Alternative options

Automotive stores sell traction control bracelets - a worthy alternative to chain equipment.

They are distinguished by the possibility of quick installation and low price. But even here the engineering thought of our motorists does not stand still; they have skillfully learned to copy factory copies. Bracelets are the same homemade snow chains, but without longitudinal elements; their advantages are as follows:

- Ease of manufacture.

- Quick installation.

- High efficiency and reliability.

To make it you will need a modest kit:

- VAZ muffler mounting element made of rubber;

- bolts 40-60 mm long, washers and nuts;

- a tube with a diameter equal to the diameter of the bolt;

- steel chain with a diameter of at least 5-6 mm.

To equip wheels with standard sizes 195 and 205 mm, 4-5 meters of hardware products will be required. Stores also sell ready-made kits for self-assembly of bracelets, with the exception of Chinese kits, they are of fairly decent quality and inexpensive. It consists of:

- blanks;

- fastening accessories;

- sling;

- clamp lock.

The kit is easy to use, transported in a special case and does not take up much extra space. An important advantage of metal bracelets is the possibility of installation on wheels with disc brakes. And if you take into account the reviews, then owners of expensive foreign cars do not hesitate to use such devices, which also says a lot.

What and how to make wheel chains with your own hands in an hour

Any experienced car enthusiast has had unpleasant moments when the driving wheels of the car began to slip in mud, ice or deep snow. It is often almost impossible to get out of such situations on your own - only with the help of another vehicle. What are our colleagues doing? Some people buy tires with studs after such incidents, others simply park their car during natural disasters. But there is another category of motorists who use homemade wheel chains and, I must say, quite successfully.

Design and types of anti-skid means

These devices are based on a simple design consisting of steel links or reinforced wire. A successful application is to distribute the elements evenly over the entire radius of the tire. Failure to comply with this condition may result in rupture of the product and loss of anti-slip properties. The classic scheme, tested by more than one generation of motorists, consists of internal and external components that run along the entire circumference of the tire. They are connected to each other by transverse parts, the so-called “lugs”. The technology for making a chain for wheels with your own hands is accessible even to beginners. Depending on the arrangement of structural elements, there are three types of devices :

- in the shape of a ladder;

- in the form of a honeycomb;

- in the shape of rhombuses.

Each type has its own advantages and disadvantages. In terms of labor costs, the first option is the most accessible - “ladder”.

Making a simple homemade chain for car wheels

It is not always possible to purchase an anti-skid device - the high price and lack of availability of the required size forces car owners to solve such issues on their own. I must say that this is a pretty good choice - all the necessary components are always available in hardware stores. In a critical situation, you can simply try to wrap the tire with a cable or a piece of metal rigging, but not everyone carries such a kit with them. Moreover, for a disc brake system this option is absolutely contraindicated - such a design will disrupt the operation of the mechanisms. Therefore, it is worth preparing homemade wheel chains in advance, for which you will need :

- steel chain with a cross-section of at least 5 mm;

- hooks;

- carabiners with a screw-on coupling;

- tension device;

- bolts, nuts and washers.

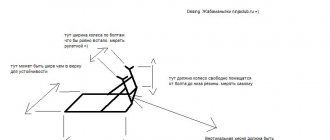

The dimensions of the blanks depend on the dimensions of the tire used, so it is important to first measure the required indicators. The number of transverse parts is also individual - craftsmen recommend making sure that there are two “cross members” at once in the plane of contact of the tire with the ground. Thanks to this scheme, the traction characteristics and reliability of the entire product will increase. The process of preparatory actions and assembling chains on wheels with your own hands consists of the following points:

- cutting longitudinal blanks;

- cutting of transverse parts;

- securing the transverse element to the 6th link of the longitudinal chain;

- installation of subsequent “crossbars” every 9 links using rings or hooks;

- In the middle of one longitudinal workpiece, fasten a segment consisting of 6 links and a tensioning device with a hook.

As can be seen from the description, if you have certain skills and tools, the operation will take no more than 40 minutes. Those with experience in welding can put it into practice and abandon threaded connections, which will certainly affect the quality of the equipment.

After checking the reliability of the finished product, all that remains is to install it on the car.

How to install chains on wheels with your own hands

The anti-skid device is mounted primarily on the leading pair and this is done using two methods :

- directly on a stationary car;

- with jacking up the desired side.

The choice of method is up to the driver, but it is worth focusing on one recommendation - you need to think about installation in advance, even before entering a difficult area . This is the only way to avoid annoying mistakes and save a lot of time.

Installation method without jacking the car

Before you begin installing a homemade chain on car wheels , you should carefully lay it down, preventing the links from twisting. Next we proceed point by point:

- Drive the drive wheel onto the product.

- Put the car on the handbrake.

- Place the chain so that the tensioning device with hook and carabiner is on the outside.

- From the inside, connect the hook and the last link of the longitudinal element.

- From the outside, place the carabiner coupling onto the tensioning mechanism and secure it.

- Distribute the transverse parts and tighten them.

Installing a chain on car wheels with your own hands using a jack is similar to the technology described above, its only advantage is that it makes the task easier. For a better installation, you must first reduce the tire pressure, but after the operation do not forget to restore normal parameters. This procedure will allow the product to fit as tightly as possible to the tire.

Alternative solutions

The thoughts of folk craftsmen do not stand still - and now they are offering an alternative solution: anti-slip bracelets . In principle, these are the same homemade metal chains for wheels, only with the difference in the absence of longitudinal elements . The advantages of bracelets are:

- ease of manufacture;

- quick installation;

- high reliability and efficiency.

So, what is needed for production:

- rubber mounting element for the VAZ muffler;

- metal chain with a diameter of at least 6 mm.

Tires with a width of 195 and 205 mm will require about 4 meters of chain. As you can see, the costs are minimal and you only need to cut the material to the required length. Another alternative option is kits for making DIY wheel bracelets using chains, which are quite affordable and of good quality (with the exception of Chinese ones). The set consists of:

- chain blanks;

- fastening accessories;

- sling;

- clamping mechanism.

