Steel pipe range

Table 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||

| 1.0 mm | 1.2 mm | 1.4 mm | (1.5) mm | 1.6 mm | 1.8 mm | 2.0 mm | 2.2 mm | 2.5 mm | 2.8 mm | |

| ES 10 round pipe | 0.222 kg | 0.260 kg | * | * | * | * | * | * | * | * |

| Pipe ES 10.2 round | 0.227 kg | 0.266 kg | — | — | — | — | — | — | — | — |

| Pipe ES 12 round | 0.271 kg | 0.320 kg | 0,366 | 0,388 | 0,410 | — | — | — | — | — |

| Pipe ES 13 round | 0.296 kg | 0.349 kg | 0,401 | 0,425 | 0,450 | — | — | — | — | — |

| Pipe ES 14 round | 0.321 kg | 0.379 kg | 0,435 | 0,462 | 0,489 | — | — | — . | — | — |

| Pipe ES (15) round | 0.345 kg | 0.408 kg | 0.470 kg | 0.499 kg | 0,529 | — | — | — | — | — |

| Pipe ES 16 round | 0.370 kg | 0.438 kg | 0.504 kg | 0.536 kg | 0,568 | — | — | — | — | — |

| Pipe ES (17) round | 0.395 kg | 0.468 kg | 0.539 kg | 0.573 kg | 0,608 | — | — | — | — | — |

| Pipe ES 18 round | 0.419 kg | 0.497 kg | 0.573 kg | 0.6 10 kg | 0,719 | 0,789 | — | — | — | — |

| Pipe ES 19 round | 0.444 kg | 0.527 kg | 0.608 kg | 0.647 kg | 0,687 | 0,764 | 0.838 kg | — | — | — |

| Pipe ES 20 round | 0.469 kg | 0.556 kg | 0.642 kg | 0.684 kg | 0,726 | 0.808kg | 0.888 kg | — | — | — |

| Pipe ES 21.3 round | 0.501 kg | 0.595 kg | 0.687 kg | 0.732 kg | 0,777 | 0.866 kg | 0.952 kg | — | — | — |

| Pipe ES 22 round | 0.518 kg | 0.616 kg | 0.711 kg | 0.758 kg | 0,805 | 0.897 kg | 0.986 kg | — | — | — |

| Pipe ES (23) round | 0.543 kg | 0.645 kg | 0.746 kg | 0.795 kg | 0,844 | 0.941 kg | 1.04 kg | 1.13 kg | 1,26 | * |

| Pipe ES 24 round | 0.567 kg | 0.675 kg | 0.780 kg | 0.832 kg | 0,884 | 0.985 kg | 1.09 kg | 1.18 kg | 1,33 | — |

| Pipe ES 25 round | 0.592 kg | 0.704 kg | 0.815 kg | 0.869 kg | 0,923 | 1.03 kg | 1.13 kg | 1.24 kg | 1,39 | — |

| Pipe ES 26 round | 0.6 17 kg | 0.734 kg | 0.849 kg | 0.906 kg | 0,963 | 1.07 kg | 1.18 kg | 1.29 kg | 1.45 kg | — |

| Pipe ES 27 round | 0.641 kg | 0.764 kg | 0.884 kg | 0.943 kg | 1.00 kg | 1.12 kg | 1.23 kg | 1.35 kg | 1.51 kg | — |

| Pipe ES 28 round | 0.666 kg | 0.793 kg | 0.918 kg | 0.9 80 kg | 1.04 kg | 1.16 kg | 1.28 kg | 1.40 kg | 1.57 kg | — |

| Pipe ES 30 round | 0.715 kg | 0.852 kg | 0.987 kg | 1.05 kg | 1.12 kg | 1.25 kg | 1.38 kg | 1.51 kg | 1.70 kg | — |

| Pipe ES 32 round | 0.765 kg | 0.911 kg | 1.06 kg | 1.13 kg | 1.20 kg | 1.34 kg | 1.48 kg | 1.62 kg | 1.82 kg | 2.02 kg |

Assortment of steel pipes, steel pipe GOST 10704 Continuation of table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||

| 1.0 mm | 1.2 mm | 1.4 mm | (1.5) mm | 1.6 mm | 1.8 mm | 2.0 mm | 2.2 mm | 2.5 mm | 2.8 mm | |

| Pipe ES 33 round | 0,789 | 0.941 kg | 1.09 kg | 1.17 kg | 1.24 kg | 1,38 | 1.53 kg | 1.67 kg | 1.88 kg | 2.09 kg |

| Pipe ES 33.7 round | — | 0.962 kg | 1.12 kg | 1.19 kg | 1.27 kg | 1.42 kg | 1.56 kg | 1.71 kg | 1.92 kg | 2.13 kg |

| Pipe ES 35 round | — | 1.00 kg | 1.16 kg | 1.24 kg | 1,32 | 1.47 kg | 1.63 kg | 1.78 kg | 2.00 kg | 2.22 kg |

| Pipe ES 36 round | — | 1.03 kg | 1.19 kg | 1.28 kg | 1.36 kg | 1.52 kg | 1.68 kg | 1.83 kg | 2.07 kg | 2.29 kg |

| Pipe ES 38 round | — | 1.09 kg | 1.26 kg | 1.35 kg | 1.44 kg | 1.61 kg | 1.78 kg | 1.94 kg | 2.19 kg | 2.43 kg |

| Pipe ES 40 round | — | 1.15 kg | 1.33 kg | 1.42 kg | 1.52 kg | 1.70 kg | 1.87 kg | 2.05 kg | 2.31 kg | 2.57 kg |

| Pipe ES 42 round | — | 1.21 kg | 1.40 kg | 1.50 kg | 1.59 kg | 1.78 kg | 1.97 kg | 2.16 kg | 2.44 kg | 2.71 kg |

| Pipe ES 44.5 round | — | 1.28 kg | 1.49 kg | 1.59 kg | 1.69 kg | 1.90 kg | 2.10 kg | 2.29 kg | 2.59 kg | 2.88 kg |

| Pipe ES 45 round | — | 1.30 kg | 1.51 kg | 1.61 kg | 1.71 kg | 1.92 kg | 2.12 kg | 2,32 | 2.62 kg | 2.91 kg |

