Profile pipes, actively used in construction, mechanical engineering, furniture production and other areas, are presented on the modern market in a wide variety. In order to streamline this diversity and classify these products according to certain criteria, such a concept as assortment was introduced.

Types of profile pipes

The word “assortment” itself, if you turn to dictionaries, comes from the word “grade” and means a list of individual types of products that are presented on the market. In relation to profile pipes, the assortment means a set of types of these products produced by manufacturing enterprises or available at the supplier’s warehouse.

The range of pipes is presented in the form of a table or a simple list in which individual types of products are listed in accordance with their names in accordance with GOST 13663 86 (profile square, profile rectangular pipes, etc.). Such a table or list should contain all available types of pipes, for each of which all names are listed and characteristics are given.

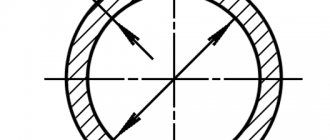

The range of pipes belonging to the profile category is very diverse. They are classified according to various parameters, but the main one is the cross-sectional profile. So, pipes are distinguished:

- with a rectangular profile;

- square section;

- flat oval;

- oval;

- with hollow ribs;

- with a special type of profile.

The assortment is compiled separately for each type of pipe, which is regulated by the requirements of the relevant GOSTs.

Basic parameters of the most common profile pipes - square and rectangular sections

Metal pipes belonging to a particular type of profile can also differ in a number of parameters. The main parameters include:

- the method by which the pipes are produced (they are cold-rolled, hot-rolled, welded);

- materials used in production;

- method of processing pipe ends;

- main purpose.

The range of pipes presented by a particular manufacturer not only allows you to get acquainted with the range of its products, but also serves as an indicator of its level of development. Consumers of such products and organizations selling them prefer to establish relationships with manufacturing enterprises whose range of pipes includes a wide range of products.

Main GOST standards for steel pipes

The technical characteristics of each type of steel pipe, depending on the method of its manufacture, are determined by the relevant GOST.

It is necessary to familiarize yourself with the contents of regulatory documents, at a minimum, in order to know the operating features of a certain type of pipe. GOST 30732-2006. Regulatory document number 30732 was adopted in 2006, and its effect applies to pipes and steel fittings with thermal insulation. Steel pipes, produced using polyurethane foam (PUF) insulation with a polyethylene sheath or protective coating of steel, are used for laying heating networks below and above ground. They are designed for a coolant temperature not exceeding 140 degrees (with a short-term increase to 150 degrees). The maximum permissible operating pressure for steel pipes with insulation according to state standard 30732-2006 with PPU insulation is 1.6 MPa.

GOST 2591-2006 (88). GOST, which determines the range of hot-rolled steel, has been in force since 2006. Some sources use the old GOST - 2591-81. The provisions of the document apply to square rolled steel produced by the “hot” method. GOST 2591-2006 (88) includes all products whose side dimensions range from 6 to 200 mm. The production of larger square pipes is possible only if the terms of the contract between the manufacturer and the buyer are agreed upon.

GOST 9567-75. The version of the document adopted in 1975 is currently in use. This standard specifies the provisions to be followed in the production of precision steel pipes. These products are distinguished by increased manufacturing precision: they can be either cold-deformed or hot-rolled (they can also be galvanized or chrome-plated). High-precision pipes in accordance with GOST 9567-75 are used mainly in the mechanical engineering industry.

GOST 9567-75 defines the parameters for the production of hot-rolled steel pipes

GOST 52079-2003. Document number 52079-2003 defines the standards to which straight-seam and spiral-welded steel products are subjected. Their diameter is in the range of 114-1420 mm. Such dimensional pipes are used in the construction of main gas pipelines, pipelines for the transmission of oil and petroleum products. GOST 52079-2003 allows the transportation of only non-corrosive products.

Steel welded products of large diameters in accordance with GOST 52079 can serve as a means for transporting substances under constant pressure (working pressure) not exceeding 9.8 MPa. Ambient temperatures can drop to -60 degrees.

GOST 12336-66. The normative document GOST 12336-66 applies to closed-type profile products having a rectangular or square cross-section. On January 1, 1981, GOST 12336-66 was cancelled, and its functions began to be performed by TU 14-2-361-79. However, the provisions of document 12336-66 remain relevant to this day.

GOST 10705-91 (80). Defines the technical conditions for the creation of electric-welded straight-seam steel pipes with a diameter of 10-630 mm. Steel pipes are produced in accordance with GOST 10705-91 (80) from carbon or low-alloy steels. The scope of application of these structures is varied: they are mainly used when laying pipelines for transporting water. The provisions of the standard do not apply to steel pipes used in the manufacture of thermal electric heaters.

Pipes produced in accordance with GOST 10705-91 are the basis of water supply systems for domestic and industrial purposes

GOST 10706 76 (91). It has become widespread to electric-welded steel pipes with a straight seam used for general purposes. The diameter of the pipes according to document 10706-76 (91) can be in the range of 426-1620 mm.

GOST 10707 80. Regulates regulations for electric-welded cold-deformed pipes of various degrees of accuracy: ordinary, increased and precision. Products according to document number 10707-80 are produced with a diameter from 5 to 110 mm. Unalloyed (carbon) steel is used for the production of pipes. Sometimes manufacturers of electric-welded (straight-seam) steel pipes indicate in the technical passport a link to the document GOST 10707 91. This is not an error, since in 1991 the validity of the 1980 standard was extended.

We will consider the main GOSTs in more detail below.

