There is a certain confusion regarding the meaning of runic occult symbolism and greetings. The enormous negative experience accumulated by humanity throughout its history, and especially during the 20th century, has imposed a kind of taboo on many gestures and signs. Not only their use, but also any talk about them is prohibited in many countries. However, here and there a swastika is depicted on the wall, and a ridge is used as a greeting. This always causes protests from most of society. Maybe the whole point is that the gesture is being interpreted incorrectly? Or is it being executed incorrectly?

Sheet metal beading: technology and equipment

Creasing (or creasing) is the work of producing surface relief on metal using a continuously rotating tool - a pair of rollers. The profile of the resulting ridges corresponds to the profile of the rollers, and both flat and volumetric workpieces can be used for processing (a typical example is cylinders).

Processing on creasing machines

Advantages of the process and rational ways to use it

The formation of the surface relief on the workpiece is not of an impact nature and can be performed on pressing equipment, but presses require a non-specialized tool - stamps, and the peculiarity of the operating scheme of bending mechanical installations involves an idle stage, when the machine slide moves to its uppermost position. Therefore, zigging on rotary machines has clear technological advantages:

- The simplicity of the design of zigmachines, and, consequently, their low price and low repair complexity.

- Compactness of the equipment (a number of companies successfully design and produce mobile crimping machines with manual drive).

- The process of beading with a rotary tool is characterized by very low energy consumption during operation, so the equipment consumes little electricity.

- On a zig machine, metal processing can be carried out continuously, and therefore the equipment is suitable for plastic deformation of long sheets and strips, moreover, even in automatic mode.

- The technological loads on the crimping tool are low. Therefore, its durability allows long-term use until it is restored. The same set can be reused as a result of regrinding to a new size.

Beading machines are especially effective in small-scale production, when different parts can be produced on the same installation by simply replacing the tool. In particular, IV2714 type zigmachines are used to successfully perform work on folding tubular joints, performing local profiling, applying periodic relief, and even cutting off individual fragments of tape/strip after deformation. Benching is also widely used when working with elements of ventilation systems.

Surface corrugation

Varieties

Sealing machines are classified depending on various factors. By drive type:

- Manual. Simple designs that begin to work after applying physical effort. The position of the rollers is changed manually. Manual beveling is not used for working with thick metal.

- Electrical. In terms of power, these models are considered average. The shafts rotate thanks to an electric motor. Electromechanical creasing machines are more expensive than manual ones, but they can process sheets of large thickness.

- Hydraulic. Powerful equipment. A special feature of hydraulic machines is reliable clamping of the rollers. Disadvantage - large dimensions, large mass.

A separate classification relates to the size and weight of equipment. There are compact, portable models that are easy to transport. Large-sized machines have been developed for enterprises that are suitable for mass production.

Types of creasing machines

The main difference between zig machines is the type of drive. He can be:

There are also modern CNC bevelers. This type of control allows you to fully automate the process, greatly speed it up and increase productivity.

The manually driven machine is capable of processing metal sheets no thicker than 1.2 mm. Securing the part and rotating the shafts is done with special handles. The zigovochny machine is attached to the work table using a clamp. The main advantages of manual equipment are that it is mobile and compact.

Read also: Capacitor for a washing machine motor

The downside is the increased requirements for operator skills. It is necessary to have certain skills in order to move the handle and hold the part in the desired position at the same time. Manual crimping machines are suitable for small production workshops or high-rise installations.

An electrically or hydraulically driven crimping machine can bend sheets of metal up to 4 mm thick. Such machines are used in large production workshops. The electric beading machine is powered by a motor, and the speed is changed using a frequency converter. Its convenience is that the worker’s hands are free, and control is carried out using a pedal or remote control. This increases productivity, which is very important for industries with a large volume of products.

A hydraulic-type crimping machine can only be stationary. The pressure shaft is lowered using a hydraulic cylinder, and the rollers are driven by an electric motor. This crimping mechanism is convenient for working with thick sheets of metal. These machines are highly productive and consume little electricity, so to some extent they can compete with machines equipped with CNC.

Technical characteristics of zig machines

Sealing machines are characterized by the following main parameters.

| Characteristic | Meaning |

| Drive type | manual, electromechanical, hydraulic |

| Roller diameter | can be from 50 to mm |

| Roller overhang | up to 350 mm is an important indicator; when performing special work, the maximum reach of the shoulders is selected |

| Number of additional pairs of rollers | usually 4 to 6 pairs |

| Metal thickness | from 0.5 to 4 mm |

| Machine dimensions | even hydraulic zigovkas take up little space |

| Machine weight | from 17 to 300 kg |

Table 1. Some characteristics of crimping machines

Application area of zig machines

The serging machine connects metal elements with a thickness of 0.5 to 4 mm. First, the lock is rolled, then the parts are connected. If required, the lock is reset manually.