| Pipe ES 48 round | — | — | 1.61 kg | 1.72 kg | 1.83 kg | 2.05 kg | 2.27 kg | 2.48 kg | 2.81 kg | 3.12 kg |

| Pipe ES 48.3 round | — | — | 1.62 kg | 1.73 kg | 1.84 kg | 2.06 kg | 2.28 kg | 2.50 kg | 2.82 kg | 3.14 kg |

| Pipe ES 51 round | — | — | 1.71 kg | 1.83 kg | 1.95 kg | 2.18 kg | 2.42 kg | 2.65 kg | 2.99 kg | 3.33 kg |

| Pipe ES 53 round | — | — | 1.78 kg | 1.91 kg | 2.03 kg | 2.27 kg | 2.52 kg | 2.76 kg | 3.11 kg | 3.47 kg |

| Pipe ES 54 round | — | — | 1.82 kg | 1.94 kg | 2.07 kg | 2.32 kg | 2.56 kg | 2.81 kg | 3.18 kg | 3.54 kg |

| Pipe ES 57 round | — | — | 1.92 kg | 2.05 kg | 2.19 kg | 2.45 kg | 2.71 kg | 2.97 kg | 3.36 kg | 3.74 kg |

| ES 60 round pipe | — | — | 2.02 kg | 2.16 kg | 2.30 kg | 2,58 | 2.86 kg | 3.14 kg | 3,55 | 3.95 kg |

| Pipe ES 63.5 round | — | — | 2.14 kg | 2.29 kg | 2.44 kg | 2.74 kg | 3.03 kg | 3.33 kg | 3.76 kg | 4.19 kg |

| ES 70 round pipe | — | — | 2.37 kg | 2.53 kg | 2.70 kg | 3.03 kg | 3.35 kg | 3.68 kg | 4.16 kg | 4.64 kg |

Assortment of steel pipes, steel pipe GOST 10704 Continuation of table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||

| 1.4 mm | (1.5) mm | 1.6 mm | 1.8 mm | 2.0 mm | 2.2 mm | 2.5 mm | 2.8 mm | |

| Pipe ES 73 round | 2.47 kg | 2.64 kg | 2.82 kg | 3.16 kg | 3.50 kg | 3.84 kg | 4.35 kg | 4.85 kg |

| Pipe ES 76 round | 2.58 kg | 2.76 kg | 2.94 kg | 3.29 kg | 3.65 kg | 4.00 kg | 4.53 kg | 5.05 kg |

| ES 88 round pipe | — | — | 3.21 kg | 3.60 kg | 4.00 kg | 4.38 kg | 4.96 kg | 5.54 kg |

| ES 89 round pipe | — | — | 3.45 kg | 3.87 kg | 4.29 kg | 4.71 kg | 5.33 kg | 5.95 kg |

| Pipe ES 95 round | — | — | — | — | 4.59 kg | — | 5.70 kg | — |

| Pipe ES 102 round | * | — | — | 4.45 kg | 4.93 kg | 5.41 kg | 6.13 kg | 6.85 kg |

| ES 108 round pipe | — | — | — | 4.71 kg | 5.23 kg | 5.74 kg | 6.50 kg | 7.26 kg |

| Pipe ES 114 round | — | — | — | 4.98 kg | 5.52 kg | 6.07 kg | 6.87 kg | 7.68 kg |

| Pipe ES 127 round | — | — | — | 5.56 kg | 6.17 kg | 6.77 kg | 7.68 kg | 8.58 kg |

| Pipe ES 133 round | — | — | — | 5.82 kg | 6.46 kg | 7.10 kg | 8.05 kg | 8.99 kg |

| Pipe ES 140 round | — | — | — | 6.13 kg | 6.81 kg | 7.48 kg | 8.48 kg | 9.47 kg |

| Pipe ES 152 round | — | — | — | 6.67 kg | 7.40 kg | 8.13 kg | 9.22 kg | 10.30 kg |

| Pipe ES 159 round | — | — | — | 6.98 kg | 7.74 kg | 8.51 kg | 9.65 kg | 10.79 kg |

| Pipe ES 168 round | — | — | — | 7.38 kg | 8.19 kg | 9.00 kg | 10.20 kg | 11.41 kg |

| Pipe ES 177.8 round | — | — | — | 7.81 kg | 8.67 kg | 9.53 kg | 10.8 1 kg | 12.08 kg |

| Pipe ES 193.7 round | — | — | — | — | 9.46 kg | 10.39 kg | 11.79 kg | 13.18 kg |

| Pipe ES 219 round | — | — | — | — | — | — | 13.35 kg | 14.93 kg |

Assortment of steel pipes, steel pipe GOST 10704 Continuation of table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | ||

| 3.0 mm | 3.2 mm | 3.5 mm | |

| Pipe ES 26 round | — | — | * |

| Pipe ES 27 round | — | — | — |

| Pipe ES 28 round | — | — | — |

| Pipe ES 30 round | — | — | — |

| Pipe ES 32 round | 2.15 kg | — | — |

| Pipe ES 33 round | 2.22 kg | — | — |

| Pipe ES 33.7 round | 2.27 kg | — | — |

| Pipe ES 35 round | 2.37 kg | — | — |

| Pipe ES 36 round | 2.44 kg | — | — |

| Pipe ES 38 round | 2.59 kg | — | * |

| Pipe ES 40 round | 2.74 kg | — | — |

| Pipe ES 42 round | 2.89 kg | — | — |

| Pipe ES 44.5 round | 3.07 kg | — | — |

| Pipe ES 45 round | 3.11 kg | — | — |

| Pipe ES 48 round | 3.33 kg | 3.54 kg | 3.84 kg |

| Pipe ES 48.3 round | 3.35 kg | 3.56 kg | 3.87 kg |

| Pipe ES 51 round | 3.55 kg | 3.77 kg | 4.10 kg |

| Pipe ES 53 round | 3.70 kg | 3.93 kg | 4.27 kg |

| Pipe ES 54 round | 3.77 kg | 4.01 kg | 4.36 kg |

Assortment of steel pipes, steel pipe GOST 10704 Continuation of table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||||

| 3 mm | 3.2 mm | 3.5 mm | 3.8 mm | 4 mm | 4.5 mm | 5 mm | 5.5 mm | 6 mm | 7 mm | 8 mm | 9 mm | |

