- March 23, 2020

- Construction

- Vera Matveeva

Reinforcement is one of the most important components of a reinforced concrete foundation. It helps to influence the loads. Thanks to it, a bending moment arises. As for concrete, it copes with this quite poorly on its own. Therefore, it is necessary to install steel elements in it. But, before purchasing fittings and installing it, it is imperative to study the information about it.

Types, brands of fittings

When choosing a material, you should definitely take into account the following characteristics of the reinforcement:

- View.

- Class.

- Steel grade. Rods are made from it.

Currently, there are three main types of reinforcement in construction. These include the following:

- Hot rolled. Such fittings are usually designated as A.

- Ropeway. This type has its own designation in the form of the letter K.

- Cold-formed. It is designated as Vr.

Hot rolled steel is used for the foundation. It is produced in accordance with GOST 5781 -81*. As for cold-worked steel, it is also used for foundations, but very rarely. Before installing it, limit state calculations are required. But rope reinforcement is more durable, but its laying for construction is not economically profitable.

Very often people ask what class of reinforcement is needed for a foundation? It is worth noting that for the construction of the house, reinforcement is used, the class of which is not lower than A400. Some manufacturers still continue to use the old markings; in this case, it is necessary to order fittings with a class of at least A111.

From the point of view of economy, you can choose a higher class, but it is unprofitable. But as for steel classes A240 and A400, they should under no circumstances be used for foundations.

It is very important to choose it wisely when purchasing steel. If we are talking about building a private house, then, as a rule, no problems arise when choosing. And if the amount of work is much larger, then the rods should be ordered at the factory. To do this, you need to fill out an application and indicate the steel grade. If this is not specified in the application, the plant will appoint it itself.

What is reinforcement and why is it needed?

Tensile and compressive forces act on the foundation of an already built house. Under the load of the house itself, the lower part is subject to tension, and the upper part is subject to compression. In winter, when the soil freezes, it also puts pressure on the foundation and lifts it, and in the warm season on the site, the soil moves and presses both from below and from the side. These forces deform and destroy the foundation, which changes the geometry of the upper structures. This, in turn, causes cracks in the walls, gaps between window frames and the walls of the house, and distortions in the floor level. This results in a draft when windows and doors are closed, swelling of the floor covering, dampening of the plaster, and in the worst case, damage to electrical wires and water supply and sewerage pipes inside the house.

| Steel reinforcement |

Foundation reinforcement is long round rods made of steel or fiberglass that strengthen concrete structures, including the foundation. The reinforcement tied into the frame takes on part of the vertical load and helps to evenly distribute the pressure of the house on the soil. A steel reinforcement bar can withstand tens of times more tension than unreinforced concrete. For comparison, the tensile strength of unreinforced concrete is 5.5 MPa, and that of reinforced concrete is in the range of 215-400 MPa. Reinforced concrete resists compression 8-10 times better than unreinforced concrete. In mass housing construction, it is impossible to build anything from concrete without strengthening it properly, since this process is regulated by SNiPs (Building Norms and Rules). Ignoring them, firstly, is dangerous for the lives of people in the building, and secondly, it means criminal liability for the head of a construction company. In private housing construction, to save budget and time, they try to build a foundation using only the lower part of the frame. This is explained by the fact that the tensile load under the weight of the house falls on the “bottom” of the foundation. But when the soil freezes and increases in volume, the lower part only contracts, and the upper, unsupported part stretches. In this case, deformation and destruction of the foundation, and then the house, cannot be avoided.

To avoid such consequences, the foundation must be strengthened with a frame made of reinforcement. Today in Russia, 90% of concrete structures are built on steel or metal reinforcement, SNiPs have been developed and used for this type of reinforcement, it has been produced in Russia by metallurgical plants since Soviet times and is considered as a traditional and proven material for strengthening concrete.

Types of fittings by purpose

Quite often people do not know what kind of reinforcement is needed for the foundation? All fittings, depending on their purpose, can be divided into three main types. It is worth noting that some types of structures in construction are not used for their intended purpose. Their division provides for many regulatory documents that regulate the design of house foundations. Such documents include, for example, the joint venture “Concrete and reinforced concrete structures”.

According to their purpose, as well as their location, the fittings can be divided into the following types:

- Working reinforcement. The location of the reinforcement directly depends on the types of foundation. So, for example, when used with a strip foundation, the rods are laid in one or even two rows, at the bottom and at the top of the strip. As for the slab foundation, its working reinforcement is as follows: rods or meshes are located in both directions. Moreover, it is worth noting that the thickness of the foundation greatly affects the number of rows of grids or rods. If it is 150 mm, or even less, then they are laid in one row.