A crimping machine is used to process sheet metal products. They allow:

- manufacture pipes, sills and other industrial elements in the shape of a cylinder,

- process shells,

- carry out thermal insulation of pipelines,

- create corrugated products.

Zig machines are used for metal roofing work.

The main advantage of crimping is that the metal is not heated, which means there is less risk of product deformation. In addition, energy and consumables are saved.

Types, advantages and disadvantages

All zigovochny equipment is divided into three large groups: manual, hydraulic and electric. The ability of the equipment to work with metal of a certain thickness depends on their type.

Manual equipment cannot cope with thick metal and requires great physical effort to operate. They are used in small tinsmith shops.

The advantages of manual crimping machines include:

- compactness;

- low cost;

- mobility;

- autonomy.

Main disadvantages:

- the ability to work only with metal having a thickness of no more than 0.8 mm;

- high labor costs.

Who's zigging today

In the modern era, a raised hand evokes unambiguous associations with the Nazi salute. In many countries, greeting in this or a similar way is prohibited by law: Hitlerism brought too many troubles to the peoples of Europe. However, there are far-right organizations that use symbols and gestures (sometimes slightly modified “for the sake of blaze”) borrowed from the terrible past. Sometimes members of neo-Nazi structures even pretend that they have no idea what ziga means and insist on the ancient Roman or ancient Slavic meaning of the gesture. In fact, they are adherents of Hitler’s methods of “population control” of migrants and foreigners. They should remember that all people have an equal right to life simply by virtue of the fact of their birth, and they cannot be killed. This has already happened and led to very unfortunate consequences.

In addition, psychologists say that a hand raised above the head indicates that the speaker obviously promises more than he can deliver, and he himself knows this very well.

How to choose the right zig machine

Equipment is selected according to several main parameters:

- Purpose. For roofing workshops and crews, hand-held machines, inexpensive electromechanical models, and universal machines with replaceable drives are suitable. Zig machines do an excellent job with metal up to 1 mm, are mobile, and easy to use.

- For mass production and the manufacture of large-sized products, for example, air ducts, more powerful equipment is needed.

- Permissible thickness of rolled products. Industrial creasing machines are capable of applying relief, cutting, and flanging rolled products up to 4 mm or more. The maximum metal thickness for low-power electromechanical and manual equipment is 0.8-2.5 mm.

- Roller offset and center distance. The characteristic determines the processing width. The larger the reach, the wider the workpieces and parts can be processed.

- Supply voltage of electromechanical machines. Most stationary models are equipped with a 380 V motor and require an electrical connection. They also produce machines for small workshops with single-phase 220 V electric motors.

When choosing machines, they also take into account the dimensions, the presence of a reverse function, hydraulic clamping, and other parameters.

DIY making

If you wish, you can assemble a manual zig machine with your own hands. To do this, it is enough to find a drawing, prepare materials, tools, and perform the work.

Do-it-yourself piecing machine (Photo: Instagram /lodkakhv)

Preparation

Before you start assembling a manual zigging machine, you need to prepare tools and consumables:

- drill with metal drills;

- a small grinder with discs;

- welding machine;

- two shafts;

- gears for transmitting force between shafts;

- metal corners, profiles, sheets for the manufacture of beds, frames, housings;

- fasteners;

- handle for rotating moving parts.

- screw for adjusting, pressing the shafts.

Features of the technological process

Metal beading is an easy operation to perform, but it requires some skills and knowledge of the technological process. Since, thanks to heaving, softer material acquires greater strength, it is necessary that the elements are made with high quality. To do this, you need to know how the process of applying relief occurs. It is as follows:

- The upper roller is raised onto the lower one to place the part for processing and then the raised upper roller is lowered onto it.

- It is very important that during the zigging process uniform corrugations are applied and the distance is taken into account, so it is imperative to use a stop.

- The degree of fixation of the workpiece is adjusted using the existing screws.

- Another feature is that if you use a more durable material, you need to take into account that for creasing in this case it is necessary to use a hydraulic or electric drive on the equipment.

- For example, if corrugation is used on aluminum or zinc materials, then it is necessary to increase the distance between the ridges, as well as increase the radius of the ridge itself.

