Home/Characteristics of Steel Grades, Rolled Metal/Wire 12x18n10t

Stainless steel wire is widely used in various industries. At the same time, depending on the quality characteristics of the final product, a wide variety of requirements are imposed on this product. This means that before buying a wire, it would be a good idea to familiarize yourself with its quality characteristics and understand the product labeling. Let's consider what criteria should be used when choosing stainless steel wire and the features of its production.

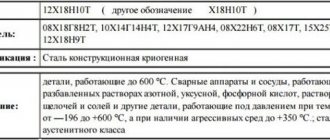

Technological properties of 12Х18Н10Т

Chrome-nickel steels 12Х18Н10Т and 08Х18Н10Т, which have become widespread and popular. They are recognized as a sought-after raw material in the production of gas distribution plants with high power and large dimensions and containers for gases (O2, N2, H2, etc.). They are distinguished by good weldability and have the property of increased viscosity at low temperatures. Steel 12Х18Н10Т, which has a high flexibility, is used after cold deformation, which increases strength. The austenite of such steels is not stable, therefore, under the influence of plastic deformation, incomplete martensitic transformation can be observed. Rods are made from steel 12x18n10t, which, unlike bronze rods, are cheaper and widely used in industry.

| Weldability 12Х18Н10Т: | no limits. |

| Flock sensitivity 12Х18Н10Т: | not sensitive. |

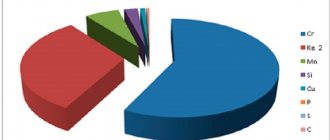

Features of the composition of steel 12Х18Н10

Austenitic alloyed corrosion-resistant steel 12Х18Н10 has iron as the main element in its composition (content up to 67%), carbon has a small proportion - up to 0.12%. The main alloying elements in the composition are nickel (its content is 9-11%) and chromium (its content is 17-19%). It is these two chemical elements in the alloy that provide the high anti-corrosion properties of 12Х18Н10 steel. A small proportion of titanium carbides (0.4-1%) allows one to avoid intergranular corrosion when the steel is in an aggressive environment and during sudden and severe temperature changes.

The steel also contains:

- manganese - up to 2%;

- silicon - up to 0.8%;

- copper - up to 0.3%;

- phosphorus - up to 0.035%;

- sulfur - 0.02%.

The steel composition is determined by GOST 5632-72 for austhenic stainless steels.

Analogues of 12Х18Н10 in composition are AISI 304, American steel - 304H, S30400, German stainless steel grades - 1.4301, 1.5301 and others.

Mechanical properties at 12Х18Н10Т at Т=20оС

| Assortment | Size | Eg. | sв | sT | d5 | y | Thermal change |

| — | mm | — | MPa | MPa | % | % | — |

| Cold-deformed pipes, GOST 9941-81 | 549 | 35 | |||||

| Hot-deformed pipes, GOST 9940-81 | 529 | 40 | |||||

| Rod, GOST 5949-75 | up to Ø 60 | 510 | 196 | 40 | 55 | Quenching 1020 - 1100 oC, Air cooling, | |

| Wire, GOST 18143-72 | 540-830 | 20-25 | |||||

| Forgings, GOST 25054-81 | up to 1000 | 510 | 196 | 35-38 | 40-52 | Quenching 1050 - 1100 oC, water, | |

| Thick sheet, GOST 7350-77 | 530 | 235 | 38 | Quenching 1000 - 1080 oC, Cooling water, | |||

| Thin sheet, GOST 5582-75 | 530 | 205 | 40 | Quenching 1050 - 1080 oC, Cooling water, | |||

| Thin cold hardened sheet, GOST 5582-75 | 880-1080 | 10 | |||||

| Thin sheet, semi-hardened, GOST 5582-75 | 740 | 25 |

Hardness 12Х18Н10Т, Forgings GOST 25054-81 HB 10 -1 = 179 MPa

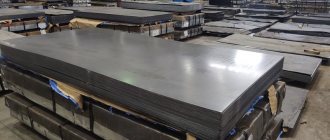

Steel wire 12x18n10t stainless steel

18.10.2021

- from Site Administrator

Stainless steel wire 12Х18Н10 is common in industry. Thanks to the indicators and characteristics of this grade of steel, wire and wire products made from it can be used without changing properties in aggressive environments. It is a metal cord or thread made of stainless anti-corrosion steel of a given grade. It is heat-treated and produced by the cold-drawn method, and has a circular cross-section in diameter.

