method, aluminum powder and RedO iron oxide are used. Make up a thermochemical equation if the formation of 1 kg of iron produces 6340 kJ of heat. [p.35]

Aluminothermy produces ferrovanadium, ferroniobium and ferrotantalum. Pure vanadium metal can be reduced by calcium reduction in a steel bomb. The resulting particles of vanadium metal, after washing, are fused into an ingot in a vacuum furnace. The metal obtained in this way contains up to 99.9% vanadium and has good ductility. Niobium and tantalum can be obtained by thermal decomposition of pentaiodides or pentachlorides at 2000 C or reduction with metallic sodium or potassium. [p.371]

This property of A1 is the basis for the method of reducing metals (Cr, Mn, W, V, etc.) from their oxides - the aluminothermy method discovered by N. N. Beketov (1859). [p.277]

Relatively pure chromium is obtained by aluminothermy [p.373]

Aluminum metal is used primarily for the production of alloys. Aluminum alloys are less resistant to corrosion due to the occurrence of galvanic microelements in places where impurities are included. Aluminum is used to produce cables, foil, mirrors, and silver paint. The ability of aluminum to reduce metals from oxides at high temperatures served as the basis for the method of aluminothermy, i.e., the reduction of refractory metals, such as chromium or manganese, from their oxides [p.152]

In terms of content in the earth's crust, chromium is a fairly common element. The main chromium ore is chromium iron ore PeO-CrOz. Elemental chromium can be obtained by aluminothermy from chromium (III) oxide [p.273]

Experiment 9.3. Carrying out aluminothermy [p.145]

Aluminothermy is the name given to reactions occurring between metal oxides and aluminum, with the formation of the corresponding free metal, aluminum oxide. Aluminothermy can produce only those metals whose heat of formation of oxides is less than the heat of formation of aluminum oxide. Metals such as Cr, Mn, T are obtained in industry using this method [p.334]

Sequence of work:

Preparatory stage

A significant role in how to weld a rail seam is played by preparation, which involves the following actions: near the joint, the rail fastenings must be loosened, and those located at the joint area must be completely removed. Next, using a burner, the rails are heated and also cleaned of rust. At the next stage, using wedges, they must be straightened both horizontally and vertically. The rails must be installed maintaining a gap of 2.5 mm, then a cutter is brought to them.

Alignment

Initially, you need to get rid of the gaskets of all fasteners, wedges are installed in their places, using a hammer they need to be adjusted to the required condition. Then you need to check how accurately the rails are laid; to do this, use a meter ruler.

Installation

At this stage, it is important to select the desired sealed form, then the burner must be placed in the middle in the area where the seam is expected to appear. You also need to seal the gaps; to do this, the mold must be pressed as tightly as possible against the seam; a spatula is also used here, which ensures a clean edge between the seam and the sand.

Heating and welding

Pre-heating of the rails is carried out with a burner at the following parameters: propane pressure – 1.5 bar, oxygen pressure – 5 bar. The flame is supplied for 1.5 - 2 minutes. When heating is complete, the burner is removed, the core is inserted and the crucible is turned. Then, at the site of the intended joint, a special barrel filled with charge is installed. In order to ignite the charge, a high-temperature fuse is used, then the liquid metal is placed in a mold and held for 4-5 minutes.

Sanding and quality control

At the end of the procedure, the joint is processed along the edges to a smooth state: while it is hot, the sagging is cut off.

Next, using abrasive tools, you need to sand the seam. To check the quality you need a ruler and a feeler gauge. It's important to keep things as straightforward as possible. The quality of the seam is checked by static bending, everything is done using measuring tools.

Aluminothermic welding of rails: technology, equipment, consumables

Rails can be welded using arch welding, gas press techniques, and using aluminothermic technology. The last method works when using an igniter.

A charge is supplied that is equivalent to one portion. The temperature increases to 1000 degrees. Any rails can melt at these numbers.

Aluminothermic welding of rail joints is considered a complex technology. It requires skill and care from the master. The material contains many carbon compounds. It won't be easy to weld.