The kit is very easy to use and does not take up much space. An important plus is the possibility of use on cars with disc brakes . Judging by the reviews, owners of expensive SUVs do not hesitate to use it, which once again speaks of the practicality of the device. For more information on how to make snow bracelets with your own hands, watch the video:

Things to remember

The use of anti-slip chains is prohibited when driving on hard-surfaced roads (concrete, asphalt). In conditions of loose snow or soil, it is recommended to maintain a speed of 10-20 km/h. Wheel slip must not be allowed.

After installing the anti-slip device, after driving the first 100 meters, you should stop and check the reliability of its fixation, as well as the tension around the entire perimeter. A poorly tensioned chain can cause damage to suspension and steering components.

Rate this article: Share with friends!

autoclub.su

The second option based on Zhiguli wheels

A complete set of disks will be needed, since tires can be placed on one pair and used for transportation on asphalt roads, and the second pair can be used as traditional lugs.

Sequencing:

- cut a steel corner with a side of 5-6 cm into pieces wider than the existing disks;

- In the center of one side, use a grinder to cut out a triangular area. It is this part that they will touch on the lug;

- Heat the corner with a burner and bend it slightly. Additionally, we tack by welding to strengthen the workpiece;

- We weld the spikes from the corners along the outer rim of the machine disk at equal intervals (a step of 15 cm would be optimal, directing the pointed part as the walk-behind tractor moves).

Similar operations are repeated for the second disk, as shown in the video.

Using our recommendations, you can make homemade lugs for any brand and model of walk-behind tractors: Agat, Salyut or Neva. The dimensional differences between the models of these cultivators are insignificant, so the lugs from the Neva MB-1 series are also suitable for later versions - MB-2, MB-21, etc., expanding the scope of their application.

Functions of lugs

Grousers are additional equipment that expands the scope of use of walk-behind tractors on the farm. Their use is necessary when plowing the land, loosening, hilling and harrowing. Thus, the main functions of the equipment are:

- Strengthening the adhesion force of the walk-behind tractor with the soil. Widely used on arable land and sandy soil.

- An increase in the total weight of the unit, which makes it possible to use other additional equipment. Walk-behind tractors come with both small and large mass, but it may not be enough to move, for example, a plow. In this case, additional weight will not hurt.

- The structure of the lug is such that when moving it produces additional loosening of the soil. Can be used to remove weeds.

Where is a car lug used?

If your car gets into trouble on a long trip and gets stuck in mud or a hole, our car grouser clamp will immediately come to the rescue. It was designed for car tires, but will also fit any car model, provided the wheel height matches. And if your wheel diameter is different, we can make a clamp for you individually, for any size you ordered.

Just imagine with what ease and absolute ease you can pull your own car out of any mud.

The grouser clamp is very easily installed on the wheel rubber and simply snaps into place. After this simple procedure, you can simply step on the gas harder, and the car will easily get out of the captivity of the off-road. Car lugs will not only help you pull your car out of a hole or deep mud, but also drive it even on the most difficult road from 5 to 10 km.

Snow chains and bracelets: which is better?

Analogues of chains for cars are bracelets, which are a pair of pieces of chains fixed on the wheels with belts. The chain sits on top of the bar and the belt sits in the hole between the rim. In this case, the bracelet, unlike the chain, is firmly tightened on the bar, which allows the chain to be located in one place.

To increase efficiency, it is recommended to attach at least three anti-skid bracelets to one wheel

Typically, three bracelets are installed on one wheel, which is enough to reach a hard surface, creating friction and pushing away the car. Unlike chains, bracelets have the following advantages:

- Speed and ease of installation. If it is recommended to install chains only before crossing a snowy or marshy area, then the bracelet can be installed even when the car is stuck.

- Compact, as they do not take up much space in the trunk, unlike chains.

- No need to jack up the wheel.

- Versatility. While chains are designed for a specific wheel diameter, bracelets are suitable for any wheel size.

- Unlike chains, bracelets are several times cheaper.

- Long service life.

Like chains, bracelets are divided into hard and soft. Some of the cheapest options for bracelets are plastic products. They are suitable for all types of cars: from small cars to SUVs, so every driver can afford them.

Bracelets, like chains, are divided into hard and soft

How else do chains differ from bracelets? Numerous observations of drivers show that the chains have better adhesion to the road surface, which has a positive effect on cross-country ability. Chains can be used to overcome snowy and icy areas until they are finished. The bracelets can only be used for short-term use up to 5-10 km.

It is important! If one link on the chain breaks, this poses a threat to the car body. Damage to the paintwork may occur, which ultimately contributes to the formation of a corrosion area.

When you know what chains and bracelets are, you can conclude:

- If you are planning a long road through marshy, snowy and icy areas, then it is recommended to use chains.

- Bracelets are used exclusively when rare trips around the city or outside of it are planned in bad weather. Even if during a trip you forget to put on a bracelet, you can do this at any time, even if the car gets stuck.

Do-it-yourself caterpillar for a motorized towing vehicle

A motorized towing vehicle, popularly called a “motor dog,” is ideally suited for use in northern latitudes with good snow cover. Using a walk-behind tractor, you can independently make an alternative to a dog sled, a high-speed tracked vehicle that can tow a sled with a person or a small load in the snow.

Making a caterpillar for a motorized dog with your own hands is not at all difficult.

You can use an old gooseneck from a Buran snowmobile. To increase the chassis, you should cut it in half and build it up using inserts. The tracks can be carriages from the old Buran. Three carriages with rollers are enough. They also need to be sawn and extended with inserts.

In the absence of old spare parts, a caterpillar for a motorized towing vehicle can be made from improvised materials using one of the methods described above. For example, from a conveyor belt.

For production you will need:

- conveyor belt with a width of 22 cm;

- metal bars for reinforcement;

- hardwood timber blocks for track tracks.

