In what state and form is carbon found in gray cast iron?

What is cast iron?

Cast iron is an alloy of iron and carbon obtained by smelting iron ore in blast furnaces. Cast iron contains from 2 to 5% carbon. How are blast furnace cast irons divided depending on their chemical composition and purpose? Depending on the chemical composition and purpose, blast furnace cast iron is divided into pig iron, foundry cast iron and special cast iron.

How are cast irons separated depending on the nature of the carbon-iron compound?

Promotional offers based on your interests:

Depending on the nature of the combination of carbon with iron, cast iron is divided into white and gray.

What is characteristic of white cast iron?

The carbon in white cast iron is present in the form of cementite (FeO), so it is very hard and is practically not processed, but is used for conversion into steel and for other purposes. The fracture of white cast iron has a matte white color.

What is the state of carbon in gray cast iron?

In gray cast iron, all or part of the carbon is in a free state in the form of graphite, which gives it a gray or dark gray color when broken. Gray cast iron is the main foundry material; it has quite satisfactory mechanical properties, is cheap, has high casting properties and is well processed by cutting tools.

What is the designation for gray cast iron?

Gray cast iron is designated by two letters and two two-digit numbers separated by a dash. The letters SCH mean gray cast iron, the first two-digit number is the tensile strength, the second is the bending strength. For example, SCh 18-36 is gray cast iron, the tensile strength is 18, and the bending strength is 36.

How is modified cast iron different from regular gray cast iron?

Modified cast iron differs from ordinary gray cast iron in that it has improved mechanical and casting properties. It is obtained by adding graphitizing additives (ferrosilicon, elico-calcium or silicoaluminum) to liquid gray cast iron. Grades of modified cast iron: SCh 28-48, SCh 32-52, etc.

How is high-strength cast iron produced?

Ductile iron is produced from gray cast iron by ladle addition before casting into magnesium molds. The result is nodular cast iron, which has high mechanical and casting properties.

Grades of high-strength cast iron according to GOST 7293-54: VCh 45-0, VCh 45-5, VCh 40-10, VCh 50-1.5, VCh 60-2. The letters VCh mean high-strength cast iron, the first two digits indicate tensile strength , and the latter - the value of relative elongation during tension.

How is malleable cast iron obtained?

Malleable cast iron is produced by long-term annealing of white cast iron in special furnaces, after which graphite is formed in the cast iron instead of free cementite.

Grades of malleable cast iron according to GOST 1215-59: KCh 30-6, KCh 33-8, KCh 35-10, KCh 37-12, etc. The letters KCh mean malleable cast iron, the first two digits are the tensile strength, and the last are relative tensile elongation.

What parts are made from gray cast iron in crane construction?

Source

Educational materials

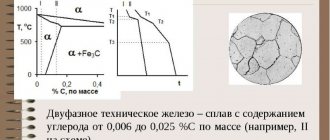

Cast iron is an alloy of iron and carbon, in which the carbon content is more than 2.14%.

In addition to carbon and iron, the alloy contains impurities: silicon, manganese, phosphorus, sulfur, etc. These impurities have a significant impact on the formation of the alloy structure, and consequently on the mechanical, physical and other properties of cast iron.

Depending on the form in which carbon is present in the alloys, white, gray, malleable and high-strength cast irons are distinguished. According to the chemical composition, cast iron is divided into carbon and alloy.

White

are called cast irons in which carbon is predominantly in a bound state in the form of cementite Fe3C (a very small amount of carbon is in the solid solution). These cast irons, whose phase transformations occur according to the Fe-C diagram, are divided into hypoeutectic, eutectic and hypereutectic. Due to the large amount of cementite, white cast iron has a high hardness of 450...550 HB, is brittle and practically cannot be machined by cutting, therefore it is practically not used as structural materials. They can be used for parts that require high surface wear resistance. For example, ball mill balls are made for grinding ores and minerals.

White cast irons are pigmentable and are used to produce steel and malleable cast iron.

Gray

are called cast irons in which carbon is predominantly in a free state in the form of graphite plates. Graphite is formed at a very low cooling rate, when the degree of supercooling of the liquid phase is low. It grows from one center and, branching in different directions, takes the form of highly curved petals. In the plane of the section, graphite has the form of straight or swirling plates, which are cross sections of graphite petals. When fractured, these cast irons are gray in color. The mechanical properties of cast iron are determined by its structure, mainly the graphite component, its quantity, shape and size of inclusions.

