To conduct communications in areas free from construction sites, they dig a trench, lay pipes, and then fill the trench. This method is the simplest, but time-consuming and not always possible. Under the road and in densely built-up conditions, this option is unacceptable. In such a situation, a soil puncture installation is used. Using modern special equipment, pipes are laid without disturbing ground structures. The trenchless method is a horizontal drilling of the soil, during which the soil is compacted.

20-series soil puncture drilling rig

BURUPG is used for various types of soil and pipe systems.

Using the installation, you can perform both controlled and unguided drilling. High pressure drilling is also possible. The machine is capable of working from rectangular and round shafts, wells and collectors. The main frame consists of two structures, which is necessary to be able to use pipes of different lengths: 500 or 1000 mm. If there is difficulty in passing the ground or increased horizontal drilling is required, the frame can be increased to 200 centimeters. This allows you to satisfy any pipe laying needs. The drilling length is from 20 to 50 meters, the diameter range is from 63 to 325 mm.

Specifications:

- Press force 196 kN.

- Pressing pitch 225 mm.

- Reverse thrust 128kN.

- Torque 4740 N*m.

- Gearbox stroke 100 mm.

- Connection size 30 rpm.

- Weight 480 kg.

- Frame width 835 mm.

- Frame length 1885 mm.

- The length of the additional frame is 500, 2000 and 3000 mm.

- The maximum possible pipe diameter is 320 mm.

- The pipe used is 500 mm.

- The pit should have the following dimensions: 200x180 cm.

From the pit to the drilling axis the distance is 36 centimeters.

Drilling rig BUP, with soil puncture

BUP horizontal drilling machines are often used for controlled and unguided drilling. They are used not only for laying canals and pipelines, but also in general construction.

The ability to increase the length of pipes appears with the presence of extensions. The maximum pipe size is almost 510 meters.

Specifications:

- Press force. For BUP it is 375 kN, for BUP.2 it is 400 kN.

- Pressing step. For both models it is 250 mm.

- The torque is also the same for the models, 5900 N*m.

- The maximum rotation speed is the same for both models. They are capable of rotating up to 44 rpm.

- The gear stroke for BUP is 170 mm, and for BUP.2 it is 2120 mm.

- The hydraulic unit is 36 for both models.

- The reverse thrust force is 250 kN, regardless of the model.

- The maximum size of the production pipe varies slightly. For BUP it is 508 mm, and for BUP.2 it is 506.

- The weight of the units is 850 kg.

- The length of the frame for BUP is 237 centimeters, for BUP.2 it is 195 centimeters.

- The length of the additional frame for BUP can be 100 or 300 cm. For BUP.2 this figure is 1000 mm.

- The frame width of both models is 250 cm.

- The reverse thrust force is 260 kN for the PDU.

The distance from the pit to the drilling axis is 50 centimeters.

Drilling rig BUP with puncture

The horizontal drilling rig is one of the most powerful systems. It is used to connect houses to communications such as sewerage, communications, water supply and gas.

The drilling rig can be used even with a small pit size, the diameter of which is 2 meters. The system is used for laying pipes up to 80 meters long.

The horizontal drilling rig is typically used for controlled pipeline laying and canal construction. Thanks to the presence of extension frames, it is possible to install cases and pipes of almost different lengths.

Technical characteristics of the PCB:

- The press force of the installation is 850 kN.

- Maximum rotation is 22 revolutions per minute.

- The torque is quite large and amounts to 18,000 N*m.

- Gearbox stroke – 190 mm.

- Reverse thrust force 450 kN.

- The connecting size of the BUP is 6 centimeters.

- The weight of the system is 1800 kilograms.

- Frame length and width: 1900x2000.

- The length of the segments is 550 mm.

- The maximum possible pipe size is 56 centimeters.

The distance to the drilling axis from the pit is 60 centimeters.

Small installation for connecting houses

The system is small in size and is a universal drilling unit, which is used to carry out work on laying communications when connecting residential buildings.

