Stainless steel structural steel 12Х18Н10Т is an alloy that can be used in a wide variety of conditions and environments. Steel 12Х18Н10Т is not subject to corrosion and behaves well under aggressive conditions in solutions of acetic and phosphoric acids, dilute alkalis, and salts. Steel 12Х18Н10Т retains its characteristics over a wide temperature range. This alloy is completely environmentally friendly, safe for health, and is therefore successfully used in the food industry. Steel 12Х18Н10Т is excellent at welding in various ways and is easy to machine, which allows the use of stainless steel in the manufacture of metal structures of any type. On our website you can place an order, view delivery information, and ask questions.

Interpretation of steel 12Х18Н10Т

Steel grade 12Х18Н10Т indicates the chemical composition of the alloy, where the letters are chemical elements, and the numbers are their percentage content in the composition.

- The number 12 indicates a carbon content of no more than 0.12%. Carbon content affects the structure and determines the strength and hardness of steel. High-carbon steel is the strongest, but suffers from a lack of ductility, toughness and sensitivity to heat treatment.

- X18 is an indicator of chromium content, which contains no more than 18%. Chromium is a common alloying additive that protects steel from corrosion and oxidation, increases strength without losing the ductility of the alloy.

- H10 indicates a nickel content of no more than 10%. Nickel is an alloying additive that promotes the formation of austenite. Together with chromium, nickel significantly increases the thermal hardening and toughness of steel.

- The letter T indicates a titanium content of approximately 1%. Titanium, like the two previous elements, promotes corrosion resistance, strengthens the metal, increases ductility and affects hardenability depending on the proportion of content (it can either increase or decrease).

The composition contains in small quantities the following elements: silicon (Si), manganese (Mn), sulfur (S), phosphorus (P), molybdenum (Mo), vanadium (V), copper (Cu), tungsten (W), aluminum (Al). The basis of the alloy is iron (Fe).

Chemical composition, % (GOST 5632-2014)

| Steel | C | Si | Mn | Cr | Ni | Ti | S | P |

| 12Х18Н10Т | no more than 0.12 | no more than 0.80 | no more than 2.00 | 17,0-19,0 | 9,0-11,0 | 5,0-8,0 | no more than 0.02 | no more than 0.40 |

Scope of application

The use of steel 12x18n10t is very extensive:

Metal can be processed using automatic and manual welding. A high thermal conductivity coefficient determines the use of steel in the manufacture of heat exchange equipment. Sheet metal is also used in the manufacture of collector elements for the transmission and distribution of exhaust gases.

Seamless stainless steel pipes, which are operated under high pressure, have become widespread. In addition, the chemical composition contains titanium, which determines low magnetic qualities. A sufficiently high concentration of carbon determines a high level of strength.

Characteristics

Steel 12Х18Н10Т belongs to high-carbon complex alloyed stainless cryogenic alloys. The main alloying components are chromium and nickel; they prevent rusting, provide the metal with cryogenic properties (resistance to cooling) and high manufacturability. Steel 12Х18Н10Т is used in the temperature range from -196С to +600С. The specific gravity of the 12Х18Н10Т alloy is 7.9 g/cm3. The price of stainless steel sheet 12Х18Н10Т starts from 250 rubles per kilogram. You will find detailed information on our company website.

Differences in hardening between stainless steel and carbon steel

All alloying elements included in the composition of corrosion-resistant steel are conventionally divided into two groups:

- The first is elements that increase the temperature of the polymorphic transformation. These include copper, vanadium, tungsten, molybdenum, titanium, niobium. For stainless steel containing such additives, an increase in the quenching temperature is required.

- The second is elements that lower the critical temperature at which a change in the crystal lattice occurs. These are manganese and nickel. With steels containing manganese, it is not recommended to allow overheating, since this element provokes the growth of austenitic grains.

Attention! Carbide-forming elements - chromium, molybdenum, tungsten, vanadium, titanium - suppress the growth of austenite grains. Therefore, steels containing them are not subject to overheating; they are usually heated to higher temperatures compared to carbon steels.

