Stand-alone generators are often indispensable, and the full list of their possible uses is very long - from providing electricity for a weekend beach party to constant operation at a private building. The wide range of work performed has given rise to a large number of types of autonomous generators, differing both in design and in characteristics. What they have in common is the principle of operation - an internal combustion engine of one type or another rotates the shaft of an electric generator, converting mechanical energy into electrical energy .

The most obvious division of groups of generators is into professional and household.

- A household generator is, as a rule, a portable unit with a gasoline engine, not intended for long-term operation, and having a power of several kVA.

- Professional generators have increased power and continuous operation time, and for greater fuel efficiency and increased service life, diesel engines are usually installed on them. At the same time, if household electric generators produce single-phase current with a voltage of 220 V, then professional generators are overwhelmingly three-phase, designed for 380 V output voltage. Large dimensions and weight force either placing powerful generators on a wheeled chassis or making them stationary.

So, in this classification we have already discovered a number of design differences. Let's look at them in order.

Operating principle and design features

The operating principle of gasoline and diesel power plants is based on the conversion of mechanical energy into electrical energy. Accordingly, the design of such devices contains an internal combustion engine (ICE), which rotates an electric machine that generates electricity. Information about the device and principle of operation of the latter can be found on our website. The main components of an autonomous generator are shown in the figure below.

Gasoline generator device

Designations:

- A – Electronic unit responsible for controlling the generator and stabilizing the voltage.

- B – Electricity generator; a synchronous or asynchronous electric machine is used in this capacity.

- C – Control devices of the electronic unit.

- D – Mounting frame, which also plays the role of a protective frame.

- E – Fuel tank neck.

- F – Fuel tank.

- G – two- or four-stroke carburetor or injection internal combustion engine.

It is necessary to talk in more detail about the power drive of the generator set.

Maintenance

Timely maintenance of the generator set has a noticeable impact on its service life . The engine, as its most complex component, requires the most frequent attention. According to the frequency specified by the manufacturer, indicated in operating hours, it is necessary to change the engine oil and service the air filter. On powerful generators equipped with more complex engines, the oil and fuel filters are also changed. Gasoline engines (gas engines are much less common) require replacement of spark plugs.

If the generator is used sporadically, you should not store it with fuel - oxidation and decomposition over time can lead to clogging of the carburetor with deposits on gasoline generators and the deposition of paraffin on diesel engines, which can completely block the flow of fuel. Also, old fuel will make starting difficult.

The generator itself is an almost eternal unit; only from time to time it is necessary to clean the brush assembly of the synchronous generator from dust and change the brushes themselves, and sometimes the rotor bearings.

ICE gas generator

Two and four-stroke gasoline engines can be used as a drive in such installations. Let's talk about the features of each of them.

Push-pull gas generator

The undoubted advantages of such mechanisms include low cost, compact size, light weight and low noise level. Significant disadvantages:

- Short resource (half that of four-stroke models).

- The need to add engine oil to gasoline. Since this mixture has a limited shelf life of two weeks, it will have to be prepared immediately before launch. In addition, the presence of oil in gasoline significantly increases the toxicity of the exhaust. That is why it is prohibited to install a generator in a garage or other enclosed spaces without an exhaust gas removal system. Violation of this requirement can lead to dire consequences; the toxic substances contained in the exhaust are harmful to humans and animals.

- The fuel mixture in an internal combustion engine of this type does not burn completely, which increases its consumption.

Portable 2-stroke mini generator brand SRGE 650 (220 volts, 0.65 kW, single-phase)

Such cheap generators are an ideal autonomous power source for outdoor recreation. Actually, for this purpose it makes sense not to purchase an installation, but to rent it.

Four-stroke installation

The main advantages of such installations are lower fuel consumption than the previous type (up to 30-35%) and twice the service life. This is achieved through a separate engine lubrication system. But for these advantages you will have to pay a higher price compared to two-stroke models. On the other hand, if we take into account the doubling of the resource, then the overpayment will be insignificant. The weight of the unit and its dimensions somewhat limit its scope of application; for example, it is not suitable for hiking and picnics.