The TS installation is used for digging channels from collectors or pits. Depending on the configuration, the unit can be used with an impact piston, flushing, or puncture.

The TS is a powerful and relatively inexpensive installation for horizontal drilling. It is highly accurate in comparison with Chinese analogues and American-made installations.

Technical indicators:

- The torque is 1000 Nm.

- Traction force – 50 kN.

- Clamping force 50 kN.

- Total length 110/160 centimeters.

- Installation width 45 cm.

- The distance from the installation axis to the drilling rig is 315 mm.

- Maximum stroke 740/1240 mm.

The vehicle for horizontal drilling, even despite its compactness, allows us to ensure reliability and high quality when passing through difficult areas when piercing roads. When carrying out conventional drilling, the use of the installation allows you to preserve the natural landscape and not disturb it.

The unit is used in directional drilling and is suitable for novice professionals.

In urban conditions, it is quite difficult to puncture a road without compromising the integrity of the asphalt surface. But the need to replace or lay new communications under railways or roads arises quite often.

To carry out work on laying pipes under the ground, the puncture method is used. Using technology, it is possible to lay pipes for communications under the asphalt surface without disturbing it.

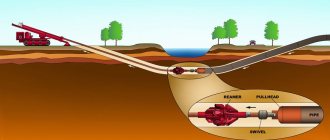

The work is carried out using horizontal directional drilling. The technique can be used even in cases where the use of traditional methods is impossible, for example, when laying pipes under reservoirs, or in the presence of specific soil.

Features of puncture under the road using HDD method

The horizontal drilling method makes it possible to lay communications when the pipe diameter is from 6.5 to 80 centimeters. That is why puncture is used for trenchless laying of pipes for electricity, sewerage and water.

First of all, test drilling is carried out using an installation with a small diameter drill head. The well is then expanded to the desired size.

The soil through which drilling is carried out may vary in density and amount of solid particles. Before starting drilling work, a soil analysis should be carried out. Special installations are used during the drilling process.

The technology also presupposes the availability of a place where the pipes to be laid will be placed, as well as special equipment. Using the technology, it is possible to lay pipes of various sizes and materials.

The average cost of 1 shift of welding HDPE pipes varies from 800 to 1000 rubles. The price of the work depends on many features, including the distance and features of the object.

The welding process is a labor-intensive process. The quality of the work performed depends on the professionalism of the specialist.

HDPE pipes have many advantages. First of all, they are quite lightweight, which makes installation much easier. A pipeline made of steel or cast iron, unlike HDPE, is heavy and expensive.

Our company employs only highly qualified specialists who will perform high-quality work thanks to modern equipment and extensive experience.

When welding, special attention should be paid to the type of pipe connections and operating conditions of the pipeline. If it will be used in places where there is high pressure. In this case, welding of HDPE pipes is used or electric couplings are used.

Welding of HDPE pipes is carried out using heating and then gradual melting of the connecting part of the ends. A heating unit is used for this. The pipes are then connected to give the desired pressure.

Installation of UPRODTUBE

The pushing force is created by hydraulic cylinders. They are fixed on a rigid frame. This allows for a symmetrical arrangement of the axes relative to the center of the pipe being pressed.

Through a pressure device resting on the hinge supports, force is transmitted to the pipe. It is a plate with guides that slide along the guide. Using the device, it is possible to lay pipes of various diameters.

The installation also includes a guide section. It is a welded frame, which consists of crossbars and guides. There are flanges at both ends. With their help, the section is fixed to the frame.

During operation of the installation, strong drag appears. As a result, a shear force occurs that has a reverse motion. To prevent shifting, the installation is equipped with a special thrust wall. This is a welded plate into which special hinges rest. It is installed vertically in the rear wall of the pit.

The operation of the installation is controlled using the control panel. It is connected to the pump and cylinders. The hydraulic valves are manually controlled. Their number is equal to the number of hydraulic cylinders. Installed in a special metal box.

The working fluid is supplied through a pump. An internal combustion engine or an electric motor can be used as a drive.

