Installation of leaves for swing gates

The question of how to install a gate is an important point among all the work performed in the manufacture of gates with your own hands, since mistakes made can lead to both a short service life of the gate and the fact that they simply will not perform their functions, for example, to open well . Installation work begins with the installation of the frame. The procedure for this looks like this.

- Hinges are welded to the leaf panels using a continuous seam. This should be the part of the loop that has a blind hole at the end.

If heavy gates are installed, they should be equipped with three hinges on each side. When installing lighter structures, two hinges will be sufficient.

- For each welded loop on the frame, its second half is put on, which is immediately welded to the support.

- The gate leaves are lined:

- 1) repeated measurements of corrugated sheets are made (this will avoid errors);

- 2) using metal scissors, cut out the required sheets;

- 3) all existing edges are thoroughly cleaned;

- 4) the sheets are overlapped in one direction;

- 5) the corrugated sheet is attached to the frame with self-tapping screws. The number of self-tapping screws used to fasten the corrugated sheet is chosen arbitrarily; the distance between them should be from 10 to 15 cm.

- The finished product is painted.

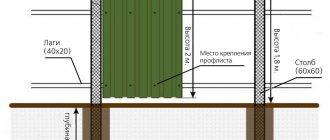

Installation of support pillars

To prevent the sashes from sagging, they install powerful pillars, for example, brick ones. A metal pipe is placed in the ground, and then covered with brick on the outside. Next, the installation points are determined, not forgetting about the brick finish of the pipe, and a meter-long hole is dug. The width of the trench should exceed the girth of the structure by 10 centimeters. The supports are covered with crushed stone and placed under a press. After this, compaction of the soil occurs. It is necessary to approach this stage with all responsibility, since if the technology is incorrect, the doors will warp and the appearance of the fence will deteriorate.

You can install support posts for fastening using mortar. To create a solution, cement (M300) and sand (1:3) are used. Water is added to the mixture, after which the mass is beaten with a drill until lumps are eliminated. After the solution is ready, crushed stone is poured into it.

After the mortar has hardened, bricks are laid. At the same time, it is important to follow the technology in which each subsequent brick closes the seam of the previous one. Next, they begin to weld the shank and pass it through the seams. Jointing is carried out only after all seams have hardened.

Dimensions of each leaf and gate

When calculating the height of the gate, it is important to take into account that at the bottom there should be a distance of 5 - 10 cm from the ground. If there are tiles or asphalt in the area where it is planned to install the gate, then this gap can be reduced to 5 cm

When talking about the size of future gates, we take into account that they must be such that a vehicle can pass through them freely. The height also depends on the height of the fence, the dimensions of the vehicle and the size of the sheet.

The dimensions of the gate should provide free and comfortable passage through it. It is believed that it is most correct to make a gate 1 meter wide and 2 meter high.

Specifics of self-manufacturing entrance structure

There is an opinion that forged products are exclusive and cannot be cheap. But modern technologies make it possible to make a simple design with your own hands.

Drawing up a drawing

A gate with forging elements consists of many details that need to be depicted in a sketch. The drawing must include the dimensions of the structure, main and decorative elements drawn to scale. The standard height of the product is 1.5 m, width is 1 m, minimum distance from the ground is 10 cm.

The structure consists of:

- supports;

- frame made of corrugated pipe with a section of 30x20 mm;

- awnings;

- patterns;

- locks, latches.

Advice: if you have no experience in designing such products, you can use a special program.

Tools needed to build a forged gate with your own hands:

- anvil;

- bugle;

- sander;

- vice;

- welding;

- machines “Torsion”, “Ex;

- Bulgarian;

- mites;

- hammer;

- stitching for forming holes.

Attention: operation will also require an open flame source that maintains the temperature at 1180˚C.

Installation of pillars

Since a forged gate is heavy, it is better to install metal supports for it. These can be round or profile pipes. To ensure the stability of the structure, they are deepened into the ground by at least 1 m and secured by concreting.

Frame construction

The basis of the gate is the frame, which is the basis for the arrangement of decorative parts of the structure. It has the shape of a rectangle and is made by welding a frame of four profiles with a cross-section of 30x20 mm. First, they are welded on top and sides, then the seams are welded, and then the arc is cut.

Manufacturing of decorative parts

Artistic forging of gates is carried out sequentially, by manufacturing individual elements. The patterns are formed from reinforcement rods, cut into the required lengths.

The blank is heated to 300˚C, and then brought to the maximum temperature in the oven. After this, the part is compacted with hammer blows, rolling it in a circle. During this procedure, scale is removed and the elements are given the desired shape.

Remember: the “crow’s feet” pattern is formed on the “Eccentric”, the curls on the “Snail”, and the twisting of the side elements is done on the “Torsion”. You can also purchase ready-made forged decorative elements from a craftsman or in a specialized store.