| Pipe ES 57 round | 4 kg | 4,25 | 4.62 kg | * | * | * | * | * | * | * | * | * |

| ES 60 round pipe | 4.22 kg | 4.48kg | 4.88 kg | 5.27 kg | — | — | — | — | — | — | — | — |

| Pipe ES 63.5 round | 4,48 | 4,76 | 5,18 | 5.59 kg | — | — | — | — | — | — | — | — |

| ES 70 round pipe | 4,96 | 5.27 kg | 5.74 kg | 6.2 kg | 6.51 kg | — | — | — | — | — | — | — |

| Pipe ES 73 round | 5.18 kg | 5.51 kg | 6 kg | 6,48 | 6.81 kg | — | — | — | — | — | — | — |

| Pipe ES 76 round | 5.40 kg | 5.75 kg | 6.26 kg | 6.26 kg | 7.1 kg | 7.93 kg | 8.75 kg | 9.56 kg | * | — | — | — |

| Pipe ES 83 round | 5.92 kg | 6.30 kg | 6.86 kg | 7.42 kg | 7.79 kg | 8.71 kg | 9.62 kg | 10.51 kg | — | — | — | — |

| ES 89 round pipe | 6.36 kg | 6.77 kg | 7.38 kg | 7.98 kg | 8.38 kg | 9.38 kg | 10.36 kg | 11.33 kg | — | — | — | — |

| Pipe ES 95 round | — | 7.24 kg | — | — | — | — | 11.10 kg | — | — | — | — | — |

| Pipe ES 102 round | 7.32 kg | 7.80 kg | 8.50 kg | 9.20 kg | 9.67 kg | 10.82 kg | 11.96 kg | 13.09 kg | — | — | — | — |

| ES 108 round pipe | 7.77 kg | 8.27 kg | 9.02 kg | 9.76 kg | 10.26 kg | 11.49 kg | 12.70 kg | 13.90 kg | — | — | — | — |

| Pipe ES 114 round | 8.21 kg | 8.74 kg | 9.54 kg | 10.33 kg | 10.85 kg | 12.15 kg | 13.44 kg | 14.72 kg | — | — | — | — |

| Pipe ES 127 round | 9.17 kg | 9.77 kg | 10.66 kg | 11.55 kg | 12.13 kg | 13.59 kg | 15.04 kg | 16.48 kg | — | — | — | — |

| Pipe ES 133 round | 9.62 kg | 10.24 kg | 11.18 kg | 12.11 kg | 12.73 kg | 14.26 kg | 15.78 kg | 17.29 kg | — | — | — | — |

| Pipe ES 140 round | 10.14 kg | 10.80 kg | 11.78 kg | 12.76 kg | 13.42 kg | 15.04 kg | 16.65 kg | 18.24 kg | — | — | — | — |

| Pipe ES 152 round | 11.02 kg | 11.74 kg | 12.82 kg | 13.89 kg | 14.60 kg | 16.37 kg | 18.13 kg | 19.87 kg | — | — | — | — |

| Pipe ES 159 round | 11.54 kg | 12.30 kg | 13.42 kg | 14.52 kg | 15.29 kg | 17.15 kg | 18.99 kg | 20.82 kg | 22.64 kg | 26.24 kg | 26.24 kg | — |

| Pipe ES 168 round | 12.21 kg | 13.01 kg | 1 4.20 kg | 15.39 kg | 16, 18 kg | 18.14 kg | 20.10 kg | 22.04 kg | 23.97 kg | 27.79 kg | 31.57 kg | — |

| Pipe ES 177.8 round | 12.93 kg | 13.78 kg | 15.04 kg | 16.31 kg | 17.14 kg | 19.23 kg | 21.31 kg | 23.37 kg | 25.42 kg | 29.49 kg | 33.50 kg | — |

| Pipe ES 180 round | — | — | — | — | 17.36 kg | — | 21.58 kg | — | — | — | — | — |

| Pipe ES 193.7 round | 14.11 kg | 15.03 kg | 16.42 kg | 17.80 kg | 18.71 kg | 21.00 kg | 23.27 kg | 25.53 kg | 27.77 kg | 32.23 kg | 36.64 kg | — |

| Pipe ES 219 round | 15.98 kg | 17.03 kg | 18.60 kg | 20.17 kg | 21.21 kg | 23.80 kg | 26.39 kg | 28.96 kg | 31.52 kg | 36.60 kg | 41.63 kg | 46.61 kg |

| Pipe ES 244.5 round | 17.87 kg | 19.04 kg | 20.80 kg | 22.56 kg | 23.72 kg | 26.63 kg | 29.53 kg | 32.42 kg | 35.42 kg | 41.00 kg | 46.66 kg | 52.27 kg |

| Pipe ES 273 round | — | — | 23.26 kg | 25.23 kg | 26.54 kg | 29.80 kg | 23.05 kg | 36.28 kg | 39.51 kg | 45.92 kg | 52.28 kg | 58.60 kg |

Assortment of steel pipes, steel pipe GOST 10704 Continuation of table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||

| 4.0 mm | 4.5 mm | 5.0 mm | 5.5 mm | 6.0 mm | 7.0 mm | 8.0 mm | 9.0 mm | |

| ES 325 round pipe | 31.67 kg | 35.57 kg | 39.46 kg | 43.34 kg | 47.2 kg | 54.90 kg | 62.54 kg | 70.14 kg |

| Pipe ES 355.6 round | 34.68 kg | 38.96 kg | 43.23 kg | 47.49 kg | 51.73 kg | 60.18 kg | 68.58 kg | 76.93 kg |

| Pipe ES 377 round | 36.79 kg | 41.34 kg | 45.87 kg | 50.39 kg | 54.90 kg | 63.87 kg | 72.80 kg | 81.68 kg |

| Pipe ES 406.4 round | 39.70 kg | 44.60 kg | 49.50 kg | 54.38 kg | 59.25 kg | 68.95 kg | 78.60 kg | 88.20 kg |

| Round pipe ES 426 | 41.63 kg | 46.78 kg | 51.91 kg | 57.04 kg | 62.15 kg | 72.33 kg | 82.47 kg | 92.55 kg |

| Pipe ES (478) round | — | — | 58.32 kg | 64.09 kg | 69.84 kg | 81.31 kg | 92.73 kg | 104.10 kg |

