Self-taught welders in most cases carry out welding work at home in places that are more or less suitable for such work.

Professional craftsmen know how important it is to provide the most comfortable and safe working conditions, so they organize special welding stations. After all, the characteristics of the workplace largely determine how safe it will be for a craftsman to use welding equipment in practice.

General and individual requirements

Regardless of the type of equipment, when organizing a post, sanitary and safety standards are observed:

- To improve the quality of welding work, provide good lighting. It should be at least 80 lux, but not interfere with the master. The lamps are installed so that no shadows fall on the desktop.

- Since welding produces vapors and gases harmful to humans, sanitary standards are taken into account when creating ventilation. Thus, exhaust equipment must cover a radius of at least 4 m, the recommended air exchange rate is more than 40 m³ per hour. When organizing a post at home, standard supply and exhaust ventilation is sufficient.

- If several craftsmen work in a room, then the installation of centralized exhaust units is required, to which all stations are connected. The dampers help regulate the air exchange rate. When working in closed containers (reservoirs, tanks), air is supplied using a mask.

- When installing single-phase welding units, an oscillator is included in the circuit. For a three-phase device, the presence of a magnetic contactor is required.

- If metal cutting will be carried out at the workplace, then a separate place will be equipped for storing and using cutting equipment.

Individual requirements are provided for different types of technologies:

- When organizing a gas welding station, a separate compartment for storing cylinders is equipped. There should be no sources of heat or open flame in the work area.

- In electrical technology, attention is paid to equipment grounding. A rubber mat is placed near the welding machine. When setting up a post on the street, a canopy is built.

- When using plasma welding, equipment is provided that quickly removes toxic products of metal combustion from the working area. There should be no flammable liquids or materials in the room.

Recommended reading: Why do you need a welding log?

Requirements for welding stations

General requirements

Requirements for the organization of welding stations are based on compliance with safety regulations and ensuring comfort in carrying out work. It is important to ensure that all energy consuming installations are grounded. To place them, it is highly advisable to make a base of concrete or brickwork. The post must have everything necessary to store not only tools, but also documentation.

Briefly about the basic requirements. Ventilation is required. The table is made of steel or cast iron. The welder must stand on a rubber mat while working.

For cases where the welder works while sitting, it is necessary to provide a special chair with a non-conductive seat. It should be durable, but light and small so that it can be moved with one hand if necessary. Naturally, the seat should be comfortable, since sometimes a specialist has to work for several hours without a break.

Productive work is impossible without adequate lighting. The brightness should not be excessive, but at the same time, even small details should be well illuminated. As practice shows, 80 Lumens are enough to work. The light source should be placed directly above the table. If this is not possible, then it is permissible to place the lighting device in close proximity to the workplace.

Even if we are talking about multi-station welding, you still need a switch, by turning which you can turn off the electricity supply in an instant. This may be needed in an emergency and to de-energize the area at the end of the working day.

Classification of posts by type of welding

The following types of jobs are distinguished:

- Gas welding stations. The room for working with such equipment is organized taking into account the technology: the melting of the metal is carried out under the influence of thermal energy released during gas combustion. The workspace is equipped with the most efficient exhaust system. The post is finished with fireproof materials.

- Electric welding. The space allocated for the welder’s work is organized taking into account the high risk of electric shock.

Equipment

Since there are several types of welding, the workplace will have to be equipped differently. The only things that remain unchanged are grounding, safety requirements for the welding station, lighting and auxiliary devices for the convenience of the welder.

- Welding with non-consumable electrodes in shielding gases requires organizing a place for gas cylinders or a compressor.

- Mechanized welding or cutting of metals is an additional unit for supplying consumables or cutting tools.

- Using three-phase voltage means installing a contactor of the required size.

- The workplace of an electric welder operating on alternating current is additionally equipped with an oscillator. Its purpose is to stabilize the electric arc.

Equipping a place where a gas or electric welder works is a serious and responsible matter. The basic and important rule here is to ensure maximum safety during welding work. Therefore, systems such as ventilation, grounding and lighting receive increased attention.