Graphite has low strength and can be considered as internal cuts, breaks in the continuity of the metal base. With increasing carbon content, more graphite precipitates and less mechanical strength of cast iron. Gray cast iron has poor tensile strength, is brittle, but has good fluidity, low shrinkage during crystallization, is easy to cut, has good anti-friction properties (graphite acts as a lubricant), absorbs vibration, and is insensitive to stress concentrators (notches, undercuts).

The specific gravity of gray cast iron ranges from 6.6...7.4 g/cm3 and depends on the amount of carbon, the degree of graphitization and the quantitative ratio of structural components.

The heat capacity of gray cast iron also depends on the above factors and in the temperature range 0...700 0C is equal to 16 cal/(g∙0C). Thermal conductivity is 0.16 cal/(cm∙s∙0C). The average coefficient of linear thermal expansion in the temperature range 0…100 0С can be taken as (10…11)∙106 cm/(cm∙0С), and in the temperature range 100…700 0С it is equal to 14∙106 cm/(cm∙0С).

The main elements in cast iron are Fe-C-Si and permanent impurities - Mn, P, S. Silicon has a strong graphitizing effect, manganese makes graphitization difficult. Sulfur is a harmful impurity that worsens the casting and mechanical properties of cast iron.

Phosphorus is a useful admixture in cast iron, as it improves fluidity. Phosphide eutectic areas increase the hardness and wear resistance of cast iron. Most often, the phosphorus content is in the range of 0.2...0.5%. For castings that require high wear resistance, the phosphorus content is allowed 0.7%, and for art casting - up to 1%.

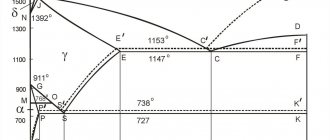

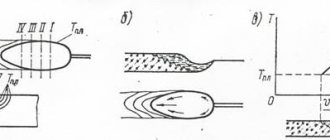

A visual representation of the influence of carbon and silicon on the degree of graphitization of cast iron and its structure is given by the structural diagram (casting wall thickness 50 mm) shown in Figure 37.

I - white cast iron; II - half cast iron; III - gray cast iron on a perlite basis; IV - gray cast iron on a ferrite-pearlite basis; V- gray cast iron with ferritic base

Figure 37 — Structural diagram

Gray cast iron is marked with the letters SCH, followed by a number indicating the guaranteed tensile strength in kgf/mm2

(10-1 MPa).

Ferritic cast irons

grades SCh10, SCh15, SCh18 are used for minor parts that experience light loads. For example, foundation plates, covers, flanges, engine frames, compressors, furnace gates and dampers, filter and oiler housings, flywheels, gearbox housings, pumps, brake drums, clutch discs, etc. The structure of gray cast iron is shown in Figure 38.

Ferrite-pearlitic cast irons

grades SCh20, SCh21, SCh25 are used for parts operating under increased static and dynamic loads. Examples include cylinder heads, pistons, steam cylinder piston ring bushings, centrifugal pump wheels, machine tool frames, gears, diaphragms, low pressure cylinders and turbine exhaust pipes.

a- on a ferritic basis; b- on a ferrite-pearlite basis;

c- perlite based

Figure 38 — Structure of gray cast iron

Pearlitic cast irons

grades SCh30, SCh35, SCh40, SCh45 are used for parts operating under high loads or in severe wear conditions: gears, cylinder liners, camshafts, etc. Small isolated graphite inclusions reduce the strength of cast iron less. Grinding of graphite inclusions is achieved by modifying liquid cast iron with ferrosilicon, aluminum or ferrocalcium (0.3...0.6% by weight of the charge). Castings made of gray cast iron are subjected to heat treatment: to relieve internal stresses - type I annealing (560 0C), normalization or hardening with tempering to increase mechanical properties and wear resistance. To increase the wear resistance of cylinder liners, camshafts and other products, pearlitic cast iron is subjected to nitriding.