| ES 530 round pipe | — | — | 64.74 kg | 71.14 kg | 77.54 kg | 90.29 kg | 102.99 kg | 115.64 kg |

| ES 630 round pipe | — | — | — | — | — | 107.55 kg | 122.72 kg | 137.83 kg |

| ES 720 round pipe | — | — | — | — | — | 123.09 kg | 140.47 kg | 157.81 kg |

| ES 820 round pipe | — | — | — | — | — | 140.35 kg | 160.20 kg | 180.00 kg |

| ES 920 round pipe | — | — | — | — | — | 157.61 kg | 179.93 kg | 202.20 kg |

| Round pipe ES 1020 | — | — | — | — | — | — | 199.66 kg | 224.39 kg |

| Round pipe ES 1120 | — | — | — | — | — | — | 219.39 kg | 246.59 kg |

| Round pipe ES 1220 | — | — | — | — | — | — | — | 268.79 kg |

Assortment of steel pipes, steel pipe GOST 10704 Continuation of table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | ||||||||||

| 10 mm | 11 mm | 12 mm | 13 mm | 14 mm | 16 mm | (17) mm | 17.5 mm | 18 mm | 19 mm | 20 mm | |

| Pipe ES 355.6 round | 85.23 kg | — | — | — | — | — | — | — | — | — | — |

| Pipe ES 377 round | 90.51 kg | — | — | — | — | — | — | — | — | — | — |

| Pipe ES 406.4 round | 97.76 kg | 107.26 kg | 116.72 kg | — | — | — | — | — | — | — | — |

| Round pipe ES 426 | 102.59 kg | 112.58 kg | 122.52 kg | — | — | — | — | — | — | — | — |

| Pipe ES (478) round | 115.42 kg | 126.69 kg | 137.91 kg | — | — | — | — | — | — | — | — |

| ES 530 round pipe | 128.24 kg | 140.79 kg | 153.30 kg | 165.75 kg | 178.15 kg | 202.82 kg | 215.07 kg | 221.18 kg | 227.28 kg | 239.44 kg | 251.55 kg |

| ES 630 round pipe | 152.90 kg | 167.92 kg | 182.89 kg | 197.81 kg | 212.6 kg | 242.27 kg | 257.00 kg | 264.34 kg | 271.67 kg | 286.30 kg | 300.87 kg |

| ES 720 round pipe | 175.10 kg | 192.33 kg | 209.52 kg | 226.66 kg | 243.75 kg | 277.79 kg | 294.73 kg | 303.18 kg | 311.62 kg | 328.47 kg | 345.26 kg |

| ES 820 round pipe | 1 99.76 kg | 219.46 kg | 239.12 kg | 258.72 kg | 278.28 kg | 317.25 kg | 336.65 kg | 346.34 kg | 356.01 kg | 375.32 kg | 394.58 kg |

| ES 920 round pipe | 224.42 kg | 246.59 kg | 268.71 kg | 290.78 kg | 312.81 kg | 356.7 kg | 378.58 kg | 389.5 kg | 400.4 kg | 422.18 kg | 443.91 kg |

| Round pipe ES 1020 | 249.08 kg | 273.72 kg | 298.31 kg | 322.84 kg | 347.33 kg | 396.16 kg | 420.50 kg | 432.65 kg | 444.79 kg | 469.04 kg | 493.23 kg |

| Round pipe ES 1120 | 273.74 kg | 300.85 kg | 327.90 kg | 354.90 kg | 381.86 kg | 435.62 kg | 462.43 kg | 475.81 kg | 481.19 kg | 515.89 kg | 542.55 kg |

| Round pipe ES 1220 | 298.40 kg | 327.97 kg | 357.49 kg | 386.96 kg | 416.38 kg | 475.08 kg | 504.35 kg | 518.97 kg | 533.58 kg | 562.75 kg | 591.88 kg |

| Round pipe ES 1420 | 347.73 kg | 382.23 kg | 416.68 kg | 451.08 kg | 485.44 kg | 554.00 kg | 588.20 kg | 605.29 kg | 622.36 kg | 656.46 kg | 690.52 kg |

Assortment of steel pipes, steel pipe GOST 10704 Continuation of table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||||

| 21 mm | 22 mm | 23 mm | 24 mm | 25 mm | 26 mm | 27 mm | 28 mm | 29 mm | 30 mm | 31 mm | 32 mm | |

| ES 530 round pipe | 263.61 kg | 275.62 kg | 287.58 kg | 299.49 kg | — | — | — | — | — | — | * | — |

| ES 720 round pipe | 362.01 kg | 378.70 kg | 395.35 kg | 411.95 kg | 411.95 kg | 428.49 kg | 444.99 kg | 461.44 kg | 477.84 kg | 510.49 kg | — | — |

| ES 820 round pipe | 413.79 kg | 432.96 kg | 452.07 kg | 471.13 kg | 490.15 kg | 509.11 kg | 528.03 kg | 546.89 kg | 565.71 kg | 584.4 8 kg | — | — |

| Round pipe ES 1020 | 517.37 kg | 541.47 kg | 565.51 kg | 589.51 kg | 613.45 kg | 637.35 kg | 661.20 kg | 685.00 kg | 708.75 kg | 732.45 kg | 756.10 kg | 779.70 kg |

Polyethylene

Advantages and disadvantages

Absolute resistance to corrosion and the ability to live happily in aggressive environments are on the same scale. On the other is the low operating temperature (up to 40 C) and the fact that compression fittings do not provide great mechanical strength to the connection, and welding still requires special equipment.

Standards and sizes

The range of round polyethylene pipes according to GOST 18559-83 is as follows (mm):

| Average outer diameter | Wall thickness of low-density polyethylene pipes, types | ||

| Prev. off | |||

| Prev. off | Prev. off | Prev. off | Prev. off |

The material for large diameter pressure pipes is HDPE, low pressure polyethylene. The range of round LDPE pipes is specified separately:

| Average outer diameter | Wall Thickness of HDPE Pipe Types | |||

| Prev. off | Prev. off | Prev. off | Prev. off | Prev. off |

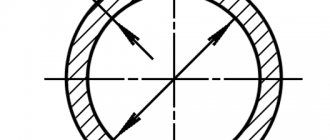

Steel pipe diameter

The diameter of the steel pipe is determined by:

- — external diameter for electric-welded and seamless pipes;

- — nominal diameter for VGP pipes.