Yamaha 4-stroke generator

Such a station, as shown in the figure above, can serve as an emergency source of electricity for a country house or cottage. In addition, it is possible to connect power tools at a construction site where there is no electricity supply.

Engine

As you know, a gasoline engine can operate on both a two-stroke cycle and a four-stroke cycle .

At the same time, low efficiency and limited service life make two-stroke engines not the best choice for driving an electric generator, although they are simpler in design, and therefore cheaper and lighter. A four-stroke engine, although it is more complex and more expensive , consumes significantly less fuel and can last much longer . Therefore, generators with a power of up to 10 kVA, as a rule, are equipped with engines of this type.

Gasoline engines of electric generators are mainly single-cylinder units with forced air cooling; the combustible mixture is prepared using a carburetor. To start them, either a cable starter is used, or an electric start is additionally included in the design (then, in addition to the battery, such generators also have a 12 V output: the battery is charged from this circuit and consumers designed for low-voltage power can be connected to it). The most common are engines with a cast iron liner and an overhead valve timing mechanism - as a rule, these are Honda GX engines and their Chinese copies.

The engines of household gas generators

are not designed for long-term continuous operation .

Exceeding the operating time specified in the operating instructions (usually no more than 5-7 hours) will reduce the life of the motor. However, even the most advanced gasoline engines have a limited service life : with proper care, they will work for 3-4 thousand hours. Is it a lot or a little? When used occasionally on the road, for example, to connect a power tool, this is a fairly large resource, but constantly powering a private house from a gas generator means rebuilding its engine every year.

Diesel power units have a significantly ; in addition, they are more profitable during long-term operation due to their greater efficiency. For this reason, all powerful generator sets, both portable and stationary, use diesel engines.

For such units, a number of disadvantages of diesel engines compared to gasoline engines (high cost, greater weight and noise) are not fundamental; there is a certain inconvenience only when starting diesel engines in cold weather.

When operating a diesel generator, it must be taken into account that

prolonged idling without load is harmful for them : the completeness of fuel combustion is disrupted, which leads to increased formation of soot, clogging the exhaust, and dilution of the engine oil by diesel fuel seeping through the piston rings.

Therefore, the list of routine maintenance for diesel power plants must include periodically bringing them to full power. In addition, there are generators that run on natural gas. Structurally, they are no different from gasoline engines , except for the power system: instead of a carburetor, they are equipped with a reducer to regulate gas pressure and a calibrated nozzle that supplies gas to the intake manifold. Moreover, such generators can use not only a liquefied gas cylinder as a fuel source, but also a gas network - in this case, fuel costs become minimal. The disadvantage of such generators is low mobility (the gas cylinder is larger and heavier than the gas tank, which, moreover, can be refueled right on the spot), as well as an increased fire hazard, especially if used improperly. However, as a source of backup power in a house connected to a gas main, this is a good option: there is no need to worry about maintaining the level and quality of fuel in the gas tank, and the engine life when running on gas is longer than when running on gasoline.

Electric machine type

A synchronous or asynchronous electric machine can be used as a generator for an autonomous power plant. A detailed description of the design and operating principle of these installations can be found on our website.

Due to their simple design, stations with asynchronous electric machines are distinguished by their simplicity of design; accordingly, brushless generators are much cheaper and have a longer service life than synchronous installations. But, it should be taken into account that with the latter it is easier to adjust the output voltage; this is done by controlling the number of revolutions. This is why synchronous generators are more efficient when the load changes sharply. To reduce voltage “sag” in installations with asynchronous machines, their design uses systems that allow a short-term increase in power.

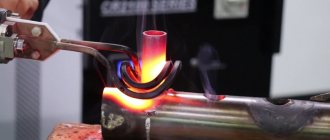

Assembly of the structure and adjustment

The gasoline generator is assembled on a suitable platform. During assembly, the main thing is to ensure strict parallelism and location of the generator and engine pulleys in the same plane. Otherwise, the belt may slip off and cause increased wear. The distance between the pulleys is chosen so that the belt is tensioned and does not slip during operation.