Assembly of the structure

When the decorative elements are ready, they should be fixed to the frame. It is important to observe the principle of symmetry. First, they are laid out on the canvas, forming a certain pattern. Then the parts are connected to the base using small tack welding. It is done so that the seams remain on the inside of the gate.

Hanging, decorating the product

All that remains is to install the finished structure on the supports. To do this, it is best to use point canopies that are welded to the pillars and frame of the structure. Additionally, the product is equipped with a latch/lock.

When the welds have cooled, they are cleaned and ground. After this, they begin painting the product. Its surface is degreased, primed, and covered with a coloring compound or patina.

Beautiful forged gates allow any area to be given a solid, respectable look. They emphasize the good taste of the owners and their status. It is not at all necessary to spend a huge amount to order such a product. With basic skills in working with metal, such a design will not cost much.

Popular trends and styles

Artistic forged elements that are used in the manufacture of entrance gates have certain styles. They are chosen taking into account the architectural trends that are present on the territory of a private house.

Forged doors with a wicket

Today the following styles are most popular:

- Byzantine. Forged structural elements are mainly dominated by complex patterns with multiple bindings, floral patterns, and geometric elements.

- Russian. Mostly there are fairy-tale characters, animal figures, and Slavic motifs.

- Gothic. The predominance of arches with pointed tops and oblong shapes. There are also images of grape leaves, roses, and clover.

- Renaissance. Forged gates with drawings, a large number of decorative patterns, a clear geometric order of the elements, usually in the shape of a spiral.

- Loft. Rough shapes, lack of intricate pictures, decorations, and other decor.

- Modern. Graceful forms without a clutter of design elements with an ascetic frame, the presence of simple lines.

Fence sections at the dacha

When making an entrance gate to organize a single architectural ensemble in the same style, lanterns, furniture, and canopies are installed.

Most artists and craftsmen, for whom the manufacture of forged elements for gates and gates is their main business, include photographs of various monograms in their catalogs, which can be purchased ready-made or a sample can be ordered separately.

Wicket and doors with forging elements

The more complex and smaller the pattern, the higher its cost. The price of large monograms is relatively low, but only small curls can give the fence a complex, beautiful design. The most popular are arrows, rounded spiral patterns, leaves, and flowers.

Sketches of forged elements

Do-it-yourself forged gates, photos of various design options can be seen below in the article.

Forged structures in the country

Preparatory work

At the preparatory stage, it is necessary to make a drawing with exact characteristics, as well as select the necessary tools and materials.

Drawing

To begin with, a drawing of a forged gate is created. On it it is necessary to note the shape and size of the entire structure, as well as its individual components. The shape of the gate can be: classic, rectangular, round, with elements of bends and peaks. The diagram must accurately reflect the distance between elements, the location of components and decorations.

The sketch includes the type of fastening of the gate with the fence, the configuration of the leaves and the type of their connection. Near the gate there is a wicket with its characteristics.

drawing of a forged gate

Tools

Make sure you have the tools listed below in advance. The material hardens quickly when welding, so to avoid failure, all means must be at hand.

- Welding equipment;

- Forge and anvil;

- Hammer;

- Ticks;

- Machine;

- Stitching;

- Gas welding machine (for spot welding);

- Vise;

- Electrodes;

- Metal grinding machine.

Materials

It is better to purchase materials in advance too. To save money and time, compare prices at different stores. Some materials will have to be ordered in advance, and this will take time.

- Steel sheets for continuous filling of 1 mm sashes;

- Sheet steel for forging pointed peaks;

- Bricks;

- Pillars;

- Mortar for installing pillars;

- Profile pipes for the frame;

- Tetrahedral elements.

How to make a forged gate with your own hands

The first step to creating your own masterpiece is choosing a sketch. You can come up with it yourself or pick up a ready-made one in one of the catalogs. The easiest way is to use a ready-made sketch or photograph of the product. Once the appearance of the gate has been determined, you can start purchasing material for it. For the frame, it is best to use a square profile pipe with a cross-section of 30 x 20 mm.

The base rods can be made from thicker material, and small curls from a square rod of small cross-section. For single curls and baroque, metal strips with a size of 12 x 6 mm are ideal. All this can be bought at any metal warehouse or in a specialized store.

- To cut rods and profile pipes, it is best to use a grinder with medium power.

It is compact and not too heavy to work with. When cutting an empty profile or metal pipe with your own hands, you need to rotate them. This way the cut will have smooth edges. - If the gate has a curved top frame bar, then this part of the profile should be bent in a device called a pipe bender. But we must remember that the edges remain smooth on both sides for more than 10 cm. Therefore, the length of the pipe must be taken a little longer than the required size.

- When all the frame parts are prepared, you can begin assembling it. This is done on a table or any flat surface. Having laid out all the parts, carefully weld them into one structure.