We bring to your attention a video showing the caterpillar manufacturing process.

Making tracks for a walk-behind tractor is a simple process, although it requires a sufficient amount of time. It is also necessary to make every effort and skill to ensure that all links of the goose are located at an equal distance from each other. This will help to avoid distortions and sliding of the caterpillar track from the load-bearing surfaces.

Combined holds

Such devices are needed not only for walk-behind tractors. Many are also interested in the question of how to make lugs for a cultivator with their own hands. For these purposes, you can use combined wheels, for example, using a tread from a tractor.

To implement such a project, halves of Zhiguli wheels should be prepared. It is also necessary to prepare tractor tires with strong tread. Then you need to cut the sides. This results in a rubber circle with excellent tread.

Read also: Why does the chandelier blink when the light is on?

Such wheels can be used on hard dirt roads, as they will not loosen the ground. They will also perform well on soft ground, but the grip on the ground will be much less than with metal discs.

If you need a wheel option not only for good traction with the ground, but also for loosening, then you need to make knife lugs that will not drive on regular roads, but are only suitable for loosening. This way the land will be cultivated.

When cultivating the land in the spring, the width of the occupied area with the help of such wheels doubles, which is good news, as it saves a lot of time.

It doesn’t matter how to make lugs and what type, the main thing is that they are made independently - simply, from improvised means, and the budget for their production is simply ridiculous.

How to choose snow chains

Their assortment is very large. When choosing, you need to take into account first of all the tire sizes, tread width, wheel arch size, as well as the conditions under which they will be used in the future.

Dimensions of links in chains for driving in winter and summer

Designation: D - diameter of links, L - length, W - width.

| № | Car make | Size of links in longitudinal branches | Size of links in transverse branches | ||||

| D | Dl | Sh | D | Dl | Sh | ||

| 1 | VAZ `winter` | 3,5 | 26,5 | 13,2 | 3,8 | 19,0 | 15,0 |

| 2 | VAZ `summer` | 4,0 | 32,0 | 15,2 | 5,0 | 21,0 | 19,0 |

| 3 | VOLGA `winter` | 4,0 | 32,0 | 15,2 | 3,8 | 19,0 | 15,0 |

| 4 | VOLGA `summer` | 4,0 | 32,0 | 15,2 | 5,0 | 21,0 | 15,0 |

| 5 | NIVA `winter` | 4,0 | 32,0 | 15,2 | 5,0 | 21,0 | 19,0 |

| 6 | NIVA `summer` | 5,0 | 36,0 | 19,0 | 5,0 | 21,0 | 19,0 |

| 7 | GAZELLE `winter` | 5,0 | 36,0 | 19,0 | 5,0 | 21,0 | 19,0 |

| 8 | GAZELLE `summer` | 5,0 | 36,0 | 19,0 | 6,0 | 24,0 | 22,0 |

| 9 | UAZ `winter` | 5,0 | 36,0 | 15,0 | 5,0 | 24,0 | 19,0 |

| 10 | UAZ `summer` | 5,0 | 36,0 | 15,0 | 6,0 | 24,0 | 22,0 |

| 11 | JEEP `winter` | 5,0 | 36,0 | 15,0 | 5,0 | 21,0 | 19,0 |

| 12 | JEEP `summer` | 5,0 | 36,0 | 15,0 | 6,0 | 24,0 | 22,0 |

| 13 | MAZ, KAMAZ `winter` | 6,0 | 42,0 | 23,0 | 5,0 | 21,0 | 19,0 |

| 14 | MAZ, KAMAZ `summer` | 6,0 | 42,0 | 23,0 | 6,0 | 24,0 | 22,0 |

The advantage of rigid chains is their better adaptability to rough off-road conditions, however, their disadvantage is the speed limit (up to 40 km/h) and the possibility of damage to vehicle transmission elements.

Soft chains allow you to reach speeds of up to 80 km/h; they are more harmless to the treads and wear out the rubber much less. However, their disadvantage is that they cope with off-road conditions much worse.

The most reliable, high-quality and more expensive chains are those made of titanium or stainless steel.

Varieties and how they differ

Many drivers, having become familiar with the disadvantages of lugs, make a negative decision about purchasing or manufacturing them. However, sooner or later a situation comes when the presence of chains will not hurt. Grunts are divided into several types. The main distinguishing parameters are: the material of manufacture and the geometric pattern of the chain product on the tire.

This is interesting! The above parameters have a corresponding impact on the car and its off-road performance when moving.

Depending on the material of manufacture, lugs are divided into the following types:

- Tough.

- Soft.

Rigid lugs

Rigid types include products made from the following types of metals: titanium, steel, aluminum. The strength of the product depends not only on the material, but also on the thickness of the links. The larger the dimensions of the links, the higher the vehicle’s cross-country ability. However, the indicators of negative impact on the car are also higher.

On the one hand, thick chains increase the vehicle’s maneuverability, on the other hand, they negatively affect the suspension and steering rack

The disadvantage of rigid products is the high noise level, as well as accelerated tire wear. On chains of this type you cannot reach speeds higher than 40 km/h. In addition, the massiveness and heaviness of the chains negatively affect the vehicle. Not all types of passenger cars can use rigid chains due to the small space between the wheel arches.

Soft lugs

Soft lugs are made from non-metallic materials, such as rubber, polyurethane and even plastic. To increase the strength of products, a method such as reinforcement is used. Soft versions of lugs for cars are more gentle, as they contribute less to rubber wear, and they are also almost silent. A car on such lugs can reach speeds of up to 80 km/h, while providing high-quality traction with the road surface.

Soft chains can hardly be called “chains” in the literal sense of the word, but when driving around the city they do just as good a job

Like hard chains, soft lugs have disadvantages that are clearly manifested when moving on ice. Soft chains perform well when moving around the city, without having a negative impact on the road surface. However, they are not able to ensure effective passage through snowy areas and mud, so in such situations only rigid chains should be used.