Preface

The goals and principles, the basic procedure for work on interstate standardization are established by GOST 1.0-92 “Interstate standardization system. Basic provisions" and GOST 1.2-2009 "Interstate standardization system. Interstate standards, rules and recommendations for interstate standardization. Rules for development, adoption, application, updating and cancellation"

Standard information

1 PREPARED by the Technical Committee for Standardization TC 357 “Steel and cast iron pipes and cylinders”. Open Joint Stock Company "Russian Research Institute of Pipe Industry" (JSC "RosNITI")

2 INTRODUCED by the Technical Committee for Standardization TC 357 “Steel and cast iron pipes and cylinders”

3 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (Minutes dated June 18, 2015 No. 47)

| The following voted for adoption: |

| 4 By Order of the Federal Agency for Technical Regulation and Metrology dated January 19, 2016 No. 9-st, the interstate standard GOST 32931-2015 was put into effect as a national standard of the Russian Federation on September 1, 2016. 5 This standard has been prepared based on the application of GOST R 54157-2010′ 6 INTRODUCED FOR THE FIRST TIME Information about changes to this standard is published in the annual information index “National Standards”. and the text of changes and amendments is in the monthly information index “National Standards”. In case of revision (replacement) or cancellation of this standard, the corresponding notice will be published in the monthly published information index “National Standards”. Relevant information, notifications and texts are also posted in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet * By Order of the Federal Agency for Technical Regulation and Metrology dated January 19, 2016 No. 9-st, GOST R 54157-2010 was canceled from September 1, 2016. ©Standardinform. 2016 In the Russian Federation, this standard cannot be fully or partially reproduced, replicated and distributed as an official publication without permission from the Federal Agency for Technical Regulation and Metrology GOST 32931-2015 |

Discreet design

All decorative elements should be aesthetically combined with the overall decor and culturally complement it. Their main goal is to create a stylish, non-trivial, unique and artistic space.

- Various light sources (chandeliers, lamps, floor lamps, sconces) will fill the space with warm light and home comfort.

- Wall art should not take up too much space. It is better to limit yourself to one majestic painting than to create a diverse composition from small canvases.

- It is advisable to use mirrors to decorate furniture, and a floor mirror will fit perfectly with the overall interior. You can also hang one mirror between the windows.

- Simple rectangular or rounded lambrequins are possible to decorate blackout curtains.

- When choosing a carpet, you should focus on small, approximately 2x2.5 m, carpets with a classic blurred or, conversely, clear pattern that will add a touch of modernity to the space.

Assortment of square profile pipes: GOST 8639-82

To get acquainted with the range of square pipes, it is worth reviewing the data from the corresponding GOST, which is presented below.

Outer diameter of pipes (Dн): classification of steel products

As mentioned above, the inner and outer diameters are different from each other. The first of them is used to designate individual elements of pipeline structures. Sales of steel products are also carried out by internal diameter. This indicator is important if it is necessary to carry out installation calculations for a water supply or gas line. In turn, the outer diameter is used to determine the strength characteristics of the pipeline and its resistance to mechanical loads.

The outer diameter allows you to determine the strength of the pipe and its resistance to damage.

The outer diameter of steel pipes is a characteristic by which all products made from this material are classified.

Depending on this parameter, there are three main types of pipelines:

- small;

- average;

- big.

Pipes that belong to the small group have a diameter range from 10 to 102 mm. Medium-sized products can have a cross-section from 102 to 426 mm. The diameter range of large steel pipes starts from 426 mm. In turn, it is recommended to determine the internal diameter using the table.

Small pipes are used when installing communications in residential buildings. Medium-sized products are used to lay urban water transportation lines, and they are also actively exploited by companies engaged in oil (crude) production. The main areas in which large steel products are used are oil and gas transportation areas. Trunk lines are assembled from large parts. The diameter of gas pipes can reach 1220 mm.

The range of steel pipes is quite wide, since these products are used in all areas where laying communications is required.

What is an electric-welded steel pipe 10704-91

A metal cylinder that is hollow inside is called a round pipe. The design feature of the product is that its cross-section is much smaller than the overall length.

External diameter

The product is used where it is noted:

- sharp temperature range;

- pressure changes;

- pumping of petroleum products;

- pumping various acids;

- discharge of industrial waste;

- drainage of wastewater.

Depending on the task at hand, samples of certain dimensions are selected.

The high strength coefficient of the 8x8 steel pipe is guaranteed by a unique alloy.

Important!

At the manufacturing stage, manganese and chromium are added to low-alloy carbon steel. Proportions are determined by technologists. Their observance is strictly mandatory!

The percentage of specific additives should not exceed 2.5. But if a DN150 or other size pipe is intended for use in a special purpose project, the inclusion of additional reinforcing ingredients increases. The maximum content of additives should not exceed 10%.

Steel pipe diameters

The diameter of the pipe, according to the measurement method, is divided into two types - internal (conventional diameter (DN, Dy) nominal size (in millimeters) and external (outer diameter). Water-gas pipes are measured by the internal diameter, electric-welded round and seamless pipes are measured by the external diameter.

Application of pipes of various diameters

Steel pipes are widely used in various industries today. These include:

- household;

- chemical;

- automobile;

- food;

- agricultural;

- construction and other industries.

First of all, such popularity of this type of rolled pipe is due to economic benefits. The main difference between steel pipes and each other is the production methods, the steel from which the pipes are made, as well as the diameters and cross-sections.