- The shafts with corresponding rollers have the opposite effect during operation, that is, they rotate in the opposite direction, which as a result creates the necessary depressions on the sheet metal.

If the first time applying relief to thin-sheet metal was not done enough, then you can carry out several more cycles along the already completed zigs. Only after achieving the desired result can the workpiece be removed.

Historical sources of ridge

In ancient Rome, both legionnaires and ordinary citizens often greeted each other by raising their right hand, first placing it on their heart. The original meaning is a wish for health, prosperity and showing respect by directing towards the sun from the heart. At the same time, ordinary people gesticulated energetically, and high-ranking “patrons” responded less diligently, only raising their palm on their half-bent right hand. The traditional ancient Roman greeting can be seen captured in the statue of Marcus Aurelius. Slavic peoples also greeted in a similar way. For example, the half-lowered hand of Dmitry Dolgoruky (monument in Moscow) is perhaps also a kind of ridge. This does not mean that the gesture contains any hint of Nazism, nationalism or fascism. By the way, on numerous Soviet monuments, Lenin and other prominent figures of the Communist Party also extended their right upper limb.

Purpose and design of beading equipment

Before you begin to understand what a crimping machine is, you need to understand why creasing is performed. In the process of carrying out this technological operation, recesses of a semicircular profile are applied to the surface of the sheet metal workpiece. Such recesses, which are called ridges, act as stiffening ribs; their presence on the surface of a thin-walled metal product makes it much stronger. The size of the recesses, for the formation of which the zig machine is used, completely depends on the thickness of the metal used for the workpiece. To select this parameter, which is very important for such a technological operation, special lookup tables are used.

Many modern manufacturers produce crimping machines, the technical capabilities of which allow them to perform a whole range of technological operations. The operations to which sheet metal blanks are subjected during their circular processing include corrugating their surface, cutting and flanging. More powerful and productive, when compared with manual equipment, are electric crimping machines. Due to the presence of a powerful electric drive in their design, such machines make it possible to successfully process workpieces made of thicker sheet metal.

Main parts of the seaming machine

Regardless of whether the crimping machine is equipped with a manual or electric drive, the design and operating principle of such a machine remain virtually unchanged. The main design elements of such machines are two shafts, the axes of which can be located horizontally or at some angle. It is these shafts, rotating relative to each other in the opposite direction, that impart rotation to the working rollers fixed at their end part. The zig machine works, both manual and electric, according to the following scheme:

- the sheet metal blank is placed between two forming rollers of the equipment;

- the machine shafts are brought together, thereby ensuring clamping of the workpiece between the working rollers;

- using a manual or electric drive, the shafts are rotated;

- when the shafts and working rollers rotate, the part sandwiched between them also begins to move; When a workpiece is moved between working rollers with protrusions of the required size and shape, corresponding depressions are formed on the surface of the sheet metal under the influence of plastic deformation.

Ziga and the Nazis

The Third Reich was conceived as a successor to previous empires with ancient Roman traditions. Its official symbols included the swastika (distorted, with the opposite direction of rotation) and the imperial eagle holding the said sign in its talons. Instead of the usual “guten morgen” or “guten tag”, members of the NSDAP, and later the entire population of Germany, used ridge. This greeting, like the symbol of eternity - the swastika - has also undergone changes. Now the palm was not applied to the heart, but went straight from the thigh. In addition to this difference, there was a certain semantic load that was unusual for ancient Roman traditions. The “Zig” gesture expressed the highest degree of personal devotion to him, the “great and infallible” Adolf Hitler, the People’s Fuhrer. The entire population of Germany was reminded of this by the verbal appendage to the greeting: “Sieg Heil - Heil Hitler!” So that they always remember in whose honor they zig. The gesture no longer had anything to do with wishes for prosperity.

Exploitation

For home-made or purchased models of staking machines, there are a number of operating rules:

- Check the integrity of the rollers, gears, and the location of the shafts before starting work.

- Turn the handle several times without the workpiece to eliminate defects.

- Keep your hands as far away from the treatment area as possible. Do not wear long sleeves.

- Do not attempt to connect parts of large thickness. Excessive effort will lead to material damage and equipment failure.

- Do not overload the electric motor.

- Lubricate moving parts with machine oil at least twice a month.

- Check the accuracy of the workpiece alignment between the rollers.

Metal beading is a simple process that anyone can do.

Metal creasing machines are used to carry out various technological processes. With their help, you can connect metal pipes and increase the strength of individual parts. You can make a homemade hand loom for your home.

