The request for "Nails" is redirected here; see also other meanings.

The request for "Nail" is redirected here; see also other meanings.

Nail

— a fastener, hardware in the form of a rod with a head and a sharp end. The shape of the rod can be cylindrical, parallelepiped, cone-shaped or pyramidal. A nail is used to fasten parts made of various materials (mostly wood) to each other. By driving with a hammer, the nail is inserted into the bodies of the parts being connected, in which the nail is held by friction.

In a number of industries, nails have special names, for example, a spike on a railroad.

What material are nails made of?

Bronze nails have been found during excavations of buildings in Ancient Egypt and other ancient cultures. Historical sources report the use of nails in the Roman Empire to nail criminals to wooden crosses [ source not specified 2692 days

]. In Russia, references to master nailers have been known since the 13th century[2].

Modern nails are made primarily of steel. In some cases, they are made of brass, copper, bronze, zinc, plastic and other materials.

Types of nails according to purpose

Products are classified by purpose. The latter determines the dimensions of the rod, the shape of the head, and the preferred material of manufacture.

- Construction is the most popular fastening material. The cap is small, the cross-section of the body is round. Maximum length – 310 mm. There are notches on the head that prevent the hammer from slipping when struck. Designed for knocking together boards, light wooden structures, and wall mounting. Most often, fasteners are galvanized. There are models made of acid-resistant steel for work in places with high humidity.

- Screw – option for loaded structures. The body of the nail is screwed into a screw along its entire length. Made from square wire. This design compensates for thermal expansion under the influence of temperature and humidity. Thanks to this shape, it can withstand high pulling loads. Screw models are used when installing wooden floors, pallets, and containers.

- Rough nails – the rod is threaded along its entire length. The thread significantly increases the permissible load on the connection - up to 5 times. Fasteners are made from hardened steel. It is usually used to secure containers. Sometimes for installation it is necessary to drill holes in the surface with a diameter slightly smaller than the dimensions of the rod. Construction Screws

Ruffed - Clubs - along the body of the nail has 2 grooves - solid or with partitions. Designed for fixing steel mesh or light reinforcement treated at high temperatures. It is also used for fastening soft tile materials: ondulin, roofing felt.

- Roofing - distinguished by a very wide large cap. This device is designed for installation of soft roofing materials. When driven in, an ordinary nail literally “sinks” into the material. The wide cap holds ondulin, slate, soft tiles and does not damage the flooring. They are made only from galvanized steel, since fasteners on the roof are constantly exposed to moisture.

- Slate - a type of roofing fastener. Since slate is a corrugated material, the nail for it is longer. The hat is made in the form of a sphere and acts as a puck. The slate nail is driven only into the ridge - it always holds the material at a certain distance from the sheathing.

Clubs

Roofing

Slate - Wallpaper or furniture . Small thin nails with large decorative caps - made of bronze, brass, copper. Elements are often decorated with embossing and enamel. They are used for upholstering upholstered furniture, decorating walls with fabric wallpaper, and decorating interior items.

- Finish - the main difference between the nail is a very small head, almost identical in diameter to the diameter of the rod. When used, the head is recessed into the material and becomes as invisible as possible. Finishing models are used when attaching wooden finishing elements: skirting boards, lining, finishing boards and panels, platbands and window frames. The load on such fasteners is small. “Invisible” nails allow you to achieve maximum aesthetics of the sheathing.

- With oval head – such a head allows you to regulate the direction of the nail when driving in – usually in the direction of the fiber. In this case, the cap does not create mechanical stress on the surface. The technique is designed for working with soft wood that is prone to warping and cracking.

Furniture

Finishing

With oval head - Shoe - a specialized element designed to attach the heel to the shoe. Fasteners are made of brass or steel. The head is conical, the shaft is quadrangular.