- Vertical reinforcement, in which clamps are located between two rows of reinforcement. At the same time, they ensure their joint work. Such reinforcement is not used when the thickness of the structure is 150 mm, or even less.

- Transverse reinforcement. This reinforcement consists of horizontal clamps. Thanks to them, the joint operation of individual working rods is ensured. This type is ideal for building a strip foundation for a house. And for pouring monolithic slabs its use is not required.

Calculation of the amount of reinforcement

It is impossible to accurately calculate the required amount of reinforcement without having a reinforcement diagram in front of your eyes. This means that you will have to start by creating a drawing - at least the most primitive one, which will reflect:

- height and width of the frame section;

- number of rows of longitudinal reinforcement;

- the number of working rods in one row and the distance between them;

- pitch of transverse reinforcement.

An example of a simple drawing

As an example, let’s calculate the reinforcement for a shallow tape, 70 cm high and a total length of 30 m, which will have only two reinforcement belts:

- For such a small building (it could be a bathhouse or a garage measuring 6 * 6 m with one internal wall), working reinforcement can be taken with a diameter of 8 mm, connecting reinforcement - 6 mm.

- With a tape width of 40 cm, in the cross section of the foundation there will be only 4 working rods: two in the bottom row, and two on top. Taking into account the number of rows of reinforcement and the length of the strip monolith, the total length of the working reinforcement will be 120 m.

- To connect the working rods into a spatial structure, at one point you will need a clamp from a rod 0.7 m * 2 + 0.4 m * 2 = 2.2 m long.

- Let's say the clamps are installed every 0.5 m, then you get 61 connections. Multiplying 61 by 2.2 m, we obtain a total length of connecting fittings of 134.2 m.

- Now let's count the wire. In each section of this frame there are 4 connections, there are 244 of them in total. One connection requires 0.3 m of wire, a total of 73.2 m.

Reinforcement diameter

Professional builders can also tell you what kind of reinforcement is needed for the foundation. Before you make your choice, you must decide on its diameter. This issue is regulated by the joint venture “Concrete and reinforced concrete structures”, as well as the “Manual on the reinforcement of elements of monolithic reinforced concrete buildings”.

For example, the minimum diameter for clamps in no way depends on the type of foundation of the house.

What diameter of reinforcement is needed for the foundation? The above documents specify the necessary values, these include the following:

- The diameter of vertical clamps that have a height of foundation structures of less than 80 cm is at least 6 mm.

- The diameter of horizontal transverse clamps, which are used only for strip foundations, is no more than 6 mm.

- The diameter of vertical clamps of foundation structures that are more than 80 cm should not be less than 8 mm.

With this information, you can quickly decide how to choose fittings. In this case, another additional condition is that the cross-section of the clamps should not be less than 0.25 of the diameter of the working reinforcement.

Basic rules for foundation reinforcement

When constructing a foundation, one should take into account the full operational load on it, the type of soil, the depth of their freezing and other factors. All parameters of the base depend on this, including its width, height, load-bearing capacity, including what and how much reinforcement is needed to reinforce the strip foundation. When constructing it, you must follow these rules:

- for longitudinal lines, only rolled periodic profiles of classes A-II (A300) or A-III (A400) are used;

- for vertical and transverse frame elements, smooth rolled products of class A-I (A240) are sufficient;

- in total, the total diameter of all rods must be at least 0.1% of the ribbon cross-section;

- the reinforcement spacing in the strip foundation for longitudinal lines should not exceed 40 cm;

- for transverse and vertical elements, the pitch of the foundation reinforcement can be in the range of 30–80 cm;

- if the length of the sides of the base is more than three meters, the diameter of the reinforcement on the foundation for longitudinal rods must be at least 12 mm;

- for foundations of shorter length, the minimum rolled diameter is 10 mm;

- when connecting joints, the launch length must be at least 30 rolled diameters on flat areas and 50 in corners;

- when installing the reinforcement cage, it is necessary to provide a protective layer of concrete with a thickness of at least 5 cm on all sides of the perimeter;

- the longitudinal rods must be of the same diameter; it is allowed to use reinforcement of two different sizes, but then the larger one is installed in the lower chord of the frame.