- If it is not possible to print the pattern from the selected sketch in full size, then you will have to draw it on a flat surface.

So, with the help of a rope you can accurately measure how much length of a metal rod is used for each curl. Beautiful original forged gate pattern - We heat up the gas forge and place the workpieces there at one end. After the end of the workpiece warms up and becomes pliable in processing, we roll it out on a machine called “eccentric”. If there is no result the first time, the workpiece is again placed in the forge and the procedure is repeated. The rolled out but not cooled blank is formed into a “crow’s foot”.

- Curls can also be made with your own hands. For this, a machine called a “snail” is used. Workpieces heated in a forge can be processed easier and faster than cold ones. If the curls are symmetrical on both sides, then you need to twist them gradually on each side, trying to maintain symmetry.

- If the pattern contains elements in the shape of a sharp peak, they are made on a familiar machine called “eccentric”. In this case, the workpiece is rotated 90 degrees with the other side each time.

- Clamps for fastening several curls or leaves are made from small metal plates measuring 20 x 2 mm. They will hide the welding areas and decorate the overall appearance of the forged product.

- To ensure that the pattern rods have a beautiful twisted shape, they are twisted on a torsion bar machine. Each of the blanks must be scrolled the same number of times so that they are the same.

- After all the details and curls of the future gate are ready, you can begin assembling the structure, strictly following the sketch.

- This work must be done slowly and observing the order of the pattern elements. Once you are sure that the pattern is symmetrical and correct, you can fasten the parts together with small welds.

- The seams can be cleaned well with a grinding wheel and a metal brush.

- If the sketch contains complex elements in the form of leaves or flowers, then it would be better to buy such blanks in a specialized store.

They are welded last. Forged gate pattern decorated in antique style - After all the elements of the gate have already been welded, and the gate itself has been cleaned and degreased at the welding points, you can begin painting. The first layer is a primer, and after it has completely dried, paint.

- They use a special matte paint, most often black. To give the gate a richer appearance, some of its elements are silvered or covered with patina.

- The finished gate can be left openwork, but if desired, it can be partially or completely covered with a sheet of corrugated board or carboxyl.

You can make forged gates yourself, but this process requires patience, some skill and skills in working with metal. Therefore, it is much easier to use another method.

Photos of beautiful gates

Making a gate that is not ordinary, but beautiful is not so difficult. And this does not always require expensive materials. What is always needed is imagination. Then even a bicycle, a shovel, a knot or a pickaxe is a material for exclusive design.

For pets))

For houses in a modern style, gates need appropriate ones. From a variety of materials... even from knots. Wood and forged elements are a win-win combination. The main component is imagination. A stencil changes even the simplest fence. Make a couple of cutouts in the boards... the original wooden gate is ready! Visiting fairy tales

A bicycle, wheels, a shovel - all the materials for making gates. To a fence made of Euro picket fence. A small fragment - a cat made of plywood. Original design from the yard side. Sources

- https://ZaborSebe.ru/vorota/kalitka-iz-profilnoj-truby-svoimi-rukami.html

- https://StrojDvor.ru/krupnye-konstrukcii/kalitka-iz-profilnoy-truby/

- https://TrubaNet.ru/izdeliya-iz-trub/kak-svarit-kalitku-iz-profilnojj-truby.html

- https://zabor-pro.ru/kalitka-iz-profilnoj-truby.html

- https://domsdelat.ru/okna_i_dveri/kalitka-iz-profilnoj-truby-svoimi-rukami-osobennosti-sozdaniya-i-poshagovaya-insturkciya.html

- https://passaz-okna.ru/dveri/kak-sdelat-kalitku-iz-profil-noy-truby-shema-i-poshagovyy-montazh-svoimi-rukami.html

- https://ZaborStroj.ru/kalitki/delaem-kalitku-iz-proftruby

- https://stroy-okey.ru/house/zabor/kalitka-iz-profilnoj-truby-i-profnastila-svoimi-rukami/

- https://stroychik.ru/zabor/kalitka-svoimi-rukami

DIY forged gates

Making a forged structure is quite difficult if you do not have the necessary experience and the appropriate tools. But, with great desire and patience, making forged gates with your own hands is a completely solvable matter. And it is not at all necessary to become a blacksmith to make them, because now there are many tools with which you can create a unique creation with your own hands.

The first step is to select a sketch of the future product. You can draw it yourself or choose from a catalog. Based on this, the necessary materials for the manufacture of the frame are purchased. A selection of individual finishing elements is also carried out.

Finished sketch of three wicket options

Let's look at how to make a gate from ready-made forged elements. To start work, you need to prepare a perfectly flat surface on which the gate will be welded. Tools you will need:

- Welding machine.

- Grinder, cutting and cleaning wheels.

- Measuring and drawing tool.

- Vise or clamps.

