How to tin aluminum

The procedure for soldering aluminum elements at home is a very problematic process, which is facilitated by the use of special materials.

The work is complicated by the immediate appearance of a thin oxide film at the stripping site, which interferes with soldering. An additional difficulty is created by the material itself, which has a low melting point (+660 °C).

Using solder for soldering aluminum, special strong fluxes and following technology, you can independently solder almost any aluminum object.

Features and principles of soldering

The low temperature value of metal melting complicates the technological process of soldering, as well as repairing products with your own hands.

Parts very quickly lose strength when heated, and structures reduce stability when the temperature reaches 300 degrees.

Low-melting solders consisting of bismuth, cadmium, indium, and tin come into difficult contact with aluminum and do not provide sufficient strength. Excellent solubility is observed in the metal in combination with zinc, which makes the soldered areas highly reliable.

Before soldering begins, aluminum elements are well cleaned of oxides and dirt. To do this, you can use mechanical force with brushes or use special fluxes made from a potent composition. Before the procedure itself, be sure to tin the areas to be treated.

The tin coating will protect the part from the formation of oxides. In order to reliably solder aluminum products, it is necessary to choose the right heating tool, taking into account the volume of metal being processed.

In addition, the reliability of the connection depends on the alloy chosen, as well as the flux for soldering aluminum.

Soldering methods

Soldering of aluminum products is carried out with an electric soldering iron, a blowtorch or a gas torch. There are three ways to solder various aluminum objects:

- with rosin;

- using solders;

- electrochemical method.

With rosin

This option for soldering aluminum objects, wires, cables is used for small parts.

To do this, the cleaned section of the electrical wire is covered with rosin and placed on a piece of sandpaper with a medium grain size. The wire is pressed from above with the tinned tip of a heated soldering iron.

This action is carried out several times, after which the procedure of soldering the electrical wires itself is performed. You can use a rosin solution in diethyl ether.

In this case, the end of the soldering iron is not removed from the end being tinned, but rosin is added on top. An electric soldering iron with a power of about 50 W is suitable for twisting thin aluminum wires. With an aluminum thickness of about 1 mm, a 100 W soldering iron is required, and parts larger than 2 mm require preheating of the joint.

Using solders

This method is the most common and is used in electrical engineering, in the repair of automobile parts, as well as other products. Before soldering aluminum, the area to be soldered is pre-coated with an alloy and the tin-plated elements are subsequently connected. Pre-tinned parts are connected to each other, as well as to other alloys and metals.

Soldering of elements can be carried out using light alloy solders containing tin, zinc, and cadmium. In addition, refractory materials based on aluminum are actively used.

Why are light alloy compounds used? Because they allow you to solder an aluminum product at temperatures up to 400 degrees. This does not produce qualitative changes in the properties of the metal and maintains its strength.

Compositions with cadmium and tin do not create sufficient contact reliability and are susceptible to corrosive effects. Refractory materials containing zinc, copper, and aluminum-based silicon do not have these disadvantages.

Electrochemical method

This procedure requires a plating facility. With its help, copper plating is carried out on the surface of a product or wire. In its absence, independent processing of the part is used.

To do this, apply a few drops of a saturated solution of copper sulfate to the area cleaned with sandpaper.

After this, the negative pole of an independent power supply is connected to the workpiece.

They can be a battery, an accumulator, or any electrical rectifier.

A cleaned copper wire with a diameter of about 1 mm, located in an insulated stand, is connected to the positive terminal.

During the electrolysis process, copper will gradually deposit on the part, after which the area is tinning and dried using an electric soldering iron. After this, you can easily solder the tinned area.

Solders, materials, fluxes

Soldering of aluminum with tin is carried out subject to the use of highly active fluxes, as well as good cleaning of parts of the parts. Such tin compounds require additional coating with special compounds, since they have low strength and poor protection against corrosion processes.

How to solder aluminum elements? High-quality solder joints are obtained by using solders with silicon, aluminum, zinc, and copper. These materials are produced by both domestic and many foreign manufacturers.

Domestic brands of rods are represented by the most used solders TsOP40, which according to GOST contain 60% tin and 40% zinc, as well as 34A (aluminum - 66%, silicon - 6%, copper - 28%). The zinc used gives high strength to the contact area and provides good corrosion resistance.