In relation to unalloyed carbon stainless steels require:

- due to worse thermal conductivity - longer exposure for high-quality heating;

- slower cooling, for which oil baths are usually used.

Physical properties

Density ρ at test temperature, 20 °C 7900 kg/cm3

Thermal conductivity coefficient λ W/(m*K) at test temperature, °C

| Steel | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 12Х18Н10Т | 15 | 16 | 18 | 19 | 21 | 23 | 25 | 27 | 26 |

Electrical resistivity ρ, nOhm*m, at test temperature °C

| Steel | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 12Х18Н10Т | 725 | 792 | 861 | 920 | 976 | 1028 | 1075 | 1115 |

Specific heat capacityc, J/(kg*K), at test temperature, °C

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | 20-900 | 20-1000 |

| 462 | 496 | 517 | 538 | 550 | 563 | 575 | 596 |

Thermal conductivity coefficient λ, W/(m*K), at test temperature, °C

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 15 | 16 | 18 | 19 | 21 | 23 | 25 | 27 | 26 |

Linear expansion coefficient α*106, K-1, at test temperature, °C

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | 20-900 | 20-1000 |

| 16,6 | 17,0 | 17,2 | 17,5 | 17,9 | 18,2 | 18,6 | 18,9 | 19,3 |

Modulus of normal elasticity E, GPa, at test temperature °C

| Steel | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 12Х18Н10Т | 198 | 194 | 189 | 181 | 174 | 166 | 157 | 147 |

Modulus of elasticity in torsional shear G, GPa, at test temperature °C

| Steel | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 12Х18Н10Т | 77 | 74 | 71 | 67 | 63 | 59 | 57 | 54 | 49 |

Advantages and disadvantages

The main advantages of steel 12Х18Н10Т are:

- resistance to rusting when in contact with water;

- maintaining performance characteristics over a wide temperature range;

- resistance to aggressive influences of a large number of acids, alkalis, salts;

- environmental friendliness and health safety;

- high levels of strength, hardness, impact strength, ductility;

- good weldability;

- lack of flake sensitivity.

Steel 12Х18Н10Т is sensitive to corrosion when in contact with substances containing chlorine, as well as sulfuric and hydrochloric acids. This is considered the main disadvantage of the alloy.

Weldability

Steel 12Х18Н10Т has no restrictions on weldability. The following methods are used for welding:

- manual and automatic arc welding;

- electroslag;

- contact

Subsequent heat treatment is not necessary, but is recommended to prevent susceptibility to knife corrosion.

Examples of designating the strength of stainless steel fasteners:

A2-50

– mild steel with a tensile strength of at least 500 N/mm² (500 MPa).

A2-70

– cold-worked steel with a tensile strength of at least 700 N/mm² (700 MPa).

A4-80

– high-strength alloy with a tensile strength of at least 800 N/mm² (800 MPa).

The marking is applied to the head of the bolts (screws) next to the manufacturer's mark, and the studs are marked on the smooth part or at the end if the stud is fully threaded. Sometimes a color coding of the alloy grade is applied to the end of the stud (for A2 - green, for A4 - red). If there is no strength class marking, then the average value of 70 is taken into account.

To compare the mechanical properties of bolts made of stainless and carbon steel, we refer to the table:

Carbon

| Austenitic A2, A4 | |||||||

| Strength class | 5.6 | 6.8 | 8.8 | 10.9 | 50 | 70 | 80 |

| Tensile strength, N/mm² | 500 | 600 | 800 | 1040 | 500 | 700 | 800 |

| Yield strength, N/mm² | 300 | 480 | 640 | 940 | 210 | 450 | 600 |

Read also: Manual argon arc welding with non-consumable electrode GOST

The table shows that at close values of tensile strength, the yield strength of austenitic alloys is lower, so they are more susceptible to plastic deformation. This property allows bolts or studs not to break when the permissible tightening torque is exceeded or when subjected to lateral bending loads. In the worst case, exceeding the force can lead to thread failure. While carbon steels are more brittle and extreme loads can lead to breakage of threaded fasteners.

