home

About company

Directory

Stainless steel circle

Due to its high technical and operational qualities, round bars made of alloy steel (stainless steel) are used for the manufacture of parts and structural elements operating in aggressive and high-temperature environments, in conditions where increased strength characteristics are required. An additional advantage is that when using alloy steels, the weighting of metal structures is insignificant: does not exceed 9%, and sometimes decreases by 10-15% due to a decrease in the calculated metal consumption; Moreover, the corrosion resistance, heat resistance, and endurance limit of alloyed structures increases significantly compared to carbon steels.

One of the most commonly used domestic grades of high-alloy steel for the production of round rolled products is 12Х18Н10Т, its foreign analogues are:

- S32109, 321, 321Н, S32100 (USA);

- X10CrNiTi18-10, 1.4541, 1.4878, X6CrNiTi18-10KT (European Union).

Depending on the production method, stainless steel circles are divided into:

- hot rolled;

- calibrated, produced by cold rolling;

- forged;

- with additional special surface treatment.

Dimensions and weight of stainless steel circle

In accordance with GOST 7417-75, which regulates the range of metal products, round stainless steel rods can be manufactured in lengths from 1.5 to 6.5 meters. The most popular and widespread are rods, about 4 meters long, which, if necessary, can be cut into the required blanks. At the request of the client, it is possible to produce stainless steel circles and other lengths:

— multiple measured;

- unmeasured length;

- measured.

The cross-section diameter can be 3 - 320 mm. Circles of small diameters are supplied in rods and coils, while larger workpieces can only be purchased in the form of rods up to 6.5 meters long.

Stainless steel circles have all the advantages of stainless steel, and are also characterized by a convenient shape for storage, transportation and processing.

The weight of the rod depends on the steel grade, diameter and length. The weight of one linear meter of a circle with a diameter of 10 mm is only 620 grams, and with a diameter of 200 mm is about 250 kilograms.

Hot-rolled round steel from corrosion-resistant and heat-resistant steel grades

Stainless steel hot-rolled circles with a diameter from 5 to 200 mm are produced in accordance with technical specifications according to GOCT 5949-75 (instead of GOCT 5949-61), geometric parameters, size range and maximum deviations are established by assortment according to GOCT 2590-2006.

The assortment also determines the standard length of the rod:

- from alloy steel from 2 to 6 meters;

- made of high-alloy steel - ranging from 1 to 6 meters.

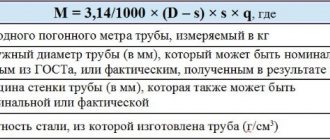

The weight of a linear meter (stainless steel circle 12Х18Н10Т) can be calculated using formula (1):

M=ρ×π×d²÷4 (kg/m),

Where:

- ρ=7920 kg/m³ (specific gravity 12Х18Н10Т)

- π=3.14

- d is the diameter of the rod in meters, or according to formula (2):

M=0.0062172×d² (kg/m), where d is the diameter of the rod in millimeters.

Estimated weight of a rod made of steel grade 12Х18Н10Т for some diameters of the GOCT 2590-2006 size range

| Diameter d, mm | Weight per meter, kg | Number of meters per ton | Diameter d, mm | Weight per meter, kg | Number of meters per ton | Diameter d, mm | Weight per meter, kg | Number of meters per ton |

| 5 | 0,155 | 6451 | 16 | 1,592 | 628 | 80 | 39,790 | 25 |

| 5,5 | 0,188 | 5319 | 20 | 2,487 | 402 | 95 | 56,110 | 17 |

| 6 | 0,224 | 4464 | 25 | 3,886 | 257 | 100 | 62,172 | 16 |

| 6,3 | 0,247 | 4048 | 30 | 5,595 | 178 | 110 | 75,228 | 13 |

| 6,5 | 0,263 | 3802 | 36 | 8,057 | 124 | 130 | 105,071 | 9 |

| 7,0 | 0,305 | 3278 | 40 | 9,947 | 100 | 150 | 139,887 | 7 |

| 8 | 0,398 | 2512 | 45 | 12,590 | 79 | 160 | 159,160 | 6 |

| 9 | 0,504 | 1984 | 50 | 15,543 | 64 | 180 | 201,437 | 5 |

| 10 | 0,622 | 1607 | 55 | 18,807 | 53 | 185 | 212,784 | 4,7 |

| 11 | 0,752 | 1329 | 60 | 22,382 | 44 | 190 | 224,441 | 4,5 |

| 12 | 0,895 | 1117 | 65 | 26,268 | 38 | 195 | 236,409 | 4,2 |

| 13 | 1,051 | 951 | 70 | 30,464 | 32 | 200 | 248,688 | 4,0 |

In addition to the size range, GOCT 2590-2006 establishes the classification of hot-rolled alloy wheels (as indicated in the rolled product designation):