- A nail with a double head - on the shaft there is a thickening equal in diameter to the head, and the head itself. This device greatly facilitates dismantling. Fasteners are used when arranging greenhouses and greenhouses: for fixing film materials and assembling temporary structures.

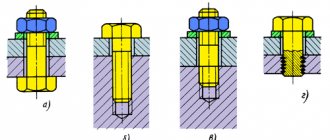

- Anchor nail – special fasteners, which, thanks to the design, can be additionally fixed. The nail can withstand significant loads and is used in critical areas. They are no longer held together by wood, but by stone, concrete and brick. The principle of operation is the occurrence of additional friction between the fastener body and the base. The techniques are different: in a spacer anchor, a three- or four-leaf sleeve is compressed like a spring, and when driven in, the petals open and create additional supports. Drive-in fasteners have the form of 2 bushings: the first with slots expands with the second and is firmly fixed in the material.

Shoe Double Hat

Anchor

There are other types of nails that are more specialized. For example, wooden fasteners - dowels - are used when installing furniture, stairs, steps, and floors. Bracket style mesh models are used to install meshes. Dowel-nails with plastic and metal sleeves are used when fixing to porous substrates.

Production technology

By the end of the 19th century, forged nails were the subject of an extensive cottage industry. Production, as a rule, consisted of the following: a worker took an iron rod, heated it in a forge, and with hammer blows pulled it back on an anvil, sharpening it at the end and leaving a thickening in place of the future head. Then the rod at the head was cut off and inserted into a block with a hole (nail), after which the nail head was flattened with a hammer. Master nailers achieved considerable speed in making nails, managing to forge two nails while the rod was cooling, and a certain James Leiston in Birmingham forged 17 thousand nails in two weeks.

In other cases, the nails were cut from an iron strip (crutches). The technology involved cutting such a strip first into transverse strips with a width equal to the expected length of the crutch, and then lengthwise into separate pieces (diagonally so that one end was pointed) to obtain longitudinal fibers in the crutches themselves. Then the blunt side was bent in the nail maker to form a head. Crutches, with their narrow heads, are used in carpentry.[3]

The same operations subsequently began to be performed by machines. Nails were forged from hot iron and from cold iron. Cast nails were made from cast iron and annealed.

Modern nailing production typically uses rotary presses; Most stages of the manufacturing process, right down to deburring and anti-corrosion coating, are automated. In the 1980s, the length of factory-made nails varied from 6 to 250 millimeters, and the thickness from 0.8 to 8 millimeters[2].

How to choose the nail size

The size of the fastener must be appropriate for the work to be done. The body length, shape and size of the cap are important.

- Having decided on the type of product, select the required length. This is the main distinguishing feature. The length is indicated in millimeters. On average, the longer the rod, the more secure the mount.

- The optimal length is 3 or 4 times longer than the thickness of the material being nailed. When choosing slate products, the length is selected taking into account the height of the ridge.

- The thickness of the nail should be no more than ¼ of the thickness of the part being nailed and no more than 1/10 of the width.

Example: to nail a board 25 mm thick and 150 mm wide, you need a nail 75–100 mm in diameter and no more than 7.5 mm in diameter. If you need to nail a 50*50 mm block, take a nail 150 mm long and 5 mm in diameter.

For the same dimensions, screw and threaded products can withstand higher loads.

Take into account the shape of the cap. Flat and wide helps to hold soft materials like wallpaper or fabric upholstery. Small heads are only suitable when fastening dense, hard wood that is not in danger of cracking.

Nails for nailers

With the advent of nail guns (nailers), a new format of nails appeared - in a cassette. Several dozen construction nails were assembled together on paper or plastic tape using a machine. For ease of operation, such cassettes are made at an angle of 21 or 34°. This has resulted in some nail cassettes having a cut-off (D-shaped) head.

Nails with a small cross-section for finishing work are glued into cassettes on special machines using glue or tape. In this production, the wire for nails is first collected into a cassette and then cut into plates of the required length.