- Hammer.

- Sandpaper.

The work is performed in the following sequence:

The frame is being made. A 20 x 30 mm profile pipe is best suited for this. The cut pieces of pipe are welded together. The most massive elements (rods, rings and other parts) are welded to the frame. All decorative elements are laid out on the gate. At this stage it is not too late to somehow change the drawing

It is important to maintain symmetry and some kind of pattern. All unfolded elements are fixed to the frame by welding. All seams are cleaned and polished. Particular attention is paid to welded seams, since it is in these places that the metal corrodes most quickly. The surface of the gate is degreased. The product is being painted. First, a layer of primer is applied, which should have anti-corrosion properties. After it dries, a layer of paint is applied

Usually matte black enamel looks best. Individual elements can be highlighted against a black background. For example, gold or silver. A completely dry gate is hung in a permanent place. The operation of the product is checked, locks and visor are installed.

Advantages and disadvantages

To begin with, gates and gates serve as protection for the house, and only then as decoration for the garden area. Therefore, high demands must be placed on the material. These products have their own advantages and disadvantages.

Wrought iron doors in the country house

Advantages:

- Durability, long service life. Forging elements can withstand temperature fluctuations from −35 to +35 °C. All designs of forged gate products are resistant to ultraviolet radiation and negative atmospheric conditions.

- Versatility. Elements made using forging are ideally combined with corrugated sheets, stone, wood, and any other finishing materials.

- Installation of automatic systems. The design of the gate leaves can be equipped with automation and CCTV cameras.

- Originality. Any handmade item is exclusive. When ordering the production of forged gates and wickets from a specialist, you can be sure that there are no others like them.

Forged structures

Flaws:

- Requires periodic maintenance. Iron fencing must be regularly treated with anti-corrosion agents.

- High price. This is the main disadvantage of all designs of forged gate leaves. But when calculating profitability, it is necessary to take into account the long operating time (more than 100 years). Against this background, the cost justifies itself.

Forged doors

What is the difficulty of creating forged products?

To start forging individual elements or a whole fabric yourself, you will need to purchase a special device for spiral longitudinal and transverse twisting. Thanks to it, you can create ornate patterns of any size and shape.

Creating a forged element requires an accurate sketch, according to which the workpiece is cut. Before welding, all elements are laid out on the surface to get the overall picture and maintain symmetry.

When forging, it is important not to overexpose the parts so that they do not end up twisted. If you do not have the experience or time to create a gate, then it is better to seek help from specialists

If you do not have the experience or time to create a gate, then it is better to seek help from specialists.

How to sew the sashes

To ensure that the gates are not only pleasing to the eye, but also fulfill their main protective function, they are sheathed with fabric made of opaque materials. The most successful combinations are made from forging with polycarbonate, corrugated sheet or wood.

Polycarbonate

Polycarbonate can be cellular or monolithic. Honeycomb material is suitable for cladding. The sheets are light in weight and easy to transport. Polycarbonate bends well and is easy to use. It has a fairly wide color palette with different levels of transparency.

Profiled sheet

Profiled sheets are very often used in cladding wickets and gates. Easy to install and also wear-resistant. Has a large selection of colors.

Tree

Perhaps forged elements look best with wood. Plus, this material is environmentally friendly. However, wood is susceptible to moisture and damage by insects, and therefore requires special care and treatment with special protective agents.

Gate covers, images

It is recommended to decorate forged gates:

- overlays;

- zhikovina;

- overhead loops.

Overlays for gates and doors are elements that have decorative qualities, practicality and serve as reinforcement for the structure. They give the product a strict and sophisticated appearance. The overlays are suitable for styles: country, gothic, baroque, modern.

Among the variety of overlays there are:

- specimens of trees and plants;

- compositions;

- geometric figures.

The use of overlays will give the main entrance to the courtyard an aesthetic appearance.

Wooden gates with forged gates and handles. Photos Svyatoslav

Zhikovinas give the products an antique elegance. They harmoniously combine with metal and wood, emphasizing the good taste of the owners of the estates. Forged gates can be decorative overlays, or they can carry loads if they also serve as gate hinges.

Overhead hinges for gates combine decorative and functional qualities. With sufficient thickness of the products, they cope well with their intended purpose. Curly hinges for gates will complement any exterior. And their wide range allows home garden owners to choose the best option that will be combined with a forged door handle and other fittings.

Reference. Photos of forged gates (how to send a photo) demonstrate designs made in accordance with cold processing technology, as well as other types of products.

Cost of wrought iron gates

The cost depends directly on the experience of the craftsman, as well as the complexity of manufacturing forged structural elements. Therefore, it is difficult to single out a specific figure. But there is a lower limit. Thus, in the main territory of the Russian Federation and in the Chechen Republic, a serial product 3 m wide will cost approximately 49–52 thousand rubles, 4 m long - approximately 75 thousand rubles.