Imported low-temperature alloys with excellent characteristics include HTS-2000, which provides maximum ease of use.

These alloys are used to work with large-sized parts (radiators, pipes) with high heat dissipation using a heating pad or objects made of aluminum alloys that have a fairly high melting temperature. Novice repairmen can familiarize themselves with the soldering process by watching an instructional video. This will help to avoid many unpleasant nuances during the work process.

In addition to solders, aluminum soldering requires the use of special fluxes containing ammonium fluoroborate, zinc fluoroborate, as well as triethanolamine and other elements.

The most popular is the domestic F64, which has increased chemical activity. It can be used even without first removing the oxide film from products.

In addition to it, 34A is used, containing lithium, potassium and zinc chlorides, as well as sodium fluoride.

Preparation of products

Reliability, as well as excellent quality of connections, is ensured not only by using the right technology, but also by preparatory work. These include the treatment of sealed surfaces. It is necessary to remove contaminants and thin oxide films.

Mechanical processing is carried out using sandpaper, a metal brush, stainless steel wire mesh or a grinding machine. In addition, various acid solutions are used for cleaning.

Surface degreasing is carried out using solvents, as well as gasoline or acetone. On the cleaned aluminum area, an oxide film appears almost immediately, but its thickness is significantly lower than the original one, which facilitates the soldering process.

Heating tools

How to solder aluminum at home? Electric soldering irons are used to solder small-sized aluminum products at home. They are a universal tool, quite convenient for soldering wires, repairing small tubes and other elements.

They require a minimum of working space, as well as the presence of an electrical network. Repair of large-sized products and welding are performed with a gas torch that uses argon, butane, and propane.

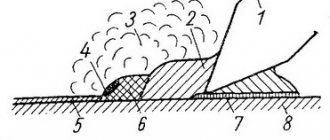

When using gas burners, it is necessary to constantly monitor their flame, which characterizes a balanced supply of oxygen and gases. With the correct gas mixture, the fiery tongue has a bright blue color. A dim hue, as well as a small flame, indicate an excess of oxygen.

Technological process

The technology for soldering aluminum objects is similar to the process of joining parts of other metal materials. The first step is to clean and degrease the areas of future adhesion. Then the connected elements are installed in working position for ease of processing.

Flux is applied to the prepared area, and the initially cold product begins to heat up using an electric soldering iron or a torch. As the temperature rises, the solder bar begins to melt, which must constantly touch the surface of the elements, controlling the heating process.

Soldering aluminum elements at home with an electric soldering iron is done in a well-ventilated room, as hazardous compounds are released during operation.

Using flux-free solder requires compliance with some nuances. To prevent the oxide film from interfering with the alloy getting onto the parts, the end of the rod makes scratching movements along the area where the elements are soldered. This breaks the oxide integrity and the solder comes into contact with the metal being processed.

Destruction of the oxide layer during soldering can be done using another method. To do this, the area to be treated is scratched with a metal brush or a stainless steel rod.

To ensure maximum strength of aluminum parts in the soldered area, the treated areas are pre-tinned. Compliance with the technology of soldering aluminum elements guarantees excellent quality of the connection, as well as its protection against corrosion.

Useful tips

To solder aluminum with tin at home, it is recommended to follow a certain sequence of actions:

- heat the aluminum part, which will destroy the oxide layer;

- shift the focus to the junction of the parts and heat it for a few seconds;

- bring the solder to the center of the flame, hold it near the aluminum part;

- As soon as the solder begins to melt, bring it to the metal so that it fills all the seams and voids.

In this way, you can solder both flat and round parts. To work with aluminum tubes that need to be soldered together, you need to heat their edges and place the solder at the junction of the two parts, where the fire is concentrated. Thanks to the flux, the solder will spread along the joint, gluing it, rather than filling the tube from the inside. If the thickness of the metal is large, tin must be applied in several layers.

For high-quality tin smelting of aluminum, it is extremely important to maintain the desired temperature when using a gas burner.

This is very difficult to achieve, especially for an inexperienced master, so you should be as careful and careful as possible while working. The aluminum soldering process involves working with tools turned on, so it is very important not to violate safety precautions. For a gas burner, it is important to check the hose for cracks and bends, as well as the integrity of the cylinder.