Advantages of nails for different types of work

Visually, everyone can choose the nail option for their own needs. This is due to several useful qualities of the fastening material:

- versatility (suitable for fastening all components without exception, the main thing is that the nails are chosen correctly);

- a wide range of fasteners, from which you can choose not only the length and thickness of the material, but also its most suitable appearance;

- ease of use, because driving nails into any type of base does not require special skills;

- ease of installation, which consists in the fact that in addition to a hammer, you can use other available means to create a reliable fastening of two elements to each other;

- the ability to fasten two or more parts, provided that the length of the nail allows this;

- long service life (even if the fastener head rusts, the internal part will continue to perform its function in the same rhythm).

Based on the positive qualities, we can come to the conclusion that in home and any other types of conditions, there is always a use for standard nails.

Construction type medium length steel nails Source sense-life.com

To manufacture standard nails for construction and repair, low-carbon steel is used, namely general-purpose wire that meets the GOST 3282-74 standard. In this case, only wire that has not been previously thermally treated is required.

To produce the declared type of wire, factories try to use special steel grades: ST 1 KP, ST 2 KP, ST 3 PS and ST 3 KP. Next, the whole process is carried out as follows:

- A coil of steel wire of appropriate marking according to GOST is loaded into a special automated machine.

- The next step is that the raw material falls under special elements that ensure perfect straightening of the wire.

- Then the straightened material enters the feeding mechanism, where the process of forming the fastening material actually begins.

- The device sets the operating speed of the device, which actually determines the length of the future fastening material.

- The next step is to move the wire towards the wire cutters. They are configured so as not only to bite off the element, but also to create a certain pointed angle (no more than 40 degrees).

- In this way, it is possible to form a tip, after which the opposite end of the wire is struck with a special mechanism.

- A cap is formed. Next, the striking device is withdrawn, the nail falls into the receiver, and the wire processing process is repeated.

The production of nails occurs quite quickly. How much fastening material will ultimately be released from the machine depends on the length of the wire coiled.

Coils of low-carbon steel wire for making nails Source metallograd-34.ru

Sales of products

Every construction site, production facility and every residential building requires the presence of nails in varying quantities. They are used for a wide variety of activities - from assembling furniture to assembling frames for pouring foundations. At first glance, the need for nails is simply enormous, and the owner of the enterprise will definitely not be left without orders. But, you need to understand that many wholesale buyers prefer to cooperate with large suppliers, and also take into account competitors. The domestic market offers nails not only from local manufacturers, but also from foreign companies. To get a competitive enterprise, you will need to thoroughly promote it with the help of advertising, produce high-quality products and sell them at low prices. Only compliance with the three specified factors guarantees the success of future entrepreneurial activity.

Of course, there is no point in standing on the market and selling nails produced at your own enterprise. Such an implementation is unlikely to recoup investments in production even after many years. Sales must be large-scale. Nails should be supplied to large construction hypermarkets and small stores. It would also be useful to sell it through online stores. You can negotiate the supply of your own products to retail outlets yourself or hire a sales manager. He will be fully engaged in this activity. With a successful combination of circumstances, in a month it will be possible to establish serious sales.

Premises (workshop)

Production will not require large areas. Can accommodate 50 sq. m, some of which will be occupied by warehouses, and some by the workshop itself with equipment.

When choosing a room, consider the following:

- all communications must be connected (electricity 380 V, water supply, lighting, heating, ventilation);

- artificial lighting in the workshop should be bright - regardless of the size of the workshop and the covering of the walls;

- It is better to maintain a warm and dry atmosphere in the warehouse to prevent moisture from affecting the wire and finished products;

- production is noisy, so renting premises in residential blocks is not worth it;

- There must be vehicular access to the premises for the delivery of raw materials and shipment of goods.

The history of the Sadhu board.