Forged

are called cast irons in which carbon is in a free state in the form of flakes. This form of graphite is the main reason for the high strength and plastic characteristics of malleable cast iron. The term “malleable cast iron” is conditional, since products made from it, like any other cast iron, are made not by forging, but by casting, and indicates increased ductility compared to gray cast iron. The composition of malleable cast iron is maintained within fairly narrow limits: 2.4…2.9% C; 1.0…1.6% Si; 0.2…1.0% Mn; up to 0.18% P and up to 0.2% S.

The low carbon content of ductile iron is necessary for two reasons. Firstly, to obtain high strength characteristics, the number of graphite inclusions should be reduced. Secondly, it is necessary to avoid the release of lamellar graphite when cooling castings in the mold (for the same purpose, the thickness of the casting wall should not exceed 50 mm).

Malleable cast iron is obtained from white cast iron by annealing, which sometimes lasts up to 5 days. According to the structure of the metal base (Figure 39), which is determined by the annealing mode, malleable cast irons are ferritic and pearlitic.

Annealing for ferritic cast iron is carried out according to mode 1 (Figure 40), which ensures graphitization of all types of white cast iron cement.

a – ferritic; b – pearlite

Figure 39 – Microstructure of malleable cast irons

Figure 40 – Scheme of annealing white cast iron for malleable

White cast iron castings are loaded into metal boxes and covered with sand or steel filings to protect them from oxidation and slowly heated to a temperature of 950...1000 0C. During a long (10...15 hours) exposure at this temperature, the first stage of graphitization occurs. It consists of the decomposition of eutectic and excess secondary cementite.

By the end of the first stage, the cast iron consists of austenite and annealed carbon inclusions (A + D). Then the temperature is slowly reduced to 720...740 0C. In this case, the second stage of graphitization occurs.

During the exposure process (25...30 hours), perlite cementite disintegrates:

P(F + C) -> F + G

and malleable cast iron on a ferritic base is formed.

Pearlitic cast iron is produced by annealing, which is carried out in an oxidizing environment according to mode 2 (see Fig. 40). In this case, the duration of the first stage of graphitization is increased, after which the castings are continuously cooled to 20 0C. Austenite turns into pearlite (A -> P), and graphite remains in the structure. The result is malleable cast iron based on pearlite.

Malleable cast irons are marked with the letters KCH, followed by numbers indicating the guaranteed tensile strength in kgf/mm2

(10-1 MPa) and elongation in percent. Ductile iron grades:

- KCh-30-6; CC 35-10; KCh 37-12 - ferritic;

- CC 45-7; CC 60-3; KCh 80-1.5 - pearlite.

These cast irons are used to make high-strength parts that operate under severe wear conditions and are capable of withstanding shock and alternating loads. The high density of malleable cast iron castings makes it possible to produce parts for water and gas installations, valve bodies, faucets, and gate valves.

Highly durable

are called cast irons in which carbon is in a free state in the form of nodular graphite. They are obtained by modification with magnesium, which is introduced into liquid cast iron in an amount of 0.02...0.08%. Due to the fact that modification with pure magnesium is accompanied by a significant pyroelectric effect, an alloy of magnesium with nickel is used.

Cast iron after modification has the following chemical composition: 3.0...3.6% C; 1.1…1.9% Si;. 0.3...0.7% Mn;. up to 0.02% S and up to 0.1% P. According to the structure of the metal base, cast iron can be ferritic or pearlitic (Figure 41).

a-ferritic; b- pearlite

Figure 41 — Microstructure of high-strength cast irons

Nodular graphite is a less potent stress raiser than flake or flake graphite and therefore reduces less the mechanical properties of the metal base. Cast irons have high strength and some ductility, retaining their strength up to 500 0C (ordinary cast iron up to 400 0C). They are marked with the letters HF, followed by a number indicating the guaranteed tensile strength in kgf/mm2 (10-1 MPa). Ductile iron grades:

- HF 38; HF 42; HF 50 - ferritic;

- HF 60, HF 80; HF 120 - pearlite.

High-strength cast irons are used in various branches of technology, effectively replacing steel in many products and structures. For example, housings of steam turbines, pumps, valves, guide vanes, crankshafts, pistons and other critical parts operating under high cyclic loads and wear conditions.

In some cases, heat treatment of castings is used to improve the mechanical properties; to increase strength - hardening and tempering at 500...600 0C; to increase ductility - annealing.