Type of delivery

The main type of supply of steel grade 12Х18Н10Т is stainless steel sheet. Sheet steel of this class is the most popular on the market, in demand in all industries, and always sells well. Flat metal can be hot-rolled or cold-rolled; some characteristics of the product depend on this, including the quality of the sheet surface. The sheet can be smooth or textured, matte or polished mirror, heat-treated or etched. Rolled sheets are used to produce long products (including shaped ones), which include strip, rod, and wire.

- Steel rod is widely used in everyday life for the manufacture of fences and various decorative elements. In industry, it is used to make fasteners, bolts, springs, studs and many other parts. Steel rods are also used as reinforcement for reinforced concrete structures in construction.

- Steel strip is steel up to 4 mm thick in rolls. It is convenient to transport, it is also widely used in construction, mechanical engineering, and furniture production. It is used to produce parts and structures intended for use in aggressive environments.

- Stainless steel wire is heat-resistant, insensitive to moisture, and is used in welding equipment as electrodes for welding stainless steels. Widely used in the chemical, food, oil refining industries, mechanical engineering, architecture and construction.

Foreign analogues

Among the steels produced in other countries of the world that are similar in chemical composition and characteristics, it should be noted:

It should be noted that in addition to the pan-European standards to which steel 12Х18Н10Т corresponds, each EU state has its own marking for this alloy. So, for example, in Germany it is X12CrNiTi18-9, in the UK it is steel grades 321S31, 321S51 and LW18. A single European standard for stainless metals has not yet been developed.

Cost of rolled steel and forgings from steel 12Х18Н10Т

The price of materials made from stainless steel 12Х18Н10Т is determined by:

In addition, the cost of the order may be influenced by its volume and the method of purchasing materials.

Very often, stainless steel 12Х18Н10Т is sold at dumping prices, which is usually explained by the low quality of the material. For example, sheet steel of this grade is sold at a price of 230-330 rubles/kg, and the maximum price for second-grade metal does not exceed 180 rubles/kg.

Rental release is carried out by weight. In this case, the quality of surface treatment and technical characteristics have a great influence. The average cost of matte sheets with a thickness of 1.0 mm is 260 rubles / kg, and a polished sheet costs two to three times more.

Another factor in determining the price of 12Х18Н10Т depends on the location of the buyer. In the central regions of the country, the cost is lower than in remote regions. This is explained by the small number of competitive offers on the rolled metal market, as well as an increase in transportation costs.

Placing an order, purchasing and delivery in companies

The companies offer all interested organizations, enterprises and individuals to buy stainless rolled steel grade 12Х18Н10Т at the best prices on the rolled metal market. To receive technical advice, clarify prices, characteristics and fill out an application, you need to call the companies. It is also possible to simply leave a request on the website and a specialist will contact you as soon as possible.

Technological properties

Steel 12Х18Н10Т can be heat treated, which improves its performance characteristics. Depending on the purpose of processing, hardening, annealing (stabilizing or stress relief), and step processing can be used. Heat treatment helps reduce the tendency to:

- general corrosion;

- intergranular corrosion;

- knife corrosion;

- tension;

- loss of plasticity.

Steel 12Х18Н10Т is insensitive to flakes. It is recommended to carry out cutting processing after hardening. The temperature of the beginning of forging is 1200C, the end temperature is 850C.

Application area

This material can be used almost everywhere, which indicates its versatility. High performance qualities allow it to be used in industry and production. The most popular use of steel is 12Х18Н10Т:

In the chemical field, metal is used for the manufacture of vessels operated under high pressure conditions, and also used for the production of liquid oxygen. In the food industry, it is intended for several sectors - alcohol, meat, dairy. The scope of use also includes the manufacture of welded devices that will be used with oxidizing agents, solvents, and acids. Pipes are made from stainless steel for pumping aggressive liquids.