How to make lugs with a more complex design?

The above methods for manufacturing lugs are very simple, but options with more complex designs can also be considered.

You need to acquire the following details:

- a steel sheet with a thickness of 3-5 millimeters, which will be used for a steel disk;

- a strip of steel with a thickness of 5 millimeters and a width of 50 millimeters; the outer hoop will be made from it. A total of six hoops are needed to make the wheel heavier and stronger;

- a steel strip with a thickness of 8-10 millimeters, it is needed for hooking;

- drill or drill;

- grinder;

- welding machine.

Arc welding is used to connect all the parts, since a gas torch cannot cope with such a thickness of metal.

The lugs are manufactured according to the following scheme:

- The axles are lengthened. This needs to be done because the size of the lugs requires more mounting space than standard wheels;

- It is necessary to be able to adjust the position of the track to process beds of different widths;

- Two central disks are made from profiled steel sheet;

- Three external hoops and hooks are welded to the end parts of the product;

- Steel plates are welded to the hoops. Their placement should be diagonal like a snake;

- Each plate is ground for optimal traction.

Designs for “advanced” farmers

Simple designs from Zhiguli wheels can be easily made, but their consumer properties are not ideal. Therefore, in special cases, there is a need for homemade assembly of lugs, which are no worse than factory models, and they can weigh down the walk-behind tractor well.

For the manufacture of complex structures, it is necessary:

- Steel sheet 4-5 millimeters for the main circle.

- Steel strip 50 millimeters, 4-5 millimeters thick for the supporting surface. There should be 6 of them. They strengthen the disc well and make it heavier.

- Sheet of steel 8-10 millimeters for creating hooks.

- Welding machine (automatic or semi-automatic), drill, grinder, drilling workbench.

All parts are connected using electric welding, since a gas torch will not be able to heat metal of such thickness.

Due to the fact that the diameter of the lugs is larger than that of conventional wheels attached to a walk-behind tractor, it is necessary to lengthen their axles.

In this case, it is advisable to provide the ability to adjust the length of such axes, since the rows on the field can be of different widths. Thus, by moving the wheels with hooks vertically, you can set them to any level, width and position. In this case, the weight of each wheel will be at least 10 kilograms, and this provides excellent traction with the ground.

You need to know that such devices are not suitable for plowing or loosening the soil, although minor soil cultivation occurs while driving across the field. The lugs on the walk-behind tractor are not suitable for loosening, since an independent support point is required here.

If the design of the structure should not be heavy, then it can be made more beautiful, with an aesthetic appearance. Such wheels can be used on light soils where loosening has been done previously. They have a small diameter, in the middle there are shaped knitting needles made of profiled steel sheet. The steel for the hooks should be no more than 8 millimeters, and the weight of the wheel should be no more than 8 kilograms.

How to make lugs with your own hands

Homemade lugs for walk-behind tractors can be made from machine disks. If a farmer has an old car that is a pity to throw into a landfill, with whole disks and rims, then they can be used to make lugs for a walk-behind tractor from car disks.

For this you will need:

- rims;

- welding machine (or grinder);

- square plates;

- drawing or diagram of lugs for the walk-behind tractor (will make the work very easy).

So, to make lugs for a walk-behind tractor from machine disks, you need to weld an axle shaft to them, onto which bearings are then put. Square plates need to be welded to the car rims.

After the completed procedures, you need to make plates-teeth that will bite into the soil, providing the necessary adhesion to it. The teeth can be made from solid metal sheets by cutting the desired size with a welding machine or by welding small plates together.

The teeth are welded to square plates on disks at a distance of 15-16 cm from each other. A deviation of 2-3 cm is acceptable, but for better operation of the unit you must strictly follow the instructions in the drawings and diagrams.

If the old car is not available, but there is a used gas cylinder, then there is another way to make lugs for the walk-behind tractor with your own hands.

For this you will need:

- gas cylinder (used);

- grinder or welding machine;

- metal plates for teeth;

- drawings or lug diagrams of a walk-behind tractor of the required brand.

First you need to cut two disks from the cylinder, which will serve as rims for the wheels of the walk-behind tractor. Then, as in the first option, weld the square plates and the teeth to them.

Another option is to weld lugs from steel plates. For this you will need:

- steel layers 4-5 mm thick;

- steel layers 6-8 mm thick;

- welding machine or grinder;

- drill or hammer drill.

A thinner sheet must be cut into two disks, in the center of which holes must be made for the hub. Cut sawtooth waves along the outer edges, with a wave depth of 100 mm. Triangles with cut corners must be cut out of a denser steel layer and welded perpendicular to the waves. The design is ready for use.

Of course, such lugs differ in appearance from their counterparts, but they also have many advantages.

Do-it-yourself lug lugs for a car - Metals, equipment, instructions

Any experienced car enthusiast has had unpleasant moments when the driving wheels of the car began to slip in mud, ice or deep snow. It is often almost impossible to get out of such situations on your own - only with the help of another vehicle.

What are our colleagues doing? Some people buy tires with studs after such incidents, others simply park their car during natural disasters.

But there is another category of motorists who use homemade wheel chains and, I must say, quite successfully.

How to make snow chains with your own hands and video of work processes

Experienced motorists can give thousands of examples when mud, ice or deep snow prevent the successful completion of a trip. The power of the driving wheels is powerless in such situations - only a tug or a winch.

After such unpleasant moments, some owners refuse to travel in bad weather, others install studded tires .

However, there is another category of drivers who prefer to independently manufacture additional equipment to increase cross-country ability.

How to choose the right lugs for a walk-behind tractor?

The correct choice of lugs is the key to their successful operation and the functionality of the cultivator itself.