Proper provision of a welding station for manual welding is not only reducing the risk of employee illness, but also preserving his health, which is very important. This is an increase in the quality of work, plus a reduction in order completion times.

Workplace safety

Regardless of the type of equipment used, rules must be followed to prevent fire and injury hazards. The main conditions for organizing work areas are the following:

- Each post is surrounded by protective screens made of fire-resistant materials. The screen cannot be equipped with a closed top part.

- Wall paneling should not touch the floor. It is recommended to leave a distance of 30 cm.

- When gas welding, an additional light protection screen with a height of more than 2 m is installed.

- The walls are sheathed with fireproof materials.

- It is forbidden to place several welding tables at one station. If such a need arises, install an additional light-protective screen.

LITERATURE

- PPR. Fire regulations in the Russian Federation. Decree of the Government of the Russian Federation of April 25, 2012 No. 390;

- State Committee of the Russian Federation for Construction and Housing and Communal Sector Resolution No. 80 dated July 23, 2001 On the adoption of building codes and regulations of the Russian Federation “Labor safety in construction. part 1. general requirements”;

- Ministry of Labor and Social Protection of the Russian Federation Order No. 701n dated November 28, 2013 On approval of the professional standard “WELDER”;

- SP 12-135-2003. Occupational safety in construction. Industry standard instructions on labor protection" (approved by Resolution of the State Construction Committee of the Russian Federation dated 01/08/2003 No. 2) from the "Construction" information bank;

- MDS 12-49.2009. Layouts of labor safety instructions for construction workers. Methodological manual" from the information bank "Construction".

Scheme and basic tools

The order in which equipment and fixtures are placed is dictated by the type of welding location.

For mobile post

When creating mobile workplaces, there are no special requirements for space and ventilation. However, basic safety rules should be followed:

- The trolley for placing devices and tools is equipped with wheels, ensuring ease of transportation. For work, a welding unit with a set of cables is used.

- The mobile post is equipped with stands on which a canopy is installed in case of bad weather.

- Tools are placed in special boxes.

- To protect others from light exposure, portable shields are used.

- When laying long communication lines, workplaces are equipped in trailers with autonomous generators.

For landline

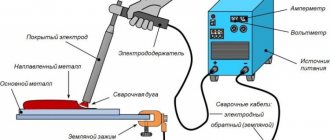

When equipping a welding station in a workshop, it is necessary to purchase all the necessary equipment for the work. The list can be expanded, but when connecting metal parts you cannot do without:

- welding unit;

- a box for storing electrodes and other auxiliary tools;

- constant current source;

- convenient landing place;

- switch for supplying and disconnecting voltage;

- exhaust chamber;

- baskets, shelves and drawers for storing small tools;

- electric holder.

When placed correctly, all these devices do not take up much space.

Basic equipment

To fully equip a welding station, it is necessary to equip it with electrical equipment, additional equipment and auxiliary means:

- a current source for the formation of a welding arc, which is a welding transformer or inverter;

- current-carrying cables in a reliable braid that can withstand high current strength and constant mechanical stress.

- conductors must have appropriate fastening at the end for connection to terminals, electrode holders and ground;

- gas burners for working with gas welding equipment;

- fixtures and other tools for welding work: clamps, clamps, holders;

- welding table;

- protective equipment: heat-resistant suit, special gloves, welder’s mask, headdress with a lapel.

A distinctive feature of a mobile welding station is that it does not have any boundaries. This is explained by the fact that a specialist needs to constantly move to perform his duties within a certain area: construction site, welding shop, production site, etc.

It is worth paying attention to the fact that this classification relates exclusively to the organization of procedures, but does not in any way regulate the nature of the manipulations performed.

Features of gas welding stations

The following must be present in the work area:

- acetylene supply device;

- oxygen cylinders with a reducer;

- gas supply hoses;

- welding torches.

We recommend reading Reinforcement welding technology

When arranging a stationary gas welding station, take into account the following recommendations:

- The surface of the welding table must be metal.

- Gas cylinders are placed as far as possible from the workbench. At enterprises, gas is supplied centrally through a pipeline.

- The post is placed at a distance of at least 10 m from sources of open fire.