When choosing an option using a flame, you need to know that for smelting you need a fire that does not smoke and burns evenly without interruption. It should be possible to increase or decrease the flame to maintain the optimal temperature.

When using a soldering iron, it is important to place it in a safe place and turn it off after use. When working with fluxes, some of them can release harmful compounds after heating, so you should take care to ventilate the workplace.

How to solder aluminum with tin, see below.

Source

How to solder aluminum with tin?

Soldering aluminum with standard solder using conventional technology is unreliable and impossible. The tin on it rolls into a ball, not wanting to stick, and if it does stick, the result is a weak connection that breaks under the slightest load. To prevent this from happening, you need to solder in a special way, and then even ordinary solder will hold tight.

Browse products for inventors. Link to the store.

- solder 60/40;

- mineral oil or petroleum jelly;

- alcohol.

How to solder aluminum correctly

An oxide film instantly forms on the surface of the aluminum, which prevents adhesion between the base and the solder. To prevent it from interfering, you need to create an airless environment at the soldering site. To do this, apply a thin layer of Vaseline to the area of aluminum that has been cleaned of dirt. You can use mineral or other automotive oil instead.

DIY electronics in a Chinese store.

If Vaseline was used, then you need to apply a soldering iron tip to it so that it melts into liquid oil. After this, take a mounting knife or other sharp object and use it to scratch the aluminum under the Vaseline.

It is important that the scratches are made on a surface that is sealed from air. As soon as the Vaseline begins to thicken, it should be melted again with a soldering iron tip.

You need to actively rub with a knife blade to remove the oxide film on the metal, and in addition to create a relief to which the solder will then stick well.

After removing the oxide film, the oil is not erased. A soldering iron tip is applied to the soldering site, and the aluminum is heated to operating temperature. Then the required amount of solder is deposited. It will sit right in the oil.

A drop of solder is lightly rubbed over the prepared surface. You need to press it into the resulting scratches. The solder will push the oil to the sides so it won't interfere with adhesion. The absence of an oxide film will allow the tin to stick to the aluminum, rather than forming into a ball that easily falls off.

Then, tinned wires, wire, or whatever is needed can be applied to the surface prepared with oil and friction. They will be soldered in a second, without taking all the tin from the aluminum, as usually happens. After soldering, the remaining oil is removed with a cotton swab soaked in alcohol.

This method allows you to achieve the same soldering reliability as when connecting two copper elements. Moreover, unlike another common method with oil, when the oxide film is removed by five minutes of friction with a hot soldering iron tip, tearing it off with a knife is faster.

How to solder aluminum correctly

Sometimes a situation arises when it is not possible to replace old aluminum wiring and you simply need to make a high-quality connection between aluminum and copper. For this, of course, you can use specialized connectors, crimps or terminal blocks, but I want to tell you how you can reliably and efficiently solder copper and aluminum.

What is the difficulty of soldering?

As you know, aluminum is a very active metal and when interacting with atmospheric air, it is almost instantly covered with an oxide film, which rejects the solder and does not allow aluminum to be simply tinned.

In order for the solder to “stick” well to the metal, you need to remove the existing film and prevent it from forming again until you apply the solder.

Special fluxes were invented specifically for these purposes: they actively use soldering acid, and use a mixture of rosin and acetone.

Preparing inventory

In order to successfully complete this work you will need: a soldering iron with a power of at least 60 W, a knife, pliers, sandpaper or a file, POS 61 or POS 50 solder, F-64 flux or its equivalent, a brush, a sponge and rags.

We solder aluminum with tin and F-64 flux

Important. Soldering of conductive elements using F-64 and any of its analogues is prohibited according to the rules of the PUE. Since the use of acid causes not only the destruction of the oxide film, but also actively destroys the metal itself, and after tinning, this acid cannot be removed and it continues destructive processes under the solder.

In this way you can, for example, solder an aluminum decorative part.

The algorithm for working with F-64 flux itself is very simple. First, we strip the insulation on the aluminum core, then use sandpaper or a knife to process the core itself in order to remove a thick layer of film.

Then we apply flux to the stripped core with a brush and clean it again under flux. Thus, the flux prevents the formation of a new film.