Important! Don't overdo the tension. This will cause a decrease in efficiency and wear on the belt and pulleys, and most importantly, the bearings of the engine and generator shafts.

Having another pulley, even if it is of small diameter, you can make a belt tensioning device using a spring of the required elastic force.

The gas tank is placed in the highest part of the structure so that gasoline can flow by gravity into the carburetor. It is important to prevent the tank from heating up with the heat of a running engine. If necessary, provide thermal insulation using asbestos pads.

One of the design options

Important! Asbestos dust is not toxic, but it can be harmful to the lungs, so you need to wear a respirator when working with asbestos.

Don't forget the fuel filter.

The assembled structure should ensure ease of starting the engine and access to all elements: carburetor, spark plugs, voltage regulator.

The adjustment consists of setting the required voltage using the generator's standard regulator. Some generators, for example, from Samara and newer cars, have a built-in regulator that does not allow adjustment.

If the voltage is below the permissible level, the uninterruptible power supply will not start, giving a signal that the battery is severely discharged. A high value may cause damage to circuit elements.

As you can see, assembling a home gas generator is quite feasible. A self-assembled gas generator can work no worse than a factory one, but you should know that this can only be done if you have at least some of the components. Manufacturing a power plant from scratch in the complete absence of parts will lead to costs exceeding the purchase of a finished structure.

Ignition system

As for the launch system, it can be manual or automatic. In the first option, the installation is turned on by a manual or electric starter directly on site. In the latter case, it is possible to organize a remote start after a small modification (if this function was not provided by the manufacturer).

In the second embodiment, the generator starts working when the centralized power supply is turned off. Stations with automatic start are the most reliable option for emergency power supply for a summer house or country house.

Manual switch

A manual switch, as intended, does not automatically change electrical sources. With a manual gear shifter, you need to turn the shifter yourself.

Converting from your main power source to portable generator power is a precise process. Always follow the instructions provided by the technician exactly after installing the transfer switch.

It is recommended that electrical devices be distributed across multiple circuits, but using the same main switch. This allows you to manually configure which devices you want connected to the portable generator and which devices you prefer not to run.

Inverter installations

The frequency of three-phase and single-phase AC power is 50 Hz, this parameter must be stabilized in the generator, otherwise the equipment connected to it may be damaged. To ensure this condition, the shaft of the electric machine must rotate at a certain speed. As a result, even at low load the internal combustion engine must operate at full power, which significantly reduces the efficiency of the station.

The problem of unnecessary fuel consumption can be solved by installing a special electronic unit at the generator output. In such a device, the alternating voltage coming from the electric machine is converted into direct current. After this, the reverse conversion is performed, but with a given frequency.

Such inverter installations are the most economical, since at low loads they allow you to reduce the speed of the internal combustion engine, thereby regulating the power of the electric generator, and, consequently, fuel consumption. Examples include inverter units Redverg, Honda, welding Champion, Eurolux, Inforce, etc.

Honda inverter generator

Load switch

It must be emphasized how important the gear selector is. A load transfer switch should always be installed for home standby generators and portable generators.

Switch - switches the load from one source of electricity to another. In this case, the transfer switch switches the load from the main power source to the generator or vice versa.

The transfer switch prevents two power sources from being supplied to the circuit at the same time, which is extremely dangerous and can even lead to failure of the device.

There are two types of transfer switches; automatic switch and manual switch. Both types are good, so choosing between them is really a matter of preference.

Classification of petrol power plants

Depending on the resource of installations and power, they are usually divided into household, professional and stationary. The first ones, as a rule, are designed to operate no more than 3 hours a day (for example, Navigator SPG 2700, as well as the model range of such manufacturers as Ergomax, Technic, Wester, Megavolt, Genctab, etc.).

), the latter can function continuously for at least 8 hours. To increase service life, cast iron liners are installed in the engine cylinders. When operating for more than eight hours, it is not advisable to use gasoline units; it is cheaper to switch to stations with a diesel drive.