Marking of produced rollers

The depth and shape of the seam depend on the choice of working rollers. How to use nozzles depending on their purpose:

| Marking | What can you do with these videos? | Application area |

| V | Shape the edges of parts, roll wire | For the production of insulating boxes and pipes |

| E, EV | Corrugate the edges of pipes to reduce the diameter | To create socket joints in ventilation and drains |

| S | Create stop and rigid ribs | For the production of various sheet metal parts |

| S.K. | Make wide rectangular ribs | For fixing rubber seals in round ventilation pipes |

| B.S., F. | Make double folding of vertical locks with selected flange height | For joining sheet metal workpieces, roofing work |

| B.C. | Bend the edges of flat elements | For beading rectangular duct parts and creating rounded plugs |

| BB | Bead the edges of the mortises | To create mortises of various shapes and vertical locks on different parts |

| K.B. | Besiege a vertical castle | For the manufacture of elements of pipelines for draining water and venting air |

| BD | Bead the edges of the parts | For creating long circular pipelines |

| Z.B., Z.A. | Roll the wire along the edge of the pipe | To increase the rigidity of thin metal pipes |

| K.A. | Connect round pipes followed by spot welding | For the production of air ducts and chimneys in small batches |

| AV | Seamlessly connect the mortises using the screw method | For the production of ventilation blanks |

| DIN 71550 | Make semicircular ribs | To create diameters on which a flexible hose is attached |

| M | Cut pipes across | For the production of any pipelines |

Some operations require additional parts. For example, cutting can only be carried out if the rollers are equipped with parallel roller pressure. To cut out rings you need a special holder. To bead the outer edges of round holes you will need a semicircular stop.

There are different types of zigs

Both in Ancient Rome, and in fascist Italy, and in Nazi Germany, subordination existed, and a very clear one, manifested, in particular, in greetings. If an ordinary party member had to stretch his hand with all his might at an angle of 45 degrees, then the bonze, depending on his rank, could use a long, medium or short gesture to greet. In the latter case, he only slightly raised his palm, as if brushing off overly annoying admirers of his own genius. Medium - for field marshals, generals and high-ranking officials of the Reich. A long ridge is the lot of plebeians, even if they are at least three times representatives of a superior race.

Selection principles

When purchasing a crimping machine you need to consider:

- dimensions of equipment, premises;

- type of drive;

- roller material;

- control system;

- number of rollers;

- thickness of metal for the manufacture of housings and moving elements.

We must not forget that there are different types of videos. They vary in shape. You need to think in advance about the purpose of using the installation and purchase a set of consumables.

Compact machine

Advantages and disadvantages

Advantages:

- mobility of hand models;

- ability to work with parts of different thicknesses;

- Ease of Management;

- low price;

- long service life;

- the ability to join metals that cannot be processed by welding.

To work with parts of large thickness, an electric or manual drive is not enough. You need to buy expensive hydraulic equipment, which takes up more space.

Design features of zig machines

One zigovochny device is structurally not too different from another. Their main elements - shafts - are located horizontally, vertically or at an angle. Forming rollers are mounted on the shafts, and the workpiece is secured between them. Due to the opposite movement of the main elements, uniform depressions appear on the metal. With their help, the necessary connection is made.

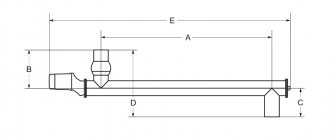

When choosing a crimping machine, you need to pay attention to the following technical characteristics:

- type of drive;

- diameter and overhang of rollers;

- the number of attached pairs of these parts;

- permissible metal thickness;

- machine size.

The smallest rollers are 50 mm in diameter, their number varies from four to six pairs.

An important indicator is roller overhang. It is better to purchase a machine with a maximum reach - up to 350 mm. This will expand the capabilities of sieving equipment.

The permissible thickness of the metal sheet is from 0.5 mm to 4 mm. The crimping machine will not take up much space (with the exception of CNC machines). Such a device can weigh from 17 to 300 kg.

Before starting work, the workpiece is fixed between the shafts and the handle is turned. On manual machines, due to their low power, it may be necessary to pass the workpiece through the rollers several times.

Main purposes of serging equipment

Such machines, according to their intended purpose, are used for work related to tin materials that have a cylindrical shape. Therefore, it is very often used to increase the strength of a metal product, as a connecting profile, and is also used in the form of processing the edges of sheet metal. In addition, it is used:

- In the production of cylindrical products in the form of ventilation and water pipes.

- With its help, special locks are made on metal products made of thin iron, which makes it easy to connect various iron parts without the use of welding equipment.

