Types of fittings

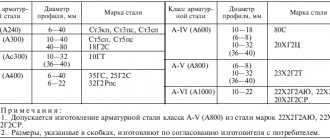

Reinforcement is a rolled metal product. Depending on its purpose, conditions of use and type of steel, it is divided into six classes. One of them is A3 (A400) fittings. There are two types of reinforcement profiles: smooth (constant cross-section) and corrugated (ribbed).

The smooth profile is mainly produced according to individual orders. Corrugated reinforcement A3 has two longitudinal ribs, which are made at equal intervals at the same angle to the longitudinal line of the rod, and two transverse protrusions. Thanks to the periodic profile, better adhesion of the reinforcing bar to the concrete is ensured.

Performance characteristics and application

The main features of this rolled metal product include the following:

- Strength of adhesion to concrete. It is achieved due to the corrugated surface of the rods. It has long been known that corrugated reinforcement holds artificial stone much better and does not peel off from it even under the influence of very high loads. In this it is much superior to products with a smooth profile.

- The reliability of the rods themselves. These products are made from durable steel grades. Accordingly, it does not collapse under loads and lasts for many years.

- Flexibility to create objects of non-standard shapes. In addition, the plasticity of the rods ensures that their integrity is maintained during vibrations. For example, during an earthquake, A3 will not break under the influence of vibration. After the end of the deforming effect, the reinforcement will return to its original form and maintain the integrity of the entire structure.

- Rust resistant. This reinforcement contains manganese. It prevents the development of corrosion and makes it possible to use A3 in difficult climatic conditions.

- Weather resistant. With a sharp change in temperature conditions, the metal frame retains its structure and ensures the integrity of the concrete it holds (artificial stone does not crack or crumble).

- Affordable prices. The low cost of products and their versatility make this type of rolled metal the most popular in many areas of application. It is not even being replaced by modern types of fittings that have more advantageous performance characteristics.

- Ease of processing. A3 products can be welded to produce durable frames of complex shapes. In addition to welding, specialists also practice connecting rods using binding wire.

Production methods

A3 reinforcement is manufactured by hot rolling. If the products are additionally hardened by heat treatment, the result is thermally strengthened reinforcement, designated At. When cold, reinforcing bars can be strengthened by drawing. Such rods are used for the production of prestressed reinforced concrete structures. The letter C is added to the name of the fittings suitable for welding; the letter K is resistant to corrosion cracks.

Scope of use

Due to its resistance to constant and short-term loads, vibrations, rust and temperature changes, this type of fittings is used for:

- Construction of buildings in difficult climatic zones. A3 is suitable for the construction of any civil and industrial facilities.

- Construction of large bridges.

- Placing metal structures in damp soil.

- Construction of road surfaces.

- Construction of tunnels, subways, underground communications and many other works.

We have the best price offers for A3 corrugated fittings . You will understand this yourself when you discuss the cost of purchased products with the employees of our company.

Diameter

A3 reinforcement can have the following rod diameters: from 6 mm to 40 mm. In this case, products from 6 mm to 10 mm are produced in coils, which are then unwound and cut into pieces 6 meters long, or in the form of rods. With a diameter of 12 mm and above, reinforcement is produced only in the form of rods 12 m long. In the construction of buildings and structures, A3 reinforcement 12 mm, 14 mm, 18 mm is most often used. As mentioned above, reinforcement products are produced in coils or in the form of rods.

The marking of various reinforcing bars must include their diameter, reinforcement class and GOST number according to which they are manufactured. For example, 10-A-3 GOST 5781-82 - this is how an A3 reinforcement rod with a diameter of 10 mm is designated.

What to look for when purchasing?

In addition to intermediary markups, the cost of products is also affected by:

- Rolled metal class.

- Brand.

- The diameter of the rods and their length.

- Type of packaging and other characteristics.

Therefore, carefully study the information on the product page and compare it with your tasks. If you don’t know how to choose an A3 for specific purposes, contact one of our employees. He will clarify the nature and scope of the work ahead of you, and then recommend a product with optimal characteristics.