Household generator Firman SPG3800

Household appliances are limited to a power of 4 kW, but there are also more powerful generators in this class. Examples include Fubag bs 6600, Ultra PG 3200, Kipor KDE6500E3.

The power of professional units, as a rule, does not exceed 15 -16 kW; such stations can be found in the model range of Shtenli, Etalon, Genset, Skat, TNG, etc. An example of such a setup is presented below.

Power plant Robin Subaru EB 14.0/230-SLE 14 kW 380V (3 phases)

More powerful units (up to 30 kW) are available in stationary versions. As a rule, such models are launched both automatically and manually. At power plants with a power of 30 kW or more, installing a gasoline engine is unprofitable due to its short service life and high fuel consumption. That is why powerful generators are driven by a diesel engine.

Stationary gasoline power plant Vepr ABP 20-T400/230 VK-BS (20 kW, with autostart, 400/230 V, 3-phase, made in Russia)

Launch

The portable generator must be placed on a flat, dry surface, and if working in an open space, it must be protected from precipitation. Since single-cylinder engines used in gasoline-powered generators are characterized by a high level of vibration, foreign objects, and especially fuel containers, should not be placed on the generator to avoid them falling.

Before starting, you must make sure that the engine oil level is sufficient and, if necessary, add it, after which the generator engine can be started.

The load can be connected to the generator only after the engine has been started. Do not run the generator while electrical appliances are connected to it.

To start a gasoline engine, a special air damper is used, which enriches the fuel mixture in the closed position. When starting the engine for the first time, especially in cold weather, it is necessary to close it more, the lower the air temperature, and gradually open it as the engine warms up. A warm engine should start without closing the throttle, otherwise you should pay attention to the carburetor adjustments. Starting, depending on the design of the engine, is carried out either by a cable starter (pull it out smoothly until you feel resistance, then sharply increase the force) or electric (to start, press and hold the start button).

Starting a diesel engine differs only in that there is no need to use the air damper, but instead you need to slightly open the decompressor - a device that reduces the pressure in the combustion chamber to facilitate cranking during startup. In addition, starting a diesel engine can be made very difficult by an airy fuel system (the first start of a new generator or if the tank was previously run dry). In this case, you will have to bleed the fuel system (the bleeding procedure differs for different engines and is described in the operating manual).

After letting the generator run for some time (in the warm season, the gasoline engine will warm up quite quickly, no more than a minute), you can connect the load, making sure that the performance indicators or voltage indicator of the generator set indicate its full functionality.

How to make the right choice?

First of all, it is necessary to determine the tasks assigned to the installation. Depending on this, the power of the station is selected. This is a very important point, because if you make the wrong choice, the following problems will arise:

- Less power than necessary leads to overload of the installation, which can cause it to stop. In addition, it should be taken into account that prolonged operation in abnormal mode reduces the resource of the station, and more fuel is consumed.

- A greatly increased power of the installation leads to inappropriate consumption of gasoline.

To avoid the situations described above, the power should be calculated. This is done as follows:

- We determine which devices will be powered from an autonomous source.

- Let's sum up the load power.

- Add 25-30% for reserve.

Despite the apparent simplicity of the process, there is an important nuance - starting power, that is, when the equipment is turned on, it will be briefly higher than the rated power. This must be taken into account, otherwise the connected device may simply not work. Therefore, it is necessary to calculate the starting power using the following formula PP = PNOM * k,

- PP – starting power;

- PNOM—nominal;

- k – power reserve factor (tabular value).