Mechanical properties

| GOST | Delivery status | Section, mm | σ0.2, MPa | σb, MPa | δ5, % | ψ% |

| no less | ||||||

| GOST 5949-75 | Bar. Quenching from 1020-1100 °C in air, oil or water | 60 | 196 | 510 | 40 | 55 |

| GOST 18907-73 | Ground rod, processed to a specified strength | 590-830 | 20 | |||

| Cold-worked rod | Up to 5 | 930 | ||||

| GOST 7350-77 (transverse samples) | Hot-rolled and cold-rolled sheets: | |||||

| hardening from 1000-1080 °C in water or air | St.4 | 236 | 530 | 38 | ||

| GOST 5582-75 (transverse samples) | hardening from 1050-1080 °C in water or air | Up to 3.9 | 205 | 530 | 40 | |

| hard-worked | Up to 3.9 | 880-1080 | 10 | |||

| GOST 25054-81 | Forging. Quenching from 1050 to 1100 °C in water or air | Up to 1000 | 196 | 510 | 35 | 40 |

| GOST 18143-72 | Heat treated wire | 1,0-6,0 | 540-880 | 20 | ||

| GOST 9940-81 | Seamless hot-deformed pipe without heat treatment | 3,5-32 | 529 | 40 | ||

Mechanical properties at elevated temperatures

| tsp, °С | σ0.2, MPa | σa, MPa | δ5, % | ψ% | KCU, J/cm2 |

| 20 | 225-315 | 550-650 | 46-74 | 66-80 | 215-372 |

| 500 | 135-205 | 390-440 | 30-42 | 60-70 | 196-353 |

| 550 | 135-205 | 380-450 | 31-41 | 61-68 | 215-353 |

| 600 | 120-205 | 340-410 | 28-38 | 51-74 | 196-358 |

| 650 | 120-195 | 270-390 | 27-37 | 52-73 | 245-353 |

| 700 | 120-195 | 265-360 | 20-38 | 40-70 | 255-353 |

Note: Quenching from 1050 to 100 °C in air.

Mechanical properties during long-term strength testing (GOST 5949-75)

| tsp, °С | Creep limit, MPa, not less | Creep rate, %/h |

| 600 | 74 | 1/100000 |

| 650 | 29-39 |

| tsp, °С | Long-term strength limit, MPa, not less | τ, h |

| 600 | 147 | 10000 |

| 650 | 78-98 |

Impact strength KCU

| Delivery status | KCU, J/cm2, at temperature, °C | ||

| +20 | -40 | -75 | |

| Strip 8×40 mm | 286 | 303 | 319 |

Note: Fatigue limit σ-1= 279 MPa at n = 107.

Sensitivity to aging embrittlement

| Time, h | Temperature, °C | KCU, J/cm2 |

| Ref. comp. | Ref. comp. | 274 |

| 5000 | 600 | 186-206 |

| 5000 | 650 | 176-196 |

Heat resistance

| Wednesday | Temperature, °C | Strength group or score |

| Air | 650 | 2-3 |

| 750 | 4-5 |

Resistance of steel 12Х18Н10Т to sulfide corrosion cracking

| Method of forming blanks | Name of parts |

| Forgings, stampings, rolled products | Body, bonnet, stem, spindle, valve seal parts, bellows end parts |

Relative erosion resistance coefficient of reinforcement parts made of steel 12Х18Н10Т

| Details of the flow part of the fittings | Part material | Erosion resistance coefficient relative to steel 12X18H10T | Maximum pressure drop at which there is no erosive wear, MPa |

| Body, pipes, rod, plunger (gate), seat | 12Х18Н10Т | 1,0 | 4,0 |

NOTE

The coefficient of erosion resistance of a material is the ratio of the rate of erosive wear of the material to the rate of erosive wear of steel 12Х18Н10Т (taken as 1).

Materials are erosion-resistant if the coefficient of relative erosion resistance Kn is at least 0.5 and the hardness of the material is HRC≥28.