Both the outer and inner diameters are of great importance for any work involving the use of steel pipes. The main fundamental difference between pipe diameter measurements is that the outer diameter does not depend on the wall thickness, but the inner one depends. For example, a 108x3 pipe has an outer diameter of 108 mm, and an inner diameter of 102 mm, calculation 108 - (3 * 2) = 102 mm. There are also water and gas pipes, which are measured by the internal diameter and have the following dimensions DN 15x2.8, in this case, the opposite is true: the internal one remains unchanged 15 mm, and the external one will be 20.6 mm, calculation 15 + (2.8 * 2) = 20.6 mm. Such pipes are manufactured in accordance with GOST 3262-75 and have the designation DU - nominal diameter.

The diameter of the pipes is considered important, since the indicator serves as a basis for classifying products. Knowing the diameters and thickness of steel pipes, for example, you can calculate in advance the required quantity for transporting any substance along the highway. And as a result, it is possible to calculate the load on the designed system, as well as identify weak points and opportunities to eliminate them.

Varieties of diameters can be seen in the table of steel pipes

The existing standardization of steel pipes is necessary for making butt connections using pipeline fittings and clearly identifying analogues of these products made from other materials. After all, the connection of parts made of different materials has made it possible to expand the scope of application of pipelines in various types of industry. That is why the diameter of a metal pipe must always match, be thinner or thicker with its connecting element or its polymer analogue, thus forming a complex system. This, for example, made it possible for specialists to select various connecting nodes during large-scale design of a wide variety of highways.

After all, if the values of the outer and inner diameters are known, then selecting the necessary elements for the connection is quite easy.

The diameters of steel pipes can be:

- pipes with especially thin walls - thin-walled;

- normal, average structures - ordinary;

- products with thin walls - thin-walled;

- elements with thick walls - thick-walled;

- pipes with particularly thick walls are thick-walled.

Also, the diameter and thickness of a steel pipe can predetermine the scope of its use.

Standard pipe diameter designation

Straight-line electric welded pipe 108x3.5 dl12m (Electric welded pipe psh 108x3.5 dl12m) 108mm outer diameter, 3.5mm wall thickness, 12m length of whip.

Water and gas pipe 50x3.5 dl6m (VGP pipe du 50x3.5 dl6m) 50mm internal diameter, 3.5mm wall thickness, 6m length of the whip.

Seamless cold-deformed pipe 35x3 n/a (Pipe bsh xd 35x3 n/d) 35mm outer diameter, 3mm wall thickness, n/a unmeasured length (from 4m to 12m)

Seamless hot-deformed pipe 60x5 n/a (Pipe bsh gd 60x5 n/d) 60mm outer diameter, 5mm wall thickness, n/a unmeasured length (from 4m to 12m).

Criterias of choice

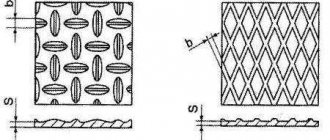

Of the entire range of modern profile pipe products, the most common are products with square and rectangular cross-sections. Traditionally, they are made from metal, but now this material is increasingly being replaced by plastic.

The main area of application of profile pipes is the production of metal structures for various purposes, where these products successfully replace solid steel bars. The big advantages of pipes compared to such bars are their affordable cost and low weight.

When choosing profile pipes from the assortment for the manufacture of a metal structure, it is very important to correctly select their profile and cross-sectional dimensions. The main criterion that guides this choice is the load-bearing capacity of pipes of both square and rectangular cross-sections. It should also be taken into account that products with different cross-sectional sizes can differ significantly in weight.

Square profile pipes

According to the production method, as noted above, the assortment includes cold- and hot-deformed steel profile pipes. In accordance with the requirements of GOST 13663 86, this also includes products manufactured using electric welding. These pipes, like cold-formed pipes, can be coated with a layer of zinc, which prevents corrosion.

The cross-sectional dimensions of profile pipes most in demand in the construction market are:

- 15x15;

- 20x20;

- 25x25;

- 30x30;

- 40x40;

- 60x60;

- 80x80;

- 100x60;

- 100x100.

Which ceiling to choose for the bedroom: single-level or multi-level?

Tension fabrics are divided into:

- Multi-level (three or more levels).

- Two-level.

- Single-level.

natyazhnoj-potolok-v-spalne-18

natyazhnoj-potolok-v-spalne-19

When installation takes place, a suspended ceiling of any kind “takes away” several centimeters of the room’s height. If the ceiling has one level, the loss will be in the area of 5-7 cm. Multi-level structures will “eat” twice or even three times as much. This must be taken into account when choosing.

A single-level surface is a classic of the genre. This is a great option for small and low rooms. Such designs are suitable for any design. A significant advantage is the affordable price. They are much cheaper than multi-level models.

If the room is large, it is more advisable to use two-level ceilings. This solution will help divide the space into zones. Canvases that are at different heights may differ in texture and shade. This looks very interesting.

Multi-level structures (more than two levels) are used extremely rarely for bedrooms. This option is used only for large premises. It is used to highlight the sleeping area.

Welding methods for straight-seam pipes

Pipe products, manufactured by bending a steel sheet (strip) into a circle and connecting its joints, are welded using several different technologies.

Furnace welding

The steel strip (strip) entering the rolling mill to give it a round shape is preheated in a tunnel furnace to a temperature of about 1300 °C. Approaching the rolling rollers, the side nozzles additionally heat the edges of the pipe with hot air to a temperature of about 1400 °C. Similar nozzles are installed in the roller zone of the forming mill and heat the edges of the strip to 1400 °C before directly bending the sheet into a circle with the extreme edges in contact.