- — Nominal diameter (DN or Dу) — internal diameter of pipes.

- — Conditional bore is a conditional value representing the value of the actual internal diatreme, rounded to the nearest standard range, and serves as a reference point for selecting the dimensions of other parts and equipment. Its value is standardized according to GOST 28338-89. Measured in inches or mm.

- — Internal diameter - the actual value of the parameter obtained by direct measurement, as a rule, indicated in mm;

- - Outer diameter of pipes (Dn or Dn) - the actual diameter of the pipe taking into account the wall thickness, indicated in mm;.

- — Thread diameter (G).

Pipe sizes are indicated in millimeters, but for VGP pipes they are often indicated in inches (“”).

Methods for producing steel pipes

Metallurgical plants use 4 main technologies in the production of pipes:

Seamless pipes are pipes that do not have a weld or other joints. Manufactured by rolling, forging, pressing or drawing:

- Cold rolling is the production of seamless pipes from pre-cooled billets.

- Hot rolling - production of seamless pipes from heated billets;

Welded pipes are divided into:

- Welded spiral rolled pipes - pipes produced using this technology are characterized by the presence of a spiral seam. Steel sheets are used as blanks.

- Welded longitudinal bars . The starting material is the same sheet blanks. Distinctive features are the presence of a longitudinal straight seam.

The use of these methods makes it possible to produce steel pipes of any type, from round “plumbing” pipes used in water supply, including oval and thick-walled ones, to “structural” pipes - square and rectangular. The peculiarities of the technological processes used impose a number of restrictions on the standard sizes of rolled pipes.

Characteristics and classification

The rolled metal product is used in many industrial and construction sectors: from large factories to pipelines in a private home. Therefore, the range of round steel pipes

according to GOST 10704 91 it is so large.

The thickness of the pipe walls varies depending on the application of the product. If we are talking about the necessary strength and resistance to pressure changes, then the choice is made in favor of thickening the walls.

Based on the type of coating, steel pipes are divided into untreated (uncoated) and treated (galvanized, chrome-plated). Coating the product with zinc provides high anti-corrosion resistance, which increases the service life of the product. Treating a steel pipe with chrome has only a decorative function; this method is often used in furniture and interior design.

According to the manufacturing method, round steel pipe according to GOST

is divided into straight-seam welding of the first type, spiral-seam welding of the second type and straight-seam welding of the third type. These categories of pipes refer to welded products. Due to their low resistance to pressure drop, they are used in areas with low pressure.

Pipe section shape

What about our form?

Pipes according to their cross-sectional shape can be divided into:

- Round;

- Oval;

- Flat oval;

- Rectangular.

Oval and flat-oval pipes are in demand not only in decorative structures, but also in the production of various liquid cooling systems: an oval pipe with the same cross-sectional area has a much larger surface area compared to a round one.

Square ones have another important difference from round ones: they are much stronger in bending. That is why they have found their application primarily in a variety of load-bearing metal structures.

Please note: profile pipes - square and rectangular - are not only resistant to bending, they are also convenient to install due to their flat surfaces, requiring minimal adjustment. They are often assembled with bolts, without welding.

Oval

The range of oval steel pipes is taken from GOST 8642-68: overall dimensions from 6x3 millimeters to 90x32 and 85x50; wall thickness - 0.5 - 2.5 mm.

Square

And here all sizes are set by the standard. According to GOST 8639-82, square steel pipes are as follows:

| External dimension in mm | Wall thickness in mm |

| 10 | 1 |

| 15 | 1 |

| 1,5 | |

| 20 | 1 |

| 1,5 | |

| 2 | |

| 25 | 1 |

| 1,5 | |

| 2 | |

| 2,5 | |

| 3 | |

| 30 | 2 |

| 2,5 | |

| 3 | |

| 3,5 | |

| 4 | |

| 35 | 2 |

| 2,5 | |

| 3 | |

| 3,5 | |

| 4 | |

| 5 | |

| 40 | 2 |

| 2,5 | |

| 3 | |

| 3,5 | |

| 4 | |

| 5 | |

| 6 | |

| 42 | 3 |

| 3,5 | |

| 4 | |

| 5 | |

| 6 | |

| 45 | 3 |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 50 | 3 |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 60 | 3 |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 70 | 4 |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 80 | 4 |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 90 | 5 |

| 6 | |

| 7 | |

| 8 | |

| 100 | 6 |

| 7 | |

| 8 | |

| 9 | |

| 110 | 6 |

| 7 | |

| 8 | |

| 9 | |

| 120 | 6 |

| 7 | |

| 8 | |

| 9 | |

| 140 | 6 |

| 7 | |

| 8 | |

| 9 | |

| 150 | 7 |

| 8 | |

| 9 | |

| 10 | |

| 180 | 8 |

| 9 | |

| 10 | |

| 12 | |

| 14 |

Rectangular

Most often, rectangular pipes according to the production method are straight-seam electric welded. The seam is clearly visible here

According to GOST 8645 82 rectangular steel pipes have the following assortment:

| Pipe sides in mm | Wall thickness in mm |

| 15 10 | |

| 20 10 | |

| 20 15 | |

| 25 10 | |

| 25 15 | |

| 30 10 | |

| 30 15 | |

| 30 20 | |

| 35 15 | 1.5; 2; 2.5; 3; 3.5 |

| 35 20 | 1.5; 2; 2.5; 3; 3.5 |

| 35 25 | 1.5; 2; 2.5; 3; 3.5 |

| 40 15 | |

| 40 20 | |

| 40 25 | |

| 40 30 | |

| 42 20 | |

| 42 30 | |

| 45 20 | |

| 45 30 | |

| 50 25 | |

| 50 30 | |

| 50 35 | |

| 50 40 | |

| 60 25 | 2.5; 3; 3.5; 4; 5 |

| 60 30 | 2.5; 3; 3.5; 4; 5 |

| 60 40 | |

| 70 30 | |

| 70 40 | |

| 70 50 | |

| 80 40 | |

| 80 50 | |

| 80 60 | 3.5; 4; 5; 6; 7 |

| 90 40 | 3.5; 4; 5; 6; 7 |

| 90 60 | |

| 100x40 | |

| 100 50 | |

| 100 70 | |

| 110 40 | |

| 110 50 | |

| 110 60 | |

| 120 40 | |

| 120 60 | |

| 120 80 | |

| 140 60 | |

| 140 80 | |

| 140 120 | |

| 150 80 | |

| 150 100 | |

| 180 80 | |

| 180 100 | |

| 180 150 |

The full range of rectangular steel pipes also includes non-standard sizes:

It is curious that standard 8645-68 specifies a slightly different range of steel rectangular pipes

. The differences are minor, but the list of special sizes includes pipes up to 230x100.

