Material such as stainless steel is often used in industry and in everyday life. Stainless steel is not subject to rust, has a long service life and is well suited for water filters, various containers, etc. Many people choose this metal to create heating or plumbing systems.

However, there are situations when products leak and special equipment is not available. Then the only correct solution is to weld stainless steel with an electrode.

We will tell you exactly what this process is and how to properly weld stainless steel with an electrode in this article.

Distinctive features of stainless steel materials

The main characteristic that distinguishes stainless steel is its resistance to corrosion processes. Due to this property, many products that are made of stainless steel are used to work with water and under high pressure. Experienced welders know how to weld stainless steel with an electrode, so welding pipes or other elements does not cause any difficulties for them. The situation is completely different with novice welders; the main problem they will face is the leak that forms after the seam cools down. In order to cope with a leak and make an even and high-quality seam, you should be very careful and careful.

Before you start welding, you need to become familiar with all the properties of stainless steel.

First of all, it is worth noting that this metal has a high expansion coefficient. This means that when the product heats up, the distance between the molecules will increase, and when it cools, on the contrary, it will shrink to its original proportions. If the seam is made of another metal, then this is fraught with cracks, or even rupture.

"Advice! Select a high-quality electrode rod that will provide a good connection between the stainless steel and other additional metal."

Another problem that can be encountered in the process of welding with stainless steel electrodes is the low melting point of this metal. With strong heating, the area that has undergone a process such as electrode welding will simply overheat and all its anti-corrosion properties will disappear. As a result, rust forms in the place where the welding was carried out. In this regard, it is especially important to turn on the correct welding mode and conduct the seam in a checkerboard pattern. By following these rules, your product will be protected from overheating.

The next nuance is that if oxygen gets into the weld pool, gas will form on the surface of the weld and large pores may appear. If such a reaction occurs, it will simply be impossible to weld the metal. To avoid this, pay special attention to protecting the weld pool from the environment. This can be done using shielding gas or by coating the electrodes. Each of these methods will result in the formation of a gas cloud in the welding area.

Method using an inverter

The job requires experience and is not available to every beginner.

Advantages of welding stainless steel with a conventional electrode:

- low cost of equipment;

- low weight and dimensions of the device;

- ability to weld parts up to 2 cm thick;

- possibility of working without protective gases and fluxes.

Disadvantages of this method:

- formation of a large amount of slag;

- destruction of the coating followed by overheating of the electrode;

- current limit;

- increased time costs.

The work is carried out in three ways:

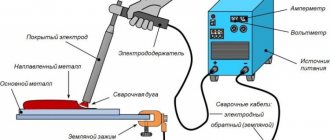

- Using manual methods. The joint between the parts is filled with molten electrode material. Only an inverter is used for operation.

- Connecting workpieces with a tungsten electrode used for thin sheets. The weld is obtained by melting the workpiece and filler wire. The welding site is protected by a layer of gas.

- Semi-automatic operation with wire feeding. Speed increases along with productivity. It is recommended to add carbon dioxide (up to 2%) to argon.

Before you cook stainless steel with an inverter at home, you need to properly prepare the apparatus and materials.

We recommend reading: How to cook stainless steel with a semi-automatic machine

Necessary consumables

Using an inverter, you need to prepare everything necessary for work:

- unit of the appropriate type;

- solvent;

- steel bristle brush;

- personal protective equipment;

- electrodes;

- crocodiles – grounding clamps;

- cables with a length of 2 to 6 m.

Joining sheets with a thickness of 3 or 4 mm and obtaining a high-quality seam becomes a difficult task, which can be accomplished using an inverter with an oscillator and the ability to carry out argon arc welding (TAW).

The popular device Aurora PRO INTER TIG 200 PULSE can become such a device. ADS allows you to create beautiful and durable seams on thin sheets or pipes.