If you are not enthusiastic about the process, you may end up with a weak connection. There may be numerous cracks that will complicate the operation of the structure. In the article we will talk about what this type of welding is.

What is aluminothermic welding

The powder is placed in a metal container. It is located above the border of two parts of the canvas. After this, the powder is melted. The crumbly mixture is necessary in order to obtain a strong connection to the base metal.

Small parts of the seam will become viscous, but the joints will be reliable. Over the course of decades, it has been determined that aluminothermic welding does not sag. This method is considered one of the most effective.

The powder that binds the canvases consists of a quarter of aluminum sand. Its main part contains iron oxide. Granules no larger than 0.5 mm in size. It is finely dispersed, yet malleable to any action.

The metal can be reduced in the oxides of the material. But this is only possible in cases where high temperature comes into play. It is necessary to ignite the mixture using the fuse method. This causes the iron oxide to become a pure alloy.

A filling container is used locally. It directs the alloy to the aluminothermic welding sites. The tightness of the structure plays an important role. Different types of rails require the use of a special shape.

After the job is completed, do you find any gaps or cracks? They must be sealed using heat-resistant coating. Due to the fact that it is liquid, the mixture will help flow into all hard-to-reach places. As a result, you end up with a lot of excess slag.

It is necessary to seal the connection while it has not lost its high temperature. The press will help with this. When the work is completed, the slag is removed using a hammer. Sanding joints using a grinder.

Advantages and disadvantages

This method is used quite often. This is because it has advantages that welders appreciate. Among them are the following:

- Fast operating speed. All stages take no more than half an hour. With a lot of experience, up to ten seams can be processed in 60 minutes.

- Do not use stationary electrical power. This allows you to move the device from place to place.

- All parts of the structure can be found in one place. They are sold in specialized stores.

- To obtain an even connection, you do not need to have a professional education. You need to try your hand at welding several times.

- If you do not forget about the rules of work and adhere to all technologies, you can get a lasting final result.

- The entire process does not pose a danger to workers if high-quality equipment and materials are used.

- Welding work can be carried out both at home, in workshops, and in the open field.

The use of aluminothermic welding involves some difficulties. They can be like this:

- The powder can easily catch fire, so you need to be extremely careful with it.

- Preparatory work is carried out carefully and in detail so as not to miss important nuances.

- The equipment you will work with must be in working order. Check its serviceability before starting welding.

- If drops of liquid get into a hot pan, then the entire mixture will splash. Don't let this happen.

Settings

Aluminothermic welding is only possible if you use all the working elements. Among them are the following:

- Barrel.

- Powder.

- Cork.

- A shape that responds to the rails.

- Liquid coating.

- Polishing device.

- Chisel.

- Hammer.

- Metal shovel.

- Light

What stages of work exist:

- Preparation. This step will determine how strong the aluminothermic rail weld joint will be. First of all, in the place that is located near the joint, make the rail fastening weaker. Remove those located at the junction. The burner will raise the temperature of the rail. They will become clean and free of rust. Wedges will help straighten them in horizontal and vertical positions. Leave a gap of 2.5 mm and connect the rails to the cutter.

- Smoothing. First remove the gaskets that are placed on the connections. Use wedges instead. They are nailed with a hammer. Using a ruler, check the accuracy of the rails.

- Installation. Select the required impervious form. The torch is then positioned in the middle where you want the connection to be made. Ensure tightness of joints. Using a spatula, press the mold firmly into the joints. The result is a dense base located between the seam and the mixture.

- Heating and metalworking. The rails are heated using a burner when the following conditions are met: propane pressure is 1.5 bar, and oxygen pressure does not exceed 5 bar. The fire passes within 120 seconds. Once the structure has heated up, the burner is no longer needed. You need to insert the rod and rotate the vessel. In the place where aluminothermic welding is planned, you need to place a container in which there will be a charge. To ignite, you need to take a well-heated fuse. After this, the liquid metal is left in the mold for up to five minutes.

- Polishing. After completing the welding work, you need to grind the structure. To check the quality of the seam, take a ruler and a feeler gauge. Measuring instruments allow us to determine how high the quality of the connection is in the end.