Laying of reinforcement in a strip foundation is carried out by connecting the rods with binding wire or by welding. Sometimes we are asked why it is impossible to weld reinforcement in the foundation. We answer that such a ban applies to electric arc welding of conventional periodic profile fittings. You can buy foundation reinforcement with the letter C in the marking. You can easily cook it.

Another answer to the question whether it is possible to weld reinforcement for the foundation will be even more concise. Knitting a frame is easier and cheaper than welding. But when assembling heavy frames, welding is usually used. In individual and low-rise construction, heavy reinforcement is extremely rare, so when purchasing reinforcement, do not forget about the binding wire.

Assembling reinforcement frame elements into a single whole is not intended to achieve high strength connections. You only need to provide it with the necessary spatial position and the ability to withstand the process of pouring concrete. After it sets, the reinforcement for the strip foundation will not go anywhere. All you have to do is check the structure for defects and damage (for example, sinks) and fix them.

Main types of fittings

In order to know what kind of reinforcement is needed for the foundation, you must first familiarize yourself with the range. Currently, the modern construction market offers a huge selection of products designed to strengthen concrete, as well as create reinforced concrete structures.

Thanks to this knowledge, the question will no longer arise about what kind of reinforcement is needed for the foundation of a house. In order to strengthen the foundation, the following types of products may be suitable:

- Reinforcement made of composite material. It is made from plastic of various compositions. This material is very durable. Its main distinguishing feature is the lack of electrical conductivity, as well as high corrosion resistance. Products made from composite materials are quite expensive. As for private construction, this material is used quite rarely.

- Metal products. Represents standard steel rods of various diameters. To produce such products, it is necessary to use steel of various grades containing carbon. This material has fairly high strength characteristics. Thanks to this, the reinforced structure can withstand heavy loads and also withstand torsional and tensile forces.

Composite materials can be divided into several categories. These include the following:

- Fiberglass. It has high corrosion resistance and a fairly low thermal conductivity. Thanks to testing by specialists, we can say that this material is able to withstand extreme tensile loads.

- Carbon fiber. This product contains a small amount of diamond chips, as well as graphite. These elements have high fracture strength and also have high impact resistance.

- Basalt. Basalt is the main element in this material. It is a melt of certain rocks. It is woven into plastic threads, and reinforcement is made from these threads. Basalt can be used in cases where wireless signals, including radio waves, are required to enter the room.

In the construction of large industrial buildings, as well as cottages, metal products with very high electrical conductivity are mainly used, and are also quite simple to install.

How to install fittings correctly?

Proper connection of reinforcement ensures high strength of the reinforced concrete base, preventing the occurrence of cracks and providing resistance to various loads.

Mating

. The reinforcement is connected by overlap, crosswise. Ribbed rods are used for horizontal elements, and smooth rods are used for crossbars. Knitting is performed using flexible steel wire with low carbon content, 1.2-1.4 mm thick. Also, special plastic clamps with a steel thread core can be used for these purposes.

As additional equipment, a special gun or drill with an attachment in the form of a crochet hook is used, which can significantly reduce labor costs. You can also use ordinary pliers. Please note that the twist after trimming the excess ends should be well fixed and pressed against the frame.

Welding

. Performed in accordance with GOST 14098–91. For high-quality connection of reinforcing elements, several welding methods can be used: electroslag, semi-automatic, bath-seam, manual electric arc, contact, bath. Depending on the strength requirements, several types of connections are used - T-joints, butts and lap joints. Welding is applied only to A400C and A500C fittings that can withstand thermal effects.

The main advantage of this technology is minimal time costs, which is especially important for large-scale construction. However, as a result of welding, the strength characteristics of the reinforcing bars at the joints are reduced, and the seam itself is characterized by increased fragility. Therefore, such load-bearing structures are not recommended for use when compacting concrete with a vibropress. Welding of reinforcement is also not carried out for foundations in areas with marshy soil.

The selection and calculation of reinforcement must be performed at the design stage of the house. Only with strict adherence to the requirements of design documentation during construction can the high quality of the foundation be guaranteed.

Reinforcement surface

Many people wonder what kind of reinforcement is needed for a foundation? Let's take a closer look. The reinforcement can have completely different surfaces. These include the following:

- Corrugated. There are special protrusions on the surface of this product. Thanks to them, the most durable connection with the concrete mixture is ensured. Moreover, such material can have a completely different shape: crescent-shaped and even combined. The most durable is the crescent shape. Therefore, it is used most often in the construction industry.