Buy a3 fittings: metallbase.com/production/armatura/klass-a3/#ves

Specialized fittings A3 35GS

One of the varieties of A3 rolled metal is A3 35GS. This is a very durable reinforcement with a round cross-section and a corrugated surface. It is made from low-alloy structural steel to create welded structures. The diameter of this product can be in the range of 6-36 mm, and the length of the rods should not exceed 11.7 m. Sometimes the length indicator is changed upward. But this is done exclusively on an individual basis.

As a rule, this type of rolled metal is used in road construction. This involves laying conventional road surfaces and concrete slabs. This scope of application is associated with the high strength of the products, high-quality adhesion to concrete and resistance to frost. The latter characteristic is due to the presence of manganese in the raw material, which tolerates low temperatures well. A3 35GS products can be installed longitudinally or transversely in concrete. If the rods are laid longitudinally, they take on tensile stress. In the case of transverse laying, the compressed section is tied and coupled. But, regardless of the location of the reinforcement, in both cases the risk of the formation of inclined cracks is reduced.

Despite all its advantages, this product also has a disadvantage. It is associated with the inability to use manual arc welding. If you need to use this method of welding metals, use another type of A3 - 25G2S rods. They also contain manganese, so they are immune to severe frosts.

A3 fittings: weight

In most cases, the amount of material required is calculated in linear meters. But for delivery to the work site, a weight calculation is often required, and you also need to know what volume the A3 reinforcement has. Weight is calculated based on the diameter of the product.

| Diameter, mm | Quantity m in 1t | Area, sq. cm | Weight 1 m, t |

| Rod d=6 | 4 504,50 | 0,283 | 0,000222 |

| Rod d=8 | 2 531,65 | 0,503 | 0,000395 |

| Rod d=10 | 1 620,75 | 0,785 | 0,000617 |

| Rod d=12 | 1 126,13 | 1,131 | 0,000888 |

| Rod d=14 | 826,45 | 1,540 | 0,001210 |

| Rod d=16 | 632,91 | 2,010 | 0,001580 |

| Rod d=18 | 500,00 | 2,540 | 0,002000 |

| Rod d=20 | 404,86 | 3,140 | 0,002470 |

| Rod d=22 | 335,57 | 3,800 | 0,002980 |

| Rod d=25 | 259,74 | 4,910 | 0,003850 |

| Rod d=28 | 207,04 | 6,160 | 0,004830 |

| Rod d=32 | 158,48 | 8,040 | 0,006310 |

| Rod d=36 | 125,16 | 10,180 | 0,007990 |

| Rod d=40 | 101,32 | 12,570 | 0,009870 |

Comparison of composite and metal reinforcement

It is advisable to use composite reinforcement in private housing construction only in individual cases or as an auxiliary frame, fiber, and so on. It cannot completely replace metal rods. Considering its features, it is better to use this material in the construction of non-residential buildings. For example, various auxiliary buildings on the site, strengthening the shore of a reservoir. Anyone who wants to become more familiar with the specifics of using fiberglass reinforcement can find additional information in SNiP dated 2003 No. 52-01. Although there are basically general rules.

Read more about the advantages and disadvantages of composite reinforcement in the article: Metal or fiberglass reinforcement

Technical requirements

For the production of class A3 fittings, carbon or low-alloy steel grades 35GS or 25G2S are used. In terms of chemical composition, carbon steel must comply with GOST 380. When producing low-alloy steel, the presence of carbon is necessary: 35GS - from 0.3% to 0.37%, 25G2S - from 0.2% to 0.29% and manganese: 35GS - from 0 .8% to 1.2%, 25G2S – from 1.2% to 1.6%. In addition, the composition of the 35GS brand also includes sulfur - 0.045% and phosphorus - 0.04%. In addition, the addition of titanium during manufacturing is allowed: from 0.01% to 0.06%.

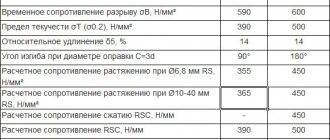

Mechanical characteristics of class A3 fittings:

- The yield strength is not less than 40 kgf/sq.m. mm.

- Temporary tensile strength is not less than 60 kgf/sq.m. mm.

- Relative elongation – 14%.

On the entire surface of the reinforcing bar, including protrusions and ribs, cracks, ruptures, rolling sunsets and caps are not allowed.