Table 1. Dependence of starting power on rated power, taking into account the coefficient k.

| Device name | PNOM (kW) | Power reserve factor (k) | PP (kW) |

| Household refrigerators | 0,70 | 3,50 | 2,45 |

| microwaves | 0,80 | 2,0 | 1,60 |

| Washing machines | 2,0 | 1,0 | 2,0 |

| Impact and non-impact drills, as well as rotary hammers | 1,0 | 1,2 | 1,2 |

| Angle grinders | 2,2 | 1,3 | 2,86 |

| Well pumps | 1,0 | 3,0-5,0 | 5,0 |

| Mixers for concrete | 1,0 | 3,5 | 3,5 |

Let's give an example of a calculation. Let’s say that in the event of an emergency power outage, it is planned to power the refrigerator and washing machine from an autonomous source, in this case the total starting power will be 4.45 kW. We add, just in case, a reserve of 20%, and we get 5.34 kW. In this case, it can be stated that the power of the Zubr ZESB 3500 and Fubag TI 3000 stations will not be enough (3.5 kW and 3.0 kW). The UBG 8200 drummer and Fubag BS 7500 are also not suitable, since their power is significantly higher (8.2 kW and 7.5 kW, respectively). The Fogo FH 5001 does not meet the 20% margin requirement, but the Fubag BS 5500 is ideal for the task.

Generator Fubag BS 5500 with built-in voltage stabilizer

Having decided on the power, we select the device taking into account its technical characteristics. In this case, it is necessary to take into account what voltage the station produces, the number of phases, the presence of additional 12 V power supply, for example, in order to be able to connect a car compressor. Such models can be found from the following manufacturers: DDE, Workmaster, Sturm, Forte, Elitech, etc.

You should decide on the need for autostart; if the station is to be used as an emergency autonomous source, then such a system is necessary.

Elemaks generator with ATS (automatic transfer system)

For installations on construction sites that are designed to work with a welding machine or other power tools, such automation is not necessary. A device such as the Makita EG 2850a or Firman FPG 7800 will cope with this task; the latter can be started manually and remotely.

If you plan to install a powerful stationary generator for your home or cottage, it makes sense to consider a water-cooled version; such devices have a longer service life.

It is important to read the description of the gas generator, which indicates the characteristics of the device. Moreover, it is advisable to obtain information from the device passport. Those who wrote the description could have made a mistake or deliberately exaggerated some parameters for marketing purposes.

Application areas of gasoline electric generator

Gasoline electric generators are used in areas that do not require long-term operation without interruption and very high power. This:

- ensuring power supply to household appliances in residential buildings during a short-term power outage;

- power supply of electrical tools and equipment at construction sites remote from centralized power supply sources or their insufficient power;

- organizing lighting for outdoor public events, photo shoots, ensuring the operation of coffee machines, refrigerators, and popcorn making units;

- ensuring autonomous operation of tools and equipment for emergency crews.

Fuel consumption

An equally important factor is gasoline consumption, for example, the Chinese Matrix and the Russian-made Vepr with a power of 3 kW consume about 1.5 liters of fuel per hour. Japanese products from Hitachi and Mitsui Power ECO, as well as from the Korean company Hyundai, with the same power of 3 kilowatts consume about 1.2 liters of gasoline per hour.

It should be noted that there are generators that use gas as fuel; such systems are somewhat more expensive than similar gasoline devices. But if we take into account the difference in the cost of gas and gasoline, then the purchase of such a station will be justified.

Why won't the generator start?

There may be several reasons for the problem. Let's look at them in more detail:

- Lack of fuel in the tank

. The problem can arise not only due to insufficient quantity of fuel, but also due to its poor quality. In this case, it is necessary to fill the tank with fresh gasoline and turn on the unit again. - Closed tap

. - Fuel hose leaking

. If there is a problem, then the product needs to be replaced. - No spark

. The spark plug is changed or cleaned and dried to remove any remaining fuel. - Air filter dirty

. It is necessary to thoroughly rinse and dry the element in order for the gasoline generator to start working again.

Advice on choosing a manufacturer from an expert

- Everything is as usual here, the products of famous brands are distinguished by their quality, which can only be exceeded by the cost of such products. If you decide to install such a gasoline generator, then it makes sense to familiarize yourself with the rating of the best manufacturers, which lists the top 10 companies. Given modern realities, do not forget to ask the seller about the availability of a service center.

- Since a gas generator has a relatively short resource, it is better to worry about the availability of spare parts in advance, because a non-working power plant is of little use. From the same point of view, it makes sense to consider models that have a self-diagnosis system, with error codes displayed on the information display.