- Smooth. This product does not have a profile on the surface. Because of this, the material does not have good adhesion to concrete. In most cases, rods are used to make floor screeds.

Composite reinforcement

This type of composite raw material has many advantages:

- it is light;

- lasting;

- not subject to corrosion.

Fiberglass reinforcement is actively used when laying foundations, although it has a number of disadvantages.

Disadvantages of composite reinforcement

The disadvantages of raw materials include:

- low heat resistance, at temperatures above 200° C the material loses its strength;

- low elasticity;

- decrease in strength under the influence of alkali.

All of the listed shortcomings are not critical, but they should still be taken into account when carrying out construction work.

Marking of reinforcement for foundation

The marking shows the strength and class of the material. In order to choose a suitable material for strengthening, it is imperative to pay attention to these indicators. Conventionally, we can distinguish the following categories that you need to know. These include the following:

- A 300. The materials are made from high-quality hot-rolled steel. This product has a ring-type corrugated surface. Ideal as a structural material, as well as for the construction of a one-story building with a light load.

- A240. This material is made from hot rolled steel. The fittings have a smooth surface. Its diameter is completely different, it can vary from 6 to 40 mm. It is practically not used as working elements. It is mainly used for connecting clamps.

- A 600. This material is quite durable. Thanks to this, it can be used for the construction of multi-storey buildings with high loads.

- A400 and A500. These materials are quite durable. They have a corrugated surface. Ideal for strengthening foundations. The diameter of such a product can vary from 6 to 40 mm.

Instructions on how to knit reinforcement

The elements placed in the lower mesh (size 10 ml) are placed at a distance of half a meter from each other. This work is carried out along the entire perimeter. The length of the steel rods should be equal to the width of the foundation strip.

The next stage is the placement of rods of smaller diameter and their subsequent connection to the main elements of the lower reinforcing mesh.

Tape type base

Before deciding what brand of reinforcement is needed for a strip foundation, you need to understand what this type of foundation is. This option is cost-effective and one of the most popular. It is actively used in the construction of cottages and private houses. This type of foundation has many advantages. These include the following:

- The materials are quite durable compared to other varieties. It is least susceptible to deformations of various types.

- Can be used to furnish a basement.

- It is definitely recommended to use a rod of a certain diameter. Many people ask what diameter of reinforcement is needed for a strip foundation? The diameter should be 12 mm. It is not recommended to use a product with a large diameter.

Many people are interested in what kind of reinforcement is needed for a strip foundation? For these purposes, rods of classes are used: A1 and A3. They are produced by the hot-rolled method.

A240 fittings have a smoother surface. Most often it is used for longitudinal strapping. As for the A300 rods, they have greater strength.

If you have this information, subsequently there will be no questions about what kind of reinforcement is needed for a strip foundation.

Plastic fittings

There are several types of such composite material, but basalt-plastic and fiberglass reinforcement are most widely used.

The first type is rods with a round cross-section. It is used for reinforcing the foundations of buildings. It is also used in laying roads and in the construction of hydraulic structures.

Slab variety

Thanks to this type of foundation, it is possible to make the building more durable and reliable. For its reinforcement, rods with a diameter of about 16 mm are used.

Monolithic slabs are used in cases where it is planned to deviate from standard parameters during construction.

Very often, many people wonder what kind of reinforcement is needed for a monolithic foundation slab?

Monolithic slabs have increased rigidity, and their purchase is a cost-effective option. The only thing is that at low temperatures they are difficult to install.

As for the reinforcement for a monolithic slab, its diameter should be about 13 mm. The choice primarily depends on the load that will be placed on the slab during its use.

If you have this information, subsequently there will be no questions about what kind of reinforcement is needed for a monolithic foundation.

Tools for tying reinforcement

When connecting transverse and longitudinal elements, the wire is tightened with the following devices:

- pliers;

- special hooks;

- screwdriver.

Special guns are also used, which significantly speed up the work process.

Fiberglass or metal (steel) reinforcement - comparative characteristics

If you have not yet decided which reinforcement to choose, then you need to weigh all the pros and cons of both types of reinforcing material.

Advantages of steel reinforcement:

- strength (with equal specific gravity, it is 9 times stronger than composite. With the same diameter, fiberglass reinforcement is 4 times lighter);

- elasticity (withstands high deflection load);

- availability;

- complex but possible bending of the rod;

- resistance to external influences;

- diameter range from 6 to 80 mm;

- maximum length 11.7 m.