Inverter setup

Before welding, the machine is set up correctly. This is done by switches on the instrument panel. The required values can be seen in the table:

| Workpiece thickness | Current value (A) | Voltage (V) | Electrode diameter |

| 1,5 | 40 – 60 | 13 | 2 |

| 3,0 | 75 – 85 | 15 | 3 |

| 4,0 | 90 – 100 | 16 | 3 |

| 6,0 | 140 – 150 | 18 | 4 |

| 8,0 | 150 – 180 | 20 | 4 |

| 12,0 | 180 – 220 | 22 | 5 |

| 15,0 | 220 – 260 | 26 | 6 |

When working in semi-automatic or argon-arc welding mode, the flow rate of inert shielding gas is set. Everything is done experimentally. Optimal values are 6-12 l/min. The movement of the wire during automatic feeding is adjusted to the maximum speed, which gives a high-quality seam.

Process step by step

Before work, the master must perform the following steps:

- remove dirt from the workpiece next to the future seam with a steel brush or emery cloth until it has a natural shine;

- treat the welding area with solvent or acetone to remove traces of fat;

- remove chamfers from workpieces with a thickness of 4 mm or more to fill the joint with molten metal;

- treat the rest of the metal with a solution of chalk in water so that hot drops do not stick;

- leave a compensation gap of 1-2 mm between the parts;

- connect thin sheets without gaps;

- place heat-dissipating plates under the workpieces;

- Thick parts should first be heated until they reach 150-170°C.

We recommend reading: How to cook stainless steel in an argon environment

When working with direct current, reverse polarity is installed.

Post-weld treatment

At the end of the work, the parts are cooled naturally. You cannot speed up the process by pouring water on them. This will lead to the formation of microcracks. After cleaning the slag, the seam is ground and then polished.

For refining, abrasive materials containing aluminum or zirconium oxide are used. Corundum products are not suitable.

To ensure that the joint remains durable and aesthetically pleasing, it is coated with a paste with anti-corrosion properties. If these recommendations are not followed, the quality of the product will decrease due to the occurrence of rust spots.

Instead of a conclusion: manual welding is often used for small household and industrial problems. It is used to connect pipes, stainless steel tanks and other products in the country, in the house, in the garage. Repaired items last for many years.

Welding methods

Currently, there are several methods for welding stainless steel.

There are three methods for welding stainless steel at home:

— Welding with electrodes. This type is different in that the consumable electrode becomes the material from which the seam is made. This method is suitable for welding both ordinary steel and thin stainless steel, and in this case the welding process is carried out by a special welding machine - an inverter.

— Argon welding with tungsten electrode. In this case, the metal of a pre-selected part is melted using an electrode. It will act as the material from which the seam will be made. Welding using argon can be done in another way. For this purpose, filler wire is used for welding, in which the function of protecting the weld pool is performed by an inert gas - argon.

Tungsten Rods for Welding

— Semi-automatic welding with consumable electrode. This type of welding is performed in a gas environment.

Electrode device for welding and surfacing

The basis of any welding electrode is a metal core. When an electric current is applied to it and an arc is formed, the core heats up and melts. There is a coating on the surface, which also melts when heated at a high temperature. Forms a layer that prevents air oxygen from entering the melting zone.

Several types of coating are used to form the coating:

the main type, used for repeated welding of seams. Before performing welding work, calcination or drying at a temperature of at least 175...180 ⁰С is required;

The acid type is used for welding workpieces that have oxide films and rust. Be sure to remove scale after completing welding work. Calcination at a temperature of 180…220 ⁰С;

rutile type, contains titanium oxide. For most jobs, manual arc welding is the most suitable option. Removal of coating residues is required; it has a pronounced acidic reaction. Alkyd-based paints cannot adhere to slag surfaces. If exposed to a humid environment, it must be calcined at a temperature of at least 185...200 ⁰С;

cellulose type, containing organic materials (corn or wood flour, cellulose, resins of organic origin). Such electrodes are marked E42...E50 with different letter designations. Operated on direct current. Calcination at a temperature of no more than 110...120 ⁰С.

For inverter devices it is recommended to use acid and rutile electrodes. The basic type is rarely used; the arc is difficult to hold. Capricious behavior does not allow obtaining a high-quality weld.