The disadvantage of high-strength cast iron is significant volumetric shrinkage, which leads to the appearance of shrinkage porosity and gas pockets in castings.

Alloy cast iron > Continue >

Chemical composition of cast iron

Cast iron is an alloy of iron and carbon, in which the percentage of carbon is not less than 2.14% but not more than 4.5%. Carbon is part of cast iron in the form of cementite or graphite. If the percentage of carbon content is less than 2.14%, the alloy is called steel.

It is known that cast iron alloy was first produced in China in the 6th century. The secret of its production came to Europe in the 14th century, and in Russia its composition was brought to perfection only in the 17th century. Over all this long time, the formula of cast iron has not changed.

The highest quality material was produced at the Demidov brothers foundry, located in the Urals.

Over the centuries, it not only has not lost its relevance, but has also acquired an even wider range of applications.

What is

Cast iron is an iron-based alloy.

Belongs to the group of ferrous metals. Ferrous metals are iron, alloys based on it (steel, cast iron, ferroalloys), manganese. According to some classifications, chromium is included in the group.

In terms of composition, cast iron is a conglomerate of iron, carbon, plus other metals. The steel formula could contain the same basic components.

The difference between these alloys is the amount of carbon. If it is less than 2.14%, it is steel. More - cast iron.

Other components are alloys and impurities (sulfur, silicon, phosphorus, manganese).

Carbon in the structure of cast iron is represented by inclusions of graphite or cementite (iron carbide, formula – Fe3C).

You can distinguish cast iron from steel visually. Steel is lighter and shiny, cast iron is dark matte.

Advantages and disadvantages

Cast iron, like any material, has positive and negative sides.

The advantages of cast iron include:

- Carbon in cast iron can be in different states. Therefore, this material can be of two types (gray and white).

- Certain types of cast iron have increased strength, so cast iron is sometimes placed on the same line as steel.

- Cast iron can maintain temperature for quite a long time. That is, when heated, the heat is evenly distributed throughout the material and remains in it for a long time.

- In terms of environmental friendliness, cast iron is a clean material. Therefore, it is often used to make dishes in which food is subsequently prepared.

- Cast iron is resistant to acid-base conditions.

- Cast iron has good hygiene.

- The material has a fairly long service life. It has been noticed that the longer cast iron is used, the better its quality.

- Cast iron is a durable material.

- Cast iron is a harmless material. It is not capable of causing even slight harm to the body.

The disadvantages of cast iron include:

- Cast iron will rust if it is exposed to water for a short time.

- Cast iron is an expensive material. However, this minus is justified. Cast iron is very high quality, practical and reliable. Items made from it are also high quality and durable.

- Gray cast iron is characterized by low ductility.

- White cast iron is characterized by brittleness. It is mainly used for smelting.

Alloy features

The main feature of cast iron is hidden in the process of its manufacture. The fact is that for different types of this alloy the melting point reaches 1200ºC, while for steel it is 1500ºC. This factor is affected by too high a carbon content. Iron and carbon atoms do not have very close bonds with each other.

When smelting occurs, the carbon atoms cannot be completely embedded in the molecular lattice of the iron, causing the cast iron alloy to become brittle. In this regard, it is not used in the production of parts that will be constantly subject to load.

This material belongs to the ferrous metallurgy industry and its characteristics are similar to steel. Products made of cast iron and steel are widely used in everyday life, and it is entirely justified.

If we compare the characteristics of these metals, we can draw the following conclusions:

Metal composition and structure

Cast iron as a structural material is represented by a metal cavity with graphite inclusions. Its main components are pearlite, ledeburite and plastic graphite. It is interesting that in different types of alloys these elements are present in different proportions or may be completely absent.

According to its structure, cast iron alloy is divided into the following varieties:

In this case, graphite may be present in it in one of the following forms:

Manufacturing technologies

As you know, cast iron is produced in special blast furnaces. The main raw material for its production is iron ore. The manufacturing process consists of the reduction of iron ore oxides and the resulting production of another material - cast iron. For its production, fuels such as coke, thermoanthracite, and natural gas are used.

To produce one ton of pig iron, about 550 kilograms of coke and approximately a ton of water are required. The volume of ore loaded into the furnace will depend on the iron content in it. As a rule, ore is used, which contains at least 70% iron. The thing is that it is not economically feasible to use a lower concentration.

