High strength bolts are fastening elements with high durability. They differ in that they are made of a special grade of metal (low-alloy and alloy steel) using modern specific technology. The material used contains carbon up to 0.4 percent. Bolts are made using regular cold or hot heading, followed by subsequent thread rolling and heat treatment, in which the high-strength element is coated with a specific protective layer of up to 50 microns. Also, the coating may not be used. All components of the product must be extremely reliable and resistant to high loads. Fastening thanks to high-strength bolts is considered shear-resistant.

Operation of bolts of this type are widely used in connecting detailed elements in the mechanical engineering industry, in agriculture, and in the formation of railway fastenings. This type of fastening element is used where the traditional simple fastening method is not able to withstand heavy loads. They are used in fastening serious structures in construction, for example, the construction of a bridge. High-strength bolts are essential elements in the engineering industry and construction.

High-strength bolts do not require drilling and cleaning of the hole, which requires a hole 3 millimeters larger in diameter. The joining surface can be cleaned in three ways: fire, sand jet, cleaning with a steel brush. A cleaned surface may cause rust to form. For this reason, an important condition is the assembly of a variety of connections on high-strength bolts, which are produced in accordance with GOST, while allocating a small amount of time during the precise and timely processing of the surface layer and also securing the bolt.

An important factor is the phased installation of bolts of the maximum strength class. They begin to install them from the middle of the joint, smoothly moving to the outskirts. Thanks to the plug fixed in the hole before fixing the bolt, it becomes possible to control a list of indicators: the geometric dimension of the future structure, the accuracy of its assembly. Before installing high-strength hardware according to GOST 22356-77, you need to clean it and turn the nut, or rather along the thread of the bolt.

It is strictly prohibited to lubricate the cutting of the product. The lubricant mixture may enter the shear cavity. It is allowed to add a minimum of lubricant to the nut thread before screwing it onto the bolt. The use of pneumatic impact wrenches makes it quicker and easier to install and tighten a durable bolt. By using a torque wrench, you can control the installation of a high strength bolt.

When installing a bolt of a high strength class, its tension is fixed and monitored. The tension of high-strength bolts is assessed in two ways:

1. The first option is to mark one of the edges of the nut and unscrew it one-sixth of a turn. Subsequently, the nut is tightened using a torque wrench, and if suddenly it shows the calculation torque at the previous position, it means that the bolt was tightened correctly.

2. The second option is to put the nut on the wrench and tighten it. A high-strength bolt is tightened to values no less than the calculated ones when the indicator shows the corresponding calculations before turning the nut. After checking, the bolt heads need to be painted.

What is a high strength bolt

This type of fastening has several classifications, but the most significant characteristic is increased resistance to heavy loads. Thanks to this, the structures connected by bolted fasteners become highly strong and durable. High-strength bolts, nuts and washers are widely used for metal structures, construction work and in heavy industry and mechanical engineering.

A bolt is a rod made of a metal alloy with an external thread applied to it and a head, usually in the form of a hexagon, for a wrench. Fastening is done by screwing on a nut of the required size. To distribute the load evenly, washers are used.

Area where hardware is used

Durable product is used:

1. Aggressive environment of chemical production.

2. High temperature conditions, machine tool construction.

3. For working with low temperatures in the Far North.

4. For agricultural equipment units, automotive industry, road construction equipment.

5. Fastenings of railway mechanisms, cranes, bridge construction, fencing fragments on highways.

Strong fastening elements are required for high breaking forces. When high demands are placed on fastening connections, where there is an increased dynamic and static load. At the same time, the reliability of the fastening unit is maintained.

Raw materials used for durable hardware

Reliable fasteners are made from steel grades 35, 20G2R, 40X. The most commonly used steel grade is 20G2R. Calibrated steel for special surface finishing is supplied in coils and rods with a diameter of 14 - 21 mm. In the form of connecting elements it is used in the mechanical engineering industry, the construction of devices and in construction work.

Application area

High-strength bolted connections are designed for the installation of complex building structures that will be subject to:

- high temperature changes;

- precipitation;

- strong and frequent winds;

- contact with chemicals.

Since the dimensions of fasteners provided for by GOST vary, the scope of application of hardware is extensive:

- machines, equipment;

- agricultural machinery, mechanical engineering;

- construction of bridges, buildings;

- shipbuilding;

- industry, production.

Friction connection with high-strength bolts perfectly copes with the task of strong and reliable installation of structures subject to dynamic loads and vibrations.

This fastener is widely used in everyday life. It is ideal for renovating apartments and balconies; it will securely fasten any structures to concrete walls. Car enthusiasts cannot do without such bolts when repairing their car, especially wheel fastenings.