- When working in closed containers, additional means of air supply are installed.

How to equip an electric welder's station

Regardless of the functionality (fixed or mobile), the place where the electric welder works must meet these requirements.

- Mandatory grounding of equipment.

- Sufficient illumination (it is best to combine natural and artificial light).

- Concrete or brick floors.

- A tabletop made of steel and cast iron, to which the ground cable is connected.

- The presence of drawers or pockets where you can put electrodes.

- To make it possible to work while sitting, the seat is made of dielectric material.

- A rubber mat to stand on.

Also, for outdoor work, a cover is installed to protect the area from precipitation.

Stationary post

Stationary posts must meet the following requirements.

- A fixed workplace is usually made in the form of a closed cabin without a roof. The area of such a post should not be less than 3 m². The height of the walls is 2 meters. The entrance to the cabin is covered with a tarpaulin screen.

- At the bottom of the cabin there should be a gap between the walls and the floor (250-300 millimeters).

- The work table is made of steel or cast iron. The countertop area is at least one square meter.

- The table itself can be adjusted in height so that the welder can work standing or sitting. For standing work, the tabletop is installed at a distance of 90 cm from the floor. For sedentary work - 50-60 cm.

- The surrounding walls of such a booth must be made of non-combustible material. They are painted in light gray tones. The white itself must absorb ultraviolet radiation.

- A good exhaust hood must be installed to remove smoke and other combustion products. Supply ventilation is also needed. At the same time, according to safety requirements, ventilation must ensure air exchange with a volume of at least 40 cubic meters. meters per hour.

- Lighting should be at least 60-80 lumens in brightness. It’s very good when such a post can combine street light with artificial lamp light.

Fixed posts are required to have all equipment grounded!

In addition, stationary welding equipment must be installed. It is necessary to have a switch that allows you to de-energize all devices in an emergency.

There are also additional drawers and mounts for consumables and tools.

Mobile post

Such posts are very convenient when welding in large spaces and working with structures with large parameters.

- All equipment for electric welding is located on a mobile cart.

- The length of the cables should ensure ease of movement during operation.

- When welding outdoors, do not provide additional ventilation. The combustion products released during the welding process themselves quickly spread.

- A portable welding station for outdoor work must have shields for quick assembly of the canopy in case of precipitation.

- To protect others from the effects of electric arc flashes, such posts must additionally be equipped with collapsible shields that can be easily moved around the territory.

- To make it convenient for the welder to work, mobile posts additionally have special stands and mounts for placing electrodes and tools.

High-quality ventilation

When arranging the hood, observe the following rules:

- Install local and general ventilation systems. The first is connected to each workbench if toxic substances are released during welding. Installation of a general hood is required in all cases.

- Ventilation equipment is equipped with a filter that removes welding aerosols from the air. The equipment removes harmful substances outside the workshop.

- When welding in a gas environment, air is supplied dispersedly. When using other technologies, directional ventilation is used.

During welding

Now let's look at the documents drawn up during the work process.

Executive scheme (form)

On the as-built diagram or form, joints, supports, and elevation marks are indicated. Indicate the distances between joints, axes and rows of the building. They record data on the welders who performed the work. Performed in drawing programs most often in Autocad.

Welding log

Certificates for welding tolerance joints or KSS (control welded joints)

Acts on control of KSS

Documents are drawn up for various controls - VIC, ultrasonic testing / RK, and mechanical tests - destructive testing.

Thematic videos:

1) About the measuring instruments that a VIC specialist should have

2) Carrying out ultrasonic testing

3) Computed radiography in action

Certificates for control of finished products

These acts (conclusions) on VIC and non-destructive testing, if provided for in regulatory and technical documentation, are drawn up during the work process, as well as upon completion, depending on the customer’s requirements. Examples of conclusions and acts can be found here.

Thematic videos: 1) Types and methods of non-destructive testing

2) Main defects of welded joints and their detection by NDT methods

This was a short list of exactly what as-built documentation is subject to execution when carrying out welding work.

After completing the welding process, it is necessary (assigned in the FNP) to clean all joints and connections made, remove slag residues, and remove contamination (sagging and metal residues). After the inspection, all identified defects will need to be corrected. It will also be necessary to fill out certain documentation in full and based on the requirements.