The first stage in the production of cast iron is its smelting. Ore is poured into the blast furnace, and then coking coal, which is necessary to pump and maintain the required temperature inside the furnace shaft. During combustion, these components take an active part in the ongoing chemical reactions as iron reducers.

Meanwhile, flux is immersed in the furnace, which acts as a catalyst. By accelerating the melting of rocks, it thereby supports the rapid release of iron. It is important to know that before loading into the furnace, the ore undergoes the necessary pre-treatment. It is crushed in a crushing plant because smaller particles melt faster. It is then washed to remove non-metal particles. Next, the raw material is fired, as a result of which sulfur and other foreign components are extracted from it.

At the second stage of production, natural gas is supplied through special burners into the filled and ready-to-use furnace. Coke is involved in heating the raw materials. Carbon is released, which combines with oxygen to form an oxide. It, in turn, promotes the recovery of iron from ore.

As the volume of gas in the furnace increases, the rate of the chemical reaction decreases. It may even stop completely when a certain gas ratio is reached. Carbon penetrates the alloy and combines with iron to form cast iron. Unmelted elements remain on the surface and are soon removed. Such waste is called slag. It is used to make other materials.

Scope of use

This metal is used in various industries. For example, it is widely used in mechanical engineering for the production of various parts.

Most often this material is used in the production of engine blocks and crankshafts. To manufacture the latter, an improved alloy with the addition of special graphite impurities is required. This metal is resistant to friction, so high quality brake pads are made from it.

In harsh climatic conditions, cast iron alloy is indispensable, as it allows machine parts made from it to operate smoothly even at the lowest temperatures.

It has also proven itself excellent in the metallurgical industry. Its excellent casting properties and relatively low price are highly valued. Products made from it are characterized by very high strength and wear resistance.

A great variety of plumbing products are made from cast iron alloy. These are radiators, sinks, various sinks and pipes. Cast iron bathtubs and heating radiators are widely popular. Their service life is very long. Many apartments still use these products to this day, because they retain their original appearance for a long time and rarely need restoration.

It is also important that the excellent casting properties of cast iron make it possible to make entire works of art from it: such as openwork forged gates and all kinds of architectural monuments.

It is noteworthy that the price for 1 kilogram of cast iron is determined by the amount of carbon in its composition, as well as the presence of various impurities and alloying components. The price of a ton of cast iron is about 8,000 rubles.

Today there is not a single area where this metal is used. Its castings and alloys form the basis of many components, mechanisms and parts. Sometimes it is used as an independent product, perfectly coping with the functions assigned to it. This iron-containing compound is unique in its kind. It remains indispensable to this day.

Source

How to distinguish cast iron from steel

At scrap metal collection points, cast iron is accepted at a low price, since it is fragile, difficult to process, and removing harmful impurities from it is not an easy task. Experts shared with us tips on how to independently distinguish cast iron from other metals:

- by sound (if you hit steel with any object, the sound comes out very loud);

- by strength;

- on magnetic properties.

Cast iron can be easily distinguished from iron. Iron rusts quickly, it is light silver in color and ductile. But it is more difficult to distinguish cast iron from steel, due to their similar composition; they are externally similar to each other, but the characteristics of the alloys are different from each other.

Steel is easier to process and is not afraid of impacts. There is an opinion that a magnet will help distinguish cast iron from steel. This is correct to some extent, because the magnetic properties of the alloy depend on its composition.

Gray cast iron

Gray cast iron is an alloy of iron and carbon, which, when the metal cools, forms in the form of flake-like or plate-like inclusions. The carbon content of the alloy exceeds 2.14%, which is higher than normal solubility. This is what distinguishes the alloy from steel, in which carbon is completely dissolved and is absent in the form of separate inclusions, the structure of which defines them as graphite.

Main characteristics

Gray cast iron is the basis of ferrous metallurgy, as it is obtained from the reduction of iron ores using carbon fuel (coke). As a result, in addition to the chemical reaction of reduction of iron oxides, the alloy is additionally saturated with free carbon.

The high free carbon content determines the mechanical properties of gray cast iron. One of the main qualities that allow gray cast iron to be used not only as a pigment metal is its high casting qualities and low shrinkage during solidification. Molten metal has high fluidity, so it can be used to make castings of complex shapes.