- In the production of thermal insulation of pipelines.

- Often used in the processing of shells.

- In roofing work for cutting and flaring drainpipes.

- In the production of ventilation shaped parts.

- It is also used in the production of components for drainage systems.

But the most common application of zig machines is the process of corrugating thin-sheet material that has a cylindrical shape.

Areas of application for creasing equipment

Equipment designed to perform beading, even though the name of such a technological operation is familiar mainly to metalworking specialists, is actively used in various fields of activity. Sealing machines are practically indispensable for the manufacture of elements of roofing structures, in particular, for the formation of their edges.

Examples of drainage elements made on a crimping machine

It should be noted that in the construction industry, bending machines have found very wide application. Using such machines, in particular, the following elements of building structures and communication systems are made from sheet metal: parts of drainage and air duct systems, insulation for heating mains, etc. In the construction industry, manual staking equipment is predominantly used, since it is characterized by its small dimensions and insignificant weight, does not require an electrical supply for its operation and can be used almost anywhere.

The creasing machine can also be used to reliably connect cylindrical workpieces made of thin sheet metal together. Rollers for equipping a zig machine of this type, when a cylindrical workpiece passes through them, form locks on it, with the help of which the two parts are connected.

Rolling the lock on the air duct elbow

When making connections using locks, unlike welding, there is no thermal effect on the metal parts, which eliminates the possibility of their warping. In addition, such a machine, which you can also make yourself, does not require any additional consumables for its use.

To expand the functionality of a staking machine, including a manual one, it can be equipped with additional working parts. Machines equipped in this way can be used not only as creasing equipment, but also as bending and profiling equipment. Modern creasing machines for industrial use are often equipped with automated control systems, which increases their productivity and accuracy of technological operations performed with their help.

Special attachments allow you to make folds for connecting thin-walled pipes

Questions and answers

What products can be made on crimping machines?

Buckets, deflectors, and funnels can be produced using crimping equipment. The machines allow you to roll thrust ridges, corrugate metal blanks, make drainage elbows, etc.

Are there any differences in the operating principle of manual and electric seaming machines?

There are no fundamental differences in the operation of manual and electrical equipment.

What machines can handle metal with a thickness of 3-4 mm?

Metal of this thickness can only be processed on electric or hydraulic industrial crimping machines.

What does roller overhang affect?

Regardless of the type of equipment drive, roller overhang affects its technical capabilities.

What type of crimping machines is best to use for roofing work?

In roofing work, it is better to use manual zig machines. They can be lifted directly onto the roof.

Benefits of use

Each type of zig machine has its own positive aspects.

Manual - economical, it does not require connection to a source of electricity, is compact and mobile. Such equipment can be installed in any place convenient for work. Also, a manual seaming machine does not consume fuel or electricity, which reflects economic feasibility.

Stationary equipment has greater power, which allows processing metal sheets up to 2 mm thick. Electric or hydraulic types of machines also show greater productivity.

In general, zig relief application increases the strength of the metal and the quality of the products produced. With its help, the structure of the resulting product acquires additional stiffening ribs, which increase strength, service life and reduce the effect of surface sliding. It is impossible not to note the increase in the aesthetics of manufactured products. Also, the advantages of creasing include the ability to connect parts without the use of welding equipment, bolting, etc.

Purpose of zigovochnyh works

Benching machines are widely used in the metalworking industry. With their help, joining profiles are applied, the strength of metal products is increased, and the edges of various metal parts are processed.

The crimping process is used:

- for the manufacture of cylindrical parts of ventilation and drainage systems;

- in the production of products that are connected to each other by a joining profile;

- in the manufacture of thermal insulation of pipelines, ventilation fittings;

- for processing shells and other elements where a neat and safe edge is required;

- corrugation of thin-walled cylindrical metal products.

The last type of operation from the list not only makes the parts more durable, but also the corrugation reduces the intensity of sliding. Metal beading also increases the aesthetics of the products.

Using beading equipment, you can connect cylindrical elements, flange edges and roll the stiffening ribs of parts during sheet metal work. This method of processing sheet metal blanks is technologically simple. There are many models of zig machines on the market; you can choose options with different drives and prices. And if you spend a little time, you can create a simple machine yourself.

Making a machine at home

It’s worth buying a professional crimping machine if you often work with sheet metal. For rare household jobs, it will be more economical to assemble the machine at home yourself. To do this, you need to find suitable drawings on the Internet or books, as well as the necessary parts. For the simplest device you will need:

- device body,

- limit shield,

- gear wheels,

- bracket,

- working shafts,

- forming rollers,

- cylinder-shank.