40 years ago, the Indian ascetic Amar Bharati raised his hand up in the name of happiness and peace on Earth and has not lowered it until now. He was very worried about the many evils and violence happening on the planet, and had compassion for all living beings. Therefore, I decided to abandon selfishness and devote my life to spiritual service.

This practice of voluntary asceticism is not uncommon in India and has existed for many thousands of years.

The word “sadhu” in India refers to ascetics who have withdrawn from the world and devoted their lives to directed spiritual practice. Often sadhus choose one practice “sadhana” and follow it for the rest of their lives.

For example, someone might choose to stand on one leg for 40 years as a sadhana, while another sadhu might vow not to cut his nails or remain silent for the rest of his life. Thus, sadhus directed all their will towards one specific intention and dedicated it to the happiness of all living beings.

Today we do something similar, but in a much more condensed form, when we stand on a board with nails. Standing on the board for at least 15 minutes requires a strong and pure intention. We can devote this intention to the fulfillment of some of our desires, and then a huge release of energy will direct our mental processes towards its implementation, sweeping away all blocks, doubts and laziness along the way.

We can also dedicate this mini-penance of standing on nails to higher intentions, such as world peace or the happiness of all beings on earth. Then it will be a real spiritual practice.

But even without the spiritual component, standing on nails has a strong healing effect on the entire body. This is why nailing has been gaining popularity in recent years.

GOST 283 75

In this case, the production of wire nails is carried out. To obtain them, special equipment is used, which may differ in terms of power, performance and functions.

Such data can take the following values:

- wire diameter – 1.2 – 9.0 mm.

- Nail length – from 12 to 320 mm.

- The power of the device is 3 - 20 kW.

How to use a dowel to attach thermal insulation can be found in the article.

Table 3 - Nail sizes

| Rod diameter, d, mm | Nail length, L, mm | Head diameter, D, mm, not less | Theoretical weight of 1000 nails, kg |

| 1,8 | 35 | 3,6 | 0,704 |

| 2 | 40 | 4 | 0,989 |

| 2,2 | 45 | 4,4 | 1,311 |

| 2,2 | 50 | 4,4 | 1,49 |

| 2,5 | 50 | 5 | 1,916 |

| 2,5 | 60 | 5 | 2,302 |

| 2,8 | 65 | 5,6 | 3,162 |

| 3,1 | 65 | 6,2 | 3,933 |

| 3,1 | 70 | 6,2 | 4,195 |

| 3,1 | 80 | 6,2 | 4,787 |

| 3,4 | 80 | 6,8 | 5,744 |

| 3,4 | 90 | 6,8 | 6,456 |

| 3,8 | 100 | 7,6 | 8,93 |

| 4,2 | 100 | 7,9 | 10,801 |

| 4,2 | 110 | 7,9 | 11,888 |

| 4,2 | 120 | 7,9 | 12,975 |

| 4,6 | 130 | 8,8 | 16,853 |

| 5,5 | 140 | 10,5 | 26,075 |

| 5,5 | 160 | 10,5 | 29,803 |

| 6 | 180 | 11,5 | 39,837 |

| 7 | 210 | 13,6 | 63,131 |

| 7,6 | 230 | 14,9 | 81,908 |

| 7,6 | 260 | 14,9 | 92,626 |

| 8,8 | 260 | 17,4 | 123,874 |

Nail production process: description

The simplicity of the product manufacturing technology is another advantage of the business:

- The metal wire (in coils) is straightened as it unwinds and enters the nailing machine.

- The machine grabs the wire and cuts it into pieces of the required length.

- The machine processes workpieces with an upsetting slider:

- caps are formed, which are given a corrugation - this reduces the risk of slipping when working with a hammer;

- notches are made on the nail shaft for stronger fastening;

- a tip is created.

- If additional surface treatment is required (galvanizing, bluing, tinning), the workpiece enters a special apparatus.

- The finished product is dumped into a receiving hopper.