Gray cast iron plates

The restriction on the use of products made of gray cast iron is due to the fact that it has low bending strength and high fragility. At the same time, the compressive strength of gray cast iron is very high.

Despite its high fragility, such a characteristic as the wear resistance of cast iron allows it to be used in products operating under friction conditions. Under these conditions, the antifriction properties of the alloy have a strong influence.

Due to the presence of carbon inclusions, welding gray cast iron is practically impossible. There are welding technologies under certain conditions. This is preheating of parts, the use of special high-carbon electrodes, but still, the structure of the weld metal is very different from the base material. The parts to be welded must be cooled slowly to eliminate stress in the weld area.

Influence of components on the properties of cast irons

Cast iron differs from steel in its higher carbon content and better casting properties. It is not capable of being processed under pressure under normal conditions and is cheaper than steel. Cast iron contains impurities of silicon, manganese, phosphorus and sulfur. Cast irons with special properties contain alloying elements - nickel, chromium, copper, molybdenum, etc. Impurities found in cast iron affect the amount and structure of released graphite.

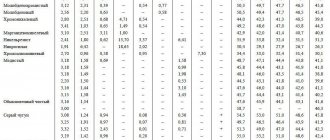

Rice. 23. Microstructures of cast iron

The mechanical properties of cast iron castings depend on its structure. Cast irons have the following structural components: graphite, ferrite, pearlite, ledeburite and phosphide eutectic. Based on their microstructure, cast irons are divided into white cast iron I (Fig. 23), containing ledeburite cementite C and perlite P; gray pearlitic cast iron II containing pearlite P and graphite G; gray ferritic cast iron III, containing ferrite F and graphite G. In ferritic cast iron, all carbon is in a free state in the form of graphite. There are cast irons with intermediate microstructures: half-Pa, which contains pearlite, ledeburite cementite and graphite; pearlite-ferrite PB containing ferrite, pearlite and graphite; high-strength IV – pearlite and spherical graphite.

The formation of a particular microstructure of cast iron is greatly influenced by its chemical composition and the cooling rate of the casting.

Carbon in ordinary gray cast iron is contained in amounts from 2.7 to 3.7%. The release of graphite increases with increasing carbon content in cast iron. In all cases, the limits for carbon content are accepted: lower ones for thick-walled castings, and upper ones for thin-walled castings.

The combined influence of carbon and silicon on the structure of cast iron is presented in the diagram (Fig. 24, a). On the diagram, the abscissa line shows the silicon content in cast iron, and the ordinate axis shows the carbon content. The diagram is divided into five areas by solid lines. The designation of the areas corresponds to the cast iron structures shown in Fig. 23. Using this chart, the percentage of carbon and silicon can be determined to produce castings with a wall thickness of 50 mm and the required microstructure.

Rice. 24. Structural diagrams of cast iron depending on: a – carbon and silicon content, b – cooling rate

A significant influence on the formation of the cast iron structure is exerted by the cooling rate of the casting, which becomes smaller the greater the thickness of the casting wall. With an increase in the cooling rate of the casting, the amount of cementite in the structure of cast iron increases, and with its decrease in the structure of cast iron, the graphite content increases. Therefore, with the same chemical composition of cast iron, a casting having different wall thicknesses will have different microstructures, and therefore mechanical properties. In Fig. Figure 24, b shows the combined influence of carbon and silicon (ordinate axis) and casting wall thickness (abscissa axis) on the structure of cast iron. The designation of the areas in this diagram also corresponds to the structures shown in Fig. 23, and areas of Fig. 24, a.

Manganese dissolves in cast iron, forming solid solutions with ferrite and cementite. Manganese to some extent prevents the graphitization of cast iron. Manganese neutralizes the harmful effects of sulfur on cast iron. The manganese content in gray cast iron is usually 0.5-0.8%. Increasing the manganese content to 0.8-1.0% leads to an increase in the mechanical properties of cast iron, especially in castings with thin walls. Phosphorus has no practical effect on the process of graphitization of cast iron. In an amount of 0.1-0.3%, phosphorus is found in solid cast iron in a dissolved state. Phosphorus increases brittleness, since in cast irons with a phosphorus content of about 0.5-0.7%, a triple phosphide eutectic (Fe+Fe3P+Fe3C) with a melting point of 950°C is formed, which is released in the form of a brittle continuous network along the grain boundaries. Phosphorus increases fluidity and wear resistance, but impairs the machinability of cast iron. For critical castings, the phosphorus content is allowed up to 0.2-0.3%. Castings intended for abrasion can contain up to 0.7-0.8% phosphorus, thin-walled castings and artistic castings - about 1% phosphorus.