The main differences between A3 and A500C

Among the classes of reinforcement, the type of rolled metal closest to A3 is A500C. These are thermally strengthened products, the production of which is carried out using the hot-rolled or cold-formed method. When producing these rods, microalloying is also used. Reinforcement of this class is made of ST3PS - structural carbon steel.

Due to thermal hardening, this product contains a minimum of alloying elements (when compared with their amount in the A3 composition). A small amount of alloying components makes it possible to produce a high-quality frame for objects using manual arc welding (after welding, there are no defects or vulnerable spots that are susceptible to loads).

The A500C reinforcement, created using the corrugated method, has transverse protrusions in the shape of sickles and two longitudinal ribs. The transverse and longitudinal protrusions do not intersect with each other. This property increases the strength of the reinforcement, because under heavy load, stress will not concentrate at the intersection of crescent-shaped protrusions and longitudinal ribs.

According to approved state standards, the carbon content in raw materials should not exceed 0.5%. In the case of class A500C, the reinforcement is manufactured from steel containing no more than 0.22% carbon. In addition, the production of this class requires much less raw materials than A3 reinforcement (in the manufacture of rods, steel is consumed approximately 20% more economically). This allows you to reduce the weight of the frame and significantly reduce the cost of its production.

The A500C production technology guarantees greater durability of structures and facilitates working with them due to easy weldability (such advantages are achieved due to the low carbon content in raw materials and heat treatment of the finished product). Such favorable characteristics make A500C fittings in demand in many fields of activity.

Having examined the main characteristics of the A500C, one should summarize all the differences between this product and the A3 and make sure that the class identity is erroneous. So, the most important differences between these classes:

- Weldability index. Rolled metal of type A3 was developed in the 50s of the 20th century. Then carbon steel was proposed for its manufacture. The percentage composition of carbon in this raw material reached 0.37%. Such a high carbon content did not allow welding work to be carried out easily, namely, the use of manual arc welding. When using this method, the rods were welded together, but the structure itself turned out to be very unstable to loads. Accordingly, it could collapse at any moment. This is a serious threat when it comes to tunnels, bridges, subways or multi-story buildings. Therefore, reinforcement with A3 should be accompanied by careful control of the work performed. If you replace A3 with A500C metal, it will be possible to carry out manual arc welding due to the low carbon content in the reinforcement.

- Yield limit. For class A3 products it is 400 N/sq. mm, and for A500C products this figure reaches 500 N/sq. mm. A higher yield strength coefficient can reduce production costs and significantly reduce the weight of the finished structure.

- Differences in the corrugated surface of products. The A500C reinforcement has crescent-shaped protrusions on the surface of the rods, while the A3 has transverse protrusions in the shape of rings. Rods of both classes are equipped with two longitudinal ribs located opposite each other. But for A3 rolled metal, the rings are in contact with the longitudinal protrusions, and for A500C products, the crescent-shaped notch does not intersect the side ribs. Consequently, A500C can rightfully be considered a more durable product that can easily withstand heavy loads. After all, the intersection of longitudinal and transverse protrusions entails an increase in stress concentration at the points of contact of the notch, instead of distributing it over the entire surface of the reinforcement.

- Protrusion pitch indicator. If we compare both classes, then the A500C has a much smaller distance between the transverse protrusions than the A3 with the same diameter. This feature of rolled metal indicates a good level of adhesion of its surface to concrete. After all, the more notches on the rod, the better it is fixed in the artificial stone, gives the structure strength and protects the monolith from cracking under the influence of thermal, mechanical or vibration loads.

Application area

The fittings are used for civil construction of buildings and structures, industrial construction. A3 reinforcement is the most common and popular class, especially for use in massive and heavy structures. Scope of use:

- Construction of metal structures.

- For reinforcing concrete products.

- Strengthening floors and walls of buildings and structures.

- Reinforcement of reinforced concrete products.

Such products are used for reinforcing concrete in order to give it additional rigidity, as well as for the production of various welded metal structures: grilles for windows and doors, metal fences, reinforcing mesh. The use of reinforcing bars extends the operational life of buildings. The strength and durability of the structures being built depends on the quality of the reinforcement used. A3 has good technical indicators, such as strength, elasticity of steel, and its weldability. A3 reinforcement is also used for monolithic concreting.