It should be based on several criteria:

- size - it is considered that the lugs on the walk-behind tractor are selected correctly if, after installation, they do not come into contact with the body part. It is important to take into account the power class of the cultivating device: for heavy series walk-behind tractors whose weight exceeds 200 kg, it is recommended to use wide lugs (d=0.7 m); medium and light cultivators function most reliably with smaller metal wheels - with a diameter of no more than 0.3-0.4 m;

- the nature of the lug surface and the type of soil (its moisture capacity, flowability, looseness) that is supposed to be processed. The outer side of the lugs can be made in the form of:

- spikes, which are evenly distributed plates of welded reinforcement of various heights. According to consumer reviews, lugs for walk-behind tractors with low spikes (about 2 cm) are difficult to use on wet, loose soils. Therefore, for black soils it is better to choose a large spike that will not clog and will not reduce the traction of the unit. On sandy areas in which moisture does not linger for a long time, this criterion can be slightly neglected and be guided only by your personal considerations and budget;

- arrow - their connecting part has an angular shape. Arrow-shaped lugs are the most popular equipment option, which is suitable for any type of soil and for any load;

- The brand and modification of a motor cultivator is the most reliable criterion, following which it is difficult to make a mistake. The lugs for a specific cultivator model are ideally adapted to its technical characteristics and are most often sold in pairs with hubs;

- price - depends on the manufacturer and versatility. When purchasing lugs for a light tillage machine, it is important to understand that you will have to fork out for auxiliary elements - weighting agents, without which the equipment will slip on heavy soils.

One of the ways to save on purchasing lugs and acquire faithful assistants for agricultural needs is to create metal wheels for a walk-behind tractor with your own hands.

Varieties of lugs according to geometric pattern

Depending on the geometry of the pattern, there are three types of snow chains:

- "Ladder".

- "Rhombus".

- "Honeycombs".

Each option has its own advantages and disadvantages, so we will consider them in detail.

"Ladder"

The “ladder” is a base in the form of longitudinally arranged branches. These branches are evenly distributed around the entire circumference of the wheel. To secure the chain on the wheel, the appropriate type of locks are used. Externally, this type of lug resembles a ladder, which is where the name comes from.

This lug option is one of the most popular, effective and in demand. Among the disadvantages of this type of chain it is worth noting:

- parallel arrangement of chains on the wheel, so the car will dig in when overcoming snowy or soil areas;

- low lateral stability, which is also due to the parallel arrangement of the chain branches;

- heavy load on the transmission.

Despite the high raking properties, ladder-type chains are practically useless on snowy ground

It is recommended to use chains of this type only when it is necessary to overcome a risky section of the route. This option is one of the cheapest, so when the need arises, most drivers prefer this option without delving into its features.

"Rhombus"

The diamond lug design is a modernized "Ladder" design. For this purpose, there are longitudinal branches that form a diamond-shaped pattern, eliminating all the negative factors that are characteristic of the “Ladder”.

The geometric shape in the form of a diamond is intended for the use of lugs when it is necessary to overcome a snowy or swampy area. The diamond shape is shown in the photo below.

Diamond-shaped chains have increased strength and high traction characteristics

The diamond-shaped shape of snow chains is popular among SUVs and crossovers, since this type of pattern on the lug increases the vehicle's cross-country ability several times. This is especially true for snow-covered and icy road sections.

"Honeycomb"

An analogue of a rhombus are “honeycombs”, which have transverse branches similar to a rhombus, but are additionally connected by straight connectors. Diamond and honeycomb are improved types of lugs, in which the products are in constant contact with the road surface. This is a big plus for both rubber and transmission, so when making lugs it is recommended to pay attention to the last two models.

“Honeycombs” ensure constant contact with the road, therefore giving the car a high level of lateral stability

It is also worth noting that when purchasing snow chains, you need to consider their size. The lugs produced in production are divided not only by size for wheels, but also depending on the type of car.

How to install snow chains on a car with your own hands and video operation

Experts recommend installing traction control equipment on all wheels, and not just on the drive ones. Incorrect installation can lead to damage to ABS sensors, brake system components and wheel arch liners, as well as side tire cuts.

- With jacking.

- On a stationary car.

The essence of the question is not only how to properly make snow chains on a car with your own hands using a video - you should think about installation work even before entering the problem area. This is the only way to enjoy the operation, save your time and avoid annoying mistakes.

There is no point in describing the first method using a jack - the procedure is elementary and will not cause any difficulties even for a novice driver. The only recommendation is to reduce the tire pressure to make the work easier.

Another question is when this device is not at hand. In this case, you can install chains on snow wheels with your own hands using the following technology:

- place the product in front of the wheel pair, avoiding twisting of the links;

- run over the product with wheels;

- apply the handbrake;

- put on the device so that the hook and carabiner are on the outside of the wheel;

- connect the hook and the last link of the longitudinal part to the inside of the wheel;

- put the carabiner coupling on the tension system from the outside and fix the knot;

- distribute the transverse elements along the entire perimeter of the tire and tighten it.

Important! To ensure uniform distribution of equipment components, drive 20-30 meters and then make final adjustments. This event will guarantee maximum adherence of the product to the rubber.

Design features of homemade chains for car wheels

The basic design is a simple structure that consists of a set of steel links or reinforced wire. Uniform distribution of components over the entire tire area is the key to successful operation of the product.

Classic DIY snow chains in the video look like two elements that are located longitudinally along the radius of the wheel on the outer and inner sides. They are connected to each other by transverse parts, the so-called lugs. The manufacturing method is not difficult even for novice motorists. The arrangement of parts is carried out according to three schemes:

Each of the above types has its own disadvantages and advantages. The first option with a “ladder” is the most affordable in financial terms, as well as in terms of labor costs. No less interesting is the solution with bracelets, which are also convenient when installed on a wheel.

How to make your lugs heavier

As mentioned earlier, for uniform tillage of the soil with special attachments, appropriate weighting agents are used, which allows the mechanism used to remain at the required depth during movement. In this case, it is necessary to consider in more detail how to make the canopies used heavier, namely:

- for purchased equipment, special auxiliary weights can be used, which are hung together;

- if necessary, you can use hanging any heavy object for uniform plowing;

- in this case, it is possible to independently create a fairly heavy device that will loosen the soil evenly;

- Often, on manufactured versions, a corresponding center of gravity is specially provided, which is achieved by the presence of a certain design;

- weighting can be an additional adjustable insert that is present on the attachment.