Factory registration

A small production of nails can be registered in the form of an individual entrepreneur (individual entrepreneur). This is suitable for small production and sales volumes. Working as an individual does not allow you to cooperate with large consumers and wholesale suppliers.

You can build a large distribution network in the form of a legal entity (LLC). Here it is possible to increase the scale of work and cooperate with construction companies and intermediaries.

When registering an activity, the OKVED code 25.93 “Production of products from wire, chains and springs” is indicated.

A certificate authorizing the industrial production of nails is not required. However, it is better to submit your product for examination to obtain a voluntary GOST certificate. Such a document will provide significant advantages to a businessman when making sales and concluding supply contracts.

Sales and Marketing

The business is considered highly competitive. There are many large, medium and small nail manufacturers in the market. To attract customers, you need to position yourself as a reliable supplier of high-quality goods.

We need advertising in print media (including thematic publications), as well as on the Internet. You need to publish and promote your ads and advertisements online using all possible online resources and tools.

Direct advertising and direct contact with large consumers are important. The best thing is to find a large wholesale buyer. This:

- construction companies;

- metal rolling bases;

- construction stores, including chain stores;

- furniture manufacturers;

- construction and repair teams.

You can establish business contacts by calling potential clients, sending commercial offers by email, and visiting offices.

Staff and packaging

To package the finished product you will need containers. Typically, nails are transported in simple wooden boxes. They are made at home independently or purchased ready-made. The main thing is to comply with the capacity parameters. One box is designed for 50 kilograms.

For the continuous operation of production, hiring of personnel will be required. One person can ensure stable production at the level of one ton per shift. This is taken into account when calculating the cost of production.

Formal side of the matter

The production must be formalized legally. This is the only way it can work within the framework of the country’s legislation. Choose a form of activity for the enterprise and a simplified taxation system of 6%. OKVED code for the enterprise: 25.93. It is extremely difficult to formalize legal proceedings on your own. There are a number of subtleties and nuances, ignorance of which can lead to delays in opening an organization. It is recommended to contact lawyers who will take on the formal side of the matter. The one-time remuneration for such employees will be about 30-50 thousand rubles.

Construction staples

Formally, these are no longer nails, but such fasteners are often indispensable when working with wood. By the way, small staples are often called mesh nails. The staples have a thickness of 6 to 16 mm, but the most popular standard is 8 and 10 mm. The product size designation includes three numbers: diameter, back and leg length.

Main purpose

Fastening logs and beams in wooden house construction. Fastening the floor and ceiling joists. Strengthening the connections of a frame house. Fixing the corner logs of the crown with each other. In general, forged staples are indispensable for the reliable connection of any large-sized lumber, not only logs and beams, but also thick boards.

Popular sizes

: 8x200x70, 8x250x70, 8x270x70, 10x200x70, 10x250x70, 10x270x70 mm.

This material is also available on our website:

https://woodschool.ru/kakie-byvayut-gvozdi.html

Finding premises for organizing activities

To organize activities, you will need a premises with a total area of at least 150-200 sq.m. On its territory there will be equipment for production, a warehouse, offices for an accountant, a technologist, a manager, a canteen and a locker room. It will be difficult to buy it, since an object with such a square footage will cost about 10-15 million rubles. It’s easier to rent production space. An object somewhere on the outskirts of a populated area would be suitable. It is desirable to have an asphalted area and equipped entrances. This will facilitate the delivery of raw materials and loading of finished products to consumers. The cost of renting a premises of 200 sq.m. it will cost about 100,000 thousand rubles per month. In small towns this figure is several times lower.