Disadvantages of metal fittings:

- susceptible to corrosion;

- significant weight.

Advantages of fiberglass reinforcement:

- low cost (almost equal to steel - the difference is 30% in favor of fiberglass, but due to the lower weight it is possible to significantly reduce transportation costs);

- any construction length of the rod is provided;

- convenient transportation (light weight + simplification of loading and unloading operations);

- light weight (almost 4 times lighter than steel with the same diameter);

- high elasticity;

- high tensile strength (2.5 times more than metal);

- does not conduct heat (helps to further increase heat retention, eliminates the formation of “cold bridges”, in contrast to the use of metal fittings);

- calmly tolerates critically low (up to - 70 °C) and high temperatures (up to + 100 °C);

- radio transparent (does not create electromagnetic interference, does not shield);

- does not conduct electricity (dielectric);

- retains its properties when exposed to salts (sea water), alkalis and acids;

- not subject to corrosion (can be used in aggressive environments, in contact with water);

- diameter range from 4 to 20 mm.

Disadvantages of fiberglass reinforcement:

- it is impossible to make a bend;

- it is impossible to carry out welding work on its surface.

Comparison of fiberglass reinforcement with steel (metal)

(comparison of differences is described in detail in the table)

Comparison of fiberglass reinforcement with steel (metal) - table

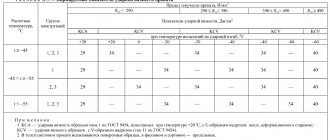

Reinforcement interchangeability table

(replacement with equivalent strength analogues – metal/fiberglass)

Reinforcement interchangeability table

Technologies for assembling reinforcement for strip foundations

Reinforcing the strip foundation with your own hands begins after installing the formwork. There are two options:

- The entire frame is assembled directly in a pit or trench. If the tape is narrow and high, it is inconvenient to work. According to one technology, the reinforcement is knitted directly in the formwork

- Frame sections are prepared close to the pit. They are transferred in parts and installed in their designated place, linking them into a single whole. It’s more convenient to work this way, except that it is very inconvenient and difficult to move connected structures made of reinforcement.

Both options are imperfect and everyone decides how it will be easier for him. When working directly in a trench, you need to know the procedure:

- The longitudinal rods of the lower reinforced belt are laid first. They need to be raised 5 cm from the edge of the concrete. It is better to use special legs for this, but pieces of bricks are popular among developers. The reinforcement is also 5 cm away from the formwork walls.

- Using transverse pieces of structural reinforcement or molded contours, they are fixed at the required distance using tying wire and a hook or a tying gun.

- Then there are two options: If contours formed in the form of rectangles were used, the upper belt is immediately tied to them at the top.

- If during installation you use cut pieces for crossbars and vertical posts, then the next step is tying up the vertical posts. After they are all tied, a second belt of longitudinal reinforcement is tied.

There is another technology for reinforcing strip foundations. The frame turns out to be rigid, but there is a large consumption of rods for the vertical posts: they are driven into the ground.

The second technology for reinforcing a strip foundation is to first drive in vertical posts, tie longitudinal threads to them, and then connect everything with transverse ones

- First, vertical posts are driven in at the corners of the tape and at the junction of horizontal rods. The racks should have a large diameter of 16-20 mm. They are placed at a distance of at least 5 cm from the edge of the formwork, checking horizontal and vertical, and driven into the ground 2 meters.

- Then vertical rods of the calculated diameter are driven in. We determined the installation pitch: 300 mm, in the corners and at the junctions of the walls it is half as much - 150 mm.

- The longitudinal threads of the lower reinforcement belt are tied to the posts.

- At the intersection of the racks and longitudinal reinforcements, horizontal jumpers are tied.

- The upper reinforcement belt is tied, which is located 5-7 cm below the upper surface of the concrete.

- Horizontal jumpers are tied.

It is most convenient and quick to make a reinforcing belt using pre-formed contours. The rod is bent to form a rectangle with the specified parameters. The whole problem is that they need to be made identical, with minimal deviations. And a large number of them are required. But then the work in the trench moves faster.

The reinforcing belt can be knitted separately, and then installed in the formwork and tied into a single whole on site

As you can see, reinforcing a strip foundation is a lengthy and not the easiest process. But you can cope even alone, without helpers. It will take a lot of time, though. It’s easier to work with two or three people: both carry the rods and set them out.