Resistance of steel 12Х18Н10Т against crevice erosion

| Resistance group | Point | Erosion resistance against steel 12X18H10T |

| Persistent | 2 | 0,75-1,5 |

Resistance of steel 12Х18Н10Т against impact erosion

| Ball resistance | NV no more | Materials |

| 5 | 150 | Austenitic chromium-nickel stainless steel grade 12Х18Н10Т |

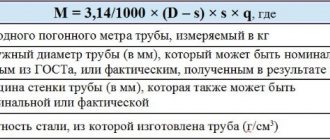

Types of seamless pipes made of steel grade 12Х18Н10Т

The requirements of GOST 9941-81 cover not only 12Х18Н10Т pipes, but also seamless tubular products manufactured by cold and warm deformation methods from other grades of general-purpose stainless steels. According to the provisions of the specified GOST, the range of such pipes consists of products whose outer diameter is in the range of 5–273 mm, and the walls have a thickness from two tenths to twenty-two mm. The requirements of GOST 9941-81 concern not only the geometric parameters of seamless stainless steel pipes, but also the technical characteristics of such products.

The permissible length of stainless pipes transferred to warehouses or consumers, which is also specified by GOST, is determined by their outer diameter and wall thickness.

Length requirements for stainless steel pipes

In the standard version, this parameter can be in the range of 4–7 m, but GOST 9941-81 also allows that seamless stainless steel pipes can be supplied to consumers in the following lengths.

- Pipes, the wall thickness of which does not exceed half a millimeter, have an unmeasured length. In this case, the minimum length of such pipes cannot be less than 0.75 m, and the maximum should not exceed the largest standard value.

- Pipe products with a wall thickness in the range of 0.5–1 mm are made of unmeasured length, the value of which does not exceed 1 meter and the maximum standard value.

- Pipes with a wall thickness of more than 1 mm have an unmeasured length, the length of which is in the range of 1.5–12.5 m.

- They also produce stainless steel pipes of measured length, the minimum value of which does not exceed the lengths of unmeasured products, and the maximum value does not exceed the maximum length specified by GOST. For pipe products whose length corresponds to this category, the maximum maximum deviation of this parameter should not exceed 15 mm. The regulatory document allows that the length of measuring pipes may be greater than the parameters specified by the standard, but for the production of such products a preliminary agreement between the manufacturer and the consumer is necessary.

- There are pipes with a length that is a multiple of the measured length, and the smallest value of such a multiple, in accordance with the provisions of GOST 9941-81, is 300 mm. When producing such pipe products, it is allowed to leave an allowance on each side of the cut, the value of which should not exceed 5 mm. In addition, the standard stipulates the maximum deviation from the full length of such products, which should not exceed +15 mm.

- If the consumer needs stainless pipes whose length exceeds 12.5 m, GOST allows the possibility of their production, but this must also be previously agreed with the manufacturer.

- Tubular products, the outer diameter of which does not exceed 25 mm, by agreement between the customer of such products and its manufacturer, can be produced with a length of up to 16 m.

Stainless steel boiler pipe KVD 57x4, length 6.5 meters

GOST 9941-81 classifies pipes 12Х18Н10Т and products made from other steel grades, not only according to their lengths and other geometric parameters, but also according to their degree of accuracy. Thus, seamless pipes made of stainless steel alloys can meet normal, high and increased precision.

The geometric parameters of seamless pipe products are associated with the maximum deviations of their wall thickness, as well as their outer diameter. GOST 9941-81 also regulates the amount of permissible curvature of rolled pipes of the seamless category, which, if measured on a pipe section 1 meter long, cannot exceed:

- 1 mm – for pipes of any diameter, the wall thickness of which is half a millimeter or more;

- 2 mm - for pipes with a wall thickness of less than half a millimeter and an outer diameter exceeding 15 mm.

Visual inspection of the pipe surface is one of the stages of quality control

For stainless steel seamless pipes with an outer diameter of less than 15 mm, the wall thickness of which does not exceed half a millimeter, such a parameter as the amount of permissible curvature is not specified in the standard. The only requirement is that there should be no sharp kinks on their surface.