Standard sizes of seamless steel pipes

Pipes belonging to this class are produced absolutely smooth, without traces of any joints. Their purpose is to move highly toxic liquids, lay oil pipelines, gas networks and heating systems. That is, first of all, seamless pipes are used if it is necessary to completely eliminate the possibility of leakage and ensure maximum tightness. Depending on the production method, hot-rolled and cold-rolled seamless pipes are distinguished.

Range of hot rolled pipes

Pipes made by hot rolling have a special wall thickness, due to which a pipeline made from such products can withstand very high pressure.

According to GOST 8732-78, the outer diameter is used to measure hot-rolled pipes, which can vary from 25 to 550 mm, the maximum pipe wall thickness is 75 mm.

The limit on the measured length of pipes is 4 - 12.5 m. A pipe of unmeasured length is also rolled within these parameters.

Range of cold rolled pipes

The minimum outer diameter of a cold-deformed pipe, according to GOST 8734-75, can be 5 mm, the maximum - 250. The pipe wall can be from 0.3 to 24 mm.

Thin-walled cold-rolled pipes are considered to be those with a ratio of outer diameter to wall thickness of 12.5 to 40 mm, as well as with an outer diameter of 20 mm and a pipe wall of 1.5 mm. Thick-walled cold-deformed pipes have a ratio from 6 to 12.5 mm, especially thick-walled ones - 6 mm or less, and especially thin-walled ones - more than 40, or with a wall thickness of 0.5 mm or less with a diameter of 20 mm. The thinner the wall, the higher the flexibility of the pipeline and its bending strength.

Elements of measured length are produced from 4.5 to 9 m, unmeasured - from 1.5 to 11.5 m.

Range of steel water and gas pipes

Water and gas pipes are a type of welded pipe products, the main difference of which is the high reliability of the weld, verified by non-destructive testing methods. These metal products are intended for the installation of water, gas, and heat supply networks. Can be used in distribution and main pipelines. Capable of withstanding high pressures of transmitted media. The range (diameter, wall thickness) of steel water and gas pipes (WGP) is regulated by GOST 3262-75. The marking of these pipe products indicates the nominal bore (DN) and wall thickness.

Table of sizes and weights of steel water and gas pipes

| Du, mm | Wall thickness, mm | Weight 1 m, kg |

| 15 | 2,8 | 1,28 |

| 20 | 2,8 | 1,66 |

| 32 | 3,2 | 3,09 |

| 40 | 3,5 | 3,84 |

| 50 | 3,5 | 4,88 |

| 100 | 4,5 | 12,15 |

Advantages and disadvantages

As already mentioned, the main disadvantage of black steel is its susceptibility to corrosion. Unfortunately, this material has been used in residential water systems for many years; The consequences will take a long time to resolve.

Galvanizing does not have this problem.

Tip: when installing galvanized water pipes, do not forget to protect the threads with paint. The zinc coating is thin, exposing corroding steel in the grooves of the threads.

But galvanizing is a different matter.

However, both pipes are quite difficult to install - either by welding or by welding. In addition, the electrical conductivity of the material should also be considered a disadvantage: the number of electric shocks through the water supply is very high.

Standards and sizes

The water and gas pipeline, or more simply, the VGP pipe, has the assortment as prescribed by the standards. Let's turn to the regulatory documents: before us is GOST 3262-75.

| Conditional pass | Outside diameter | Pipe wall thickness | Weight of 1 m of pipes, kg |

| ordinary | reinforced | ordinary | reinforced |

The size table is valid for both galvanized pipes and pipes without anti-corrosion coating. As we can see, the range of VGP pipes ends at a diameter of 150 mm.

However, in addition to intra-house utility networks, there are also highways. Pipes for them are seamless hot-deformed steel pipes GOST 8732-78, having dimensions of 20-550 mm with a wall thickness of 2.5-75 millimeters; however, the pipe range is not limited to them - there are also cold-formed pipes GOST 8734-75.

Their diameters are 5 - 250 millimeters, wall thickness - 0.3 - 24 mm. Of course, small-diameter pipes are not used for heating mains and water supply to neighborhoods and microdistricts.

Pipe range, materials and applications

The topic of this article is what pipes you can buy and where to use them. Let’s clarify right away: we will not touch upon decorative structures and furniture frames.

We are interested in water and gas pipelines, and if so, the range of round pipes associated with them.

What are highways, water pipelines and gas supply systems made of now? Let's consider the most popular materials.

We will not encroach on global research: we will not touch on exotics such as copper, stainless steel or cast iron.

- Black steel. Its use is only meaningful in gas pipelines. There is only one reason: corrosion;

- Galvanized steel. Beautiful and durable material, protected from rust by zinc coating. The only disadvantages that can be written down are the relatively labor-intensive installation by welding or threaded connections;

- Metal-polymer pipes. Their areas of application are water supply systems, hot and cold. The limitation on operating temperature will not allow the use of metal-polymer pipes for the manufacture of heating mains, and the method of assembling connections affects the maximum diameter. If so, you won’t see metal-plastic in cold water mains either;

- Polyethylene. Only cold water and gas; but any size. large diameters have been successfully used for water supply mains in many countries for several decades;

- Polypropylene. It is successfully used in all indoor water supply systems for both hot and cold water. It is also used for cold water mains; but the route to the heating mains is closed. Again, there is a temperature limit.

In this order we will move forward.

Electric-welded pipes: range and technical characteristics

Electric-welded tubular products of round cross-section are metal products in demand for the transmission of liquid and gaseous media, in construction, for the creation of welded and prefabricated metal structures for various purposes. Available in spiral and straight seam. The assortment complies with GOST 10704-91.