After joining the edges, heated to high temperatures under pressure by rollers, a strong seam is formed, obtained by the method of mutual diffusion of molten metals. Next, the pipe is once again pulled through a furnace with forming rolls to give it the correct geometric shape. The technology refers to types of steel processing using hot deformation.

Rice. 5 Scheme of furnace and electric arc welding in a flux environment

Electric welding

Electric welding is more often used than other methods when welding round pipes; it allows you to obtain a high-quality seam on thin walls. Pipe products used for pipelines in the oil and gas industry are manufactured using submerged arc welding. To carry out welding work, a round-shaped pipe shell is formed in a forming rolling mill; if the diameter of the product is too large, the circle is assembled from two sheets, which are molded under a press until a semicircular shape is obtained.

Automatic electric welding is carried out simultaneously from both sides until a uniformly welded longitudinal seam is obtained; wire is used as an electrode. After removing the grand, ultrasonic testing and hydrotesting, the pipe is ready for use.

Rice. 6 Electric welding in inert gases - principle

Electric welding in shielding gas

The disadvantage of welding in air is the harmful effect of oxygen on the joint; as a result, air bubbles form in the seam strip, its chemical composition changes due to carbidization of alloying elements, and scale appears on the surface.

The use of inert shielding gases in the field of welding: carbon dioxide, argon and helium allows you to get rid of these harmful factors that arise due to the influence of environmental oxygen on the metal. During operation, neutral gases, being heavier than air, displace it from the working area, eliminating contact of the molten weld pool with atmospheric oxygen. Refractory tungsten products are used as electrodes.

Welding in an inert gas environment is more often used to connect parts made of stainless or high-alloy steel; the seams are characterized by homogeneity of the material, uniform thickness, high surface quality, and provide excellent tightness and strength of the joint.

Pipe products produced by electric welding belong to the group of cold-deformed products.

Rice. 7 HDTV welding schemes

High frequency (induction) welding

The modern high-speed method of pressure welding (pressing melted edges against each other with physical force), in which the edges of the workpiece are heated by high-frequency high-frequency currents until softening, is widely used in pipe production. The current density is maximum in the surface layer of the product and sharply decreases when immersed deep into the workpiece (surface effect), due to which only a thin layer of the outer shell with a depth of 0.1 - 0.15 mm is strongly heated.

Heating of the joining edges is carried out by an inductor located in close proximity to their edges; it generates induction currents along the edges of the workpiece using two electrodes sliding along the pipe shell.

During induction welding, the joined pipe edges of the workpiece have the shape of the letter Y; the HDFs are brought to the edges by means of an inductor or a rotary roller so that it passes through the point of their convergence. The distance from the conductive contacts to the junction varies in the range from 25 to 300 mm.

There are several induction welding technologies; to connect pipe edges made of ferrous and non-ferrous metals, the pressure welding technique with fusion is most often used. The heating rate with this technology is 15·104 °C/s, precipitation is 2000 mm/s, the technology ensures high quality welding joints.

Rice. 8 Physical parameters of metals of heat-treated and hot-reduced straight-seam pipes of classes A and B (GOST 10705-80)

Profile pipe. Dimensions. Weight 1 meter. Tables

Square section GOST 8639-82

| Dimensions bxh , mm | Wall thickness, t , mm | Weight 1m, kg | Meters in 1 ton |