Rods of size d=10 mm are used as the main reinforcement when used in low-rise construction, and as clamps for beams and crossbars in high-rise construction. A3 with a diameter of 12 mm is used in main load-bearing structures, foundations and monolithic walls. Due to its larger diameter, it has a smaller laying step - 20 cm. For the foundation, rods of at least 10 mm in size are used. The larger the diameter of the reinforcing bars, the stronger the foundation frame.

Purpose of reinforcing steel class A3

A3 is used for reinforcing conventional and prestressed structures as working reinforcement (installed according to design calculations of structures for loads and impacts) and as mounting reinforcement (in case of installation due to structural and technological necessity).

Class A3 reinforcement is used in the production of reinforced concrete products, in the construction of foundations, for reinforcing plaster layers, concrete screeds, strengthening walls made of sand-lime brick, aerated concrete structures, etc.

A3 fittings: GOST standards

A3 reinforcement is produced in accordance with GOST 5781-82 “Hot-rolled steel for reinforcement of reinforced concrete structures”. Since the quality of the resulting product depends on the source raw material, and the strength and reliability characteristics of future buildings and structures depend on it, GOST imposes strict requirements on steel, which is used for the manufacture of reinforcement products. At3 reinforcement is produced in accordance with GOST 10884-94 “Thermomechanically strengthened reinforcing steel for reinforced concrete structures.” It replaced the previously valid GOST 10884-81 “Reinforcement rod steel thermomechanically and thermally strengthened with periodic profile.”

Material advantages

The high prevalence of A3 fittings is primarily due to its excellent performance properties, among which the following are especially worth noting:

- Long term of use without loss of its qualities;

- Immunity to biological and chemical influences;

- High strength values, both tensile and compressive, as well as external mechanical load;

- Excellent anti-corrosion properties;

- Excellent weldability;

- High-quality adhesion to the concrete mass, as well as low expansion of the material in this environment;

- Safety.

How does A3 differ from A400

Quite often, people who need A3 fittings for a small construction project also come across the A400 marking. This is very confusing - despite exactly the same characteristics, appearance, composition and cost, the rods have different markings. In fact, there is no reason to worry - these are the same building material. It’s just that the A3 marking is classic, and the A400 began to be used relatively recently. So, when you come to the store to choose products, you can pick up products with any marking - you definitely won’t have to regret the bad choice later.

In addition, problems may arise when identifying S400 fittings - this is the same class of fittings, but only according to a different classification. Therefore, the scope of application is no different, as are other important technical characteristics.

A500S and B500S fittings according to GOST R 52544-2006

And the last regulatory document that we will focus on is GOST R 52544-2006. It is valid only on the territory of the Russian Federation. Determines production standards for rolled products of classes A500C and B500C. Why is this regulatory act important to us? It's simple. It states that reinforcing steel can be produced not only using hot rolling. Please note that index B has appeared. This means that B500C is cold-deformed and mechanically strengthened reinforcing metal. The index C means that it is welded. We hope you understand that 500 is the yield strength in N/mm². Moreover, despite the index A, A500C reinforcement can also be thermomechanically strengthened.

The main direction of use is usual - reinforcement of reinforced concrete structures. This type of metal products is produced in coils and rods (rods). Nominal diameter from 4.00 to 40.00 mm (A500C from 6.00 to 40.00 mm, B500C from 4.00 to 12.00 mm). Products with a diameter of up to 6.00 mm are produced in coils, and in coils and rods from 6.00 to 12.00 mm. Above 14.00 mm all rolled products are in rods. Their length is from 6.00 to 12.00 meters, regardless of manufacturing technology. Please note that the profile shape of both cold-deformed and hot-rolled steel is different.

This is where we will end our review. We hope that it has now become clear for this type of product such as A3 reinforcement, which type of long products it is. Read our blog. Now we have considered the question: “What is A3 fittings?” In subsequent materials we will talk about areas of application, features of choice, advantages and disadvantages.

Do you need A3 fittings? You can always buy it from our company, on favorable terms, with full documentary support. We'll help you make the right choice. Contact us!

What is rolled reinforcing metal A1?

