Metal deformation during welding is a terrible thing. Everything seemed to be going well, the part was almost ready, and then all of a sudden it was all twisted, like the Leaning Tower of Pisa.

An inexperienced production worker will blame the welder and his crooked hands for this. However, he is an inexperienced production worker. An experienced production worker understands that in most cases, metal deformations during welding cannot be avoided in principle.

You can make them invisible and not affect anything - however, it is not the welder who should think about this, but the one who gives him the task. There are tasks that in any case will lead to deformation. Even if a welder of the sixth category works. Yes, even if a welder of the thirty-sixth category existed in nature, and it would be he who would work.

Let's figure out why deformations occur when welding metal and how you can deal with them.

What is voltage

Welding voltage is defined as the force acting per unit area of the product. It can be caused by tensile, bending, torsional, compressive or shearing forces.

These forces reach such magnitudes that during operation, stress and deformation in individual parts lead to the destruction of the entire structure. In addition, the anti-corrosion properties decrease, the geometric dimensions and rigidity of the structure change.

Stresses and deformations can be temporary or residual. Which welding deformations are called temporary and which residual are simply determined. Temporary ones appear during welding of parts, the second ones appear and remain after the end of welding and cooling of the structure.

Deformations during welding. Ways to deal with them

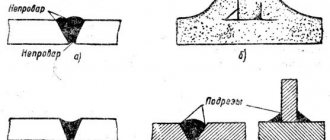

When heated to the welding temperature and subsequent cooling, the parts experience deformation, which ultimately leads to a physical change in their size and shape. This change may or may not be noticeable to the naked eye. Thermal deformations are a consequence of the occurrence of internal structural stresses of the metal, which arise due to uneven temperature distribution and, accordingly, unequal changes in volume in different sections of the part during its cooling. The reasons for the appearance of structural deformations (warping and bending) as a result of welding work are:

- Localized high-temperature heating and local expansion of the metal volume while the rest of the part remains relatively cold;

- Shrinkage phenomena in the deposited layer

- Phase transformations that a metal experiences when the temperature is gradually reduced to room temperature.

How to minimize welding deformations?

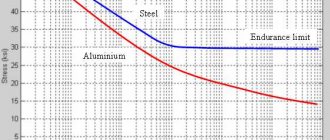

The choice of welding type can greatly reduce deformation. If arc welding is used, then the largest leads will be with RDS, or as it is commonly called today in the Latin letters MMA; they will be significantly reduced if you use TIG (argon) and MIG/MAG (semi-automatic welding). The use of PULSE modes makes it possible to significantly reduce the heat input into the metal and reduce deformations, which is very clearly seen in the example of welding thin-sheet steels. It should also be noted that gas welding has the greatest deforming effect on the product, since significant areas of the product are subject to high-temperature influence; and the least is pressure welding (in vacuum, ultrasound). However, arc melting technology is most often used, so further we will talk specifically about this type of production of permanent connections.

Technological techniques to reduce deformation during arc welding

The first thing that comes to the mind of every amateur welder is the organization of heat dissipation, which makes it possible to slightly reduce the tension of steel components. Copper pads and other devices are usually used as a heat sink. There is a cheaper method, such as applying wet asbestos near the weld.

The technique of performing the work also plays a significant role. To compensate for stress, welding is used in a checkerboard pattern or by alternately melting diametrically opposite sections of the connection. What is meant is clearly seen in the example of a welded I-beam shown in Fig. 1. The numbers indicate the sequence of work.

Welding according to the “reverse step” principle involves dividing the connection line into small sections and then welding them in the manner shown in Fig. 2nd order. This method allows you to obtain minimal deformations, since two principles are simultaneously fulfilled that allow you to achieve this result, these are:

- Short seam;

- The sequence of its application allows to compensate for warping.

If the assembly has loose tolerances, the reverse deformation method can be used. In this case, the sheet is bent by the amount of welding deformation (which can be determined experimentally) in the direction opposite to the direction of its action.

Another simple way to reduce metal leashes is to put tacks on before starting welding with a continuous seam, using one of the methods indicated above in the text; or force the part using tooling.

The following will help minimize deformation:

- accompanying local heating of the product with burners or preliminary heating in an electric furnace

- Post-weld heat treatment

- Or hot and cold forging

- Straightening products in a cold state

- Almost completely relieves internal welding stresses by high tempering at T = 550 -560 °C

Obviously, any high-temperature heating in air leads to changes in the size and shape of the product. The degree of changes can be noticeable to the naked eye or when monitoring using various tools: a caliper will allow you to measure linear dimensions, an indicator on the stand will help you monitor runouts. It is impossible to completely get rid of deformities. However, there are still ways to significantly reduce them or even get rid of them after final machining by:

- Selecting the optimal product design;

- Organize allowances sufficient to completely remove the leash.

Reasons for appearance

The main causes of stress and welding deformation are:

- non-uniform heating of metal workpieces;

- shrinkage changes in the alloy in the weld;

- phase changes that occur during the transition of molten metal from one state to another.

One of the properties of metals is their ability to expand when the temperature rises and contract when cooled.

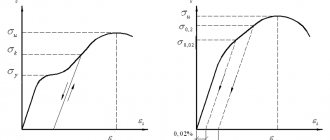

During melting, a non-uniform thermal zone appears in the area of the welding joint. It causes compressive or tensile stress. If these stresses exceed the yield strength of the metal, then the shape of the product changes and residual deformations occur.

The types of deformations depend on the extent to which they occur. There are three genera. Deformations of the first kind act in macrovolumes, deformations of the second kind occur within crystal grains, and deformations of the third kind occur in the crystal lattice of the metal.