Organizational structure

| Tariff rate (salary) per month, rub. | Allowances, rub | Monthly wage fund per unit, rub. | Monthly wage fund for all units, rub. | Deductions | Total for social contributions | |||

| Regional coefficient | Northern surcharge | Personal income tax | Contributions for social needs (34%) | Injuries (1.5%) | ||||

| 27000 | 8100 | 8100 | 43200 | 43200 | 5616 | 14688 | 648 | 20952 |

| 15000 | 4500 | 4500 | 24000 | 24000 | 3120 | 8160 | 360 | |

| 12000 | 3600 | 3600 | 19200 | 19200 | 2496 | 6528 | 288 | |

| 6250 | 1875 | 1875 | 10000 | 20000 | 2600 | 6800 | 300 | 9700 |

| 6250 | 1875 | 1875 | 10000 | 20000 | 2600 | 6800 | 300 | |

| 2900 | 870 | 870 | 4640 | 4640 | 603,2 | 1577,6 | 69,6 | 2250,4 |

| 2900 | 870 | 870 | 4640 | 4640 | 603,2 | 1577,6 | 69,6 | |

| 36150 | 10845 | 10845 | 57840 | 67840 | 8819,2 | 23065,6 | 1017,6 | 32902,4 |

( 1 rating, average 5 out of 5 )

Is nail production profitable: financial plan

The amount of initial costs is 1.56 million rubles.

As an example, let's take the production of nails measuring 3.0 x 80 mm. In an 8-hour shift, 216 thousand products (935 kg) can be produced. The workshop will operate in one shift 22 days a month. The production volume for this period is 4.752 million units. (20.6 t).

The average price of 1 kg of material is 75 rubles. So in a month you can earn 1.545 million rubles.

The total monthly costs will be 740 thousand rubles.

Net profit - 805 thousand rubles.

Under ideal conditions, the business can pay for itself in less than 2 months. But given the high competition and other risks, it is almost impossible to sell all the goods produced in a month.

Taking into account that 30% of the entire monthly volume produced will be wasted, we determine that the payback period increases at least three times. And taking into account the seasonality factor - even more. If you actively promote your products, your nail business will pay for itself in about 6-9 months.

Table 2. Economic justification for the business idea.

| Basic indicators | Meaning |

| Initial investment amount | RUB 1.560 million |

| Monthly expenses | 740 thousand rubles. |

| Productivity per month | 4.752 million ed. (20.6 t) |

| Monthly income | RUB 1.545 million |

| Net profit per month | 830 thousand rubles. |

| Payback period | 2 months (6-9 months) |

Equipment

It won’t take a lot of money to purchase equipment. You'll definitely need a nailing machine. The machine is selected depending on the type of product being produced.

If the creation of ordinary construction nails requires simple equipment, then for other types additional machines are needed;

- Wire holder. Reels with raw materials are attached to it.

- Apparatus for processing the appearance of nails. Galvanizing, bluing, varnishing, hardening, tinning and other operations significantly improve the characteristics of products.

- Hydraulic trolleys for transporting raw materials and finished products in the workshop and warehouse.

In this business plan, we will take as an example a 1C 0.9-16 machine with a productivity of 450 pcs./min.

Carpentry and furniture nails

Carpenter's nails, also known as cladding or trim nails, were specifically created for decorative work. They are characterized by a long head of a semicircular (usually) shape and a small diameter.

This shape makes the nails almost invisible after driving - so we can use them to install decorative strips, panels and visible furniture elements.

Materials

The material for making nails is low-carbon steel. It is manufactured in a metal rolling mill. The wire is supplied in the form of spools wound on spools of varying weights. When choosing a volume, it should be taken into account that a larger reel will require an appropriate unwinding apparatus. Wire for making nails, the price of which varies from 20 to 30 thousand rubles. per ton, determined by the quality of the material and diameter.

Galvanized nails can be made from ordinary steel wire. The finished product is coated with a layer of zinc. A more expensive option is to purchase galvanized wire, which eliminates the need to coat the resulting nails.

If the goal is to produce hardened products that are durable, then the raw materials must be made of high-carbon steel that has undergone preliminary heat treatment. The production process itself is not available at home and is expensive, which makes the products more expensive. Hardened nails are a by-product due to their limited scope of application.