In everyday life, the use of cellulose-coated consumables is also limited, and the price is quite high.

Coating thickness

In practice, the thickness of the coating on the surface of the electrodes is determined in mm:

- 0.8…1.8 – thin coating. Used as widely as possible. Up to 90% of manufactured products have this thickness.

- 2.0…3.6 – average thickness. Such electrodes are used for welding critical parts designed for dynamic loading with sharply varying loads.

- 4.0...6.0 – greater thickness. Electrodes are used for critical work - welding pipelines with high pressure inside. When transporting aggressive media.

Core material

Low carbon steel is used to make most electrodes. It contains no more than 0.72...0.78% carbon. Metal:

- Relatively easy to melt. The temperature in the arc zone is at the level of 1750...1950 ⁰С.

- The melt fills the space provided to it. It flows into the cavities formed when heated.

- Heating is close to the boiling point, so the melted coating lowers the temperature of the melt.

Malleable cast iron is used for welding high-carbon steels and cast irons. However, there are special features when welding gray cast iron. It is necessary to preheat the materials to an austenitic state (730...850 ⁰С). After the process is completed, slow cooling must be ensured. If rapid cooling occurs, then white cast iron will form near the weld areas. It has high cold brittleness.

Manganese steel is used for welding alloy materials. Base and cellulose coatings are used.

Stainless steel is used for welding stainless steel pipelines. Alloys containing manganese and copper are also used.

Special types of electrodes

For welding stainless steel and high-alloy steels, electrodes are used that do not burn out during the welding process. They only create an arc. Here filler wires are used, which melt and enter the heating zone.

Titanium is used in such technologies. It can withstand heat above 2200 ⁰C. Filler wires are made of stainless steel 18ХН9Т. The melting point is 1340…1380 ⁰С.

When welding alloyed products, KhVS, KhVG, KhS12, KhN9T and others wires are used as filler material. They have a melting point of 1420...1510 ⁰С.

For refractory steels, filler rods made of KhNG, 12ХВ10Т, Т10ХВ are used. These alloys melt at a temperature of 1670…1820 ⁰С.

Selecting Electrodes

In order to weld stainless steel efficiently and reliably, important attention should be paid to the choice of electrodes.

These conductors must have the following characteristics:

- slight thermal expansion

- they must be elastic

- must conduct heat well and be wear-resistant,

- they must have a special coating that is designed to work with stainless steel.

The choice of electrodes in construction stores and on the market is quite large. Electrodes OK 67.60 from the Swedish company ESAB are widely popular. Among domestic manufacturers of electrodes, the OZL-8 and TsL-11 brands stand out. The price of such electrodes is lower than imported ones, but during the welding process they require special care and professionalism from the person performing the work.

The table shows the main indicators that must be observed when welding metal of different thicknesses.

| Metal thickness, mm | Type of current | Current strength, A | Electrode or wire diameter, mm | Passage speed, cm/min | Voltage, V | Argon consumption, l/min |

| 1 | Constant | 30..60 | 2 or 1.6 | 12 – 28 | 11…15 | 2,5…3 |

| 1 | Variable | 35…75 | 2 or 1.6 | 15 – 33 | 12…16 | 2,5…3 |

| 1,5 | Constant | 40..75 | 2 or 1.6 | 9 – 19 | 11…15 | 2,5…3 |

| 1,5 | Variable | 45…85 | 2 or 1.6 | 1 — 14 | 12…16 | 2,5…3 |

| 4 | Constant | 85…130 | 4 or 2.5 | — | 11…15 | 10 |

Electrodes for stainless steels and ferrous metals

The combination of stainless steel and ferrous metal is quite possible. But this process is fraught with certain difficulties. The thing is that these metals have different structures. There are three methods you can use to perform this operation:

- welding using coated consumables;

- welding with non-consumable tungsten rods;

- welding under protective gas, as a rule, argon or gas mixtures based on it are used for this.