According to GOST 5781, A1 reinforcement is designated differently - reinforcement (reinforcing steel - hereinafter AC) AI (A240). This is a more correct name for this rolled metal and is used by all its manufacturers and professional consumers. In the technical language of GOST 5781, which classifies all types of reinforcing steel produced according to it for the reinforcement of conventional as well as prestressed various reinforced concrete structures, this designation stands for “class A1 reinforcement.”

The division into classes in this GOST is made according to one of the mechanical characteristics of the speakers - the yield strength. Its conditional value for product A1 is indicated in parentheses after the index A - the number 240. This is the value of the yield strength in kgf/mm2, but multiplied by 10. Thus, reinforcement A1 has a yield strength of 24 kgf/mm2 (corresponds to 235 N/mm2 ).

According to GOST 5781, AI speakers are manufactured only with a smooth profile - without corrugation of the surface of a regular round cross-section. Externally, depending on the nominal thickness, it looks like steel wire or rod.

Fittings without corrugation

AC A240 is produced hot-rolled and only from carbon steel. In this case, according to standard 5781, only brands St3sp, St3kp and St3ps are used. It is precisely because of this that A1 reinforcement, in contrast to smooth AC of other classes of GOST 5781 and produced in accordance with GOST 10884, is most in demand and is used both for reinforcement and as ordinary rolled metal - for the manufacture of various steel parts and structures. After all, St3 is the most flexible, ductile of all carbon and, especially, low-alloy grades and is better weldable than all alloys. Its chemical composition for finished AI fittings must meet the requirements listed in GOST 380.

The range of production of smooth AI speakers includes 14 standard sizes in diameter in the range of 6–40 mm. Products with a thickness of 6–12 mm are produced in rods or in the form of coils, and larger diameter A1 reinforcement is supplied only in rods. AS A240 rods are manufactured in lengths of 6–12 m. They are available in measured or unmeasured lengths. Together with the measured ones, unmeasured rods with a length of at least 2 m and in an amount equal to a maximum of 15% of the mass of the released batch can be supplied. The consumer can order the option he needs, and by agreement with the manufacturer, it is also possible to produce rods of 5–25 m.

Production of A1 fittings

There are 3 types of A1 rods, differing in production technology:

- hot rolled reinforcement;

- marked T - strengthened during heat treatment, hardening;

- marked B - cold-rolled, strengthened by drawing.

The material is produced in rolling mills using the method of deforming steel blocks. Source material - standard structural steel St3kp, St3ps or St3sp:

- low-carbon - for non-stressed reinforcement;

- high-carbon - for intense.

The characteristics of rods (strength, geometry, ratio of weight and cross-sectional diameter) are regulated by GOST 5781-82, GOST 2590-2006, DSTU 3760-98, as well as other current regulatory documents. The permissible deviation of the actual parameters of the finished product is 3...9%.

Standard sizes of fittings A1

Products are classified according to two basic indicators:

- Length - 6-12 m for measured products or arbitrary for non-measured fittings. The length of the measuring rod is determined by the diameter (the reference parameter is 10 mm).

- Cross-sectional diameter - 6-40 mm. The production step is 2-3 mm.

Class A1 materials are supplied in the form of rods or coils (coils) weighing from 1.5 tons. Wire with a diameter of up to 10 mm is rolled into coils.

Features and Benefits

A1 reinforcement forms contact with concrete in a number of ways:

- during adhesion (for example, when concreting a steel element into a block);

- during compression (for example, with reinforced concrete after concrete shrinkage);

- in shear bond zones;

- during friction;

- electrochemically - when the cement solution interacts with the surface of the steel.

At the low price of A1 reinforcement per meter and ton, the material has a considerable number of advantageous characteristics:

- flexibility, elasticity;

- hardness, strength;

- ease of welding;

- resistance to corrosion, exposure to chemically aggressive environments (chlorine, natural gas);

- durability.

The second marking of reinforcement A1 - A240 - indicates the fluidity index, or the stress value, above which metal deformation begins.

Areas of application

- Construction: Reinforcement of beams, columns, floors, foundations, framing frames.

- Formation of cast and metal structures, reinforced concrete blocks.

- Strengthening the strength of monolithic structures - tunnels, bridges.