There are quite a lot of options for increasing the mass of this device; here you just need to rationally use such weighting so that during operation the device does not fall deep enough into the ground. Otherwise, damage to the coupling mechanism or deformation of the tillage mechanism itself may occur.

Important. When working with such equipment, weather conditions should be taken into account, as well as the humidity and softness of the soil surface being treated.

What is the lug used for?

The lug is used to obtain additional traction force for transporting goods on unpaved roads. It should be noted that using a walk-behind tractor on public roads is prohibited, even if it is equipped with high-quality wheels.

Many owners of small agricultural equipment make their own lug lugs. In this case, you just need to make a similar mount, like the “iron horse”. If necessary, additional wheels are mounted.

When the walk-behind tractor is used exclusively in the field, then rubber tires are not needed. When designing your own structure, you don’t have to make rubber wheels, but use only lugs for everyday work.

This design is not know-how, but has been in demand for a long time. They had never made rubber tires before. The wheels in tractors and walk-behind tractors were metal, and transverse steel plates were additionally installed on the drive wheels for better traction.

What sizes should you take?

On the Internet you can find many drawings and diagrams for making lugs yourself. But what sizes correspond to which brand? Sometimes this is not indicated in the drawings.

So, the most common motorized cultivators are: Neva, Mole, Salyut, Oka, Bison, Centaur. Let's look at Neva walk-behind tractors.

The lug lugs for Neva walk-behind tractors are perfect for the Salyut and Favorit walk-behind cultivators. Dimensions for homemade tools for a walk-behind tractor: height - 34 cm, width - 11 cm. These dimensions are shown in the drawing, and all the small details that must be observed to work well with the ground are indicated.

Let's look at the main functions of lugs on the Neva walk-behind tractor:

- Better quality plowing of land.

- The installed tools make the walk-behind tractor heavier and easier to use, which improves soil work and allows you to work with heavy mounted structures.

- This product helps you climb uphill with a full trailer in a fairly short time.

- The teeth catch small and large plant roots, tearing them out.

Optimal sizes

It's no secret that heavy equipment cultivates the land better than light equipment. This is evidenced by the fact that people began to become interested in the question of how to make lugs for a car with their own hands. Such equipment can even handle hard soil, which a light tractor cannot handle very effectively. Such units require large lugs. To generalize, the design parameters will depend on the size of the walk-behind tractor.

Thus, we can distinguish the following popular walk-behind tractors :

- "Neva". Walk-behind tractors that adapt to any conditions are common. But in the case when the farm already has a Neva tractor, which due to its characteristics is not considered universal, you can make soil cutters yourself. It is necessary to take into account that the diameter of the device should not be more than 36 centimeters, and the width should not be more than 11.

- MTZ. Even though such units are Belarusian, the price for them is considerable due to the highest quality. You can focus on a price of 5,000 rubles or more. The bottom line is that the wheels of these walk-behind tractor models are quite large. To make high-quality lugs, a lot of labor is required. It is important that the dimensions are selected correctly and that the triangular plates that engage the ground are carefully welded to the main lug wheel.

- "Firework". This device is assembled according to the Neva scheme.

- "Centaur". The wheels in such a device are somewhat similar to the Neva. But the first car has 11 centimeters longer wheels. If a lug is made for the Centaur, its length should be 450 millimeters and width 110. It can also fit other models of walk-behind tractors, including those from other manufacturers.

It will also be useful to make an extension for the lugs. They are designed to increase the angle of rotation of the structure and the width of the potassium and counterweight. To do this, you need to attach a sleeve with a slot to the hub. An additional axle is inserted into such a sleeve, which is secured with a bolt. Finally, you need to secure the soil cutter wheel to the axle.

Thus, there are many options for making soil cutters with your own hands without much labor and emptying your pocket on expensive factory models.

What third-party wheels are suitable for the Neva walk-behind tractor?

Wheels from Muscovites and Lada are best suited for installation on the Neva walk-behind tractor. There is no need to change anything in them, since their diameter is ideal for installation on a walk-behind tractor. They only need to be slightly modernized by welding.

Zhiguli wheels on a Neva walk-behind tractor

Factory options will cost much more.

The main task when modernizing Zhiguli wheels is to make them heavier, since in the factory configuration they are very light.

Listed below are the main stages of manufacturing wheels for a walk-behind tractor from car tires:

- An axle shaft is installed inside the wheels;

- To make it easier to change wheels, square plates are installed on the axle and holes are made in them. And then the wheels from Zhiguei are attached to these plates;

- A cap is placed on the outside to protect against external factors;

- The tubes should be removed, and only the tires should be left (to improve the quality of traction, winter tires should be used).

Using tires from other cars is problematic because they have a larger diameter or width, so they need to be additionally adjusted using an axle extension or some other method, and this is not always possible for everyone.

To improve the lug-holding properties, some people additionally cover the wheels with a chain. When driving, the chain digs into the ground and provides additional traction. The effect of it is especially noticeable when driving after rain or snow.

The video demonstrates how to install Zhiguli wheels on a Neva walk-behind tractor:

Combined design

If the equipment is homemade and the soil is not too difficult, the wheels should be appropriate. You can make hooks using tractor protectors.

We take halves of wheel rims from a Zhiguli car . We choose tires with good tread from the tractor. We cut off the sides, we get a rubber closed ring with a good protector. We open the halves of the wheel rims and, after laying the tires, twist them firmly. With such lugs, you will be able to move along a compacted dirt road without fear of loosening it. On the soft soil of a plowed field, the wheels will not fail, but the traction force will be less than in the case of the metal version.