In the country

Installation of forged gates and gates will emphasize the individuality of the owner of the site. Modern machines allow you to make any patterns that will be a decoration, regardless of the landscape design of the surrounding area.

What details and patterns are used to decorate gates and gates?

The following forged elements are used to decorate gates with and without wickets:

The vine completely imitates plant patterns and carries artistic value. The use of the hot forging method allows you to create leaves and berries that are quite realistic.

Gate, wicket and fence with grapes, vines and leaves. Photo Iron Age

Curls are equilateral, versatile and C-shaped. Suitable for classical styles: Renaissance, Baroque, Rococo.

Wrought iron gates with a built-in wicket are decorated with peaks and scrolls. Photo by TNV Kovka

Leaves and petals. The presence of a double-sided texture makes the appearance of the products natural. They harmoniously combine with the vine and various floral motifs.

Closed gate with curls, leaves and flowers

Roses and flowers. These decors will suit any stylistic motif. They have a noble and elegant appearance. Fragile, sophisticated and delicate flowers will make any fence exclusive and attractive.

Types: solid and transparent, with elements and others

There are a large number of types of forged gates . The types of products presented below will help you choose the best option and translate it into metal:

- arched and rectangular gates, as well as products of non-standard shapes;

- various floral designs, the most popular are items made in black;

- the style of the item can be very diverse, products are made in modern and historical directions;

Wrought iron gate with wicket in Romanesque style. Reiri Photos

- double-leaf structures resembling gates are popular;

Double forged gate. Photos Kovka-Opt

- Lattice items can be decorated with a variety of elements.

Kinds

Forged fences and gates are divided into three types.

- Protective. The name already indicates their functional purpose. They have simple shapes, easy production, and relatively low cost. Their installation is simple and takes relatively little time, because they consist of stamped blocks.

- Decorative. These are exclusive, highly artistic fences with beautiful forging. The design is non-standard, as it is made by hand according to individual orders. Hence the high cost. Initially, the master develops sketches and demonstrates them to the customer, who chooses the option he likes. Soldering and welding are practically not used when connecting decorative parts. For this, clamps and rivets are enough.

- Combined fences. Contains elements of previous options. They combine expensive exclusive components with stamped sections. They are the most popular because they are beautiful, and installation is cheaper than purely decorative fences.

Metal structures of any kind come in different heights and designs. They are not suitable for every building and site.

Option for a wrought iron fence with lanterns on posts

Which material to choose

The main structural elements of gates are leaves and posts. Considering the weight of the structure, we can suggest the following materials:

- For pillars - galvanized profile pipe measuring 100x80x6 mm. It is better to use a seamless one, but this is a rare material; you can also use an electric welded one with a wall of at least 2.5 millimeters.

- Cement, sand and gravel for concreting pillars, including the calculation of filling the internal cavity of the pipe with mortar.

- Brick for cladding pillars.

- Galvanized sheet 0.5–0.7 millimeters thick for the manufacture of pole tops.

- Profile for the assembly of casement frames. Typically, profile pipes with dimensions of 20x40x2.5 mm, angle 45x45, round pipes with a diameter of 40 millimeters or more, preferably seamless, are used for this.

- Materials for the door leaf. If a blind design is preferred, the blade can be made of cold-rolled steel sheet with a thickness of 1.2–2.0 mm. This material has a higher surface quality. For transparent structures, they are filled with rods of various profiles and sizes, and a strip for making twisted elements.

- Forged parts can be ordered for individual production according to your own sketches and when installing the sashes, they can be welded to the canvas.

When purchasing metal, you should pay attention to the grade of steel profiles and sheets. The carbon content in the metal is of decisive importance, which determines such an important quality for work as weldability. Recommended brands from Art.0 to Art.20. These indicators can be clarified from the seller using a quality certificate for the metal. An experienced home craftsman can approximately determine the suitability of the metal for welding with a simple file by running it along the sample.

Photo gallery: rolled steel of “fence” assortment

A popular material for gates is cold-rolled steel sheet

For the manufacture of gates, a rolled profile is used. For the frame of the gate, a material of increased strength is required. Steel rods of round or square cross-section are used for the manufacture of forged elements.

The procedure for calculating the need for materials

The basis for calculating the need for materials is the preliminary design of the gate.

Actually, they consist of two identical doors in a mirror image. The width of the gate in practice is chosen at 3.8–4.2 meters. That is, the width of one leaf is 2 meters. If a 20x40 mm pipe is chosen as the material for the frame, then 2x2 + 2x1.8 meters of material will be used for the sash. With a calculated sash height of 1.8 m, 7.6 m of pipe will be needed. In addition, to strengthen the structure, it is necessary to install stiffening ribs on the sash, which are made of the same material. They are installed approximately 40 centimeters from the lower and upper contours.