What is the difference between domestic hardware and other manufacturers?

In European countries, durable fasteners are designated HV. High strength products are used mainly when working with metal structures and bridge areas. The regulations of EN and DIN countries provide for a “set set”. The set is filled with bolts, washers and nuts. Mandatory adherence to important rules: parts from the same brand. Mixing fasteners from different manufacturers is prohibited.

The domestic selection of fasteners is called bolt sets and does not require a set from one manufacturer. Our rules for durable products are based on ISO standards, which were adopted in 1984. All German documentation today was introduced in 2006. There are differences in them compared to modern standards.

When considering the mechanical properties of fasteners, you can find some discrepancies in the characteristics:

1. Relative narrowing.

2. Elongation.

3. Difference in strength limits.

4. Different hardness.

5. When comparing our rules with European standards, it can be noted that our yield limit is not fixed, but European standards oblige them.

Classification by strength and marking

This fastener is manufactured strictly in accordance with GOST and is marked accordingly. It's easy to decipher:

- In terms of the strength class of the coating of the top layer of fasteners, bolted hardware occupy the best positions on a scale from 6.8 to 12.9. Marking of high-strength bolts starts from 8.8. To make it better visible, the designation of high-strength bolts is placed on the head of the fastener.

- The additional letters ХЛ on the marking next to the strength class of the bolts mean that the fasteners can be used in conditions of very low temperatures down to -60 ° C.

- Marking with the letter U limits the low temperature regime - not lower than - 40°C.

- English S informs about the increased dimensions of the bolt head.

Thanks to the markings on the head of the hardware, you can quickly select the required fastener.

What is considered an advantage of fastening material?

The use of high strength fasteners is increasing year by year. Their advantages:

- Durability, resistance to high loads, for example, a 12.9 bolt can burst under a stress of 1200 N/mm?, and the same diameter, having a low class of 4.8 - 420 N/mm?, with a 2.7 times lower load stress (under the influence of the strength class ).

- The use of fasteners with smaller parameters with the same load.

- Reducing the metal consumption of fastening materials and reducing the cost by 30-40% with the cost of parts.

The advantages of high strength fasteners also include taking into account a greater number of issues at the time of design. It is possible to design fastening units with high strength hardware, small dimensions, and designed to withstand heavy loads. Elements with higher resistance characteristics at mechanical resolution.

The use of high-strength bolts reduces the metal consumption of the structure, since in addition to reducing the weight of fasteners, developers have the opportunity to more flexible design of structures by reducing the geometric dimensions of mating elements, for example, flanges.

The use of high-strength fasteners is ideal for subsequent repair and restoration work and audits, since the possibility of repeated reuse of fasteners is significantly increased and the service life of the equipment is increased.

Steels for making bolts

For the manufacture of high-strength fasteners, alloy carbon steel of increased strength and durability is used. Special manufacturing technologies include hot or cold heading of blanks, which significantly increase the level of strength. Mandatory heat treatment in electric furnaces gives the product anti-corrosion properties, greatly increases strength, and extends service life.

Material selection criteria

Detachable connections can be provided with high-strength parts with small dimensions, which are not inferior to welding and exceed the strength of rivets. Frequently used equipment and massive building metal structures require the use of high-strength fasteners. It is unacceptable to try to reduce costs and install low-strength fasteners. This will lead to the destruction of structures. To avoid galvanic corrosion, the selection of hardware should be carried out taking into account the compatibility of the metal with the structure.

Comparative merits

What are the options for high strength fasteners compared to welded fasteners:

1. Bolted fastening reduces the complexity of installation, it becomes possible to allow workers who have average qualifications to assemble, it is possible to carry out automation and mechanize the assembly process.

2. Use high-strength fasteners when assembling metal structures using elements made of difficult-to-weld steel that has increased strength.

3. It is easier to control the integrity of the connected bolts, while hidden defects are detected in the welds.

Advantages compared to rivet fastening

Rivets are now obsolete. They have been replaced with high strength bolted sets that distribute stress evenly. They can be easily replaced in case of wear, they are easy to use when assembling/disassembling structures, they can be used repeatedly, which facilitates the work when repairing mechanisms and components.

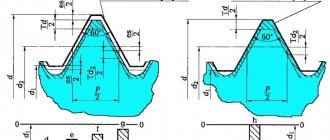

Dimensions

The dimensions of high-strength bolted connections exactly correspond to GOST 52644 standards:

- Diameter of hardware in ascending order: from bolt M10 (smaller) to M48 (larger).