Then, using a well-heated soldering iron, we begin to apply tin to the prepared core. At the same time, you use a soldering iron to rub in solder.

Once you have tinned one track, apply flux again and repeat the procedure. This way you can completely cover the core with solder and then solder it to the place or part you need.

After you have completely processed the veins, you must rinse it in a soda solution (five tablespoons of soda per 200 grams of water). This is necessary to wash away the remaining active substances, which are part of F-64.

Soldering aluminum to copper using tin and rosin

In order to solder the conductive cores of copper and aluminum wires, you cannot use acid fluxes, but you need to use liquid rosin, which will also ensure a reliable connection.

This rosin can be purchased ready-made, or you can prepare it yourself; for this you will need lump rosin (it is crushed into powder) and pure alcohol.

Then we mix these two components in the following proportion: 60% rosin and 40% alcohol. Then put the bottle in warm water, wait until it warms up and mix thoroughly until the rosin is completely dissolved.

That's it, the solution is ready and you can use it.

Also, in addition to all the above equipment, we still need to prepare a small container into which we will immerse the stripped end of the wire.

We also remove the insulation and clean the core from a thick layer of foam, then immerse our bare end of the wire so that it is completely in liquid rosin and use a knife to process the core again.

Next, we take a preheated soldering iron and begin to process the core at the very surface of the rosin, rotating it and removing it as the wire is tinned.

The trick is to tin the aluminum right at the border between the rosin and the air so that the air does not oxidize it.

Make sure that the soldering iron does not lose temperature and, if necessary, remove it from the bath so that it warms up well.

Important. This work produces a lot of smoke, so it is better to do it outdoors or in a room with excellent forced ventilation.

After you have tinned the aluminum, the residual trace of rosin can be easily removed with a rag soaked in alcohol. You can then twist the tinned aluminum and copper wires into a classic twist and immediately solder it.

Tin will serve as an excellent neutralizer of the galvanic interaction of copper and tin and guarantees that such a connection will last a very long time and trouble-free.

Perhaps the only and significant drawback of such a connection of copper and aluminum is the fact that soldering in a distribution box located under the ceiling and in the absence of the proper supply is almost impossible.

In this case, it is better to use other methods of connecting the wires in the junction box.

That's all I wanted to tell you about soldering aluminum using special solders and regular tin with rosin. I hope you find this article useful and interesting. Thank you for your attention.

Source

Application of technology

When tinning, tin or alloys based on it are used.

Tin coating is used for:

- application to brass parts that are subject to soldering;

- protection of surfaces of steel products during nitriding;

- separating metal products by applying a layer of tin when mating copper surfaces with steel or aluminum in order to equalize the electrode potentials;

- To protect against the effects of sulfur contained in the rubber insulating layer, it is necessary to tin the cable;

- applying a corrosion-resistant coating to tin, which is used for the manufacture of canning containers;

- protection of various metal products from rust.

Tin-lead coating (PLC) is used in the following cases:

- preparing radio components for soldering and protecting them from corrosion;

- Tinning wires to improve solderability.

The recommended thickness of the poluda layer is given in the table.

| Purpose | Thickness, microns |

| Protection of steel parts: | |

| from corrosion | 21-24 |

| during nitriding | 9-12 |

| when gumming | 12-15 |

| Improved solderability: | |

| spring parts | 3-9 |

| steel parts | 6-15 |

| parts made of copper and copper alloys | 3-9 |

| parts made of aluminum and its alloys | 6-15 |

How to tin aluminum?

The highest quality aluminum welding is argon arc welding. However, this method requires both expensive equipment and highly qualified welders, which often does not always correspond to reality.

In addition, the equipment for this welding method is quite cumbersome and in some places its use is generally prohibited. In this article we will talk about alternative and inexpensive methods for welding aluminum without the use of argon.

Method 1: using Zeller 480 aluminum electrode

The Zeller 480 repair electrode with 12% silicon content is designed for welding a wide range of aluminum alloys including silumin and duralumin. This method allows you to reliably weld aluminum without the use of expensive argon arc equipment.

