Tensile strength

A certain threshold value for a specific material, exceeding which will lead to the destruction of the object under the influence of mechanical stress. The main types of strength limits: static, dynamic, compressive and tensile. For example, the tensile strength is the limit value of a constant (static limit) or variable (dynamic limit) mechanical stress, exceeding which will rupture (or unacceptably deform) the product. Unit of measurement: Pascal [Pa], N/mm² = [MPa].

Using the properties of metals

Two important indicators - plasticity and PP - are interrelated. Materials with a large first parameter degrade much more slowly. They change their shape well and are subjected to various types of metal processing, including die stamping - that’s why car body elements are made from sheets. With low ductility, alloys are called brittle. They can be very hard, but at the same time have poor stretching, bending and deformation, for example, titanium.

Resistance

There are two types:

- Regulatory - prescribed for each type of steel in GOSTs.

- Calculated – obtained after calculations in a specific project.

The first option is rather theoretical; the second is used for practical tasks.

Ways to increase strength characteristics

There are several ways to do this, two main ones:

- addition of impurities;

- heat treatment, for example, hardening.

Sometimes they are used together.

General information about steels

All of them have chemical and mechanical properties. Below we’ll talk in more detail about ways to increase strength, but first, let’s present a diagram showing all the varieties:

Also watch a more detailed video:

All of them have chemical and mechanical properties. Below we’ll talk in more detail about ways to increase strength, but first, let’s present a diagram showing all the varieties:

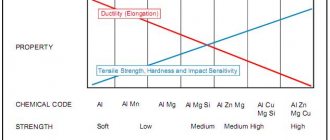

Carbon

The higher the carbon content of a substance, the higher the hardness and the lower the ductility. But the composition should not contain more than 1% of the chemical component, since a larger amount leads to the opposite effect.

Manganese

A very useful additive, but with a mass fraction of no more than two percent. Mn is usually added to improve machinability. The material becomes more susceptible to forging and welding. This is due to the displacement of oxygen and sulfur.

Silicon

Effectively increases strength characteristics without affecting ductility. The maximum content is 0.6%, sometimes 0.1% is enough. Combines well with other impurities; together, they can increase corrosion resistance.

Nitrogen and oxygen

If they get into the alloy, but worsen its characteristics, they try to get rid of them during manufacturing.

Alloying Additives

You can also find the following impurities:

- Chrome – increases hardness.

- Molybdenum – protects against rust.

- Vanadium – for elasticity.

- Nickel – has a good effect on hardenability, but can lead to brittleness.

These and other chemicals must be used in strict proportions according to the formulas. In the article we talked about tensile strength (short-term resistance) - what it is and how to work with it. They also gave several tables that you can use while working. To finish, let's watch the video:

To clarify the information you are interested in, please contact our managers by phone;; 8 (800) 707-53-38. They will answer all your questions.

Tensile strength of steel

Steel structures have long replaced other materials, as they have excellent performance characteristics - durability, reliability and safety. Depending on the technology used, it is divided into brands. From the most common with a PP of 300 MPa, to the hardest with a high carbon content - 900 MPa. This depends on two indicators:

- What heat treatment methods were used - annealing, hardening, cryotreatment.

- What impurities are contained in the composition. Some are considered harmful, they are discarded for the purity of the alloy, and others are added to strengthen them.

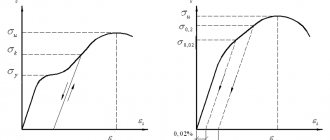

Proportional limit (σ)

The maximum stress value for a particular material at which Hooke’s law still applies, i.e. The deformation of the body is directly proportional to the applied load (force). Please note that for many materials, reaching (but not exceeding!) the elastic limit leads to reversible (elastic) deformations, which, however, are no longer directly proportional to stress. In this case, such deformations may be somewhat “lag” relative to the increase or decrease in load.

Diagram of the deformation of a metal sample under tension in the coordinates elongation (Є) - stress (σ).

Source: www.smalley.ru

Proportionality limit

This is an indicator that determines the duration of the loads applied to the deformation of the body. In this case, both values should change to different degrees according to Hooke’s law. In simple words: the greater the compression (tension), the more the sample is deformed.

The value of each material lies between absolute and classical elasticity. That is, if the changes are reversible after the force ceases to act (the shape becomes the same - for example, compression of a spring), then such parameters cannot be called proportional.

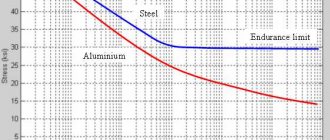

Endurance limit or fatigue limit (σR)

The ability of a material to withstand loads that cause cyclic stress. This strength parameter is defined as the maximum stress in a cycle at which fatigue failure of the product does not occur after an indefinitely large number of cyclic loads (the basic number of cycles for steel is Nb = 10 7 ). The coefficient R (σR) is taken to be equal to the cycle asymmetry coefficient. Therefore, the fatigue limit of the material in the case of symmetric loading cycles is denoted as σ-1, and in the case of pulsating ones - as σ.

Note that fatigue tests of products are very long and labor-intensive; they involve the analysis of large volumes of experimental data with an arbitrary number of cycles and a significant scatter of values. Therefore, special empirical formulas are most often used that connect the endurance limit with other strength parameters of the material. The most convenient parameter is considered to be the tensile strength.

For steels, the bending endurance limit is usually half the tensile strength: For high-strength steels, you can take:

For ordinary steels during torsion under conditions of cyclically changing stresses, the following can be accepted:

The above ratios should be used with caution, because they were obtained under specific loading conditions, i.e. during bending and torsion. However, when testing in tension-compression, the endurance limit becomes approximately 10-20% less than in bending.