Organization of stations for different types of welding

Since craftsmen use several technologies, work areas are equipped differently. The basic set of tools, safety rules, and equipment grounding remain unchanged. Individual points include:

- Arrangement of the installation site for gas cylinders and a compressor during argon arc welding with non-consumable electrodes.

- The use of additional devices for supplying consumables and cutting devices in mechanized welding processes.

- Use of equipment grounding and neutralizing equipment during electric welding.

- Installation of a separate screen for a plasma installation. The height of the screen in this case should be at least 220 cm.

The procedure for issuing permits and permits for hot work.

It is recommended to carry out fire hazardous work during daylight hours, i.e. during the day (except for force majeure and accidents) and with the participation of specialists with special training and relevant documents (certificates, certificates, certificates) confirming their qualifications.

Previously, the head of the unit or the head of the team (shop, department, section) must prescribe an exact plan for future work, equipment must be installed in explosive areas to secure the facility, power supplies have been turned off, devices and installations that pose a threat to life and health during the work process have been stopped, and signs indicating the boundaries of dangerous zones have been installed.

All specialists associated with the work must undergo appropriate targeted training, be provided with fire protection equipment, tools must be checked, and the workplace must be prepared.

Only after all these measures have been ensured is a permit issued to carry out fire hazardous hot work.

Admission rules

According to paragraph 437 of the Fire Regulations in the Russian Federation, for carrying out hot work (fire heating of bitumen, gas and electric welding work, gas and electric cutting work, gasoline and kerosene cutting work, soldering work, cutting metal with a mechanized tool) in temporary places (except for construction sites and private households), the head of the organization or the person responsible for fire safety issues a work permit to perform hot work in the form provided in Appendix No. 4 (it is below). The permit is filled out either on a regular A4 sheet or on the company’s letterhead in two copies. One of them is transferred to the work manager, the second to the employee who is responsible for fire safety at the enterprise.

A work permit for hot work is a permit document that clearly states the facility where the work will be carried out, its name, information about the specialists receiving access to it, the persons in charge, as well as the fire safety measures taken at the workplace.

Instructions for filling out the work permit for hot work

- In the upper right part of the document the full name of the enterprise whose employees carry out hot work, as well as the structural unit to which they belong, is indicated.

- In the upper left part, information about the head of the enterprise is entered, as well as the date of registration of the permit. Here, after the final completion of the document, the director will have to sign.

- Below in the center of the line is the name of the document.

- Then, in separate paragraphs, it is written down to whom the permit was issued (i.e., the person responsible for carrying out the work), for what kind of work, as well as information about the object (here you must indicate the name of the object and its actual address).

- The fourth paragraph contains information about the performers: here you need to indicate their profession, qualifications, and the date of the last training completed. Each participant in the work must sign opposite his/her name.

The following paragraphs of the permit relate directly to the hot work being carried out .

- First you need to indicate their start and end times (hours, minutes), then the fire safety measures taken (in detail).

- Further, it should be noted that hot work, as well as measures taken to ensure fire safety, have been agreed upon with the responsible services of the facility - here it is necessary to indicate a specific person, his position, surname, initials, and the date of approval.

- Finally, in the last paragraph of this part of the work permit, we similarly note the employee responsible for preparing the workplace for the implementation of assigned labor tasks.

- According to the rules, a work permit must be issued for all types of work separately for one day shift.

- If the work is not completed within the period established by the permit, then in paragraph 9 you need to make an entry indicating until what time they are extended (but not more than for one work shift). The next paragraph should include a note about agreeing to extend the permit for hot work.

- If changes are made to the composition of the performing team (some workers are replaced by others, or someone is simply excluded or added), this should be noted in a special table.

- After all the work is completed, the fact of completion of the work, the date and time are recorded, and the signature of the person in charge is affixed. After final registration, the work permit is submitted to the head of the enterprise for approval and signature.

Create your own post

You can organize your workspace with your own hands. When creating a mobile welding station, additional components are required to carry tools and consumables.

A stationary office does not need such devices.