Further reinforcement of the frame is made with corners made of sheet steel 2 millimeters thick. The size of the corner is approximately 15x15 millimeters. One sash will require 8 of these parts. The weight of one part must be multiplied by their number.

To calculate materials you will need a graphical display of the object

When drawing up a project, it is very important to take into account cutting the material with minimal waste. Therefore, before starting its development, it is advisable to find out what material in sizes the local market can offer and use this information.

Table: weight per linear meter of some profile pipes according to GOST 8645–68, kg/meter

| Pipe sizes | Wall thickness | ||

| 2,2 | 2,5 | 2,8 | |

| 30x20 | 1,59 | 1,76 | 1,94 |

| 40x20 | 1,955 | 2,16 | 2,38 |

| 40x25 | 2,13 | 2,35 | 2,59 |

| 40x30 | 2,27 | 2,55 | 2,59 |

| 100x80 | 6,47 | 7,67 | 8,20 |

Here is the weight of sheet metal that may be needed to make a gate, kg/m2 (here the first indicator is the thickness of the sheet):

- 1,5 – 11,77;

- 2,0 – 15,70;

- 2,5 – 19,62;

- 3,0 – 23,55;

- 4,0 – 31,4.

In the manufacture of gates, various square or round rods, strips and other materials can also be used.

Data on the weight characteristics of any metal product can be found on the Internet. Recalculation is necessary since prices are formed based on weight parameters.

The design of the door leaf also depends on the size of the metal available on the local market. Thus, the gap between the horizontal additional stiffening ribs should be close in size to the size of the sheet. And if this place is covered by a grille, then the total of the lower and upper gaps should be close to this parameter.

The grating is made from pieces of square or round grade metal measuring 12–16 millimeters, located vertically. The distance between them is determined by the designer and is 10–15 centimeters. The calculation is made as follows:

- The opening width of a two-meter sash is 2000 - 80 - 10 (profile size and width of the gap between the sashes) and is equal to 1910 millimeters.

- We divide the resulting result by 15 (the number of openings between the bars of the lattice) and get the result: 1910: 15 = 127 mm.

- The number of rods will be one less, that is, 14 pieces.

- The need for a profile will be 14 x L, where L is the length of one rod.

The need for metal for twisted or bent elements is determined in the same way on an individual basis.

Tips and tricks

Although developing a sketch of the future gate design is one of the most important steps, before you begin it is necessary to decide which of the various types of construction will be most suitable for the site.

To do this, you will need to make calculations and take into account some parameters:

- Design level. Depending on the purpose, the height of the structure can vary from 1.5 to 3 m: a small one is suitable for decorative items, and a three-meter high gate provides the highest level of security.

- Width. Depends on the width of the access road, as well as on the overall width of the site: the larger it is, the wider the gate.

- Parameters and design of the fence.

- Design functionality. This is the most important point for calculations, determining the distance between sections, the presence of a wicket inside the gate, the mechanism of movement of the leaves and their type.

Another important aspect is the combination of forged gates with a fence.

A nice bonus is that forged structures look great with various types of fences:

- A hedge in combination with a wrought-iron gate adds mystery and originality to the entrance area of the site, especially if this hedge is molded. But a simple interweaving of vines can also give the site the unique look of a fairy-tale estate.

- The combination of a wrought iron gate with a wrought iron fence is not uncommon, but this type of entrance group cannot provide the proper level of privacy, and if you spend money on a solid type of fence, it will be a rather expensive purchase.

- The way out of this situation in terms of financial savings is to use corrugated sheets. But a significant disadvantage is that often this material, along with forged patterns, looks out of place and alien.

- A fence made of brickwork in combination with forged elements is one of the best solutions in terms of combining forging and a fence.

- A stone fence, along with brickwork, very elegantly complements a wrought-iron gate, but this type of fencing is quite expensive. The way out of this situation is to purchase an imitation stone.

- Also, a very elegant way to decorate the gate and fence in the same style is to combine forging elements on the gate and the fence itself with another type of material, be it stone or its imitation, wood, brick or profile.

Here are some tips that can be useful to everyone when buying wrought iron gates:

Forged structures are easy to maintain, but taking care of their technical condition will only have a positive effect on the performance properties of the product.

Here are some tips for caring and maintaining wrought iron gates:

- If rust stains, paint webs and other defects appear, which especially often happens when the metal is negatively affected by climatic conditions, additional painting may be required. Rust spots, chips and defects are treated with sandpaper until completely clean, and then covered with paint.

- It is necessary to check the condition of the gate once a year and get rid of any shortcomings so that you do not have to completely paint or replace them in the future.

- To protect metal from rust, it is necessary to treat it with specialized compounds.

Tips for choosing

First you need to choose the optimal type of design. It depends on the landscape of the garden area.