| Square pipe 10x10 | 1,0 | 0,269 | 3717,5 |

| Square pipe 15x15 | 1,0 | 0,426 | 2347,4 |

| 1,5 | 0,605 | 1652,9 | |

| Square pipe 20x20 | 1,0 | 0,583 | 1715,3 |

| 1,5 | 0,841 | 1189,1 | |

| 2,0 | 1,075 | 930,2 | |

| Square pipe 25x25 | 1,0 | 0,740 | 1351,4 |

| 1,5 | 1,070 | 934,6 | |

| 2,0 | 1,390 | 719,4 | |

| 2,5 | 1,680 | 595,2 | |

| 3,0 | 1,950 | 512,8 | |

| Square pipe 30x30 | 2,0 | 1,700 | 588,2 |

| 2,5 | 2,070 | 483,1 | |

| 3,0 | 2,420 | 413,2 | |

| 3,5 | 2,750 | 363,6 | |

| 4,0 | 3,040 | 328,9 | |

| Square pipe 35x35 | 2,0 | 2,020 | 495.0 |

| 2,5 | 2,460 | 406,5 | |

| 3,0 | 2,890 | 346,0 | |

| 3,5 | 3,300 | 303,0 | |

| 4,0 | 3,670 | 272,5 | |

| 5,0 | 4,370 | 228,8 | |

| Square pipe 40x40 | 2,0 | 2,330 | 429.2 |

| 2,5 | 2,850 | 350,9 | |

| 3,0 | 3,360 | 297,6 | |

| 3,5 | 3,850 | 259,7 | |

| 4,0 | 4,300 | 232,6 | |

| 5,0 | 5,160 | 193,8 | |

| 6,0 | 5,920 | 168,9 | |

| Square pipe 42x42 | 3,0 | 3,550 | 281,7 |

| 3,5 | 4,070 | 245,7 | |

| 4,0 | 4,560 | 219,3 | |

| 5,0 | 5,470 | 182,8 | |

| 6,0 | 6,300 | 158,7 | |

| Square pipe 45x45 | 3,0 | 3,830 | 261,1 |

| 3,5 | 4,400 | 227,3 | |

| 4,0 | 4,930 | 202,8 | |

| 5,0 | 5,940 | 168,4 | |

| 6,0 | 6,860 | 145,8 | |

| 7,0 | 7,690 | 130,0 | |

| 8,0 | 8,430 | 118,6 | |

| Square pipe 50x50 | 3,0 | 4,310 | 232,0 |

| 3,5 | 4,940 | 202,4 | |

| 4,0 | 5,560 | 179,9 | |

| 5,0 | 6,730 | 148,6 | |

| 6,0 | 7,800 | 128,2 | |

| 7,0 | 8,790 | 113,8 | |

| 8,0 | 9,690 | 103,2 | |

| Square pipe 60x60 | 3,5 | 6,040 | 165,6 |

| 4,0 | 6,820 | 146,6 | |

| 5,0 | 8,300 | 120,5 | |

| 6,0 | 9,690 | 103,2 | |

| 7,0 | 11,000 | 90,9 | |

| 8,0 | 12,200 | 82,0 | |

| Square pipe 70x70 | 4,0 | 8,070 | 123,9 |

| 5,0 | 9,870 | 101,3 | |

| 6,0 | 11,570 | 86,4 | |

| 7,0 | 13,190 | 75,8 | |

| 8,0 | 14,710 | 68,0 | |

| Square pipe 80x80 | 4,0 | 9,330 | 107,2 |

| 5,0 | 11,440 | 87,4 | |

| 6,0 | 13,460 | 74,3 | |

| 7,0 | 15,380 | 65,0 | |

| 8,0 | 17,220 | 58,1 | |

| Square pipe 90x90 | 5,0 | 13,000 | 76,9 |

| 6,0 | 15,340 | 65,2 | |

| 7,0 | 17,580 | 56,9 | |

| 8,0 | 19,730 | 50,7 | |

| Square pipe 100x100 | 6,0 | 17,220 | 58,1 |

| 7,0 | 19,780 | 50,6 | |

| 8,0 | 22,250 | 44,9 | |

| 9,0 | 24,620 | 40,6 | |

| Square pipe 110x110 | 6,0 | 19,110 | 52,3 |

| 7,0 | 21,980 | 45,5 | |

| 8,0 | 24,760 | 40,4 | |

| 9,0 | 27,450 | 36,4 | |

| Square pipe 120x120 | 6,0 | 20,990 | 47,6 |

| 7,0 | 24,180 | 41,4 | |

| 8,0 | 27,270 | 36,7 | |

| 9,0 | 30,280 | 33,0 | |

| Square pipe 140x140 | 6,0 | 24,760 | 40,4 |

| 7,0 | 28,570 | 35,0 | |

| 8,0 | 32,290 | 31,0 | |

| 9,0 | 35,930 | 27,8 | |

| Square pipe 150x150 | 7,0 | 30,770 | 32,5 |

| 8,0 | 34,810 | 28,7 | |

| 9,0 | 38,750 | 25,8 | |

| 10,0 | 42,610 | 23,5 | |

| Square pipe 180x180 | 8,0 | 42,340 | 23,6 |

| 9,0 | 47,230 | 21,2 | |

| 10,0 | 52,030 | 19,2 | |

| 12,0 | 61,360 | 16,3 | |

| 14,0 | 70,330 | 14,2 |

Rectangular section (GOST 8645-68)

| Dimensions bxh , mm | Wall thickness, S, mm | Weight 1m, kg | Meters in 1 ton |