Sulfur is a harmful impurity; it forms iron sulfide (FeS) during solidification and impairs the casting properties of cast iron (reduces fluidity, increases shrinkage and increases the tendency to cracks). Iron sulfide forms a low-melting eutectic (Fe+FeS) with iron, which melts at a temperature of 988°C. The eutectic solidifies last and is located between the grains, leading to brittleness and a decrease in the strength of cast iron at elevated temperatures, i.e., red brittleness. The addition of manganese in an amount 5-7 times higher than the sulfur content neutralizes its harmful effects. Sulfur forms with manganese manganese sulfide MnS, which is in the molten cast iron in a solid state because it melts at 1620°C. Most of the resulting manganese sulphide passes from the liquid iron into the slag. The sulfur content in cast iron is limited to 0.12%, and in high-strength cast iron it should be no more than 0.03%.

Alloying elements (Cr, Ni, Mo, Ti, Mn, Cu, etc.) improve the properties of cast iron. Chromium and nickel are usually used together for alloying cast iron. As a result of alloying cast iron, pearlite is crushed or other, even finer structures are formed.

Chemical composition and structure

The chemical composition of the alloy, in addition to iron and carbon, also includes some silicon content. The properties of the alloy depend on the cooling conditions, since the time of temperature change affects the formation of the internal structure of the material.

With slow cooling, large iron crystals are formed, and metal-carbon compounds acquire a pearlite base. Slow cooling causes an increase in the geometric dimensions of not only iron crystals, but also carbon inclusions, therefore, pearlite metal has high strength, but increased fragility.

Microstructure of gray cast iron

Under conditions of rapid cooling, carbon does not have time to form large graphite inclusions, so the alloy acquires a ferritic structure.

Ferritic gray cast iron is slightly less brittle than pearlitic.

By choosing a cooling mode for a cast workpiece, you can influence the final properties of the material in a certain way, depending on the requirements.

Ductile iron

It has a ferritic or pearlitic structure (see Fig. 23), and is a type of gray cast iron modified with magnesium. Simultaneously with it or a little later, ferrosilicon is introduced into the liquid cast iron. As a result, small inclusions of spherical graphite are obtained (see Fig. 25, 6). This cast iron has increased strength compared to conventional gray cast iron. Depending on the tensile strength (σв) and relative elongation (δ), high-strength cast irons (GOST 7293-79) are divided into the following grades (the numerical values of hardness NV are indicated in parentheses): VCh 38-17 (140-170), VCh 42 -12 (140-200), HF 45-5 (160-220), HF 50-2 (180-260), HF 60-2 (200-280), HF 70-3 (229-275), HF 80 -3 (220-300), HF 100-4 (302-369). HF 120-4 (302-369).

The mechanical properties of high-strength cast iron make it possible to use it for the manufacture of machine parts operating under severe conditions, instead of forgings or castings of steel. High-strength cast iron is used to make parts of rolling mills, forging and pressing equipment, steam turbines (guide vanes), tractors, cars (crankshafts, pistons), etc. For example, the crankshaft of a Volga passenger car is made of high-strength cast iron of the following composition : 3.4-3.6% C; 1.8-2.2% Si; 0.96-1.2% MP; 0.16-0.30% Cg; <0.01% S; <0.06% P and 0.01-0.03% Mg. The low content of sulfur and phosphorus and small limits for the content of other chemical elements are ensured by the fact that such cast iron is smelted not in a cupola, but in an electric furnace. After heat treatment, the mechanical properties of cast iron are very high: σв = 620-650 MPa, δ = 8-12% and hardness HB = 192-240.

Application

Gray cast iron is widely used in casting products for which high compressive strength is important. This property is important mainly in the manufacture of cast tool beds. The use of the material is limited by the increased fragility of products in the presence of significant bending forces.