Sash in the fence

Then you should decide on the type of gate. First of all, they pay attention to products that can complement the landscape design.

It is not recommended to choose a forged gate that will stand out from other buildings.

It should not be forgotten that the wicket is primarily a protection.

When choosing a forged product, the style of the house and garden area is taken into account. If it’s a classic, then it’s better to choose a classic style of product. For European design, the same designs will be required.

At a private house

Peculiarities

The main feature of gates with forging elements is their attractive appearance. Depending on what details you choose to decorate the base of the gate, you can get different results. A simple gate with a minimum of decor will look good against the backdrop of a modern building. And next to a house stylized as a medieval castle, it is better to install a richly decorated gate that will turn your house into a real fortress.

Artistic forging is a process that requires from the master not only a huge amount of time spent, but also a rich imagination. This is why the appearance of gates and fences is so highly valued. Most often, this is exclusive work that is performed according to individual sketches.

Such gates always look attractive due to the fact that forged elements look great against the background of all other materials. Artistic forging can perfectly complement structures made of corrugated sheets, metal and brick fences. Such gates will decorate a site in any style, be it exquisite Provence, discreet modern or shocking rustic.

It is also important to note that despite their fragile and elegant appearance, such products are actually quite durable. The structures are not afraid of bad weather or time

In order for the new gate to serve you for many years, you should treat it with a protective layer of a special composition or cover it with a neat visor on top. In some cases, the beauty of forged gates is hidden with an additional layer of corrugated sheeting, which allows only those who enter the yard to admire the structure.

And finally, the last advantage is environmental friendliness. The material from which durable metal patterns are made is safe for both you and the environment.

We spare nothing for the right pillars

We spare no expense, time and effort. In other words, all the resources you have.

Support pillars must be as stable, durable and strong as possible. Everything rests on them, this is half the success of the whole work, believe me.

The components are a metal pipe, mortar and facing bricks. Your task is to make sure that all this stands on the ground as stable as possible.

- To do this, we dig two holes, as deep as possible. The depth of the hole must be at least one meter. But you need to carefully monitor the width: it should be slightly wider than the metal pipe. This difference should not exceed 10 cm, otherwise the pillars may become loose in the future: after all, metal gates with a lot of weight will be hung on them, so the load will be more than serious.

- When installing pipes in holes, fill them with crushed stone and compact them at the same time. We plumbly monitor the verticality of the pipes, which is extremely important in the construction of gates: after all, at the slightest deviation, the doors will lean in one direction or another.

- Fill the filled crushed stone with a solution of cement and sand in proportions of 1:3. When pouring the solution, we again carefully check the verticality of the pipe. It is better to take M300 cement.

- Give the solution time to dry thoroughly, usually several days. Don’t rush, let the concrete dry for real, we agreed not to spare anything, including time.

- We weld special fastenings for the valves to the pipes, which are called shanks. Their width should be at least 6 - 7 cm, they should be visible from under the bricks.

- We line the pipes with alternating bricks: the next seam should overlap the next one.

And again we give our new pillars time to stand. At least for a couple of days. After all, we have something to do at this time - doors.

How to make a forged gate with your own hands

The first step to creating your own masterpiece is choosing a sketch. You can come up with it yourself or pick up a ready-made one in one of the catalogs. The easiest way is to use a ready-made sketch or photograph of the product. Once the appearance of the gate has been determined, you can start purchasing material for it. For the frame, it is best to use a square profile pipe with a cross-section of 30 x 20 mm.

The base rods can be made from thicker material, and small curls from a square rod of small cross-section. For single curls and baroque, metal strips with a size of 12 x 6 mm are ideal. All this can be bought at any metal warehouse or in a specialized store.

- To cut rods and profile pipes, it is best to use a grinder with medium power.

It is compact and not too heavy to work with. When cutting an empty profile or metal pipe with your own hands, you need to rotate them. This way the cut will have smooth edges. - If the gate has a curved top frame bar, then this part of the profile should be bent in a device called a pipe bender. But we must remember that the edges remain smooth on both sides for more than 10 cm. Therefore, the length of the pipe must be taken a little longer than the required size.

- When all the frame parts are prepared, you can begin assembling it. This is done on a table or any flat surface. Having laid out all the parts, carefully weld them into one structure.

- If it is not possible to print the pattern from the selected sketch in full size, then you will have to draw it on a flat surface. So, with the help of a rope you can accurately measure how much length of a metal rod is used for each curl.

Beautiful original forged gate pattern

Forged gate pattern decorated in antique style

You can make forged gates yourself, but this process requires patience, some skill and skills in working with metal. Therefore, it is much easier to use another method.

Variant of forged gate pattern made from profile pipes

Building design

Gates are usually made swinging.