If it is necessary not only for the wheels to be grippy, but also to additionally loosen the soil in the rut, knife-type hooks are made. You can create a homemade rim to mount them or weld them to the rims. The only drawback of the blade design is that it does not allow you to move the walk-behind tractor in the usual way.

When loosening in spring together with traditional attachments, the width of the soil processed per pass will double, which will save a lot of time.

Required tools and equipment

Before carrying out the relevant work, you must first make sure that you have the appropriate materials and tools. You can watch the process of making snow chains on video, but the disadvantage of videos is the lack of information about the necessary equipment.

To make a simple “Ladder” type chain, you will need the following materials:

- Steel chain. The thickness of the reinforcement must be at least 5 mm.

- Carabiners with a coupling and thread. Products with latches are not suitable for making lugs.

- Chain tension device.

- Bolts, nuts and washers.

- Hooks.

For the manufacture of snow chains, carabiners with a coupling and thread are required

The main material is a chain, the length of which for two middle wheels with a diameter of R15 must be at least 15 meters. Buying a chain separately and making a lug from it yourself is much cheaper than purchasing a finished product.

To make lugs, you will also need a set of tools:

- Vise;

- Grinder with a circle for metal;

- Roulette;

- Hammer;

- Wrenches for tightening bolts and nuts.

As you can see, the supply of materials and tools is insignificant, so after preparation, you can begin making snow chains.

What is needed to make homemade car snow chains for wheels?

The inability to purchase factory-made devices that increase cross-country ability, as well as their high price, push car enthusiasts to solve the problem on their own. It should be noted that this is a completely reasonable choice - the necessary components can be found in any hardware store, and every self-respecting driver has a minimum set of tools.

It should be said that information on how to make snow chains with your own hands and videos include a list of design elements. Let's focus on the simplest model, made according to the “ladder” scheme. To implement it you will need:

- chain with a cross section of at least 5 mm made of steel;

- carabiners with a threaded coupling;

- tension mechanism;

- washers, bolts and nuts;

- hooks, carbines.

On average, about 15 meters of chain ; more accurate figures will be known only after specific measurements. It is recommended to use stainless metal hardware as chains. The preparatory process ends with the collection of tools:

general information

- By design, these devices are wheels with spikes. Today there are many different device transformations, and you should choose them wisely. To a large extent, the quality of work is determined by the weight of the unit. The most functional awnings can only be hung on heavy walk-behind tractors or medium-weight units. If the unit is of high quality and does not give the desired result, you need to additionally purchase wheels with lugs for it.

- Standard devices are metal wheels with spikes that dig into the ground and engage the walk-behind tractor with it. To make devices yourself, you will need to know their structure, which drawings and diagrams will greatly help with. You will need to determine the diameter of the canopy, select the material of manufacture, and, of course, select the necessary tools. The first thing you need is a welding machine and an angle grinder.

- First of all, we decide on the size of the devices. Their height and width depend on the tasks for which the hooks are mounted on the walk-behind tractor. You also need to take into account the requirements for the weight of the devices, because the wheels are put on with them to improve the traction of the walk-behind tractor with the ground. This requires wheels of considerable weight, which a walk-behind tractor may lack. The minimum weight of wheels is 20 kg. If necessary, weights are hung on the soil hooks. This is necessary to achieve better results, or is used when the weight does not reach the norm.

Making your own hooks

- The easiest way, perhaps, is to make lugs from unnecessary rims from car wheels. Using a welding machine, an axle shaft is attached to the disks, onto which bearings are then placed. Square metal plates are welded to car rims so that they touch the edges of the rim.

- Then the plates are bolted to the rim. Next, teeth are made - steel hooks that will go into the ground. For this purpose, you will need a steel plate, for example, a corner, which is cut into pieces by a grinder, and from these parts the same teeth are welded, which are made in the factory. The resulting hooks are placed on the wheel rim 15 cm from each other.

- Homemade hooks can be made from an old gas cylinder. Two disks are cut out of it for wheel rims, 5-7 cm wide and 30 cm high. Next, the same operations are performed as with car disks.

- To improve the performance of wheels with hooks, you can weld another tooth on top of each hook and lengthen the teeth to 60 cm. An axle is made: a metal plate is attached to one rim on which this axle will be placed.

- The lugs can be made from any round-shaped blank. The main thing is to choose the right width and diameter of the future wheel with hooks. The dimensions of the wheel are determined functionally, that is, based on the purpose of use on the walk-behind tractor.

For "Neva"

Each brand of walk-behind tractor has attachment options that are more suitable to its design than others. It is better, of course, to purchase a universal walk-behind tractor, for which almost all awnings are suitable. Wheels with lugs Ø 340×110 are produced for the Neva.

In design, these lugs are slightly larger than the homemade ones we described. You must follow the instructions above, but choose rims of other sizes. The height of the wheel to hook the Neva should be 340 mm, the width of the homemade device should be 110 mm.

For "Centaur"

The lugs for walk-behind tractors of this brand differ only in size. The dimensions that needed to be taken into account when converting old wheels into lugs for the Neva were described above. The same scheme is used for the manufacture of wheels with large hooks. The wheel height is selected 450 mm. The wheel width should be 110 mm, as for the Neva. Such hooks are suitable for the Centaur 2060 and 2090 walk-behind tractor and units with similar parameters. The factory version will cost about $30.

For "Bison"

The walk-behind tractor of this brand is a heavy professional equipment, and it can be equipped with the best available attachments. In order for the “Bison” to penetrate the ground perfectly, it needs lugs. The standard devices that fit it have a 200 mm tire and a height of 700 mm. Wheels of this width are only suitable for heavy walk-behind tractors and, in addition to the Zubr JRQ78 and 79, are also suitable for the Centaur 1070D, Aurora 101 and Aurora 81, Zirka LX1080D and 1090. In the factory version, the distance between the hooks is 14.5 cm. The wheel hub has a diameter of 60 mm. They are attached to the walk-behind tractor using an additional hub.