- Length from 40 to 300 mm.

- The weight of 1000 pieces depends on the diameter and length. It can be determined from the corresponding tables according to GOST. The mass of M16 fasteners, for example, will be 115-515 kg, M20 - 200-800 kg, and M48 - from 2500 to 5000 kg.

- The thickness of the additional coating is also regulated by GOST, depending on the diameter of the hardware. Thus, high-strength bolts M24 have a coating thickness of 40 microns, and M16 - 25 microns.

High-strength bolt GOST R 52644-2006 for bridge metal structures of steel 40Х

| Catalog / high-strength bolt GOST R 52644-2006 st. 40Х for bridges |

High-strength bolt GOST 52644-2006 with an increased turnkey size is most often used in mechanical engineering, industry and construction as connection parts, as well as for steel bridge metal structures and in heavy engineering.

Accuracy class: B. Steel grade: 40Х; 30Х3МФ; 30X2RNMFA; 20Х2НМТРБ. Analogues: DIN 6914 (EN 14399-4), ISO 7411: 1984. Strength class: 6.8; 8.8; 9.8; 10.9; 12.9.

Climatic version on the cap xl:

- U (for areas with an estimated temperature of -40°C and above).

- HL (for areas with an estimated temperature of -65°C and above).

The bolt head is additionally marked with the letters HL.

Bolt size range: M6, M8, M10, M12, M16, M20, M24, M27, M30, M36, M42, M48, M52 and others.

Bolt GOST 52644-2006 high-strength for bridge structures with a hexagonal head. Bolt price GOST 52644.

| d | 16 | (18) | 20 | (22) | 24 | (27) | 30 | 36 | 42 | 48 |

| Thread pitch | 2 | 2,5 | 3 | 3,5 | 4 | 4,5 | 5 | |||

| d 1 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 36 | 42 | 48 |

| Key size, S | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 60 | 65 | 75 |

| Head height, k | 12,0 | 13,0 | 14,0 | 15,0 | 17,0 | 19,0 | 23,0 | 26,0 | 30,0 | |

| e, no less | 29,9 | 33,3 | 35,0 | 39,6 | 45,2 | 50,9 | 60,8 | 72,1 | 83,4 | |

| r | From 1.5 to 2.0 | From 2.0 to 2.5 | From 3.0 to 4.0 | From 4.0 to 5.0 | ||||||

| Thread length, b | 38 | 42 | 46 | 50 | 54 | 60 | 78 | 90 | 102 | |

| Bolt length L, mm | Theoretical mass (weight) of 1000 pieces of products, kg | |||||||||