Equipment collection plan

The case is made with a removable lid and a protective casing made of metal up to 5 mm thick. Its height depends on the size of the shafts, plus you need to take into account the distance between them. To freely lift the pressure shaft, you will need at least 2.5 cm.

To secure the device, you will need a frame with a height of about 25 cm and a width that matches the size of the case. It is made from two metal plates mated in a T-shape. The device is fastened with a special locking screw; the cylindrical shank must fit into the cup of the bracket around which the machine body rotates.

Gears are usually taken from old motorcycles. And the shafts are machined to their internal diameter. A hole for the handle needs to be drilled in the lower working shaft. The handle itself can be welded or a part from a regular meat grinder can be used. A movable support is placed under the front bearing of the pressure shaft for easier material removal.

You will have to grind the roller parts yourself. Those who often use crimping equipment should choose hardened steel for these elements. It’s worth turning out several pairs of different profiles at once. After grinding, they will need to be well polished. The main diameter of each part must correspond to the distance between the centers of the wheels with teeth during working coupling.

Read also: DIY snow removal engine

Holes for the roller elements are drilled in the center of the metal limit shield. On average, its length will be 18 cm, width – 12 cm, thickness – 3 mm. The rollers are secured with cotter pins, under which holes are drilled. This takes into account the length of the rollers themselves and the thickness of the washers. It is possible to replace cotter pins with studs or even ordinary nails.

Electric creasing machine

At home, you can create an electric crimping machine. The mechanical part is similar to the manual product, but the rotation of the rollers will be carried out using an electric drive. The machine is equipped with a gear motor with a power of 200 B and 15 rpm. Worm gear ratio is up to 1:100. You can set the equipment in motion using a pedal, for example, from an old sewing machine.

A zig machine will allow you to connect metal elements in cases where welding is impossible or uneconomical. Carrying out zigovka at home is quite simple and does not require special knowledge or additional consumables.

A creasing machine is specialized equipment that allows you to perform such a technological operation as creasing. This method of processing, which sheet metal blanks are subjected to, is not particularly difficult in technological terms, but to carry out such processing it is necessary to use special machines. Such equipment, presented on the modern market in a wide variety of serial models, can be equipped with a manual, electric or hydraulic drive. If desired, it is easy to make a simple crimping machine with your own hands.

Operation of a seaming machine: applying a double round seam to a cylindrical workpiece

Design and principle of operation

The zig machine consists of several elements:

- lower, upper shaft;

- handle for rotating shafts (for manual machines);

- screw for adjustment;

- rollers with the help of which parts are processed;

- gears transmitting rotational force between moving shafts;

- housings made of impact-resistant materials;

- cast bed for stable holding of the machine.

Regardless of whether the installation is equipped with an electric drive or not, there are no significant changes in the design or operating process. Zigovka is carried out in several stages:

- The parts are fixed between movable rollers.

- The shafts are aligned to securely hold the workpiece.

- The operator begins to rotate the handle or starts the electric drive.

The workpiece begins to rotate behind the shaft. The depressions are formed under the pressure of the protrusions on the rollers.

Machine device

Classification of serging equipment by drive type

The simplest, both in its design and in its operating principle, is the manual zigovochny machine. All manipulations with such equipment, as its name suggests, are carried out manually. Such manipulations, in particular, include: pressing shafts with working rollers, for which a special handle located in the upper part of the device is used; scrolling the rollers together with the workpiece sandwiched between them: this action is also performed using a special lever-type handle.

To effectively use the simplest manual type crimping machine, certain skills and dexterity are required, since its operator must simultaneously turn the handle and hold the workpiece in the required position, thereby using both hands. Due to the low power of the drive installed on it, a manual creasing machine can be used for processing sheet blanks whose thickness does not exceed 1.5 mm.

Manual crimping machine is suitable for occasional use in the home workshop

A more powerful, productive, but also more expensive in terms of cost is an electrically driven staking machine. Such zigging machines are most correctly classified as electromechanical equipment, since their design also includes a manual mechanical drive, which ensures compression of the sheet workpiece between the working rollers. Due to the electric drive of such equipment, the working rollers rotate and, accordingly, the rotational movement of the workpiece being processed.

The electric drive of the machine is switched on and off using a foot pedal, so that both hands of the operator always remain free to manipulate the workpiece. The presence of an electric drive, which is equipped with such beading machines, as mentioned above, significantly increases their productivity, which makes it possible to successfully use these machines to equip enterprises producing metal products in large batches. In addition, the power of such a machine allows it to be used for processing sheet metal workpieces, the thickness of which reaches 5 mm.