Additional equipment, such as a submersible pump, can be connected to the hydraulic pump. It allows you to pump water out of the pit.

Advantages of installing UPRODTRUB

The UPRODTRUB installation, used for pushing pipes and casings, has several modifications that meet all technical requirements.

Over several years of use, the installation has shown reliability and efficiency. All enterprises that carry out pipeline stretching using pushing have a number of advantages over their competitors.

With the help of the installation, the work is done efficiently and quickly enough. The UPRODTRUB installation has a number of features that allow you to evaluate all its capabilities:

- Possibility of working in soils of various categories.

- The equipment can be used in a variety of climatic conditions at temperatures from -18 to +40 degrees.

- Depending on the wishes of the customers, the installation can be manufactured taking into account northern climatic conditions.

- The distance between pits can be up to 90 meters.

- The unit can be equipped with a diesel, gasoline or electric engine.

- Low operating costs. When using diesel fuel, its consumption is no more than 3 liters per hour.

- The working pressure in the hydraulic system is 70 MPa.

- The installation can be used in small pits.

- The design is unique. The work is carried out accurately and with great speed.

- Possibility of using pipes with a diameter of 15 to 50 centimeters.

- Increased service life of the installation thanks to high-quality Swiss-made components.

- Quite a wide selection of configurations. This allows the installation to be selected according to customer requirements.

UPRODTRUB drilling rig equipment:

- Power block. It can consist of 2, 3 or 4 hydraulic cylinders. Fixed on the frame.

- The pump is hydraulic. Equipped with a diesel, gasoline or electric engine.

- Base plate.

- Remote Control.

- Guide sections.

- Lunettes.

- Brackets.

- Pressing device.

- Devices for removing soil.

- Tips and bushings.

- Manual.

The delivery set also includes connecting sleeves.

Necessary equipment

Brief list of equipment for HDD:

- Classic type drilling machine.

- Installations with auger cutting part.

- The main and auxiliary tools used to drill a hole in the ground.

- Hydraulic winches for laying pipes.

- Mixing installations for preparing and supplying drilling fluid.

If you plan to perform work in conditions of negative air temperatures, then a device is needed to warm up the working fluid and the power unit. The autonomous heater runs on motor fuel, which burns in the boiler. Heated air is supplied by a fan; a control thermometer can be used in the design.

UPRODTRUB installation and its analogues

Today there are quite a lot of analogues of the UPRODTRUB drilling rig on the market. But they are often inferior in their technical characteristics. Not every installation is capable of developing a force of up to 800 tons and laying a pipeline whose diameter can be up to 202 centimeters.

In addition, similar installations are not characterized by high productivity, and the pushing speed is several times lower than that of UPROTDRUB UPPT.

For analogues, the length of continuous punching is usually achieved by using pipes of smaller diameter. The choice of drive for similar installations is not as wide as that of the Horizon. Often the possibility of using additional equipment is not available with analogues.

Technical characteristics of UBPT UPRODTRUB are presented in the table:

| Options | Light class | Middle class | Heavy class |

| Pushing force | 400 | 600 | 800 |

| Stroke in mm | 1200 | 1200 | 1200 |

| Number of cylinders (pcs.) | 2 | 3 | 4 |

| Pipe diameter in cm | 15-80 | 15-160 | 140-202 |

| Maximum punching length (m). | 90 | 90 | 90 |

| Power block weight (kg) | 1600 | 4750 | 4450 |

| Power block dimensions (L/W/H) in cm | 165/130/130 | 185/150/150 | 205/170/170 |

| Nominal pressure MPa | 70 | 70 | 70 |

| Nominal flow l/min. | 5 | 7 | 9 |

| Tank capacity (l) | 100 | 150 | 200 |

| engine's type | electric, diesel or petrol | electric, diesel or petrol | electric, diesel or petrol |

| Engine power | 13 | 18 | 22 |

| Hydraulic unit weight (kg) | 245 | 555 | 695 |

| Total weight (t) | 2 | 5,5 | 10 |

Hydraulic pumps are used to drive HDD installations and other hydraulic equipment. They are capable of continuously working for about 1400 hours. Hydraulic pumping stations have electromagnetic or manual control, allowing you to work with double-acting or single-acting tools.