- by rolling class: regular B1, B2, B3, B4, B5, increased B1, high A1, A2, A3, especially high AO1.

- by length: measured length MD, multiple measured length CD, unmeasured length ND, OND, in skeins NMD.

- by curvature class: class I, II, III, IV.

Depending on the conditions of further use, hot-rolled steel in accordance with the technical conditions of standard 5949-75 is divided into subgroups:

- subgroup a

- hot rolled products intended for subsequent cold drawing or pressure treatment; - subgroup b

- hot rolled products, used later for milling, turning, cutting, etc.

An example of a symbol (hot-rolled circle with a diameter of 36 mm, increased degree of rolling, curvature class II, measured length 6 m, made of steel 12Х18Н10Т, intended for machining, assortment according to GOCT 2590-2006, technical specifications GOCT 5949-75):

Calibrated stainless steel circle

Due to additional polishing and grinding, this type of product is characterized by a more attractive appearance and high surface quality, in comparison with hot-rolled rods. The dimensions of calibrated rods are more accurate. It is used as a blank for rolling, stamping and for many other purposes, including as decoration. To increase elasticity and hardness, the workpieces are subjected to heat treatment.

Manufactured by cold rolling followed by calibration from steel grades AISI 304, AISI 316 (acid-resistant), AISI 321 (heat-resistant) and other grades. Calibrated circles with a diameter of up to 25 mm (inclusive) can be produced in coils. The technical conditions of the material are regulated by GOST 5949-75, and the product range is regulated by GOST 7417-75. The stainless steel calibrated circle meets the European standard DIN EN 10060-2004.

Alloyed round bars with special surface treatment

Technical conditions for the production of stainless steel circles with additional surface treatment (diameter from 0.2 to 50 mm and length, depending on the diameter, from 0.7 to 4 m) are regulated by GOCT 5949-75 and GOCT 14955-77, size range and limits deviations are determined by the assortment from GOCT 14955-77.

Surface finishing may include the following operations: turning with grinding, roughing with subsequent polishing. The surface quality is divided into 4 groups: A, B, B, D, E, E; according to the manufacturing accuracy, a stainless steel wheel with a treated surface is divided into eight grades: h5, h6, h7, h8, h9, h10, h11, h12.

For the symbol of this rolled product according to GOCT 14955-77, the following characteristics are indicated:

- Type of delivery, in rods or coils.

- Diameter in mm.

- Surface quality group.

- Quality.

- Type of steel - hard-worked H or heat-treated T

- Steel grade.

- Standard (technical conditions and assortment), GOCT 14955-77.

For example, a rod with a diameter of 10 mm, group E, quality h9, made of cold-worked H steel 08X13 is designated as follows:

Rod 10-E-h9-T-08X13 GOCT 14955-77.

Forged and hot-rolled stainless steel circle

A rolled metal product with a matte surface of unmeasured and measured lengths, manufactured by hot rolling. For its production, stainless heat-resistant steel grades 14Х17Н2, 12-40Х13, 12Х18Н10Т, 08Х17Т and others are used. Technical conditions must comply with GOST 5949-75, and the chemical composition - GOST 5632-72, assortment - GOST 2590-88. The diameter of the rolled metal product varies from 8 to 320 mm.

The appearance of an untreated hot-rolled stainless steel wheel is somewhat worse - the surface is darker. To give it a marketable appearance, the rods are ground, turned and cleaned.

Semi-finished products are intended for further processing: OMD (under pressure) or mechanical (planing, milling, etc.)

Calculate pipe weight

To calculate the weight of pipe, sheet or coil products, you need to enter the following information in the open tab:

- type of rolled metal - it can be pipes, angles, circles, squares, sheets, strips, hexagons;

- product type (if necessary);

- steel grade;

- dimensions – length, diameter, wall thickness;

- quantity.