Electromechanical creasing machines, as a rule, can be equipped with additional devices for processing workpieces of complex configurations

Sealing machines can also be equipped with a hydraulic drive, which further increases the power of the equipment. The technical capabilities of such machines make it possible to successfully use them for processing sheet metal of even fairly significant thickness. The hydraulic drive of this type of beading equipment is responsible for pressing the working rollers to the surface of the workpiece, and their rotation and, accordingly, the movement of the workpiece is provided by an electric drive mechanism. Despite all the advantages that hydraulic crimping machines have, they also have disadvantages: large overall dimensions and significant weight, which is why such equipment is mainly used by large manufacturing enterprises.

Ziga. What is ridge?

What would you think when you saw a group of strong young guys who, stretching their right arms forward and upward, shouted: “Sieg Heil!”? Are these stupid suckers who don’t understand anything in life? Or maybe all these people don’t know Russian history well, since they give the Nazi salute. After all, the phrase “Sieg Heil!” (“Sig Heil”), popularly “Sig” is the most popular salute that was in circulation in Germany from 1933 to 1945. And surely young people don’t know how much grief the peoples of Russia suffered from the attack of those whose behavior they have now adopted? But no, upon closer examination it turns out that these guys and girls know the history of Russia very well. In addition, among them there are many people of very worthy age. And, “throwing out the ridge,” that is, greeting each other in the German-fascist style, they do not praise the actions of Germany, but approve of the policies pursued by the Wehrmacht. Basically, this adoption concerns only domestic politics. The actions of Adolf Hitler and others like him in foreign policy spheres cause rejection even among the most inveterate romantics of fascism in the modern world. Although not for everyone. "Sieg Heil!" or "Sieg Heil", or "Heil Hitler" or simply "Heil" as a greeting originates from Ancient Rome. In a similar way, the Romans greeted their elders in position or rank and wished them health. In the 20th century, it was copied by the Italian fascists, and the German National Socialists (Nazis) adopted it from them. The only difference is that both the Romans and Italians threw their right hand forward, having previously pressed it to their chest in the area of the heart. And the “Roman greeting” was a kind of cordial, benevolent gesture. The Nazi action carries more aggression and challenge and is performed from below, from the right hip. The author of the phrase “Sieg Heil” was Rudolf Hess, who at one time proposed, on behalf of the German leadership, to British Prime Minister Winston Churchill to conclude a separate peace against Russia. After Churchill’s refusal, Hess did not even think of retreating and proposed the same to the British government, but with the condition that Churchill himself be removed from office and arrested. But even here he found himself out of work. The British government, following its prime minister, refused to enter into negotiations with Germany and any “guests” from its territory.

As always and everywhere in similar situations, when the personality of one person, usually a ruler, is identified with the Personality of God or is close to Him, in Germany “Sieg Heil” at the very end of the Second World War became mandatory for everyone. If at first it was used only by intelligence officers, police and members of the National Socialist Party of Germany, then later it began to be used by all residents of German-speaking countries without exception.

At the same time, there were groups of the population who refused to greet each other in this way. Most often they were guided by a religious feeling, because people who believe in God, in their opinion, should not praise a person. Such people were identified and brought to justice by the Gestapo. “It’s good” that in Germany the desire of some people to report others to the competent authorities was openly encouraged. And any deviation from the generally accepted code of conduct immediately became known to the relevant persons. In this case, measures were immediately taken, most often punitive.

Russia and other countries that were once almost entirely Caucasian are now subject to total settlement by other races. It is impossible not to see this. It is obvious that in the very near future the white race will cease to exist as an obsolete race due to its depravity. This is how Rome perished, this is how Byzantium perished, this is how many peoples, countries and even civilizations ceased to exist. Many people feel this today. But some people agree with this, tolerantly enduring the dominance of foreigners in their countries, while others protest in such non-trivial ways as Nazism, one of the brightest manifestations and an indispensable attribute of which today is “zig”.

How to make staking equipment with your own hands

Purchasing a serial crimping machine, even a manual type, makes sense if working with sheet metal is part of your professional activity. In all other cases, if such equipment is needed to perform simple housework, it is better to make it yourself, especially since it is not so difficult to do. What is important is that such a machine with your own hands can be made from very accessible and inexpensive materials.

Before you start making your own crimping machine, you need to find drawings of such a device, and you can take serial equipment as a basis. This is not difficult to do, since many home craftsmen post machine drawings and even video instructions on the Internet.