In addition, the pumps are equipped with a pressure gauge that is resistant to vibration. There are also special filters necessary for oil purification.

If necessary, the installations can be equipped with devices for heating the oil, cooling it, or wheels for moving the station. Pumps can have more than 3 flows, allowing other hydraulic equipment to be connected to them.

Electrically driven hydraulic pumps are designed to drive installations used to replace or lay pipelines using the trenchless method. They are equipped with distributors and hydraulic pumps that are mounted on a control panel or mounting plate. Manual control using a special hydraulic distributor.

Regardless of the installation model, the nominal pressure indicator is 70 MPa. Tank volume – 150 liters. The supply voltage is 380 V. They can be single-flow or double-flow.

Diesel-driven hydraulic pumps are used to power the installation for laying pipelines using the trenchless method. They are quite economical due to low operating costs.

Pressure build-up in the system is ensured using a three-position distributor. The working pressure is maintained for quite a long time.

The installation is controlled manually. The nominal pressure in the system is 70 MPa. Depending on the model, the tank volume varies from 100 to 150 liters. The flow rate of the working fluid also depends on the model of the pumping unit and ranges from 3 to 7 liters per minute.

Gasoline-driven hydraulic pumps are used to supply working fluid to the hydraulic cylinders of the installation. Most often they are used in conditions where it is impossible to connect to the power supply network. The unit is equipped with a hydraulic distributor. The control is manual, which allows you to work with double-acting or single-acting tools. In addition, the hydraulic type distributor allows for holding, returning and lifting.

Such installations belong to the heavy class. They are equipped with a diesel drive and are used to provide equipment with energy.

The pump unit panel is equipped with a control valve, a hydraulic distributor, a fuel supply lever, a pressure gauge for pressure control, an oil cooling button, and an ignition switch.

The station consists of several parts:

- diesel engine;

- oil tank with a volume of 100 liters;

- fuel tank;

- pump group, which includes a pump, high-pressure hose, coupling and flywheel;

- battery;

- oil cooler;

- casing with muffler and exhaust pipe;

- handle to regulate the rotation speed.

Pumping stations are installed at the site of replacement work and pipeline laying. Installation is carried out using quick release couplings and special hoses.

Specifications:

- Dimensions (L/W/H/) – 188/100/131 cm.

- Weight 850 kg.

- Pump operating volume 40 cm3/rev.

- Pump flow 100 l/min.

- The nominal pressure is 17 MPa.

- Supply voltage 12 V.

- Fuel tank volume 60 l.

A distinctive feature of the northern version of the installation is that it is capable of operating at temperatures from -10 to -50.

In densely built areas or in the presence of already laid pedestrian paths, highways or railways, the problem of communication arises. Today, trenchless laying technology is popular, making it possible to install utility networks without compromising the integrity of above-ground or underground facilities.

The technology allows the pipeline to be installed in landscaped areas, while green spaces and roads will remain unaffected. There are two ways to conduct communications using trenchless technology.

Horizontal drilling locating systems

Since the drill head is located deep in the soil, special locating equipment is used to control the direction of the puncture. If there is no control, the drill head may collide with rocks or deviate from the specified trajectory. An additional problem when performing horizontal drilling is existing utility networks: erroneous movement of the tool can cause destruction of the lines.

The design of the geolocation control system includes a small-sized probe for horizontal drilling, which is fixed on the front part of the cutting tool. The operator tracks the position of the probe on the screen of the device, which detects radio frequency radiation. The operator relays information to a crew member who operates the hydraulic drilling rig.

Since the distance between people is 100-200 m or more, a radio station is used for communication. There are location systems with a dual control device; an additional display is installed on the drilling rig. Location systems are selected depending on the depth of the highway, soil density and route length. To ensure work safety, it is recommended to control drilling along the entire length of the puncture in the ground.