The ends of seamless pipes, according to GOST 9941-81, must be cut strictly at an angle of 90°, and after such cutting they must be cleaned of burrs. When cleaning, roughness and chamfer may form on the surface of the pipes, the presence of which is allowed by the standard. The consumer of pipes whose wall thickness exceeds 5 mm, if necessary, can specify that their cut ends must be specially chamfered for welding.

Purpose and application of 12Х18Н10Т

Stainless chrome-nickel steel 12Х18Н10Т is one of the most used stainless steels on the domestic market. It finds application in:

- food industry in the production of alcohol and meat and dairy products;

- chemical industry;

- oil industry and fuel and energy sector;

- mechanical engineering;

- construction (channel, angle, circle, calibrated hexagon, mesh, etc.).

12Х18Н10Т steel is used to produce narrow-purpose parts that operate under high pressure and at extremely low temperatures, for example, in the production of liquid oxygen, vessels made of 12Х18Н10Т steel are used. The ability of 12Х18Н10Т steel to retain its properties under high heat allows its use in welding equipment.

Approximate application as heat-resistant steel

Heat-resistant steel is used at critically high temperatures for a short time and in an unloaded state. It is resistant to corrosion and can be used in gas environments. Steel 12Х18Н10Т as a heat-resistant steel is used in exhaust systems and for the manufacture of pipes.

Approximate application as heat-resistant steel

Heat-resistant steel, unlike heat-resistant steel, can withstand loads at critical temperatures and can work for a long time. Resistant to corrosion and gas environments. Steel 12Х18Н10Т as a heat-resistant steel is used in the manufacture of pipes and pipes, furnace fittings, and manifolds. The maximum temperature for long-term operation is 800C.

Application of steel 12Х18Н10Т for bodies, covers, flanges, membranes and valve assembly made from rolled products, forgings (stampings) (GOST 33260-2015)

| steel grade | ND for supply | Temperature of the working medium (wall), °C | Additional instructions for use |

| 12Х18Н10Т GOST 5632 | Long products GOST 5949. Sheets GOST 7350. Forgings GOST 25054. Pipes GOST 9940, GOST 9941 (made of 12Х18Н10Т) | -270 to 350 | For welded fittings operating in aggressive environments: HNO3, alkalis, ammonium nitrate, food media, special equipment media, ship fittings, cryogenic media, hydrogen sulfide-containing media; for membranes |

| St. 350 to 610 | For welded reinforcement assemblies in the absence of a requirement for resistance to intergranular corrosion |

Application of steel 12Х18Н10Т for fittings fasteners (GOST 33260-2015)

| Steel grade, according to GOST 1759.0 | Material standard or specification | Application options | |||||

| Bolts, studs, screws | Nuts | Flat washers | |||||

| Ambient temperature, °C | Nominal pressure Pn, MPa (kgf/cm2) | Ambient temperature, °C | Nominal pressure Pn, MPa (kgf/cm2) | Ambient temperature, °C | Nominal pressure Pn, MPa (kgf/cm2) | ||

| 12Х18Н10Т | GOST 5632 | -196 to 600 | Not regulated | -196 to 600 | Not regulated | -196 to 600 | Not regulated |

The use of steel 12Х18Н10Т for the manufacture of spindles and rods (GOST 33260-2015)

| steel grade | ND for supply | Working environment temperature, °C | Additional instructions for use |

| 12Х18Н10Т GOST 5632 | Long products GOST 5949 | -270 to 350 | It is used for work in aggressive environments: nitric acid, alkalis, ammonium nitrate, food environments, environments of special equipment, shipbuilding, cryogenic equipment and hydrogen sulfide-containing environments. Used for welded joints |

| Long products GOST 5949 | St. 350 to 610 | Suitable for use in environments that do not cause intergranular corrosion |