| Rectangular pipe 15x10 | 1,0 | 0,348 | 2873,6 |

| 1,5 | 0,488 | 2049,2 | |

| 2,0 | 0,605 | 1652,9 | |

| Rectangular pipe 20x10 | 1,0 | 0,426 | 2347,4 |

| 1,5 | 0,605 | 1652,9 | |

| 2,0 | 0,762 | 1312,3 | |

| Rectangular pipe 20x15 | 1,0 | 0,505 | 1980,2 |

| 1,5 | 0,723 | 1383,1 | |

| 2,0 | 0,919 | 1088,1 | |

| 2,5 | 1,090 | 917,4 | |

| Rectangular pipe 25x10 | 1,0 | 0,505 | 1980,2 |

| 1,5 | 0,723 | 1383,1 | |

| 2,0 | 0,919 | 1088,1 | |

| 2,5 | 1,090 | 917,4 | |

| Rectangular pipe 25x15 | 1,0 | 0,583 | 1715,3 |

| 1,5 | 0,841 | 1189,1 | |

| 2,0 | 1,080 | 925,9 | |

| 2,5 | 1,290 | 775,2 | |

| Rectangular pipe 30x10 | 1,0 | 0,583 | 1715,3 |

| 1,5 | 0,841 | 1189,1 | |

| 2,0 | 1,080 | 925,9 | |

| 2,5 | 1,290 | 775,2 | |

| 3,0 | 1,480 | 675,7 | |

| Rectangular pipe 30x15 | 1,0 | 0,661 | 1512,9 |

| 1,5 | 0,959 | 1042,8 | |

| 2,0 | 1,230 | 813,0 | |

| 2,5 | 1,480 | 675,7 | |

| 3,0 | 1,710 | 584,8 | |

| Rectangular pipe 30x20 | 1,0 | 0,740 | 1351,4 |

| 1,5 | 1,080 | 925,9 | |

| 2,0 | 1,390 | 719,4 | |

| 2,5 | 1,680 | 595,2 | |

| 3,0 | 1,950 | 512,8 | |

| Rectangular pipe 35x15 | 1,5 | 1,080 | 925,9 |

| 2,0 | 1,390 | 719,4 | |

| 2,5 | 1,680 | 595,2 | |

| 3,0 | 1,950 | 572,8 | |

| 3,5 | 2,200 | 454,5 | |

| Rectangular pipe 35x20 | 1,5 | 1,190 | 840,3 |

| 2,0 | 1,550 | 645,2 | |

| 2,5 | 1,880 | 531,9 | |

| 3,0 | 2,190 | 456,6 | |

| 3,5 | 2,470 | 404,9 | |

| Rectangular pipe 35x25 | 1,5 | 1,310 | 763,4 |

| 2,0 | 1,700 | 588,2 | |

| 2,5 | 2,070 | 483,1 | |

| 3,0 | 2,420 | 413,2 | |

| 3,5 | 2,750 | 363,6 | |

| Rectangular pipe 40x15 | 2,0 | 1,550 | 645,2 |

| 2,5 | 1,880 | 531,9 | |

| 3,0 | 2,190 | 456,6 | |

| 3,5 | 2,470 | 404,9 | |

| 4,0 | 2,730 | 336,3 | |

| Rectangular pipe 40x20 | 2,0 | 1,700 | 588,2 |

| 2,5 | 2,070 | 483,1 | |

| 3,0 | 2,420 | 413,2 | |

| 3,5 | 2,750 | 363,6 | |

| 4,0 | 3,050 | 327,9 | |

| Rectangular pipe 40x25 | 2,0 | 1,860 | 537,6 |

| 2,5 | 2,270 | 440,5 | |

| 3,0 | 2,660 | 375,9 | |

| 3,5 | 3,020 | 331,1 | |

| 4,0 | 3,360 | 297,6 | |

| Rectangular pipe 40x30 | 2,0 | 2,020 | 495,0 |

| 2,5 | 2,470 | 404,9 | |

| 3,0 | 2,890 | 346,0 | |

| 3,5 | 3,300 | 303,0 | |

| 4,0 | 3,680 | 271,7 | |

| Rectangular pipe (42)x20 | 2,0 | 1,770 | 565,0 |

| 2,5 | 2,150 | 465,1 | |

| 3,0 | 2,520 | 396,8 | |

| 3,5 | 2,860 | 349,6 | |

| 4,0 | 3,170 | 315,4 | |

| Rectangular pipe 45x20 | 2,0 | 1,860 | 537,6 |

| 2,5 | 2,270 | 440,5 | |

| 3,0 | 2,660 | 375,9 | |

| 3,5 | 3,020 | 331,1 | |

| 4,0 | 3,360 | 297,6 | |

| Rectangular pipe 45x30 | 2,0 | 2,170 | 460,8 |

| 2,5 | 2,660 | 375,9 | |

| 3,0 | 3,130 | 319,5 | |

| 3,5 | 3,570 | 280,1 | |

| 4,0 | 3,990 | 250,6 | |

| Rectangular pipe 50x25 | 2,0 | 2,170 | 460,8 |

| 2,5 | 2,660 | 375,9 | |

| 3,0 | 3,130 | 319,5 | |

| 3,5 | 3,570 | 280,1 | |

| 4,0 | 3,990 | 250,6 | |

| Rectangular pipe 50x30 | 2,0 | 2,320 | 431,0 |

| 2,5 | 2,860 | 349,6 | |

| 3,0 | 3,360 | 297,6 | |

| 3,5 | 3,850 | 259,7 | |

| 4,0 | 4,300 | 232,5 | |

| Rectangular pipe 50x35 | 2,0 | 2,490 | 401,6 |

| 2,5 | 3,090 | 323,6 | |

| 3,0 | 3,600 | 277,8 | |

| 3,5 | 4,120 | 242,7 | |

| 4,0 | 4,620 | 216,4 | |

| Rectangular pipe 50x40 | 2,0 | 2,650 | 377,3 |

| 2,5 | 3,250 | 307,7 | |

| 3,0 | 3,830 | 261,0 | |

| 3,5 | 4,390 | 227,8 | |

| 4,0 | 4,930 | 202,8 | |

| Rectangular pipe 60x25 | 2,5 | 3,050 | 327,9 |

| 3,0 | 3,600 | 277,8 | |

| 3,5 | 4,120 | 242,7 | |

| 4,0 | 4,620 | 216,4 | |

| 5,0 | 5,550 | 180,1 | |

| Rectangular pipe 60x30 | 2,5 | 3,250 | 307,7 |

| 3,0 | 3,830 | 261,0 | |

| 3,5 | 4,390 | 227,8 | |

| 4,0 | 4,930 | 202,8 | |

| 5,0 | 5,940 | 168,3 | |

| Rectangular pipe 60x40 | 3,0 | 4,300 | 232,5 |

| 3,5 | 4,940 | 202,4 | |

| 4,0 | 5,560 | 179,9 | |