The probes are equipped with radio frequency transmitters, allowing you to select the range for transmitting signals. The frequency is selected taking into account minimal exposure to airborne interference. The external receiver is equipped with a color liquid crystal display with a diagonal of up to 11 inches, which displays the trajectory of movement and has an additional area for launching third-party applications. The screen can display the temperature of the cutting tool, pressure in the working fluid supply system and other parameters.

Soil puncture

The technique is used in cases where it is necessary to lay a pipeline under a railway or highway. First of all, two pits are dug on both sides of the road. The first is the initial or starting one. It is in it that the equipment for performing the work is located. The second pit is the receiving pit.

A special metal tip is put on the first pipe, with the help of which the puncture will be performed. It will make the process easier. After the second part of the pipes approaches the entry point, the next section is fixed to it. The soil around the pipeline is compacted, and there is no need for its disposal.

The following factors influence speed and energy consumption:

- The type of soil where the puncture is carried out.

- The material from which the pipes are made.

- Final well size.

- Puncture method.

In the construction of utility networks, several types of soil punctures are used. The most popular is hydropuncture. During operation, a stream of water is supplied into the pipe. In this case, special equipment is used.

Vibration puncture can also be used. To perform the work, special vibratory hammers are used. Piercing the soil for communications can be done using pneumatic punches. The mechanism has a hammer, which is driven by compressed air. In swampy areas or rocky areas, the pneumatic punch is not used.

The puncture method allows you to stretch a pipeline up to 50 meters in length and with a diameter of up to 42 centimeters.

Devices for puncturing soil based on a pump

Pumping units are used in sewerage, water supply, heating, fuel and oil supply. There are also pump-based installations. They are used to erode soil. There are also methods when a casing pipe with a sharp edge is carried out at a certain depth. There is a pipe inside it through which water is supplied under pressure.

The soil is eroded, and the casing pipe is lowered down by the worker under its own weight. The puncture method, which is based on a similar technology, is popular.

The method of conducting communications arose in cases when, when constructing utility networks, it became necessary to cross roads, railways, or other communications. Before carrying out work, the presence and depth of communications should be established.

Soil puncture is carried out using special equipment. Work should be carried out only by highly qualified specialists. Installations with a pump require sufficient physical strength. Using the machine, you can lay communications with a length of 15 meters and a diameter of up to 50 meters.

Before work, pits are dug on both sides of the road. In the first, a puncture is made towards the finishing pit. A pointed nozzle is fixed to one end of the pipe. A hose from a pump is connected to the second, which is installed in a container with water. It comes out through the hose under great pressure.

The direction of the puncture is determined in advance. The force on the pipe is determined by the type of soil. The softer it is, the less force is required.

The pumping unit must be powerful enough and the hose must be of the required length. It is important to monitor the water level so that its flow is sufficiently intense. Most of the water returns along with the eroded soil to the pit. It can be reused using a pump.

To avoid damage to the pumping unit as a result of large particles entering it, it is necessary to install a filter for deep cleaning. The volume of the water container must be at least 500 liters.

The pipe used to carry out the puncture can be made multi-sectional. Extension is carried out using couplings. The nozzle is fixed on the thread. This is necessary so that it can be replaced if necessary. The hose must be attached to the pipe using a dismountable connection. The work should be carried out by two workers for safety and convenience.

Laying pipes using the pipeline puncture method: rules and recommendations of soil puncture specialists

In cases where communications cross railway tracks or a highway, laying pipes is difficult or impossible. To solve the problem, the soil puncture method is used. The technology makes it possible to install utility networks in particularly difficult conditions.

Soil punching

The technology is similar to soil puncture. At the initial stage, they also dig a pit and install frames with jacks. When performing a puncture, a tip is put on one end of the pipe, but in the case of pushing, the work is performed without its use. Instead of a metal tip, the pipe has a cutting edge.

Jacks operate in forward and reverse motion and allow you to press the pipe into the soil. The soil that remains in the pipe cavity is removed manually. A special mechanism can also be used for this purpose.