The gate consists of supports in the form of pillars and a door leaf on a frame, which is fixed to the posts using canopies. To close, locks are installed. The pillars are made of brick, steel, reinforced concrete or wood. Inside monolithic and stone supports, embedded parts made of thick metal, angles or rods are inserted in order to weld a gate frame made of corrugated pipe to them.

The door is made as a separate passage in the fence or combined with a gate. In this case, the frame of the gate is placed in one of the leaves. If there is a sidewalk in front of the yard, the opening is made inward so as not to disturb pedestrians. In this case, the size of the leaf is taken into account so that there is a distance for the sash to fully swing open.

Hinged or sliding

The first option is considered an inexpensive design that is easier to cook and install. Such a gate does not require a base to install guide beams; it does not need a counterweight or roller elements. The swing system is combined with the gate and saves space at the entrance. At the bottom, the canvas is cut to height in areas with heavy snowfall. This way, the resulting snowdrift does not affect the opening.

Sliding schemes are more complicated, since guide girders are often placed at the bottom and require a level foundation. There are options with a device for cantilever movement of the leaf, in which the beam is hung so that it does not limit the height of the span, and the rollers are placed inside the sash frame. Automation is installed on swing and sliding systems.

Types of forging

Forging can be done in two ways: cold and hot.

Cold

The metal is treated with special equipment without being exposed to high temperatures. Cold forging is much cheaper than hot forging, since the parts are repeated and do not have complex patterns. Doors made using this method are sold in stores. They are simply welded to the finished frame.

The most popular cold forging parts:

- Vine. Simulates a plant trunk.

- Plasticine. Rods without edges, imitation of hand molding.

- Baroque. Combined option. The details have from 4 to 8 curls, complemented by sharp peaks and petals.

- Vine shoot. Metal rods are intertwined in a spiral.

- Monogram. A figurative element resembling a dollar symbol.

- Twisted pipe. An imitation of a braided braid is performed.

- Basket. Lightweight inserts made of several thin rods intertwined with each other.

Even on simple wrought iron gates there are:

- cast clamps;

- twisted squares;

- bagels;

- peaks.

Hot (artistic)

This is how they worked with iron blanks back in the old days. Artistic forging differs from cold forging in that metal must be forged at high temperatures. Hot raw materials are more flexible. It is easier to design different openwork compositions and patterns from it.

It is artistic forging that allows you to create compositions that have no analogues. In terms of service life, they are many times longer than those made using the cold method.

The customer can provide a sample or sketch from which the blacksmith will create a design.

The only negative is the high price.

You will learn about the technological processes of forging methods in the article: “Forged fences for a private home.”

Ornament on gates made of metal profiles

Patterns on metal gates, made from rolled sheets and iron rods, look original and strengthen the gates. Such ornaments increase the inaccessibility of the fence.

Corrugated sheet construction

The openwork ornament installed above and below the metal profile creates the illusion of airiness of the heavy metal structure. Elements of a contrasting tone against a background of colored fabric add volume and an aesthetic appearance. You can decorate the entrance to the site entirely or partially with your own hands. Artistic forging is mainly used:

Patterns on metal profile doors

For land owners who do not have a forging workshop, stores sell ready-made decoration elements. First, you should familiarize yourself with their assortment, and then draw up a life-size drawing of the ornament. After which you need to divide everything into simple elements and perform each one twice, if the gate is swinging and there are two leaves.

The pattern is laid out and welded on the ground, then attached to the canvas or to the frame. When decorating with metal ornaments, the age of the gate does not matter.

The photo shows a metal entrance group.

Decorative embossed sheet metal decoration

Decorating with forged elements made of sheet metal allows you to create three-dimensional images and even paintings. Beginners are recommended to assemble a pattern from simple elements.

For example, make a border around the perimeter of small flowers, leaves and curved stems. The petals are formed in a special die and made by embossing. The elements are connected to each other by welding and attached to the leaf panel.

Using three-dimensional forging from sheets, specialists create entire paintings that depict:

Forged patterns and embossing

Painted in golden or silver on a dark background, forged designs turn the area into a fairy tale and give the fence a luxurious look.

Photos of patterns on metal gates demonstrate the unlimited number of options and beauty of the entrance to the yard.

Leaf ornaments

A thin sheet 0.8–1 mm thick turns into an ornament in skillful hands. Small fragments of the pattern are attached in the area of loops and locks, strengthening the panel. Two-color designs create a beautiful look. The background is the gate material. The image is cut out from the sheet.

Sheet metal and forging patterns

A design is applied to thin metal, the dimensions of which coincide with the gate leaves. The holes must have a closed contour. Then everything is cut out and cleaned with a grinder and other tools. The finished decoration, made by yourself, is attached to the frame of the doors by welding or bolts.

The topic can be anything. The gates look original, decorated with trees, fantastic plants, and complex patterns. Drawings made from sheets that protrude beyond the metal profile at the top look especially unforgettable.