Collection of tools and materials

When organizing a welder’s workspace you will need:

- Current supply devices. These include transformers or generators, often operating from a 380 V network.

- Cylinders with inert or active gas. Large capacity containers are installed at stationary posts.

- Set of fixing tools. These include vices and clamps.

- Means for pre-processing of metal parts - cold rolling and rolling devices, pipe benders.

- Inverters, semi-automatic welding machines for mobile posts.

- Electrodes, filler wire. It is recommended to purchase different types of materials.

We recommend reading: How to get a NAKS certificate

How to assemble

In the process of creating a welding booth with your own hands, follow the following rules:

- The recommended length of the working area is 2 m, width – 2.5 m. The ceiling height should be at least 2 m. The upper part of the office should not be closed.

- To assemble the walls, sheet steel or plywood treated with a non-flammable composition is used.

- For preliminary preparation and welding of metal parts, a convenient welding table is organized. It can be made stationary or foldable. For assembly, profile pipes and thick steel sheets are used. Tables must be equipped with metal holders that secure the current-carrying cable and grounding wire coming from the power source.

- Containers for storing electrodes and welding wire are placed on the side of the table. Drawers are installed in which small tools and technical documentation will be stored.

- Install single or multi-station arc power sources. The first option is preferable when organizing your workspace yourself. In the second case, the use of current-carrying busbars will be required.

- Install a switch to control the welding current.

Device in stages

A welding room can be set up in a garage, at a production site, or at a technical inspection station. In this case, the following scheme of work is used:

- Choose a place. It is recommended to locate the post away from flammable liquids, materials and gases.

- Assembling the cabin. From the floor to the bottom edge of the walls, leave gaps of 5 cm for ventilation. When working with inert gases, this distance is increased to 30 cm. Ventilation meshes are installed. A tarpaulin or plastic non-flammable screen is hung at the entrance.

- Mount a table with a tabletop. Provides the ability to adjust the height of the racks and the area of the tabletop.

- Install lighting fixtures.

- The cabin walls are painted with light gray paint that absorbs ultraviolet rays. Choose paint compositions based on titanium or zinc.

- Install a forced-type exhaust system. Connect the equipment to a centralized air exchange system.

- The floor is poured with concrete. Brick can be used to form flooring.

- Install a switch for emergency shutdown of welding machines.

At the last stage, connect the equipment to power sources.

Basic requirements for arranging welding stations

Regardless of what equipment the post is equipped with, the fire safety requirements are almost the same. All their points are aimed at ensuring safe working conditions and making them as comfortable as possible. Primary requirements:

- The welder's place should be protected with shields or screens made of fireproof materials. the top should be left open;

- welding work using inert gases is allowed only in those booths where there is no top, the light opening between the fences and the base is 30 centimeters or more, and the walls of the fences are at least 2 meters;

- the inside of the post along the perimeter is sheathed with fireproof materials;

- The cabin area must be at least 4.5 square meters. This space is enough to accommodate welding equipment, accessories, various devices, systems for storing tools and consumables;

- when operating a plasma cutting machine, the height of the fences must be at least 2.2 meters, and the surface inside must be covered with fireproof materials;

- You should not install two welding machines inside one booth at once. And if this is really necessary, then a separating light-protective screen must be installed between them. It will prevent the possibility of a fire.

When arranging a welder’s workplace, the organization of a ventilation system is important. The production site foreman must check the ventilation performance of each station, since the safety of not only a specific welder, but also the work site as a whole directly depends on the efficiency of air exchange.

Practitioners advise:

- Ensure parallel operation of two exhaust systems at once: general and local.

- Local hoods are equipped with filters that purify the air from harmful aerosols and combustion products.

- When performing welding work in a protective environment, air is supplied dispersedly into the booth. In other cases, it may be pumped into the upper area of the cabin.

- It is desirable that the walls inside are matte. Then the welding glare will not be reflected.

If all the requirements for organizing the supply and exhaust ventilation system are met, then the workplace is ready for use. Before starting welding work, the specialist must wear protective clothing and a mask. Otherwise, he risks damaging his eyes and getting burns from hot metal drops.