Benefits and Applications

- If the welding process is followed, the quality of the weld made using the Zeller 480 electrode is not inferior to argon arc welding;

- High surfacing productivity;

- Dense deposited metal without pores;

- Thanks to the soft, uniform arc, the seam is even and smooth;

- Zeller 480 is the only aluminum electrode available in a “low temperature” 2mm size;

- The electrode is equipped with a special protective coating, which is highly moisture resistant, which significantly extends the service life of the electrode;

- Welding is carried out without flux, since all the necessary elements for removing the oxide film are contained in the protective coating of the electrode;

- Used for welding aluminum sheets, profiles, busbars, tanks, aluminum castings, eliminating casting defects, crankcases, car bodies, etc.

Important! Since the coating of aluminum electrodes contains hygroscopic salts, after completing all welding work, the packaging should be hermetically sealed and stored in a dry, warm place.

Instructions for use

Step 1. Before starting welding, make sure that the prepared metal sample is dry, since aluminum is hygroscopic (absorbs moisture). Using a stainless brush, clean the joints to a metallic shine and remove any remaining dirt in the area around the seam.

Step 2. If necessary, dry the electrodes for 1-1.5 hours at 100°C.

Step 3. Heat the aluminum sample to a temperature of 150-200°C using a burner.

Important! Welding cannot be carried out without heating!

Step 4. Welding is carried out using direct current of reverse polarity. The most vertical position of the electrode while maintaining a short arc. The electrode should be fed into the fusion zone quickly, moving forward as much as possible and maintaining a very short arc.

Step 5: Weld one layer in one pass.

Be careful! The welding speed is the same as that of semi-automatic welding.

The tensile strength of the weld is 200 newtons per square millimeter, which is close to the tensile strength of the base metal. Therefore, this welding method can be used on critical structures.

Method 2: Using HTS-2000 or Castolin 192 solder

HTS-2000 or Castolin 192 solder is an alloy in the form of a zinc tube filled with solid flux powder in the center, which makes welding quick and easy.

The solder is made using high technology and is specially designed to carry out work on the restoration of parts made of aluminum.

At the same time, welding does not involve the use of high-cost technologies.

All you need to repair aluminum parts is just the solder itself and a gas torch for welding.

General recommendations for achieving the best results when working with solder

- Clean the work surface immediately before applying solder.

- You should not melt the solder in a torch flame, as this will prevent it from bonding to the metal.

The solder must melt on its own on the surface of the part! - In the liquid state, solder is quite fluid, so it is worth tinning the surface well to eliminate the presence of cracks, especially at the soldering site.

- Also make sure that the forming elements fit tightly together.

- When applying solder, wait until it absorbs.

Otherwise, sufficient adhesion of the metals will not occur, and, as a result, the required strength of the product will not be achieved.

How to solder aluminum with a soldering iron at home?

Aluminum is a metal that is difficult to solder. This is due to its tendency to form a strong oxide film on the surface of products, which prevents the part from being wetted by molten solder.

Mechanical cleaning of the surface alone does not help, since new oxide is formed instantly after removing the old one. For this reason, special fluxes are used for soldering aluminum and special technology is followed.

Connecting wires

Typically, aluminum soldering is used in cases where the parts to be joined are small enough and the use of argon welding is impossible or absent. One example of the use of soldering is connecting electrical wires made of different materials.

Often in practice it is necessary to connect copper and aluminum wires. Such connections cannot be made by twisting, since this pair of metals forms a source of electrochemical corrosion . In this case, soldering aluminum to copper can be an excellent connection option.

This operation can be performed with ordinary soft lead-tin solder, but you should use a special flux for soldering aluminum. The procedure must be performed in the following sequence:

- first you need to strip the copper wire and tin it using rosin;

- to tinning an aluminum wire, after mechanical stripping of the oxide film, it should be coated with a layer of flux for soldering aluminum;

- for better mechanical strength of the connection, tinned wires can be twisted;

- By heating the joint with a soldering iron and adding flux, the solder melts and a solder is formed.

The connection obtained in this way can be safely embedded in the wall; it will last for a very long time.

Removing the oxide film

Usually, if you have a good flux specifically designed for soldering aluminum, the use of any special tricks is not required; it is enough to mechanically clean it and moisten the surface to be soldered with flux.