There is no need to enter any professional parameters (density, temperature), this confuses the inexperienced user. Just click on the rectangular “Calculate” button so that after a second the total calculated mass and the mass of 1 linear meter appear below.

The weight calculation is based on the density of specific steel grades, which depends on the rolling temperature. Our program defaults to specific gravity and density at 20°C for all items.

Properties of stainless steel circles

All wheels made of stainless steel have several common characteristics, in particular:

— high level of heat resistance, which makes it possible to manufacture parts for operation at high temperatures;

— good corrosion resistance;

— welding capability;

— wear resistance;

- strength;

— possibility of mechanical processing, including in a cold state.

Why do you need to calculate mass?

Accurate calculation of metal mass allows:

- take into account the obtained data during construction, installation of pipes and utilities;

- find out the total weight of the batch when transporting from the warehouse.

The actual weight of the rental may vary, since the calculator works based on accurate data. In production, small deviations from the exact geometric dimensions are possible, which is reflected in the weight. The larger the batch, the more noticeable the deviation.

The program, which operates online, is periodically updated and supplemented with information regarding new steel grades. If you do not find the brand you need in the list, contact us, we will add it to the calculator list.

Classification and sizes

For cold-rolled stainless steel structures, thickness dimensions range from 6 to 60 mm, and the width of the strip can be from 200 to 1050 mm. Workpiece lengths of 2–18 m are allowed, but products of 5–12 m are considered in demand.

For hot-rolled structures, the width parameter is in the range of 11 - 200 mm, and the thickness is allowed in 4 - 60 mm. The length of the whips is made from 2 to 6 m.

Finished rolled metal products vary in accuracy class:

- regular – marked with the letter “B”;

- elevated – marked with the letter “A”;

- high – marked with the letter “B”.

Another parameter that determines the quality of the whips is the crescent shape. This is the degree of curvature of the strip, which differs by class:

- Class I – the coefficient is up to 0.2% of the length of the workpiece;

- Class II - the coefficient does not exceed 0.5% of the length of the whip.

Any AISI 304 strip can be produced in measured or unmeasured lengths. Options for multiple pieces are also possible. The corners of the whips can be sharply cut or rounded. The surface itself can be matte or additionally polished.

For hot-rolled structures, the permissible thickness deviations of 12/25/28 mm amount to an excess of up to 15/25/35 mm. If the width of such workpieces is less than 400 mm, then deviations within the range of -2.5/+2.0 mm are possible. For structures up to 800 mm wide or greater than 850 mm, the tolerances are -3.0/+2.0 mm and -3.0/+4.0 mm, respectively.

| Size, mm | Brand | Sectional area, cm² | Meter weight, kg | Dulled angles, mm |