To facilitate the work, vibration-impact or hydraulic-washing installations are used. They erode the soil, allowing the pipe to enter unhindered. By pushing the soil, you can lay a pipeline whose length will be up to 60 meters and its diameter up to 3 meters. During one shift, workers lay about 10 meters of utility networks.

Hydraulic installations can not only reduce labor costs, but also make work easier and eliminate damage to above-ground and underground objects. Thanks to the latest technology, the process of working with soil has become several times more productive.

Laying cables using soil puncture method

When it becomes necessary to lay one or more cables, the pipe is laid first. Its diameter should slightly exceed the cable cross-section by 20 centimeters.

The case is placed first, and then the pipes. The space formed between them is filled with a special solution. To prepare it, you can use cement M-100.

The case helps reduce the load on installed communications, including cables, and reduces the risk of damage.

Vibro-, hydraulic puncture of soil and soil punching technology

In the construction of utility networks, vibration and hydraulic punctures of the soil are distinguished. To carry out hydraulic puncture of the soil, water is used under high pressure. It is fed through a special tip.

Puncture technology is used in sandy soils that are susceptible to water. The puncture technique helps to make a hole whose diameter is up to 50 centimeters. At the same time, the time costs are minimal. But if the technology is used, the maximum length of the pipeline can be up to 30 meters.

Vibration puncture of the soil is carried out using vibration. For this purpose, special shock-vibration installations are used. The pipe is pressed in due to the action of a vibrating hammer. The technology is used on sandy and floating soils not only for laying communications, but also for the purpose of extracting pipes. The diameter of the formed well reaches up to 50 meters, and the length is up to 60 meters.

Punching is performed using the same technology as puncture. But the pipe is directed into the ground with its open end. As it advances, soil remains in the cavity, which is developed.

Punching technology is carried out using jacks, the power of which can reach 400 tons. Before carrying out work, a thrust wall and a jack are used.

Mini HDD

A mini installation for horizontal directional drilling will allow you to quickly and efficiently lay communication lines, gas pipelines, water pipes, and sewer networks. The installation is capable of working with pipes with a diameter of up to 22 centimeters.

Features of working with mini HDD

Due to its low weight, the unit can be transported by truck or disassembled. The set includes rods for 52 lm.

Only 2 people are required to operate the installation. Thanks to this, the customer will not have to pay a whole team of workers.

Mini HDD is characterized by high productivity and low maintenance costs. The equipment can be used to destroy cases and metal pipes with a diameter of up to 22 centimeters.

The installation is capable of operating even at temperatures of -25 degrees. Mini HDD is one of the best among other compact installations for puncturing or pushing through soil.

The equipment is used for trenchless pipeline installation and replacement of previously installed communications and does not require the use of bentonite solution.

One of the advantages of the installation is its low cost. Some manufacturers quote a price of 240,000 rubles. But this is just a frame. The cost of the equipment also includes drill rods. Each of them costs about 5-6 thousand rubles.

Kits also do not include attachments, grips or oil stations. As a result, the total cost of the installation with all the necessary elements is no less than 900 thousand rubles. But this is uncontrolled drilling.

To carry out controlled drilling to lay a pipeline with a diameter of up to 16 centimeters, a complete set of equipment costs more than 1,500,000.

But the choice of installations today is quite small.

Mini HDD is capable of working in difficult conditions when air temperatures are down to -40 degrees. But it is important to know that water freezes at subzero temperatures. That is why it needs to be stored and maintained at its temperature. The equipment is capable of working in loamy and clayey soil, but is not suitable for use in the presence of sand.

In order to carry out utility networks, they dig a trench. But if there are intersections with railways or highways, parks and other objects, this is impossible to do. In this case, a closed communication method is used. These can be punching, drilling or horizontal directional drilling technologies.

Prices for horizontal directional drilling

The cost of HDD in Moscow depends on the method used and a number of other factors. In the Eurolos company the price of the service is:

- Manual drilling - from 20 thousand rubles;

- Drilling using mini HDD - from 25 thousand rubles.