It is also possible to use acid for soldering aluminum. They use hydrochloric acid in which zinc is dissolved (soldering acid), and fluxes based on orthophosphoric acid are also used.

But if such a flux is not available or, due to poor quality, does not provide soldering, you can go another way. There are several ways to remove the oxide film for successful tinning of the workpiece.

Preparation of material

To achieve good properties of the connection, it is necessary to use not only the right technologies, but also to be able to perfectly prepare the surface to be treated . All dirt and oxide films must be removed. Mechanical processing is carried out using sandpaper or an iron brush, and from time to time a stainless steel wire mesh and a grinding machine are used. You can also use various acid mixtures.

Interesting read: Aluminum staples for staplers

The surface must be degreased using solvent, acetone or gasoline. When the duralumin surface is cleaned, an oxide film is immediately created. But its thickness will be lower than the initial one, and therefore the soldering process will be easier.

Tinning aluminum with tin – Metals, equipment, instructions

Aluminum is a metal that is difficult to solder. This is due to its tendency to form a strong oxide film on the surface of products, which prevents the part from being wetted by molten solder.

Mechanical cleaning of the surface alone does not help, since new oxide is formed instantly after removing the old one. For this reason, special fluxes are used for soldering aluminum and special technology is followed.

In rosin

An aluminum wire or other part can be freed from the oxide film by immersing it in liquid rosin. To do this, you can either melt it or prepare an alcohol solution.

After immersing the part in rosin, use a sharp knife to scrape off the oxide film. The rosin layer prevents the access of air and the formation of new oxide. After this, the part can be tinned using a heated soldering iron with solder.

Abrasive powder

In the absence of flux and rosin, aluminum soldering can be done as follows. A paste is prepared consisting of abrasive powder and transformer oil.

Fine metal filings can also be used as an abrasive. The workpiece is coated with this composition, after which it is rubbed with a hot soldering iron with solder.

As a result of this, the abrasive grains or metal shavings remove the film, and the surface is immediately wetted with solder without access to air. After tinning, the product can be easily soldered.

Chemical cleaning method

In essence, this method is nothing more than copper plating of an aluminum surface. It is performed as follows.

That part of the aluminum billet that is to be coated with a layer of copper is moistened with a solution of copper sulfate. Then take a direct current source with a voltage of 4.5 volts.

This could be a battery or accumulator. The aluminum part is connected to the negative terminal of the power source. A copper wire is connected to the positive terminal, the end of which is entangled in the bristles of a toothbrush.

Next, the brush is moistened with a solution of copper sulfate. The wire located in the bristles must be well moistened. After this, rub the area of the part previously moistened with the solution with a brush.

As a result of the galvanic reaction, the surface of the aluminum is coated with a thin layer of copper, allowing it to be soldered as if it were a copper part.

Warming up the part

When soldering fairly massive parts, the power of a conventional electric soldering iron may not be enough to heat the workpiece to the required temperature.

You can use a gas burner to heat aluminum at home. For this purpose, it is better to use a portable burner powered by a small gas cartridge. In this case, you need to work very carefully. It is unacceptable to overheat the base metal to the point where it begins to melt.

You can also use a combined heating method. For example, place a massive aluminum piece on the burner of a kitchen gas stove and light a small fire. You can use an electric soldering iron at the soldering site.

Everything that has been said about methods for soldering aluminum applies to various alloys based on this metal. Only the topic of silumin soldering is somewhat isolated. This material is an aluminum alloy containing silicon (roughly speaking, sand).

Soldering this alloy presents particular difficulties. Attempts to solder silumin often fail.

Even after seemingly successful soldering, it turns out that the connection does not have the required strength and may break. Experts do not recommend soldering this material. The best way to join this alloy is argon arc welding.

High temperature process

Industrial methods of aluminum soldering are distinguished by the use of harder solders containing aluminum. To use this technology, factory equipment and special fluxes are required.

Thus, heating and soldering of workpieces is carried out in special tunnel-type furnaces. The soldering process is carried out in an environment of inert gases at temperatures reaching 600 ℃. This technology is used in the manufacture of aluminum radiators and heat exchangers of modern cars.