| Stainless steel strip 20x3 | AISI 304 | 0,60 | 0,471 | 2,0 |

| Stainless steel strip 20x4 | AISI 304 | 0,80 | 0,628 | 2,0 |

| Stainless steel strip 20x6 | AISI 304 | 1,20 | 0,942 | 2,0 |

| Stainless steel strip 20x10 | AISI 304 | 2,00 | 1,570 | 2,0 |

| Stainless steel strip 25x3 | AISI 304 | 0,75 | 0,589 | 2,0 |

| Stainless steel strip 25x4 | AISI 304 | 1,00 | 0,785 | 2,0 |

| Stainless steel strip 25x6 | AISI 304 | 1,50 | 1,178 | 2,0 |

| Stainless steel strip 25x8 | AISI 304 | 2,00 | 1,570 | 2,0 |

| Stainless steel strip 25x10 | AISI 304 | 2,50 | 1,963 | 2,0 |

| Stainless steel strip 30x3 | AISI 304 | 0,90 | 0,707 | 2,0 |

| Stainless steel strip 30x4 | AISI 304 | 1,20 | 0,942 | 2,0 |

| Stainless steel strip 30x5 | AISI 304 | 1,50 | 1,178 | 2,0 |

| Stainless steel strip 30x6 | AISI 304 | 1,80 | 1,413 | 2,0 |

| Stainless steel strip 30x8 | AISI 304 | 2,40 | 1,884 | 2,0 |

| Stainless steel strip 30x10 | AISI 304 | 3,00 | 2,355 | 2,0 |

| Stainless steel strip 40x3 | AISI 304 | 1,20 | 0,942 | 2,5 |

| Stainless steel strip 40x4 | AISI 304 | 1,60 | 1,256 | 2,5 |

| Stainless steel strip 40x5 | AISI 304 | 2,00 | 1,570 | 2,5 |

| Stainless steel strip 40x8 | AISI 304 | 3,20 | 2,512 | 2,5 |

| Stainless steel strip 40x10 | AISI 304 | 4,00 | 3,140 | 2,5 |

| Stainless steel strip 40x20 | AISI 304 | 8,00 | 6,280 | 2,5 |

| Stainless steel strip 50x4 | AISI 304 | 2,00 | 1,570 | 2,5 |

| Stainless steel strip 50x5 | AISI 304 | 2,50 | 1,963 | 2,5 |

| Stainless steel strip 50x6 | AISI 304 | 3,00 | 2,355 | 2,5 |

| Stainless steel strip 50x8 | AISI 304 | 4,00 | 3,140 | 2,5 |

| Stainless steel strip 50x10 | AISI 304 | 5,00 | 3,925 | 2,5 |

| Stainless steel strip 60x5 | AISI 304 | 3,00 | 2,355 | 3,0 |

| Stainless steel strip 60x6 | AISI 304 | 3,60 | 2,826 | 3,0 |

| Stainless steel strip 60x8 | AISI 304 | 4,80 | 3,768 | 3,0 |

| Stainless steel strip 60x10 | AISI 304 | 6,00 | 4,710 | 3,0 |

| Stainless steel strip 80x6 | AISI 304 | 4,80 | 3,768 | 3,0 |

| Stainless steel strip 80x8 | AISI 304 | 6,40 | 5,024 | 3,0 |

| Stainless steel strip 100x4 | AISI 304 | 4,00 | 3,140 | 3,0 |

| Stainless steel strip 100x6 | AISI 304 | 6,00 | 4,710 | 3,0 |

| Stainless steel strip 100x8 | AISI 304 | 8,00 | 6,280 | 3,0 |

| Stainless steel strip 100x10 | AISI 304 | 10,0 | 7,850 | 3,0 |

Scope of application

Stainless steel strip is most often used in construction. This material is a raw material for the further production of welded structures:

- fences and fencing;

- stairs;

- arches;

- decorative elements of the facade and interior.

In the automotive industry, springs are made from such strips. Also, blanks are purchased by enterprises producing and repairing railway cars or sea vessels. The strip is used by food and chemical industries, and is also suitable for the manufacture of furniture and household appliances.

At metallurgical plants, profile products and angles are made from rolled steel. Stamped metal structures are also produced.

Download priceStainless steel strip AISI304

| Name | Price from 0.5 tons (RUB/ton) |

| Stainless steel strip nickel-containing 20×4 | 279200 |

| Stainless steel strip nickel-containing 25×4 | 243200 |

| Stainless steel strip nickel-containing 30×3 | 275100 |

| Stainless steel strip nickel-containing 40×4 | 248400 |

| Stainless steel strip nickel-containing 40×8 | 246200 |

| Stainless steel strip nickel-containing 50×5 | 242100 |

| Stainless steel strip nickel-containing 60×6 | 242100 |

| Stainless steel strip nickel-containing 80×8 | 242100 |

Advantages of stainless steel

The demand for strips made of stainless alloys is explained by its performance characteristics. Rolled steel can withstand temperature changes and exposure to acids and alkalis. It also allows increased loads on the whip, eliminating the deflection effect. The material with zero flammability is quite flexible and durable.

The structures can be installed by welding or bolted connections. Even if there are welded seams, elements of a construction project, parts of automotive or factory equipment do not corrode.

Rental properties

Compared to a regular strip, stainless steel is resistant to heat and can come into contact with moisture. Therefore, it can be used in damp environments without the risk of corrosion.

The alloy contains a large percentage of chromium (about 20%). This condition determines the increased resistance of rolled products to aggressive operating conditions. The presence of nickel, titanium and silicon makes the strip resistant to planned and increased loads. Therefore, the blanks can be used for standard construction or manufacturing purposes, as well as in complex projects.

Among the popular stainless alloys are heat-resistant:

- chromium based;

- with nickel content;

- with manganese additives.