For welding dissimilar metals, the OZL-312 grade is used. To perform the assembly of critical structures, EA-395/9 is used. OZL-312 stainless steel welding rods are suitable for welding steels with an unidentified composition.

But, as practice shows, no one has come up with an optimal quality seam better than joining workpieces under gas protection. In this process, gas plays the role of protecting the weld pool from the effects of the atmosphere, in particular from nitrogen and oxygen. When welding with argon, there is one subtlety. To ensure the quality of welding, a welding rod is used, which must be held strictly at an angle of 90 ⁰ to the surfaces being processed.

Based on the above, we can draw the following conclusion: materials of wide application are used to perform welding of dissimilar metals.

Application area

Welding stainless steel with an inverter has found its active use both at home and in industrial settings.

Welding stainless steel pipes with electrodes will be relevant only if it is necessary to create short seams. Manual arc welding is often used in the following types of work:

- production of small-sized parts,

- installation of metal structures,

- surfacing,

- used when it is necessary to get rid of defects in small areas of the seam.

To summarize the above, it is worth emphasizing once again that welding stainless steel with an electrode is carried out only if the work is not very large-scale.

Which welding machine to choose

Some craftsmen rent welding machines. To work with alloy metal, you need to choose modern welding equipment that generates direct current; with such a device it is easier to maintain a short arc, and smooth seam stitches are obtained. You can weld metal with a transformer, but in this case, sagging may form, reducing the strength of the restored element. It is better to choose welders with additional functions. The risk of sticking the electrode and burning through the workpiece will be reduced. A good option is a universal generator that produces direct and alternating current. It is permissible to use an inverter that produces high-frequency alternating pulse current.

Welding technology

Unlike ordinary steel, to weld thin stainless steel with an electrode, you need a much smaller amount of current (20%).

"Note! If you are welding thick metal, then there must be a gap between the workpieces. Otherwise, cracks may form.”

The length of the electrodes should be no more than 35 cm. If the wrong temperature is set, the material may lose its anti-corrosion properties. The heating temperature should not exceed 500°C.

Classification of special purpose electrodes

There are many criteria for classifying consumables, and this review does not aim to outline all possible types and classes. We are interested in stainless steel electrodes for high-alloy special alloys. Here's where they belong:

Electrodes by purpose

- for low-alloy carbon alloys, names begin with the letter “U”;

- for alloy steels with the initial letter “L”;

- for alloyed heat-resistant steels with the letter “T”;

- for high-alloy steel alloys with special properties with the letter “B”;

- for surfacing surfaces with special properties, letter “N”.

Types of coating and labeling standards.

We may also be interested in the classification of electrodes by type of coating (for more details on coatings, see below):

- A – acidic coatings;

- B – basic coatings;

- C – cellulose;

- R – rutile;

- mixed and other types of coatings.

The principles of marking electrodes on stainless steel are quite cumbersome. There is no purpose in this review to list them in full.

Welding stainless steel at home

In order for the seam to be of high quality, the following recommendations should be followed when welding stainless steel:

- In order to connect steel from stainless steel, a current of reverse polarity must be used. During the welding process, pay attention to the seam. If it does not melt, then it is done correctly.

- A small gap should be left in the weld joint.

- Welding stainless steel using a conventional electrode is usually typical for work at home. If you need to bond thick surfaces, then you need to use electrodes with a larger diameter.

- In order to correctly determine the required welding current value, use the table presented above. It indicates all the necessary values, based on the thickness of the material. Typically, in order to obtain a high-quality and durable connection, you need to use a current with a minimum value of 20% of the current that is used for welding low-carbon steels.

- Upon completion of the seam making process, you need to wait some time until it cools down. Thanks to this, the steel will be resistant to corrosion processes.

- Use copper pads to cool the seam.

Selection of products according to other parameters

The type of current, as well as the polarity of its connection, are the most important parameters of welding operations. Welding inverters primarily produce direct current, which can be connected to the workpiece and the electrode in two circuits.