- Domestic military models, which are unpretentious in operation, but are distinguished by their “gluttony”, have proven themselves to be quite good.

- There are cases when counterfeit products are sold under the guise of branded products, so always check the certificate of conformity.

The best generators with power up to 2 kW

These devices are just as suitable for home use, but their capabilities are slightly better. Among the 2 kW gas generators there are also three most popular models on the market.

- Huter DY3000L. A budget solution that is characterized by high operational stability. 196cc four-stroke engine cm and a 12-liter tank allow the generator to operate autonomously for 10 hours.

- Wert G3000. An ideal option for the price among similar devices. The manufacturer is a Chinese company. The active power indicator reaches 2300 W. The 10-liter tank allows you to work for 9 hours.

- FUBAG HS 2500. The best indicator of autonomy among 2 kW generators. German quality combined with 14 hours of operation without refilling. This value is achieved thanks to the installed tank of 15 liters. Enhanced safety measures include overload protection.

Frequently asked questions from readers

There is a single-phase gasoline generator Fubag BS 6600 A ES 6 kW. There are 3 phases coming into the house. Will this generator work with a 3-phase automation unit Startmaster BS 6600 D 400V for gasoline stations BS 6600 DA ES FUBAG 838221 if jumpers are placed on the generator input connection bus in the automation unit? Will it be possible to deceive the 3-phase automation by connecting a single-phase generator to it?

No, the Fubag BS 6600 A ES single-phase gasoline generator can work with the Startmaster BS 6600 230V single-phase automation unit. The design of the latter allows you to connect a single-phase generator to a single-phase electrical system. In this case, the automation unit functions as follows:

— In automatic mode, it continuously monitors the presence of voltage in the main source - the external distribution network. If a potential difference is present, this will be indicated by the control lamp.

— When the Startmaster BS 6600 automation unit detects a lack of voltage in the electrical circuit, it sends a control signal to start the gasoline generator.

— If the gasoline generator starts successfully, the operation control lamp lights up and indicates the supply of voltage from an independent source. The Startmaster BS 6600 automation unit constantly monitors the presence of supply voltage at the output and checks the resumption of power from the “central network”.

— After the supply voltage is restored, a control pulse is received in the electrical circuit to turn off the generator. Which is taken out of operation and disconnected from the electrical circuit.

If we consider this process in the format you described, then the Startmaster BS 6600 D automation unit for a three-phase electrical system will not be able to control the presence of three-phase voltage at the output from a single-phase generator. Therefore, it will turn off the Fubag BS 6600 A ES due to non-compliance with the three-phase mode, and shorting the terminals will not help in this situation.

Generator operating principle

The operation of a gasoline generator to generate electricity is based on the phenomena of electromagnetic induction, which were studied in a school physics course. The bottom line is that a conductor passes through an electromagnetic cloud and receives an impulse, which is subsequently processed into a constant current. All operations follow one another:

One of the components of the generator is the engine. Its task is to generate electricity by burning fuel, most often gasoline or diesel fuel.- The burned fuel produces combustion products, that is, gas, under the pressure of which the crankshaft begins to rotate.

- The purpose of the crankshaft is to transmit an impulse to the driven shaft, which provides a certain amount of electrical energy at the output.

The overall picture is clear, but it is necessary to understand that a positive result is guaranteed only if the calculations and connections of the main structural parts are carried out correctly.

Generators come in different capacities. The consumption of fuel resources is also different. But, regardless of the listed parameters, two components are fundamental: the rotor and the stator. The armature is used to create electromagnetic fields , which is why it consists of magnets equidistant from the core. The purpose of the stator is to drive the rotor and regulate the state of electromagnetic fields.

Voltage characteristics of inverter generator

Power parameter - 0.8 - 0.9 kW; fuel - gasoline; The output potential is single-phase, 220 V. The voltage waveform is sinusoidal with minor distortion. The quality of the sine wave is affected by the level of harmonic curvature, the permissible value is 8%.

The difference between conventional and inverter generators Source planeta-instrument.com.ua