Table of diameters, thicknesses and weights of electric-welded metal pipes according to GOST 10704-91

| Outer diameter, mm | Wall thickness, mm | Weight 1 m, kg | Outer diameter, mm | Wall thickness, mm | Weight 1 m, kg |

| 16 | 1,5 | 0,54 | 89 | 3,5 | 7,38 |

| 18 | 1,5 | 0,61 | 89 | 4 | 8,38 |

| 20 | 1,5 | 0,68 | 102 | 4 | 9,67 |

| 25 | 1,5 | 0,87 | 108 | 3,5 | 9,02 |

| 26 | 2 | 1,18 | 108 | 4 | 10,26 |

| 32 | 1,5 | 1,13 | 114 | 4 | 10,85 |

| 32 | 2 | 1,48 | 127 | 4 | 12,13 |

| 40 | 1,5 | 1,42 | 133 | 4 | 12,73 |

| 42 | 3 | 2,89 | 133 | 5 | 14,26 |

| 45 | 1,5 | 1,61 | 159 | 4 | 15,29 |

| 45 | 2 | 2,12 | 159 | 4,5 | 17,15 |

| 48 | 1,5 | 1,72 | 159 | 5 | 18,99 |

| 48 | 2 | 2,27 | 159 | 6 | 22,64 |

| 51 | 3 | 3,55 | 219 | 5 | 26,39 |

| 57 | 2,5 | 2,97 | 219 | 6 | 31,52 |

| 57 | 3 | 4,00 | 219 | 8 | 41,63 |

| 57 | 3,5 | 4,62 | 273 | 8 | 52,28 |

| 76 | 3 | 5,4 | 426 | 10 | 102,59 |

| 76 | 3,5 | 6,26 | 1020 | 12 | 298,31 |

| 89 | 3 | 6,36 |

Division into classes

Conventionally, pipe products are divided into the following classes:

- Class 1 pipes can be used for gaseous and liquid media in irrigation systems. In addition, it is possible to manufacture fencing structures or supports from such products.

- Class 2 pipes can be used in pipelines operating at low and high pressure, transporting oil and petroleum products, gas or water.

- Class 3 pipes are suitable for work at high temperatures.

- Class 4 includes thick-walled drill pipes that can resist strong torsion.

- Class 5 pipes are used in the construction of carriages, cars, overhead cranes, drilling rigs and some furniture structures.

- Class 6 pipes are used in the engineering industry as blanks from which bearings, cylinders, pumps and receivers are produced.

standards for rectangular, round, seamless products, GOST 8645 82

In the article we will look at the main types of steel pipes currently produced, the regulatory documents regulating production and find out what the range of different types of steel pipes can be.

Production methods

According to the manufacturing method, pipes are distinguished:

- Electric welded with straight seam;

- Electric welded with a spiral seam;

- Seamless hot-formed;

- Seamless cold-deformed.

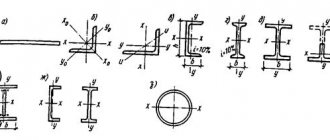

Steel pipes differ not only in size, but also in profile

Electric-welded straight-seam

These steel pipes are assorted according to GOST 10704-91: the outer diameter of the pipe is from 10 to 1420 millimeters with a wall thickness from 1 to 32 mm.

In addition to dimensions, the standard regulates maximum permissible deviations:

| Outer diameter of pipes, mm | Limit deviations in outer diameter with precision manufacturing | |

| ordinary | increased | |

| 10 | ±0.2 mm | ¾ |

| 10 — 30 | ±0.3 mm | ±0.25 mm |

| 30 — 51 | ±0.4 mm | ±0.35 mm |

| 51 — 193,7 | ±0,8 % | ±0,7 % |

| 193,7 — 426 | ±0,75 % | ±0,65 % |

| 426 — 1020 | ±0,7 % | ±0,65 % |

| up to 1020 | ±0,6% | ±6.0 mm |

It is allowed to exceed the size of the measuring pipe:

| Pipe length, m | Maximum deviations along the length of measuring pipes, mm, classes | |

| I | II | |

| Until 6 | +10 | +50 |

| Over 6 | +15 | +70 |

In addition to dimensions, the standard establishes the degree of ovality of the pipe and the uniformity of its wall thickness.

The cheapest to produce and most common pipes

Electric welded with spiral seam

The range of spiral welded steel round pipes is specified among other requirements in Standard 8696-74.

The full list of possible sizes looks like this:

| Outer diameter in mm | Linear density of pipes in kg/m with wall thickness, mm | |||||||||||

| 3,5 | 4,0 | 5,0 | 6,0 | 7,0 | 8,0 | 9,0 | 10,0 | 11,0 | 12,0 | 13,0 | 14,0 | |

| 159 | 13,62 | 15,52 | — | — | — | — | — | — | — | — | ||

| 219 | — | 21,53 | 26,79 | — | — | — | — | — | — | — | — | — |

| 273 | — | 26,94 | 33,55 | — | — | — | — | — | — | — | — | — |

| 325 | — | 32,15 | 40,05 | 47,91 | — | — | — | — | — | — | — | — |

| 377 | — | 37,35 | 46,56 | 55,72 | — | — | — | — | — | — | — | — |

| 426 | — | 42,25 | 52,69 | 63,05 | 73,41 | 83,70 | — | — | — | — | — | — |

| 480 | — | 47,66 | 59,45 | 71,18 | 82,87 | 94,51 | — | — | — | — | — | — |

| 530 | — | 52,66 | 65,70 | 78,69 | 91,63 | 104,5 | 117,4 | — | — | — | — | — |

| 630 | — | — | 78,22 | 93,71 | 109,1 | 124,5 | 139,9 | 155,2 | — | — | — | — |

| 720 | — | — | 89,48 | 107,2 | 124,9 | 142,6 | 160,2 | 177,7 | 195,2 | 212,6 | — | — |

| 820 | — | — | 102,0 | 122,3 | 142,4 | 162,6 | 182,7 | 202,7 | 122,7 | 242,7 | — | — |

| 920 | — | — | — | — | — | 182,6 | 205,2 | 227,8 | 250,3 | 272,7 | — | — |

| 1020 | — | -. | — | 152,3 | 177,5 | 202,6 | 227,7 | 252,8 | 277,8 | 302,8 | — | — |

| 1220 | — | — | — | — | 212,5 | 242,7 | 272,8 | 302,9 | 332,9 | 362,9 | — | — |

| 1420 | — | — | — | — | — | 282,7 | 317,8 | 352,9 | 388,0 | 422,9 | 457,9 | 492,7 |