| 5,0 | 6,730 | 148,6 | |

| Rectangular pipe 70x30 | 3,0 | 4,300 | 232,5 |

| 3,5 | 4,940 | 202,4 | |

| 4,0 | 5,560 | 179,9 | |

| 5,0 | 6,730 | 148,6 | |

| 6,0 | 7,800 | 128,2 | |

| Rectangular pipe 70x40 | 3,0 | 4,780 | 209,2 |

| 3,5 | 5,490 | 182,1 | |

| 4,0 | 6,190 | 161,6 | |

| 5,0 | 7,510 | 133,1 | |

| 6,0 | 8,750 | 114,2 | |

| Rectangular pipe 70x50 | 3,0 | 5,250 | 190,5 |

| 3,5 | 6,040 | 165,6 | |

| 4,0 | 6,820 | 146,6 | |

| 5,0 | 8,300 | 120,5 | |

| 6,0 | 9,690 | 103,2 | |

| Rectangular pipe 80x40 | 3,0 | 5,250 | 190,5 |

| 3,5 | 6,040 | 165,6 | |

| 4,0 | 6,820 | 146,6 | |

| 5,0 | 8,300 | 120,5 | |

| 6,0 | 9,690 | 103,1 | |

| 7,0 | 10,990 | 91,0 | |

| Rectangular pipe 80x50 | 3,0 | 5,720 | 174,8 |

| 3,5 | 6,590 | 151,7 | |

| 4,0 | 7,440 | 134,4 | |

| Rectangular pipe 80x60 | 3,5 | 7,140 | 140,0 |

| 4,0 | 8,070 | 123,9 | |

| 5,0 | 9,870 | 101,3 | |

| 6,0 | 11,570 | 86,4 | |

| 7,0 | 13,190 | 75,8 | |

| Rectangular pipe 90x40 | 3,5 | 6,590 | 151,7 |

| 4,0 | 7,440 | 134,4 | |

| 5,0 | 9,080 | 110,1 | |

| 6,0 | 10,630 | 94,1 | |

| 7,0 | 12,090 | 82,7 | |

| Rectangular pipe 90x60 | 4,0 | 8,700 | 114,9 |

| 5,0 | 10,650 | 93,9 | |

| 6,0 | 12,510 | 79,9 | |

| 7,0 | 14,290 | 70,0 | |

| Rectangular pipe 100x40 | 4,0 | 8,070 | 123,9 |

| 5,0 | 9,870 | 101,3 | |

| 6,0 | 11,570 | 86,4 | |

| 7,0 | 13,190 | 75,8 | |

| Rectangular pipe 100x50 | 4,0 | 8,700 | 114,9 |

| 5,0 | 10,650 | 93,9 | |

| 6,0 | 12,510 | 79,9 | |

| 7,0 | 14,290 | 70,0 | |

| Rectangular pipe 100x70 | 4,0 | 9,960 | 100,4 |

| 5,0 | 12,220 | 81,8 | |

| 6,0 | 14,400 | 69,4 | |

| 7,0 | 16,480 | 60,7 | |

| Rectangular pipe 110x40 | 4,0 | 8,700 | 114,9 |

| 5,0 | 10,650 | 93,9 | |

| 6,0 | 12,510 | 79,9 | |

| 7,0 | 14,290 | 70,0 | |

| Rectangular pipe 110x50 | 4,0 | 9,330 | 107,1 |

| 5,0 | 11,440 | 87,4 | |

| 6,0 | 13,460 | 74,3 | |

| 7,0 | 15,380 | 65,0 | |

| Rectangular pipe 110x60 | 4,0 | 9,960 | 100,4 |

| 5,0 | 12,220 | 81,8 | |

| 6,0 | 14,400 | 69,4 | |

| 7,0 | 16,480 | 60,7 | |

| Rectangular pipe 120x40 | 5,0 | 11,440 | 87,4 |

| 6,0 | 13,460 | 74,3 | |

| 7,0 | 15,380 | 65,0 | |

| 8,0 | 17,220 | 58,1 | |

| Rectangular pipe 120x60 | 5,0 | 13,000 | 76,9 |

| 6,0 | 15,340 | 65,2 | |

| 7,0 | 17,580 | 56,9 | |

| 8,0 | 19,730 | 50,7 | |

| Rectangular pipe 120x80 | 5,0 | 14,580 | 68,6 |

| 6,0 | 17,220 | 58,0 | |

| 7,0 | 19,780 | 50,5 | |

| 8,0 | 22,250 | 45,0 | |

| Rectangular pipe 140x60 | 5,0 | 14,580 | 68,6 |

| 6,0 | 17,220 | 58,0 | |

| 7,0 | 19,780 | 50,5 | |

| 8,0 | 22,250 | 44,9 | |

| Rectangular pipe 140x80 | 5,0 | 16,150 | 61,9 |

| 6,0 | 19,110 | 52,3 | |

| 7,0 | 21,980 | 45,5 | |

| 8,0 | 24,760 | 40,3 | |

| Rectangular pipe 140x120 | 6,0 | 22,880 | 43,7 |

| 7,0 | 26,370 | 37,9 | |

| 8,0 | 29,780 | 33,6 | |

| 9,0 | 33,100 | 30,2 | |

| Rectangular pipe 150x80 | 6,0 | 20,050 | 49,9 |

| 7,0 | 23,080 | 43,3 | |

| 8,0 | 26,010 | 38,4 | |

| 9,0 | 28,860 | 34,6 | |

| 10,0 | 31,620 | 31,6 | |

| Rectangular pipe 150x100 | 6,0 | 21,930 | 45,6 |

| 7,0 | 25,280 | 39,6 | |

| 8,0 | 28,530 | 35,0 | |

| 9,0 | 31,690 | 31,6 | |

| 10,0 | 34,760 | 28,8 | |

| Rectangular pipe 180x80 | 7,0 | 26,370 | 37,9 |

| 8,0 | 29,780 | 33,6 | |

| 9,0 | 33,100 | 30,2 | |

| 10,0 | 36,330 | 27,5 | |

| 12,0 | 42,520 | 23,5 | |

| Rectangular pipe 180x100 | 8,0 | 32,290 | 31,0 |

| 9,0 | 35,930 | 27,8 | |

| 10,0 | 39,470 | 25,3 | |

| 12,0 | 46,290 | 21,6 | |

| Rectangular pipe 180x150 | 8,0 | 38,570 | 25,9 |

| 9,0 | 42,990 | 23,3 | |

| 10,0 | 47,320 | 21,1 | |

| 12,0 | 55,710 | 17,9 |

Technical characteristics of steel water pipes

State VGP standards also concern such technical characteristics as length and weight.