Gray cast iron product

Previously, the good casting properties of the material were widely used in the manufacture of various products for household and industrial purposes. A variety of kitchen and household utensils - cast iron pots, frying pans, irons - made by casting with minimal subsequent processing had low cost and ease of production.

Currently, casting is also used to produce highly loaded machine elements where they are not subjected to bending loads. These are pistons and cylinders of internal combustion engines.

High-strength parts cast from gray cast iron have minimal cost and long service life. Without exaggeration, we can say that cast beds and machine bodies are almost eternal compared to other elements of the device.

Source

Malleable iron

Malleable cast iron is a conventional name for cast iron that is more ductile compared to gray cast iron. Malleable cast iron is never forged. Ductile iron castings are produced by long-term annealing of white cast iron castings with a pearlite-cementite structure. The thickness of the casting walls should not exceed 40-50 mm. During annealing, white cast iron cementite disintegrates to form flake-shaped graphite (see Fig. 25, c). For castings with a wall thickness greater than 50 mm, undesirable flake graphite will form during annealing.

Depending on the structure of the metal base, a distinction is made between ductile ferritic cast iron and ductile pearlitic cast iron. Ferritic malleable cast irons are obtained from white cast irons smelted by the duplex process and containing 2.4-2.8% C; 0.8-1.4% Si; 0.3-0.4% MP; 0.08-0.1% S, 0.2% R. To protect against oxidation during annealing, white cast iron castings are placed in special metal boxes and covered with sand, steel filings or fireclay. Annealing of white cast iron consists of slow heating (20-25 hours) to a temperature of 950-1000°C and long exposure (10-15 hours) at this temperature. During the holding process, the first stage of graphitization occurs, which consists of the decomposition of eutectic and excess secondary cementite, which is present in small quantities at this temperature. By the end of holding, the first stage of graphitization ends and the cast iron consists of austenite and annealed carbon inclusions. Then the temperature is reduced to 720-740°C and the cast iron is again kept for 25-30 hours (Fig. 26, mode 1). At this time, the second stage of graphitization occurs, during which the perlite cementite decomposes. Ferritic malleable cast iron is also called black-core due to the type of fracture, which, due to the large number of graphite inclusions in the ferrite base, has a dark matte color.

Rice. 26. Annealing white cast iron

Pearlitic malleable cast irons are obtained from white cast irons, smelted primarily in cupola furnaces. For this purpose, white cast iron must have the following chemical composition: 2.8-3.4% C; 0.5-0.8% Si; 0.4-0.5% MP; 0.2% P and 0.12% S. To reduce the carbon content, annealing is performed in an oxidizing environment. To do this, the castings are covered with scale or crushed iron ore. The annealing mode consists of heating to a temperature of approximately 1000°C, long-term exposure at this temperature (the first stage of graphitization) and continuous slow cooling to room temperature (Fig. 26, mode 2). With such annealing, a significant part of the carbon burns out, and complete decarbonization is observed in the surface layer up to 1.5-2.0 mm deep. Therefore, when fractured, cast iron turns out to be light-colored and is called light-hearted. Pearlitic malleable cast irons have less use than ferritic malleable cast irons.

Depending on the tensile strength (σв) and relative elongation (δ), malleable cast iron (GOST 1215-79) is divided into the following grades (the numerical values of hardness HB are indicated in parentheses): KCh 30-6 (163), KCh 33-8 (163), CC 35-10 (163), CC 37-12 (163) – ferritic black-hearted and CC 45-6 (241), CC 50-4 (241), CC 56-4 (269), CC 60- 3 (269), CC 63-2 (269) – light-heart pearlite.

Malleable cast iron is widely used in automotive, agricultural and textile engineering. High-strength parts are made from it, capable of withstanding repeated variable and shock loads and operating under conditions of increased wear, such as the rear axle housing, brake pads, hubs, pins of cutting devices of agricultural machines, gears, hook chains, etc. Widespread use of malleable cast iron, which occupies an intermediate position in mechanical properties between gray cast iron and steel, is due to the better casting properties of the original white cast iron compared to steel, which makes it possible to obtain castings of complex shapes. Malleable cast iron is characterized by fairly high anti-corrosion properties and works well in an environment of moist air, flue gases and water.