How to solder aluminum at home with a soldering iron

| Aluminum is highly durable and a good conductor of heat and electricity. It has a low specific gravity, is easy to process, and is environmentally friendly. However, all these positive qualities create almost insurmountable obstacles when solving the problem of how to solder aluminum at home with a soldering iron. This cannot be done using traditional methods, so you have to use special welding methods and optimally selected materials. Technical difficulties in soldering aluminum products and partsSoldering aluminum structures and other elements is always quite difficult, especially if it is done at home by novice craftsmen who have not fully studied the process. Basically, such soldering is performed industrially using special equipment. However, it is quite possible to create the most suitable conditions for welding parts made of aluminum. To achieve this goal, it is necessary to resolve several technical problems:

Preparation for soldering aluminum partsGreat importance is attached to preparing aluminum for upcoming soldering. There are several ways to do this to ensure connection reliability:

|

Peculiarities

Aluminum is a metal that has sufficient density, but is also lightweight. It is these advantages that have made it possible to use this material so widely for the manufacture of tableware. The process of using aluminum products is not complicated, but from time to time situations arise when it is necessary to eliminate a crack, hole, or solder parts of the cookware. In addition to kitchen utensils, aluminum is used to make wire, which is convenient to work with due to its softness but good strength.

There is only one drawback to this wire - it is very difficult to solder.

Most metals can be heated and soldered, but aluminum is a special substance that oxidizes when exposed to air and becomes coated with an oxide film that no metal can sit on top of. To solder this material, you need to select a suitable flux.

Flux is a substance or several components that can be used to remove oxides from metals that need to be soldered. Thanks to the organic and inorganic compounds of fluxes, it will be possible to remove surface tension and improve the spreading of liquid solder. In addition, it allows you to protect the material from environmental influences.

Since aluminum is an unusual metal, it is worth looking for a special flux for it. Soldering aluminum with tin is considered the simplest and most convenient option in which you can get the desired result. The advantages of using tin for aluminum smelting include:

- low price of the material;

- the ability to use tin for parts with different thicknesses;

- high melting rate and the ability to cover the entire surface of the aluminum part on which work is being carried out;

- low melting point, which allows you to quickly cope with the task;

- general availability of tin.

In addition to the advantages, it is worth mentioning the disadvantages:

- the possibility of destruction of the finished connection under the influence of high temperature;

- inability to withstand strong mechanical loads;

- It is not always possible to achieve the desired result on your own.

To melt aluminum, you need to know about the basic methods of this process and be able to use them.

Submerged Soldering

To remove the oxide film from the surface of aluminum, different fluxes are used (F-59A, FTBF-A, F-61A). The use of a specific composition depends on the characteristics of the alloy and the intended purpose. Soldering sequence:

- Clean the core from insulation at a distance of 5 cm from the edge. During all this, the knife is held at an angle so as not to destroy the core.

- The surface of the alloy is cleaned with small sandpaper.

- Cover the core with flux using a brush.

- Clean the alloy again with a knife.

- A heated soldering iron is used to tin the wire.

Fundamentally!

Solder is applied starting from the end of the wire to avoid damage to the insulation.

During tinning, the soldering iron is moved back and forth along the wire, clearing the film from the aluminum surface. It will not be possible to cover the core moderately with solder the first time. The function is repeated for open areas. After obtaining a suitable result, the end of the wire is washed with aquatic soda (5 tablespoons per 200 ml of water) to neutralize active acids. Flux residues under the insulation or solder will corrode the aluminum over time. As a result, the joint space will heat up and char.

Soldering duralumin wires

During electrical installation, the iron cores of the cables are connected by soldering. This guarantees reliable contact at the commutation point. But, if you simply apply solder to a copper wire, it is somewhat more difficult to coat the duralumin core. In addition, it is not allowed to directly connect two alloys - they form a galvanic couple. When an electron current passes through the twist, it will heat up.

For your information!

When cleaning the core, it is important not to destroy the main alloy. Notched aluminum may simply break.

The difficulty of soldering is that there is an oxide film on the surface of the alloy, which is difficult to remove. It appears instantly when aluminum comes into contact with oxygen in the air. This is justified by the highest chemical activity of the alloy. Without the protective film, it would completely react with oxygen. In order for the solder to moderately cover the wire and adhere firmly to it, its surface is cleaned by etching with fluxes or without access to air.