Scheme of a crimping machine

Shaft drawing (the upper shaft is made without space for the handle)

Shaft housing drawing

Zig machine bed: height 25 cm, width determined by the height of the box

Thrust-limiting shield: dimensions 18x20 cm, thickness 0.2-0.3 cm. Side struts are welded

A suitable handle can be selected separately, so as not to have to make it yourself

Drawing of machine working rollers

To assemble your beading machine (even a simple manual type machine), you will need to prepare the following structural elements of the machine:

- device housing with a protective casing;

- bracket;

- cylindrical shank;

- two working shafts;

- retaining bolt;

- screw equipped with a folding handle;

- spring type device;

- gear elements;

- directly the videos themselves.

Homemade manual crimping machine

The device is fastened using a special screw, while the shank of the mechanism fits into the cup of the bracket, around which the machine body must rotate freely. The device body is fixed in a certain position using a locking bolt. A spring mechanism, activated by rotating the handle, is responsible for moving the upper shaft of the machine relative to the lower one.

To rotate the working rollers of the machine, another handle is used, which is connected to the working shafts through a gear drive. To make the work of the operator of such a machine safer, the elements of its gear transmission are covered with a protective casing. On the Internet, you can easily find videos that demonstrate in detail the process of making homemade crimping equipment.

Homemade electrically driven zigging machine

The process of processing sheet metal workpieces performed on a crimping machine, the details of which can also be found in the video, is as follows:

- a stop is pre-installed on the workpiece, the position of which can be adjusted using special screws;

- the processed edge of the part is mounted on the lower roller;

- by rotating the handle, the second roller is lowered onto the edge of the workpiece;

- By rotating the handle of the machine, the rollers and the part sandwiched between them are set in motion.

After the required processing result is achieved, which may require several cycles of turning the workpiece, the upper roller is raised and the finished product is removed from the machine.

“Ziga” - what is it and where did the gesture come from?

Remember the film “Seventeen Moments of Spring”, how in the Reichstag building the Nazis greeted each other by throwing their hands up? That's it... Now imagine a stadium full of football fans - how do they “handle” if their favorite team scores a goal? That's right, they throw it up. In both cases, it is the right hand that “works.”

Where is he from?

The question is, “Ziga” - what is it and where does it come from? Let's take a closer look at the history of this gesture. There is a version of its origin back in the distant times of the Roman Empire. The image on the famous Column of Trajan says that people greeted each other by throwing their right hands up when meeting.

Slavic brothers

There is another version. The concept of "zig" - what is it? A greeting that was used by the ancient Slavs? Our ancestors were pagans, and worshiping a pagan god was a right thing. Thus, the greeting of the most revered Sun god took place in the following way: a person pressed his right hand to his chest in the area of the heart and then straightened it forward so that the palm was open. This gesture symbolized the return of energy, that is, openness of intentions, kindness of thoughts. By the way, the Slavs did not use this gesture when meeting an enemy.

Other versions

And yet, “zig” - what is it? A shout, a gesture, or something general? There are also explanations:

The English play “Sieger-Sager” was popular in the late sixties of the last century. It looked at a problem that desperately needed a solution: football, football fans, hooliganism.- Now let’s look at the concept of “ridge” from the other side. What does this have to do with football? After all, this concept is used by fans. It is believed that it appeared thanks to one Chelsea fan (London), who, with the help of this chant, “turned on” the fans who responded to his shouts, and it took root. Later, there was even a funny song using this word.

Ole, football!

When you look at the stadium where thousands and thousands of fans of your favorite team have gathered, their raised hands fascinate with their coherence. After all, this is truly a wonderful tool to show players how men and women of all ages and statuses support and worry about them. Football brings people together and unites them during the game. And how many conversations are there after the end of the match: at home, in transport, at work.

Why do they "zig"?

The most unpleasant fact is that the “zig” is a gesture used by representatives of nationalist organizations that are completely unrelated to football and most likely far from the veneration of the sun god. A gesture that carries a certain message, an energetic “charge-discharge”, is associated with manifestations of fascism, evil, which has contained a huge number of people in its mouth: babies, women, old people.

Conclusion

The article briefly examines the main options that answer the question: “Ziga” - what is it? The gesture is also used by football fans, and neo-fascists also use it. We sometimes copy the gestures of others without knowing for sure what it means. The old grandfather, who carried the pain of loss in the war in his heart, will probably move away to the side, and the fans, on the contrary, will respond with the same “zigging” lunge with their right hand. Two opposite sides of one gesture...