Steel 12Х18Н10 is a stainless steel containing titanium of the austenitic class; it has high anti-corrosion properties. As a rule, for ease of storage, use and transportation, the wire is wound onto spools or collected into skeins (depending on its diameter).

The surface of stainless steel wire is matte and free of tarnish and oxides. Wire made of steel 12Х18Н10 has normal accuracy. The composition and properties of steel are determined by GOST 18143-72. Its analogue abroad is steel grade AISI 321.

Physical properties of 12Х18Н10Т

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 1.98 | 15 | 7920 | 725 | ||

| 100 | 1.94 | 16.6 | 16 | 462 | 792 | |

| 200 | 1.89 | 17 | 18 | 496 | 861 | |

| 300 | 1.81 | 17.2 | 19 | 517 | 920 | |

| 400 | 1.74 | 17.5 | 21 | 538 | 976 | |

| 500 | 1.66 | 17.9 | 23 | 550 | 1028 | |

| 600 | 1.57 | 18.2 | 25 | 563 | 1075 | |

| 700 | 1.47 | 18.6 | 27 | 575 | 1115 | |

| 800 | 18.9 | 26 | 596 | |||

| 900 | 19.3 |

Buy wire 12Х18Н10 in Nizhny Novgorod

The House of Steel company in Nizhny Novgorod offers all types of rolled metal in Nizhny Novgorod. We have pipes and rods of different sections, sheets and wire of different sections. We offer all types of structural, alloy, tool steels and non-ferrous metal products. We also provide professional cutting of rolled metal products and products. If the alloy or brand you need is not available, our employees will help you choose an analogue based on characteristics and purpose. To clarify information about availability or characteristics, ask a question, or to order, call us by phone number or fill out the application form on our website.

From us you can buy stainless steel wire 12Х18Н10 in coils or skeins. We offer the lowest and most favorable prices on the rolled metal market in the region and favorable terms of cooperation for regular customers.

Application of steel 12x18n10t

The linear expansion coefficient of 12x18n10t and the thermal conductivity coefficient of 12x18n10t determine the possibility of using the material in the manufacture of products that can be operated at high temperatures. The chemical and oil industries use containers and elements made from 12x18n10t that come into contact with petroleum products and various chemicals. In mechanical engineering, various products are made from 12x18n10t that will be used in high humidity and exposure to chemicals. In the fuel industry and energy industry, 12x18n10t steel is used because it can withstand high temperatures. There are quite a lot of requirements for products used in the food industry. The metal should not interact with food and drinks, so 12x18n10t is used.

Sheets 12x18n10t are widely used as substrates for rubbing parts, replacing brass sheets. Cold-rolled sheets and strips made of heat-resistant and corrosion-resistant steel 12Х18Н10Т are used for the manufacture of structures resistant to aggressive environments and parts for machines.

When producing Ni steels, two heat treatment modes are usually used. When performing normalization, the first stage is carried out at a temperature of approximately 9000C to equalize the presence of nickel in austenite. The second stage of normalization, carried out at 8000C, is intended for crushing the austenite grain. For such steels, due to the high nickel content, ferritic transformation occurs at approximately 5000C, which makes it possible for the γ→α change to be carried out during air cooling, using the martensitic or bainitic method. After heat treatment, microstructures of the martensitic or bainitic type are formed in the steel. High tempering transforms the microstructure in the range of 550...6000C into dispersed sorbitol, which has a certain proportion of persistent retained austenite.

Main advantages of stainless wire

The main advantages of the wire are due to the properties of steel 12Х18Н10 - it is quite high heat resistance and resistance to corrosion. The wire is stable in its physical properties in the temperature range from -400°C to +800°C. The wire also has high ductility and when used in the welding process, this indicator has a positive effect on the speed, quality and convenience of the welding process. As a result of its use, a sufficiently strong, durable and load-resistant weld is formed.

Another advantage of steel is its high level of ductility and low fragility, which is an important indicator for wire.

It is extremely resistant to water, steam, acids, alkalis and bases, and solvents. The wire is characterized by durability, it is strong and this makes its application the widest possible among stainless wire metal products.