At first glance, such costs may seem irrational, since the puncture can be done with your own hands, without the involvement of specialists. But let's look at what the costs look like if you decide to do this work yourself.

| DIY drilling costs | |

| Large hand-held construction hammer (used to push the bailer) | 40 000rubles |

| Used tractor hydraulic cylinder for liner production | from 5,000 rubles |

| Manufacturing and cutting of crowns and bailers | price negotiable |

| Extension pipes | from 300 rubles per meter |

| Semi-automatic welding machine | from 4,000 rubles |

| Your time | priceless |

As a result, the costs will be at least 50 thousand rubles (excluding the manufacture of the bailer and the cost of pipes) - the difference is obvious.

Independent manual drilling will require much higher costs than hiring specialists.

Let's not discount the time spent on work. Where experts can do it in a few hours, a non-specialist can spend more than one day.

| Drilling costs using mini HDD | |

| Mini HDD installation | from 200,000 rubles |

| Set of navigation equipment and location | from 50,000 rubles |

| Stacked rods to obtain the required length | from 7,000 rubles per piece |

| Installation power costs | gasoline, diesel, electricity |

| Your time | priceless |

As you can see, independent drilling in any case leads to very large unjustified costs. To avoid unnecessary costs of time and money, it is more logical to order a turnkey installation service for an autonomous sewer system.

Ground puncture

Puncture is performed by creating a hole in the ground by compacting the soil and pulling a pipe of the required diameter into it. The pipeline is pressed in using a hydraulic jack.

Before starting work, two pits are dug on both sides of the road. A pipe link is placed in the first, at one end of which an iron conical tip is attached. Then it is pressed into the ground along the entire length of the rod.

The second pipe link is welded to the first, further work is repeated until the length of the pipeline is sufficient.

The puncture method is used in highly compressible soils. The technology makes it possible to lay pipes with a diameter of 10 to 40 centimeters. To carry out communications in sand or sandy loam, additional vibration is required.

Excavation

To lay utility networks under normal conditions, a trench is first dug.

A pipe is laid at the bottom and the trench is backfilled. The technology has been used for quite a long time, but in urban areas it is quite difficult to use such a method. Laying communications in this way requires large financial and time costs. The trench method of laying pipes cannot always be used, especially when crossing roads, railways, reservoirs and various cultural objects. It is not always possible to interrupt the heavy traffic of cars on highways, even for a few hours.

In these cases, the use of a different technology, such as trenchless pipeline installation, is required. There are several technology methods: puncture, punching, pneumatic punching, horizontal drilling or shield penetration.

The soil is punctured by forming a hole due to compaction of the soil when a pipe is pressed into it. A conical tip is fixed to one end of it. A hydraulic jack is used for pressing.

After the pipe is laid in the pit, it is pressed into the ground along its entire length. When the rod returns to its initial position, the pressure pipe is inserted. The work process is repeated. After the first pipe link is completely pressed into the ground, it is joined to the next one and welded. Then the next link is pressed in, the process is repeated until the desired length of the pipeline is reached.

The puncture method is used in highly compressible soils. The technology makes it possible to obtain a well with a diameter of up to 50 centimeters. If the soil is of low compressibility, vibration and lateral effects are used.

Soil punching is used to lay large diameter pipelines, which can be up to 140 centimeters. The technology is based on the sequential pressing of cases or pipes that are welded together. The soil remaining in the pipe cavity is removed manually or developed using an auger device.

Pipes can also serve as cases for subsequent communication lines and electricity.

Horizontal drilling is carried out using a special drilling rig, which causes it to rotate. A cutting crown is first fixed at the end of the pipe.

The installation is located in a pit. The forward movement is carried out by a rack jack, which is mounted to the rear wall of the prepared pit. The soil that fills the pipes is removed in the same way as during punching.

Pneumatic punching is carried out using a tunneling tool. It is a self-propelled pneumatic machine. Reciprocating movements are carried out under the influence of compressed air. As a result, the device strikes the rear end of the pipe and clogs it. Pneumatic punching allows for the laying of communications with a length of 50 meters and a diameter of 30 centimeters.