Application of steel 12Х18Н10Т for bellows (GOST 33260-2015)

| steel grade | ND for supply | RD for the production of bellows | Working environment temperature, °C | Operating pressure Pp, MPa (kgf/cm2), no more | Additional instructions for use |

| 12Х18Н10Т GOST 5632 | Sheet GOST 5582. Tape GOST 4986, (for steel 1.4541) | GOST 21744, GOST 22388 | -260 to 550 | From 0.6 to 25.0 (from 6 to 250) | For water, steam, inert gases and cryogenic temperatures. For mildly aggressive environments up to a temperature of 350°C. For corrosive environments up to 150°C |

| Pipe GOST 10498 | -260 to 465 | From 0.15 to 3.10 (from 1.5 to 31.0) |

NOTE: The table shows temperature and operating pressure limits. Specific combinations of application parameters (working pressure, axial stroke, temperature and full assigned life) are given in the regulatory documentation for bellows.

Application of steel 12Х18Н10Т for valve valve assembly

| steel grade | Working environment temperature, °C | Hardness | Additional instructions for use |

| 12Х18Н10Т GOST 5632 | -100 to 300 | 155…170 HB | The functionality of the valve assembly is ensured by the presence of surfacing or other wear-resistant coating in the mating part |

Application of steel 12Х18Н10Т for helical coil springs

| steel grade | ND for supply | Application temperature, °C | Additional instructions for use |

| 12Х18Н10Т GOST 5632 | Wire | -253 to 400 | Safety, control valves, low-magnetic springs |

Application of steel 12Х18Н10Т for gaskets

| steel grade | Type of semi-finished product | Application temperature, °C | Additional instructions for use | |

| Name | ND for supply | |||

| 12Х18Н10Т GOST 5632 | Thick heat-treated sheets | GOST 7350 | -253 to 600 | Suitable for use in corrosive environments |

Application of steel 12Х18Н10Т for the manufacture of main parts of nuclear power plant fittings

| steel grade | Type of semi-finished product or product | Maximum permissible temperature of use, °C |

| 12Х18Н10Т GOST 5632, GOST 24030 | Sheets, pipes, forgings, long products. Fasteners | 600 |

Maximum permissible temperature for the use of steel 12Х18Н10Т in environments containing ammonia

| steel grade | Temperature of application of steels, °C at partial pressure of ammonia, MPa (kgf/cm) | ||

| St. 1(10) to 2(20) | St. 2(20) to 5(50) | St. 5(50) to 8(80) | |

| 12Х18Н10Т | 540 | 540 | 540 |

Maximum permissible temperature for the use of steel 12Х18Н10Т in hydrogen-containing environments

| steel grade | Temperature, °C, at partial pressure of hydrogen, PH2, MPa (kgf/cm2) | ||||||

| 1,5(15) | 2,5(25) | 5(50) | 10(100) | 20(200) | 30(300) | 40(400) | |

| 12Х18Н10Т | 510 | 510 | 510 | 510 | 510 | 510 | 510 |

NOTE

The parameters for using steels indicated in the table also apply to welded joints.

The partial pressure of hydrogen is calculated by the formula: P H2= (C*P p)/100, where C is the percentage in the system; P H2 partial pressure of hydrogen; P p operating pressure in the system.

How to harden low-carbon stainless steel with pre-carburization?

Stainless steel grades with low carbon content (0.1-0.3%) are not suitable for hardening. To harden rolled products and products made from such alloys, saturation of the surface layer with carbon (cementation) is often used, followed by hardening and low tempering. The purpose of this treatment is to obtain a hard, wear-resistant surface, which is achieved by enriching the top layer with carbon to a concentration of 0.8-1.2%.

The results that carburization in combination with hardening and tempering can achieve:

- the core of the product, not saturated with carbon, remains viscous even after hardening;

- wear resistance increases;

- endurance limit increases.

Hard carburization of stainless steels is carried out by placing the product in boxes with a carburizer, which uses crushed graphite or other material, followed by hardening and low tempering. Solid carburizer is used at home or in small-scale production. For mass production of metal products, carburization in a gas environment is in demand. Options are liquid and vacuum cementation.