Processing capabilities

Thin-walled and thick-walled pipes 12Х18Н10Т seamless type are considered one of the best in terms of operational and mechanical characteristics. The scope of their application is extensive.

When choosing a rental, you need to know the standards in order to purchase quality products. The color of the pipes should be light. Certain types of rolled products of the presented type may have a matte surface. It has a gray tint, which acquires during the production process under the influence of a number of established factors.

In most cases, pipes of this type are subjected to an etching procedure. It occurs in a vacuum or in a special protective environment. Etching occurs after heat treatment. This is necessary in order to remove tarnish from the surface.

After processing, a product is obtained that can be welded, forged or cut. Each of the listed procedures has certain features. So, there are no restrictions when welding this type of pipe. You can use such techniques as RAD, ES, RD, AF, CT and MP for this purpose. After welding, it is recommended to subject the product to additional heat treatment.

Forging is performed at temperatures from 850 to 1200ºС. Cutting also has a number of features. In the hardened state, this process is carried out at 169 HB and a material hardness of 608 N/mm².

Features of wire production

The material in question is made from heat-resistant and corrosion-resistant steel grades. The quality characteristics of the steel used are transferred to the finished product. But, nevertheless, in production conditions, products are subject to careful control, thanks to which the company can guarantee the quality of its products. Thus, among the control methods there are the following:

- rod and curl diameter control;

- bend and tear test;

- studies of electrical resistance parameters;

- chemical composition of the steel used.

Thus, if you, for example, buy 12x18n10t wire , then after reading the specification of this material you can be sure that all the characteristics indicated in it correspond to reality.

Weight

To calculate the cost of rental, you need to determine the weight of a meter of 12Х18Н10Т pipe. This indicator is not precisely established in GOST. Therefore, you will need to perform a simple calculation. About 20 grades of different steel fall under the requirements of the presented standard. Therefore, you need to determine the quantities of interest yourself.

If you want to purchase 12Х18Н10Т profile or round pipes, you need to use a simple method. It is presented in the standard. Using the formula, you can calculate the specific gravity of a pipe with given parameters:

Vpm = 3.14/1000 * (Dn - Ts) * Ts * Ps, where:

- Wpm is the weight of a linear meter of pipe, measured in kilograms.

- DN – diameter of the outer edge of the pipe in mm. It can be nominal (taken from the standard reference book) or real (obtained during measurement).

- Tc is the wall thickness of the rolled product in mm, which can be either actual or nominal.

- PS is the density of steel, which is measured in g/cm³.

The characteristics of the 12Х18Н10Т pipe can be taken from GOST. Here is information about the density of steel grades. So, for 12Х18Н10Т this figure is 7.9 g/cm³. So, the calculation of a meter of seamless pipe is calculated as follows:

Vmp = 3.14/1000 * (50-4) * 4 * 7.9 = 4.56 kg.

The result obtained is used to calculate the weight of the entire product. This indicator allows you to determine the cost of rolled pipe.

Characteristics

Today, stainless steel GOST pipes of this type must meet numerous, detailed, strict requirements:

The composition of the 12Х18Н10Т alloy is clearly regulated.- Pipes are treated thermally, unless the consumer refuses this.

- Yield strength of at least 216 MPa. This characteristic shows at what value the product will continue to collapse even without increasing the load.

- Must withstand stretching at a temperature of 350 °C. Maximum high value: +600 °C. Minimum: -197°C. Although during operation it is recommended not to cross the threshold of 350 °C.

- Pipes that meet the requirements of the document have a minimum number of various types of deformations: cracks, dents, etc. Limit deviations are also established. Some of the defects can be eliminated by cleaning.

- The surface is light gray.

- The product can withstand flattening within acceptable limits. The distance that will be obtained between the involved surfaces is determined by a special formula. It depends on the outer diameter and wall thickness.

- Permissible hydraulic pressure is within the framework of GOST 3845. This characteristic is largely determined by the production technology of the product.

- Pipes are not afraid of ultrasonic influence. The corresponding check is carried out if necessary, at the request of the consumer. The dimensions of artificial defects are determined by agreement.

- Resistant to intergranular corrosion. Tests here are carried out using the AMU, PT, AM methods.