Panel penetration is carried out under the protection of a special shield. It is a special ring structure open on both sides. The inner diameter is equal to the outer section of the tunnel

On the front of the shield in the upper part there is a visor, which serves to protect workers from ground collapses. When the shield moves, the cutting edge cuts into the ground, which is carried out under the influence of hydraulic jacks. They are located along the entire perimeter of the shield, resting on one side against the protrusion of the cutting edge, and on the other against the edge of the tunnel lining.

The lining is assembled from tubes, which are installed in place of the erector. The blocks are connected to each other with bolts. The soil, which is collected in the area of the main part of the shield, is developed manually or using jackhammers to the mouth.

If the tunnel is long enough, it is divided into sections. Vertical shafts are installed at their junction. Jacks that advance the shield. They have a rod stroke equal to the width of the tube.

After installing the ring, the jacks are rearranged. As the shield moves, a cavity is formed due to the clip. A cement-sand mortar is pumped into it. When it sets, the soil becomes more durable.

Punching method

Pipe pushing technology is used for laying pipelines with diameters from 50 to 180 centimeters. Using the technique, it is also possible to lay pipes with a square or rectangular cross-section. Moreover, its length can be up to 80 meters.

After preparing the pits, pipes are successively pressed into the soil. Soil remains inside them, which is removed using a special installation or developed.

The hydromechanical method of pushing is used in the presence of easily eroded soils. Pipes can also be used as cases for subsequent communication or electricity lines.

What is the ground/soil puncture method?

Soil piercing is a technology that allows you to build communications without digging a trench. The work is done by compacting the soil around the pipe. The method is suitable for laying steel structures. The diameter of the pipes used can be from 10 to 50 centimeters, and its length up to 50 meters.

The method of piercing the soil under the road is by far the most popular and sought-after method of laying communications.

Controlled soil puncture technology is used to:

- Metal and plastic pipes.

- Cases for further installation of communication lines, gas or electricity.

- Cases for telephone and power cables.

The technique is used not only for laying pipes under the road, but also for installing wells in wells, and conducting communications under ground objects.

Drilling

Horizontal directional drilling is used in cases where the soil is quite clayey. Using the technology, it is possible to lay a pipeline with a length of 800 meters to 1 kilometer.

When laying the first pipe, a cutting bit is fixed to its end, the diameter of which is slightly larger than necessary. It rotates using a special motor mounted on the drill head.

The rack and pinion jack transmits translational motion to the pipe. In order to prevent its reverse action, it is fixed to the rear wall of the pit. The soil that remains in the pipe is removed using the installation.

Pneumatic punching

The technique is carried out using a tunneling tool that has a vibration-impact effect. It's called a pneumatic punch.

The device is a pneumatic machine. Her body is working. It is he who forms the well. Reciprocating movements are performed using compressed air. The blows are delivered to the inner front body, driving it into the soil.

When using the installation, it is possible to lay a pipeline up to 50 meters long. The diameter of the pipes can be up to 30 centimeters. A pneumatic punch allows you to significantly increase labor productivity in contrast to classical methods of laying a pipeline.

UPG.2 is used to puncture the soil for the purpose of laying utility networks, regardless of the type of soil under railway tracks, roads, reservoirs, and green spaces.

The unit operates from a hydraulic station or tractor hydraulic system. It is an indispensable device for the construction, replacement or repair of communications, especially in difficult geological conditions.

UPG.2 is used for water supply, sewerage, gas pipelines, communication lines, electricity, and fiber optic networks.

Features of the technology

Small-sized drilling equipment is used to install underground water supply, supply main gas, power and telephone cables, and other engineering systems. The technology is used even under water, when communications need to be carried out through a body of water.

The soil puncture installation acts on the soil with a static load without rotation or with a rotating force. The choice of equipment for HDD is carried out taking into account the characteristics of the soil and the length of the pipeline. On some soils, a puncture requires flushing with drilling fluid, and then the Atom HM 771 installation is used.