- Straight polarity. With this scheme, the plus is connected to ground, and the minus to the welding electrode.

- Reverse polarity. This scheme involves connecting the minus to ground, and the plus, respectively, to the holder with the electrode.

If you cook with an inverter using straight polarity, the surfaces being connected are subject to significant heating, which does not happen when connecting the polarity in the opposite way. This is why choosing reverse polarity is advisable in the following situations.

- When welding parts of small thickness with an inverter. Reverse polarity in such cases will help protect the material from burn-through.

- Reverse polarity is used to weld parts made of high-alloy steels, which are very sensitive to overheating.

Working with inverter welding

Direct polarity, during which the workpiece is subjected to significant heating, is optimally used for joining materials that are very thick and massive.

When performing any welding work using an inverter, the most significant are three parameters that are interconnected:

- welding current strength;

- electrode diameter;

- thickness of the parts to be connected.

The thickness of the parts being connected has a direct influence on the choice of electrodes. If it is necessary to connect thin parts (up to 1.5 mm), manual welding is not used; semi-automatic machines or devices that allow welding in a protective argon environment are better suited for this purpose.

Options for electrode position when welding

When deciding which electrodes to choose for welding structures of a certain thickness, you can be guided by the following criteria:

- for parts whose thickness is 2 mm, electrodes Ø 2.5 mm are best suited;

- when connecting parts with a thickness of 3 mm, you should choose electrodes Ø 2.5–3 mm;

- if the thickness of the parts to be welded is 4–5 mm, then electrodes Ø 3.2–4 mm are suitable;

- parts with a thickness of 6–12 mm are best welded with electrodes Ø 4–5 mm;

- when the thickness exceeds 13 mm, then the optimal choice is electrodes Ø 5 mm.

Welding electrodes

If such information is not contained on the packaging, then you can follow the following recommendations:

- for welding with electrodes Ø 2 mm, the welding current should be set to 55–65A;

- for products Ø 2.5 mm, a current of 65–80A is used;

- electrodes Ø 3 mm - current 70–130A;

- for electrodes Ø 4 mm, choose a welding current of 130–160 A;

- products Ø 5 mm - current 180–210 A;

- It is better to cook with 6 mm electrodes at a current of 210–240 A.

As it becomes clear from all of the above, for high-quality welding with an inverter, the correct choice of electrodes according to their diameter is important. You should also set the optimal welding current. If, for example, you plan to weld thin metal with an inverter, using large-diameter electrodes, or the welding current exceeds the permissible values, then pores may form in the finished weld, which will significantly reduce its quality characteristics.

Weld protection

Stainless steel is highly sensitive to mechanical cleaning after completion of the welding process. Cleaning involves removing the top oxidized layer, which is precisely intended to protect the weld from rusting. The oxidized layer is restored only after 5-6 hours. It is important that during this time nothing gets into the stripping zone, which is most often simply impossible. But there is one way to help deal with this problem. After mechanical cleaning is completed, it is necessary to coat the steel with a special spray, which consists of passivating additives and synthetic oils.

To summarize, we can come to the conclusion that the strength and quality of welds when welding stainless steel depends only on the person performing the work. If you approach all requirements with full responsibility and follow all recommendations, the result will meet your expectations. Therefore, it is important to carry out the welding technology in detail, choose a good inverter and buy high-quality electrodes.

Which electrodes to choose for stainless steel

The risk of cracking will be reduced if you choose an additive with a rod that is similar in chemical composition to the workpiece. Several types of rods are produced for welding stainless steel:

- TsL-11 was created for welding chromium-nickel alloy, they have a fluorine-carbonate coating, welding can be performed at temperatures up to +450°C. The electrode can be used in any position.

- OZL-6 is intended for heat-resistant steels; if you cook other workpieces with it, the electrode will straighten out more slowly and the weld will be weak;

- NZh-13 – for food grade stainless steel. Can be used for chromium-nickel steel alloyed with molybdenum. The coating forms a small layer of slag that protects the melt pool from oxidation.