Deformations and stresses during welding also occur during crystallization of the weld, when shrinkage of the liquid metal occurs. The volume of cooling liquid metal decreases, this causes stress inside the metal. Stresses are formed parallel and perpendicular to the axis of the weld seam, which cause a change in the shape of the product. Longitudinal forces cause changes in the length of the weld, and transverse forces lead to angular deformations.

When certain limiting temperatures are exceeded when welding carbon and alloy steels, their structural transformation occurs. They have a different specific volume and the coefficient of linear expansion changes, which leads to enormous welding stresses.

The largest of these occur in alloy steels. Hardening structures are formed in them, which, when cooled, do not return to the previous structure of the metal, as in most cases, but retain colossal stresses that can lead to the destruction of the weld.

For these alloys, special technological processes are being developed to reduce residual stresses and deformations.

What is the best welding method for welding thin sheet metal?

The higher the temperature in the heating zone, the more likely it is that the metal will move.

Different types of welding have different temperature conditions, so if you often need to weld thin metal, then you should think about the following:

- Oxy-acetylene welding is not the best option for welding thin sheet metal. The greatest deformations occur precisely with this type of welding, since its temperature reaches 3100 °C.

- MMA welding () is everyone’s favorite manual arc welding with a coated electrode. In manual arc welding, the temperature occurring at the end of the electrode is much lower, from 2400 to 2700 °C. Therefore, this type of welding is more preferable for joining thin sheet metal.

- Semi-automatic MIG/MAG welding - the heating temperature is about 1500 °C, and the welding speed is even faster than with manual arc welding. Therefore, MIG and MAG are the most convenient for welding workpieces made of thin sheet steel.

And lastly, this is the correct organization of heat removal in the welding zone. For these purposes, you can use both special heat-removing copper plates and improvised means. For example, you can use wet asbestos to place it next to the weld seam or other materials.

Share on social networks

How to prevent

To prevent the harmful effects of welding deformations, the following rules must be observed and several measures must be taken:

- there should be a minimum of welds and they should be as short as possible;

- the number of intersecting and different-thickness seams is also reduced to a minimum;

- welding joints are made with a smooth transition of thicknesses;

- metal is deposited in a minimal amount;

- in the most intense places of the structure, no seams are made at all;

- leave allowance for shrinkage.

It is necessary to choose the right welding method, which depends on the weldability of the materials, energy and mode. To reduce the heating zone, you need to increase the welding speed. To increase the welding depth (heating up to thickness), it is necessary to increase the current strength.

To reduce the harmful effects of heat in the welding zone, the welder should avoid tack welding whenever possible.

The use of clamps and other welding devices gives positive results. They allow you to maintain the mobility of parts when welding in the longitudinal direction and prevent angular movement.

The workpieces are positioned in such a way that the welding deformations that occur during cooling are opposite to the stresses.

To reduce residual stresses and deformations, preheating must be used. In addition, you need to choose the right welding technology.

The sequence of sutures should balance the resulting stresses. The seams must be placed so that the parts being welded have the greatest mobility.

During the welding process, the weld is forged, which deforms the cooling welded joint and reduces the effect of shrinkage.

Methods used in the welding process

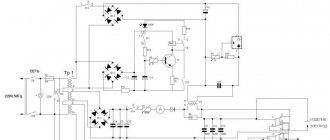

1. Reduced welding energy input due to more economical modes. The method is used relatively often.

2. Reducing the area of the plastic deformation zone by cooling with water, for example, during contact or gas-electric welding.

3. Fastening in the device. Widely used in production. The positive effect is achieved due to the rigidity of the device. Complete elimination of deformations is not achieved.

4. Rational sequence of assembly and welding operations (Fig. 135, d). In some cases, this is the only way to avoid significant permanent deformations.

5. Loading the welded joint with tensile forces (Fig. 135, d). It is almost never used in production.

Methods for eliminating stress

Stresses are eliminated by annealing or mechanical methods. Annealing is the most effective method of stress relief. It is used when increased demands on the accuracy of geometric dimensions are imposed on the product.

It can be general or local. Most often, annealing is carried out at 550-680 °C. There are three stages: heating, holding, cooling.

Mechanical methods for eliminating stress include forging, rolling, vibration, and explosive treatment, which lead to plastic deformation of the opposite sign.

Forging is done with a pneumatic hammer, and vibration treatment is done with a special device that causes vibration of the product with a resonant frequency in the range of 10-120 Hz for several minutes.

Deformations or “leashes” are a natural reaction of metal to welding

You know that any substance changes volume under the influence of temperature. The volume of steam is greater than the volume of water produced from it. The volume of water is greater than the volume of ice produced from it. So, metals change their volume very actively when heated.

Now imagine a puzzle. Yes, a puzzle picture made of pieces of the same size with notches that cling to each other. This is our metal product with its internal connections.

And now one piece of the puzzle - that is, one piece of metal - will suddenly heat up to enormous temperatures. What is the temperature of the cathode spot there, 2400–2700 degrees Celsius? Okay (for a proper understanding, let me remind you that the combustion temperature of wood usually does not exceed 1000 degrees, and gasoline - 1400 degrees). In this case, the neighboring pieces of the puzzle will naturally begin to heat up from it - the further away, the less. And on parts of a fairly large part remote from the welding zone, the temperature of about 25 degrees, which was in the room before work began, will remain.

And each of the pieces will change its size in accordance with the accepted temperature.

You understand that such a puzzle would be simply impossible to assemble - the pieces simply do not fit together in size. However, the problem is that it is already assembled.

And sections of metal with different temperatures begin to press on each other - or, conversely, stretch each other. This is called metal stress. When the stress reaches a critical threshold, the metal will relieve it as best it can - deformation will occur.

And here is an example of a case produced by Metal-Case:

Medical holder for flasks (5 photos)