| 16 | (18) | 20 | (22) | 24 | (27) | 30 | 36 | 42 | 48 | |

| 40 | 111 | |||||||||

| 45 | 118 | 151 | ||||||||

| 50 | 126 | 161 | 198 | |||||||

| 55 | 134 | 171 | 211 | 267 | ||||||

| 60 | 141 | 180 | 223 | 282 | 367 | |||||

| 65 | 149 | 190 | 235 | 297 | 386 | |||||

| 70 | 157 | 200 | 247 | 312 | 404 | 538 | ||||

| 75 | 164 | 210 | 259 | 326 | 421 | 560 | 621 | |||

| 80 | 172 | 219 | 271 | 341 | 438 | 582 | 648 | |||

| 85 | 180 | 229 | 283 | 355 | 456 | 604 | 676 | |||

| 90 | 188 | 239 | 295 | 370 | 473 | 627 | 703 | 1081 | ||

| 95 | 195 | 249 | 307 | 384 | 491 | 649 | 730 | 1120 | ||

| 100 | 203 | 258 | 319 | 399 | 508 | 671 | 758 | 1159 | ||

| 105 | 210 | 268 | 331 | 414 | 525 | 693 | 785 | 1199 | 1723 | |

| 110 | 218 | 278 | 343 | 428 | 543 | 715 | 812 | 1238 | 1776 | |

| 115 | 226 | 288 | 355 | 443 | 560 | 737 | 839 | 1277 | 1830 | |

| 120 | 233 | 297 | 367 | 457 | 578 | 759 | 867 | 1316 | 1884 | 2462 |

| 125 | 241 | 307 | 379 | 472 | 595 | 781 | 894 | 1356 | 1937 | 2532 |

| 130 | 249 | 317 | 391 | 487 | 612 | 803 | 921 | 1395 | 1991 | 2602 |

| 140 | 264 | 336 | 415 | 516 | 646 | 847 | 976 | 1474 | 2098 | 2743 |

| 150 | 279 | 356 | 439 | 545 | 682 | 891 | 1030 | 1552 | 2205 | 2883 |

| 160 | 293 | 373 | 461 | 572 | 714 | 932 | 1080 | 1625 | 2304 | 3004 |

| 170 | 309 | 393 | 485 | 601 | 748 | 976 | 1135 | 1703 | 2412 | 3145 |

| 180 | 324 | 412 | 509 | 630 | 783 | 1020 | 1189 | 1782 | 2519 | 3285 |

| 190 | 340 | 432 | 533 | 659 | 818 | 1064 | 1244 | 1860 | 2626 | 3425 |

| 200 | 355 | 451 | 557 | 688 | 853 | 1108 | 1299; | 1939 | 2733 | 3566 |

| 220 | 386 | 490 | 605 | 747 | 922 | 1196 | 1408 | 2096 | 2948 | 3846 |

| 240 | 416 | 529 | 654 | 805 | 992 | 1285 | 1517 | 2253 | 3162 | 4127 |

| 260 | 447 | 568 | 702 | 863 | 1061 | 1303 | 1626 | 2410 | 3377 | 4408 |

| 280 | 478 | 607 | 750 | 922 | 1131 | 1461 | 1735 | 2568 | 3591 | 4688 |

| 300 | 509 | 646 | 798 | 980 | 1200 | 1549 | 1844 | 2725 | 3806 | 4969 |

At the request of the consumer, they are coated by chemical galvanizing or thermal diffusion. Packed in wooden boxes of 50, 60 kg. Boxes are placed on pallets.

Example of a symbol:

Bolt GOST 52644 with a hex head with an increased wrench size with a thread diameter d = 20 mm, length 1-75 mm, bolt body design 2, head design 1, strength class 10.9, climatic version U, with a chemical phosphate coating according to GOST 9.306 thickness 10-15 microns:

Bolt 2.1 M20 x 7510.9 chemical phos 10-15 GOST R 52644-2006

Bolt 52644 with a hex head with an increased wrench size with a thread diameter d = 22 mm, length 1-75 mm, bolt body design 2, head design 1, strength class 10.9, climatic version U, with chemical phosphate coating according to GOST 9.306 thickness 10-15 microns:

Bolt 2.1 M22 x 7510.9 chemical. phos 10-15 GOST R 52644-2006

High-strength bolt GOST 52644 with a hexagonal head with an increased wrench size with a thread diameter d = 24 mm, length I = 100 mm, bolt body design 1, head design 1, strength class 10.9, climatic version HL:

Bolt M24 x 10010.9HL GOST R 52644-2006

Bolt of execution HL high-strength GOST 52644 with a hexagonal head with an increased wrench size with a thread diameter d 30 mm, length I = 100 mm, bolt body design 1, head design 3, strength class 10.9, climatic version U, with thermal diffusion zinc coating (TD) according to GOST R 9.316 with a thickness of 10 microns:

Bolt 1.3 M30 x 10010.9HL TD10 GOST R 52644-2006

Technical requirements and reference standards

| Material | Steel1) | |||||

| Thread | Tolerance field | 6 | ||||

| National standard | GOST 1759.1, GOST 24705, GOST 16093 | |||||

| Mechanical properties | Strength class 2) | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 |

| National standard | GOST R 52643, GOST 52627 | |||||

| Tolerances | Accuracy class | IN | ||||

| National standard | GOST 1759.1 | |||||

| Surface quality | National standard | GOST 1759.2 | ||||

| Coating | Normal | Black oxide film | ||||

| free | Zinc thermal diffusion according to GOST 9.316 | |||||

| Metallic or non-metallic inorganic according to GOST 9.306 | ||||||

| Acceptance | GOST R 52643 | |||||

| Matching nuts | GOST R 52645 | |||||

| Matching washers | GOST R 52646 | |||||

| 1. Recommended steel grades are given in GOST R 52643. | ||||||

| 2. Recommended strength classes for bolts with different thread diameters and made of different grades of steel are given in GOST R 52643. | ||||||

| 3.Black oxide film with a thin residual oil coating indicates normal surface quality resulting from heat treatment. | ||||||

Standard GOST R 52644-2006 analogue of GOST 22353-77, DIN 6914, ISO 7411, ISO 7412.

Fasteners in addition to high-strength bolts and bolts GOST 7798-70:

- GOST R 52645-2006 High-strength hex nut with increased wrench size.

- GOST R 52646-2006 Washer for high-strength bolts.