- ZIO-8 is for heat-resistant alloys; problems will arise with it when welding household stainless steel.

- NII-48G is a universal additive with the main type of coating.

- EF400/10U, OLZ-17U – professional electrodes designed for austenitic alloys. It is not advisable to use such rods in everyday life; the coating contains harmful components.

How to hold the burner correctly

Manipulations during argon arc welding are performed with a special argon torch. Due to its design features, a tungsten electrode is installed in the burner so that its tip protrudes above the surface of the limiting ceramic nozzle by several millimeters. Typically, the welder controls the torch with his right hand, bringing it as close as possible to the weld pool.

A short arc increases the depth of metal penetration, and externally makes the seam aesthetically pleasing. Therefore, in order for argon welding to occur correctly, learning how to manipulate the torch to maintain the correct arc length is not the last thing. Unlike electric arc welding with a stick electrode, frequent oscillatory movements are not allowed when argon welding is performed; video lessons will allow you to learn the correct technique for working with a torch.

Types of stainless steel

Stainless steel is divided into three separate types:

- Heat-resistant alloys are materials with the ability to effectively resist aggressive environments at high temperatures.

- Corrosion-resistant steel - used in everyday life and small businesses. Such metals can be found at oil refining and light industry facilities. The material variant is suitable for the production of various tools and equipment.

- A heat-resistant type of steel is necessary to maintain mechanical properties (shape, strength) during high temperatures.

Corrosion resistant steel

Heat-resistant stainless steel

Based on their chemical structure, stainless alloys are divided into various types:

- Martensitic steels have obtained excellent corrosion-resistant qualities in normal open space conditions and environments with low levels of aggressiveness. This stainless steel is used for devices that are subject to wear and tear. In particular, knives and elastic elements for chemical and food production are made from martensitic alloys. Such material can be used in low concentrations of salt and acid solutions.

- Austenitic stainless steels differ in physical properties, including hardness and ductility. Stainless steel is actively used in the mechanical engineering industry. This variant of the alloy can exhibit magnetic force when subjected to cold deformation forces. The high manufacturability of the material allows the use of parts for structures and devices.

- Ferritic alloys can be found in oxidizing atmospheres. This material performs excellent functions in household appliances, heating systems, and heat exchange systems. The alloy is also highly valued in the food production segment. The alloy is not affected by nitrogen concentrates, liquids with ammonia and similar aggressive environments.

- The austenitic-ferritic base exhibits a higher yield strength of the material compared to similar metals. The combined metal exhibits low grain growth with a two-phase structure. Due to the low amount of nickel, austenitic ferritic steel bonds well during welding. Such alloys are successfully used in aircraft construction, chemical production, and heavy industry.

Structure of martensitic steel

Martensitic steel

Structure of austenitic stainless steel

Electrodes for special purpose stainless steel

While the general property of stainless steel is resistance to corrosion, additional special-purpose properties will vary depending on the alloying additions to the alloy. All types of stainless steels are high-alloy alloys with different properties. This means a high percentage of certain additives. Taking this into account, electrodes are also strictly divided according to their performance characteristics.

For high strength corrosion resistant alloys

Such alloys do not oxidize even at temperatures of 600°C. Widely used in the aviation industry, which speaks for itself. These alloys are used to make steel cables for bridges, the most important parts in electrical machines, transformer cores, bolts, connecting rods, all systems that require high resistance to shocks and other force impacts.

Criteria for selecting electrodes for stainless steel welding.

Even in this seemingly very special segment, high-strength stainless steels are divided into grades with their own characteristics.

Electrodes are considered in the same way: for each grade of metal there are different consumables:

- For steel grades 12Х21Н5Т and 08Х21Н6М2Т there are several types of electrodes: E-08Х20Н9Г2Б, E-09Х19Н10Г2М2Б , etc.

- For grades of special high-alloy alloys 12Kh25N5TMFL, 10Kh25N6ATMF, 12Kh21N5T and 08Kh21N6M2T, only one type E-08Kh24N6TAFM , which produces a special weld with strength equal to the base metal.