According to GOST 3262 75, the length of the finished product can vary between 4-12 m

Taking this parameter into account, this type of product is divided into 2 categories:

- measured length or multiple of measured length - all products in the batch have the same size (a deviation of 10 cm is acceptable);

- unmeasured length - a batch may contain products of different lengths (from 2 to 12 m).

The cut of the product for water supply should be made at a right angle. An acceptable end bevel is a deviation of 2 degrees.

Special requirements apply to galvanized products. This zinc coating must be continuous with a thickness of at least 30 microns. There may be areas on the threads and ends of the finished product that are not coated with zinc. Places with bubble coating and various inclusions (oxides, hartzinc) are strictly prohibited - such products are considered defective.

Based on wall thickness, products are divided into 3 types:

- lungs;

- ordinary;

- reinforced.

Light pipes

A feature of lightweight pipes is their small wall thickness. Of all the possible varieties of VGP, light types of this high-quality rolled metal have the smallest thickness. This figure varies from 1.8 mm to 4 mm and directly depends on the outer diameter of the product.

The weight of 1 meter in this case is also characterized by the lowest values. Products with an outer diameter of 10.2 mm in quantities of 1 m weigh only 0.37 kg. Thin-walled products should be chosen if increased demands are placed on the object in terms of weight. However, water supply using such rolled metal has a limited scope of application. The liquid pressure in such pipes should be no more than 25 kg/sq.cm. When labeling, light weight products are designated with the letter “L”.

Ordinary pipes

Rolled metal of this type has an ordinary wall thickness. This figure varies between 2-4.5 mm. The main influence on this characteristic is the diameter of the product.

Ordinary steel pipes are considered the most common; they should be chosen in cases where there are no special requirements for laying a water supply system.

The list of advantages of this type of rolled metal includes:

- optimal weight - in comparison with thick-walled products, such products can reduce the total weight of the finished structure;

- the permissible pressure is the same as for thin-walled ones (25 kg/sq.m), however, water hammer is allowed here;

- average cost - achieved due to the weight indicator.

When marking, there is no special designation for an ordinary pipe. The letter designation is assigned only to lightweight and reinforced products.

Reinforced pipes

Products of this type include those steel pipes that have increased wall thickness - from 2.5 mm to 5.5 mm. The weight of such a finished structure will be very different from the weight category of a structure made from light or even ordinary products.

However, such water and gas systems also have an advantage - they are suitable for objects with high pressure (up to 32 kg/sq.cm). When marking such pipes, the designation “U” is used.

Threaded pipes

The quality of threaded steel pipes is controlled by GOST 6357 and must fully comply with accuracy class B.

To achieve high quality products, the thread must meet several important requirements:

- be clear and clean;

- The presence of burrs and flaws is not allowed;

- there may be a small amount of blackness on the threads (if the thread profile is reduced by no more than 15%);

- according to GOST, there may be torn or incomplete threads on the thread (their total length should not exceed 10% of the total);

- The gas supply pipe may have a thread whose useful length is reduced by 15%.

Advantages of profile pipes

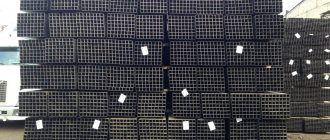

The profile category includes all pipes whose cross-sectional shape differs from round. The most widespread of the entire assortment are products with square and rectangular profiles, the dimensions of which correspond to 25, 60, 100, 40x80, 40x100, 50x50 mm.

Steel profile pipes with dimensions exceeding 100 mm are used primarily as structural elements. Such products, which have four stiffening ribs, are distinguished by high strength characteristics and low specific weight.

Rectangular profile pipes

Products with a 60 mm profile have excellent resistance to bending, which is why they are successfully used in construction and in the arrangement of various utilities.

Any profile pipes allow you not only to create complex steel structures with their help, but also to significantly save on the cost of expensive metal.

Among the advantages of profile pipes made of steel are the following.

- Their entire range is characterized by low metal consumption, which makes it possible to save up to 25% of metal even when constructing one construction project.

- When using such elements, construction projects are erected with high efficiency.

- The entire range of profile pipes produced by modern industry meets sanitary and hygienic requirements; the pipes are easy to maintain and disinfect.

- Such products also meet fire safety requirements.

- Even the most complex structures are installed with maximum efficiency when using these elements.

Profile pipe is widely used in many areas of production

About ESV galvanized

Among rolled metal products, galvanization occupies a special place. The scope of its application is extensive due to its special strength and reliability.

ESV 76.1×3 Polished

It will no longer be exposed to aggressive environmental influences, no matter where it is used. Such products are completely immune to high moisture, chemical environments and mechanical stress.

This product retains its properties in the most difficult conditions:

- under heavy wind load;

- when exposed to chemicals;

- at high humidity;

- under difficult climatic conditions.

An example of a heating system for a private house

The advantages of galvanized metal are a high degree of protection against ruptures and the longest service life.