Homemade snow chains with quick installation

Winter is approaching, not to mention that there are already quite a lot of puddles and mud outside the city. To overcome such obstacles, you need a good SUV, or you can make snow chains for your car and carry them with you.

The main problem with such devices is that they are difficult to quickly install on a car, especially in winter, when you need to work in snow and cold. But having passed the problem area, the chains must also be removed, since driving on them for a long time is harmful to the tires, and driving on the highway is prohibited.

One author came up with the idea of attaching snow chains using rubber bands with hooks. Now you don't need wrenches or anything to install chains. For structural reliability, it is best to use springs instead of rubber.

Materials and tools for homemade work:

Materials: - steel chain (length and thickness will depend on the diameter of the wheels); - elastic bands with hooks or steel springs for fixing chains; - a pair of carabiners for quickly connecting chain links.

Snow chain manufacturing process:

Step one. We measure the circumference of the tire. First of all, you will need to make two rings from the chain; their diameter should be such that they lie approximately half the width of the tire, or further to the center. The author connects the rings using threaded carabiners.

These rings are needed to attach the transverse elements that engage the road.

Well, then you need to cut the required number of chains of the required length. The length should be such that the chains on the wheel are well tensioned, otherwise they will fly off. Here they are adjusted depending on the width of the tire and the location of the side rings.

Step three. Final assembly Now all the parts are connected to each other, forming solid tracks. Everything is connected using good strong carabiners. Well, after this, the tracks need to be installed on the wheel, and in order to tension the chains, you will need metal springs or, in extreme cases, rubber. For ease of fastening, the author installed hooks at the ends of the rubber strips.

Important to remember

Any traction control equipment adversely affects the safety of tires, as well as the condition of the chassis. You need to be especially careful when choosing locks for homemade chains on car wheels , since the trouble-free operation of the car depends on them.

Moving on hard surfaces is unacceptable. When driving on loose snow or mud, you should maintain a driving speed of 20-30 km/h; it is not recommended to allow wheels to slip. Experienced drivers advise periodically checking the tension of the equipment along the entire inner and outer perimeter of the tire while driving.

Hello. I want to share with you a very useful idea. I saw how prepared SUVs dashingly jump out of ambush on sandtrucks. So I decided to create something similar for a civilian car. Something you could always take with you and not get in the way in the trunk.

Track tracks

Tracks are the main part of any track. Fortunately, you don't have to buy them in specialty stores. They are quite easy to make yourself from various materials. The main thing that needs to be taken into account is the level of load that is planned to be placed on the walk-behind tractor. Tracks can be made from:

- plastic pipes;

- wooden blocks;

- metal tracks.

To make tracks from plastic pipes, you will need water pipe No. 40. It is cut into pieces the length of which is equal to the width of the track. After this, each such segment is cut lengthwise into two halves. A circular saw with a wood cutting disc will help with this.

When all the tracks are ready, they can be attached to the main structure. For this, furniture bolts No. 6 and large hemispherical heads are used. With these bolts, each segment is attached to the structure itself.

Thus, we get an excellent relief track for a walk-behind tractor, allowing it to pass through difficult places even in winter.

A caterpillar made of wooden blocks is suitable for light loads, since the structural strength is not so great. To make a track from this material, you will need birch blocks of the same size and length equal to the width of the tracks.

It is not surprising that the most common and reliable are metal tracks for tracks, because their level of strength is quite high. Most often, metal pipes or a profile are used, which is cut into pieces of suitable length and attached to the track in the same way as was done in previous methods.

The main disadvantage of this design is the large mass and difficulty of repair. If one of the tracks bends during operation, you will have to spend a lot of effort to replace it.

It is recommended to make tracks from iron only in cases where the walk-behind tractor operates under heavy loads. In other cases, it is better to resort to other methods.

It is not so difficult to make a caterpillar for a walk-behind tractor with your own hands, although it takes quite a lot of time. It is important to treat the process with the utmost care and perform all calculations correctly. Also, it is necessary to assess the degree of load with which the walk-behind tractor operates and select the most suitable materials for the product.

Features of installation on a car

Making chains is only half the battle. Now you need to install them correctly on the car. There are several ways to do this. The first of them involves jacking up the car. To do this, the driver should perform the following manipulations:

- Before an obstacle, you need to stop on a hard surface, then set the car in first gear and squeeze the handbrake;

- Using a jack, you need to hang up the part of the car on which you plan to install the chain;

- As soon as the wheel is hung, you should begin installing the lug;

- This process usually takes about 10-15 minutes for one wheel. In this case, you need to make sure that the chain is securely fastened.

The product is installed in a similar way on the second side and, if necessary, for all four wheels. The second option involves installing a chain without lifting the wheels:

- You need to stop, and then place chains on both sides in front of the wheels.

- Drive the chains to the middle of their size.

- Secure the product from the inside with a hook or carabiner.

- Straighten each link, then connect the tension adjuster.

If there is no jack, it is possible to run over chains lying on the ground

This option seems simple, but in reality it is not. After installing the chain on the wheel, you need to drive a few meters and then adjust the tension. Then you can storm the obstacles.

Making lugs for the Zubr walk-behind tractor

We have already told you what size wheels are put on a heavy Zubr walk-behind tractor. The Zubr JRQ78 and 79 walk-behind tractor will also easily fit 700x100 mm lugs. They are smaller in width and, in addition to heavy ones, can be used together with medium-heavy walk-behind tractors.

The same lugs for the Zubr walk-behind tractor are suitable for the Neva walk-behind tractor. It is precisely with better compatibility that lugs of this size are in great demand. After all, you can only put 700x200 wheels on heavy units; they are intended more for processing virgin soil, and 700x100 wheels are suitable for average farm needs and you can easily save and attach them to another walk-behind tractor when your current one becomes outdated, even if it is weaker in power .

You can make it yourself with your own hands, or you can buy it in a store. 700x100 lugs will cost you about $70.