- For steel grades 08Х226Т and 08Х21Н6М2Т, types OZL-40/08Х22Н7Г2Б and OZL-41/10Х20Н7М2Г2Б . The seams in this case are characterized by extremely high corrosion resistance to alkaline environments.

For acid-resistant, corrosion-resistant alloys

This group of alloys is not susceptible to exposure to acidic environments, that is, they are corrosion resistant in aggressive environments. They are needed in many branches of industrial production: aviation, mechanical engineering, mining, chemical, etc. The main functional words in this case are aggressive environment.

It is from such alloys that components and main parts of equipment are made, intended, for example, for mines with acidic water, sewer pipes, industrial chimneys, and so on. The requirements for consumables for such alloys are no less stringent: the seams must have the same qualities as the steel being welded.

Brands of electrodes and their scope.

These include:

- in “soft” modes - temperatures not exceeding 360°C, you can use a wide group of electrodes of the types EA-400/10T , EA-400/10U , OZL-8 , OZL-12 , L-39 and EA-606/10 . The resulting seams do not involve further thermal exposure; only acid resistance “in its pure form” remains.

- for steel parts with the necessary tempering at the end of welding, electrodes of the EA-989/21 , which make it possible to make seams that are resistant to MCC before and after the work process.

- To work in nitric acid, tips of the type E-08Х19Н10Г2Б , of which the brands TsT-15 and ZIO-3 are .

- There are special low-carbon acid-resistant steels with a low carbon content of up to 0.03% with high ductility of the alloy; consumables of the types E-04X20N9 and E-02X20N14G2M2 .

We cook thin steel

This is one of the most difficult methods, requiring knowledge and skills in equal measure. In addition to accurately selecting suitable consumables, it is necessary to set the correct voltage with the current reduced by approximately 20%. You can only work with short rods - no longer than 35 mm. Do not allow high heating temperatures, the upper limit is 500°C, in no case higher.

Operating principle of MMA welding.

Household welding of thin stainless steel sheets is carried out using an inverter machine with strict production rules:

- Under no circumstances should the temperature level exceed 150°C in the joint area and general heating of surfaces.

- Use only low current values, but at high speed.

- To prevent the formation of holes and overheating of the working area, place gaskets in the form of plates under the workpieces: in this way, excess heat will dissipate.

- If the metal sheets are thinner than 3 mm, there is no need to trim the edges. The gap between the surfaces in this case should be no more than 2 mm.

The following electrodes are designed for working with thin stainless steel:

- TsL-11 , a public favorite, produces a very corrosion-resistant weld even in unfavorable environmental conditions.

- OK 63.20 works well in liquid aggressive media at high temperatures.

Technological process

The process of welding stainless steel material has its own technology; how to weld stainless steel with an electrode is indicated below.

The process is carried out as follows: First of all, the surfaces to be welded are cleaned of dirt, oily deposits, paint coating, etc. The presence of such substances excessively foams the weld site.

When connecting metal plates with a thickness of more than 5 mm, the edges are cut. Using the method of making bevels of 45 degrees and a gap of 1 mm, when welding products of smaller thickness, such preparation is not performed.

Thanks to the close alignment of the parts, the seam is attractive and smudges on the reverse side are eliminated. After welding is completed, it is not recommended to pour water on the metal; it should cool gradually and on its own.

Welding stainless steel main factors of difficulty

The difficulties that arise when welding stainless steel have been discussed more than once in the article; in this section we will simply summarize these factors.

High coefficient of linear expansion

This factor leads to deformation during cooling since the metal expands greatly when melted. The solution is to reduce the welding current and increase the welding speed.

Low thermal conductivity

This factor leads to overheating and spreading of the weld pool. The solution is to reduce the welding current and use a heat sink.

Intergranular corrosion

This factor is caused by severe overheating of the molten metal in the weld pool and the heat-affected zone. The solution is to not overheat the metal in the weld pool, control the temperature during multi-pass welding and allow the previous layer to cool.