How to buy high-strength bolts GOST R 52644-2006 for bridge metal structures of steel 40X at low prices:

- fill out the simple “Place an order” form at the top of the page;

- call on the phone +7;

- send your application by email;

Delivery within the Russian Federation: Moscow, St. Petersburg, Arkhangelsk, Astrakhan, Barnaul, Belgorod, Bryansk, Vladimir, Volgograd, Vologda, Voronezh, Yekaterinburg, Ivanovo, Izhevsk, Yoshkar-Ola, Kazan, Kaluga, Kirov, Kostroma, Krasnodar, Kurgan, Kursk, Lipetsk, Omsk, Orenburg, Penza, Perm, Pskov, Rostov-on-Don, Ryazan, Samara, Saransk, Saratov, Sevastopol, Simferopol, Smolensk, Stavropol, Tambov, Tver, Tomsk, Tula, Tyumen, Ulyanovsk, Ufa, Chelyabinsk, Yaroslavl, etc.

The information presented on this website contains a catalog of reference information on more than 3,000 types of metal products, is for informational purposes only, and can be used in various areas of enterprise activity.

| Steel wire Welding electrodes Steel rope Fasteners | Metal mesh Hex bolts Nut GOST, DIN Steel rivets | Adjustable cotter pins GOST, DIN washers Threaded rods Calibrated rolled products | Slings, rigging Construction nails Steel cable Screws GOST, DIN |

High strength bolt technology

One of the important components in fastening technology is the clear recording of the time period after preparation and lubrication of the thread before the direct use of the fastener. This period should not exceed 10 days, which should be indicated in a special journal for installing high-strength bolts after their delivery from the manufacturer. If the preparation was carried out independently, then the data is also recorded by filling out a log. An example of the order of fastening a bolted connection:

- Prepare the entire structure for docking and installation.

- Prepare the necessary fasteners according to standards.

- Carry out installation and installation of the structure.

- Tighten the bolts.

- The joints of all fasteners are sealed.

- Carry out quality control of the assembly of the object.

Preparing High Strength Bolts, Nuts and Washers

Before installation into the structure, high-strength bolts, nuts and washers must be prepared. It includes:

- Technological cleaning of preservative factory lubricants, as well as dust and dirt. It is performed in a heated alkaline solution at a temperature of 80-100 ° C, which includes water, detergents, soda ash and caustic soda, liquid glass and trisodium phosphate. The ratio is strictly observed according to GOST. The fasteners in a special container are dipped into the solution for 20 minutes, after which they are washed 3-5 times in a washing solution.

- Drying is carried out hot for several minutes, blowing with compressed air.

- Perform running on a lathe or wrenches, checking and lubricating the threads.

- Mandatory lubrication of fastener threads is carried out by immersing it in a solution of special gasoline GOST 2084 and mineral oil GOST 0799 in a ratio of 9 to 1.

- Purified hardware is collected and stored in closed containers. When assembled, each bolt is equipped with a nut and two washers.

- Carry out quality control.

Preparation for use

In practice, no one prepares high-strength bolts for use on a construction site. Fasteners are most often delivered in factory lubricant and immediately begin to be used, thereby making a mistake. Experienced specialists have several clever tricks on how to prepare high-reading bolts for use:

Before using hardware, they must be boiled. Add washing powder or detergent to the water. This action helps get rid of grease, scale and dirt.

Then you need to carefully inspect the fasteners and remove all products with cracks and defects.

Before using the bolts, you should coat their threads with oil. In some cases, it is recommended to immerse boiled hardware in a gasoline-oil solution.

High strength fasteners are mounted using two washers. One is installed on the bolt side, and the other on the nut side.

Rules for tightening BVP

Tensioning of high-strength bolts is carried out in two stages:

- Align the holes of the parts for high-strength bolts and fix the position of the structural parts using mounting plugs.

- At the first stage, bolt fasteners are inserted and plugs are removed. Next, using wrenches, the bolt fasteners are tightened only to 50-90%. At the beginning of tensioning, the fastener head must be held from turning. If it is impossible to eliminate the scrolling, the element is replaced.

- At the second stage, fastening is carried out completely, using torque wrenches. The tension of the bolts is carried out after checking the compliance of the geometry of the entire structure with respect to standards and rules, and checking the tightness of the structure's screed.

Excellent technical characteristics of connections made with high-strength bolts ensure the strength of the entire structure. If all instructions are followed, the structure will last for many decades.

Did you manage to solve your problem using the recommendations from the article?

Yes!

46.43%

No. More answers required. I'll ask in the comments now.

38.42%

Partially. There are still questions. I'll write in the comments now.

15.14%

Voted: 799