| 1620 | — | — | — | — | — | — | — | — | — | — | — | — |

| 1720 | — | — | — | — | — | — | — | — | — | — | — | — |

| 1820 | — | — | — | — | — | — | — | — | — | — | — | — |

| 2020 | — | — | — | — | — | — | — | — | — | — | — | — |

| 2220 | — | — | — | — | — | — | — | — | — | — | — | — |

| 2520 | — | — | — | — | — | — | — | — | — | — | — | — |

| Outer diameter in mm | Linear density of pipes in kg/m with wall thickness, mm | |||||||||||

| 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | ||

| 159 | — | — | — | — | — | — | — | — | — | — | — | |

| 219 | — | — | — | — | — | — | — | — | — | — | — | |

| 273 | — | — | — | — | — | — | — | — | — | — | — | |

| 325 | — | — | — | — | — | — | — | — | — | — | — | |

| 377 | — | — | — | — | — | — | — | — | — | — | — | |

| 426 | — | — | — | — | — | — | — | — | — | — | — | |

| 480 | — | — | — | — | — | — | — | — | — | — | — | |

| 530 | — | — | — | — | — | — | — | — | — | — | — | |

| 630 | — | — | — | — | — | — | — | — | — | — | — | |

| 720 | — | — | — | — | — | — | — | — | — | — | — | |

| 820 | — | — | — | — | — | — | — | — | — | — | — | |

| 920 | — | — | — | — | — | — | — | — | — | — | — | |

| 1020 | — | — | — | — | — | — | — | — | — | — | — | |

| 1220 | — | — | — | — | — | — | — | — | — | — | — | |

| 1420 | 527,5 | 562,3 | 597,0 | 631,6 | 666,3 | 700,8 | 735,4 | — | — | — | — | |

| 1620 | 602,6 | 642,6 | 682,1 | 721,8 | 761,4 | 801,0 | 840,5 | 880,0 | 919,4 | — | — | |

| 1720 | 640,1 | 682,4 | 724,6 | 766,8 | 808,9 | 851,0 | 893,0 | 935,0 | 976,9 | — | — | |

| 1820 | 677,7 | 722,5 | 767,2 | 811,9 | 856,5 | 901,1 | 945,6 | 990,1 | 1034,5 | 1078,8 | — | |

| 2020 | 752,8 | 802,6 | 852,3 | 902,0 | 951,6 | 1001,2 | 1050,7 | 1100,2 | 1149,6 | 1199,0 | 1248,4 | |

| 2220 | 827,9 | 882,6 | 973,4 | 992,1 | 1046,7 | 1101,3 | 1155,9 | 1210,3 | 1264,8 | 1319,2 | 1373,5 | |

| 2520 | 940,5 | 1002,8 | 1065,1 | 1127,2 | 1189,4 | 1251,5 | 1313,5 | 1375,5 | 1437,5 | 1499,4 | 1561,2 |

Important: the assortment does not include main (oil and gas) steel pipes. There is a separate standard for them - GOST 20295-85.

According to this GOST, pipes can have an outer diameter from 159 to 820 millimeters with walls 3 - 12 mm thick.

Main pipes have their own standard

Hot-formed seamless pipes

The range of hot-formed seamless steel pipes is contained in GOST 8732-78. The size chart is too large to list in its entirety; it includes pipes with a diameter from 20 to 550 mm with walls thick from 2.5 to (just don’t be alarmed) 75 millimeters. You may find it interesting that a linear meter of 550x75 pipe weighs 878 kg.

Production technology allows them to be manufactured with very thick walls

Cold-formed seamless

Unlike the previous ones, the mechanical processing of the sleeve - a blank for such a pipe - takes place in a cold state. This steel pipe is assorted according to GOST 8734-75; the full list of possible sizes is huge here too, so we will limit ourselves to indicating the extreme sizes: diameter 5-250 mm, wall thickness 0.3 - 24 mm.

The pipe is manufactured in measured and unmeasured lengths from 1.5 to 11.5 meters.

As is easy to understand from the name of the production method, the workpiece is cooled before the rollers

Pipe section shape

What about our form?

Pipes according to their cross-sectional shape can be divided into:

Oval and flat-oval pipes are in demand not only in decorative structures, but also in the production of various liquid cooling systems: an oval pipe with the same cross-sectional area has a much larger surface area compared to a round one.

Square and rectangular profile pipes have another important difference from round ones: they are much stronger in bending. That is why they have found their application primarily in a variety of load-bearing metal structures.

These pipes, along with channels and I-beams, are used in the assembly of load-bearing structures

Please note: profile pipes - square and rectangular - are not only resistant to bending, they are also convenient to install due to their flat surfaces, requiring minimal adjustment. They are often assembled with bolts, without welding.

Oval

The range of oval steel pipes is taken from GOST 8642-68: overall dimensions from 6x3 millimeters to 90x32 and 85x50; wall thickness - 0.5 - 2.5 mm.

How to apply markings

Manufacturers can mark pipes in several ways:

- branding;

- knurling;

- indelible paint;

- ink;

- laser;

- electrograph.

The height and width of the signs depends on the size of the pipes and can vary between 5–30 and 3–12 mm, respectively.

This is how pipes are marked at one of our supplier enterprises - Chelyabinsk Pipe Rolling Plant PJSC, part of the Pipe Metallurgical Company

Metal-plastic

Advantages and disadvantages

These pipes are cheap and beautiful, easy to assemble into a water supply system and do not require special tools for this. However, due to both the characteristics of the material and installation, they often leak after several seasons.

Advice: metal-plastic is often used for underfloor heating, and its use there is justified. It is only important to lay a solid pipe in the screed, without joints.

Standards and sizes

The range of pipes made of metal-polymers is not regulated by GOST R 53630-2009 “Multilayer pressure pipes for water supply and heating systems”; GOST specifies only pipe quality standards.

The actual range of pipe products made of metal-plastic sold in Russia comes down to six standard sizes: 16, 20, 26, 32, 40 and 50 mm.

Important: strictly speaking, the word “assortment” implies not only a list of sizes, but also a set of other characteristics: say, the grade of steel or the method of pipe production. However, we focus on pipe diameters simply because in most cases during construction it is necessary to decide on them.