Not only its load-bearing capacity, but also its elasticity and resistance to the influence of temperature deformations depends on how well the soil is compacted. The land itself for future buildings is heterogeneous. It can form voids, zones of increased and decreased density. If compaction is not carried out and construction begins immediately, then under the influence of mechanical loads deformations will begin, which will lead to subsidence. As a result, potholes will appear on the roads, and buildings will also begin to collapse faster. If you compact the soil even by 1%, its strength characteristics and resistance to mechanical loads will increase to 10-15%. Therefore, it is important to perform this procedure using any of the available methods.

2.3. Preparatory work

2.3.1.

Soil compaction work must be determined by the design and work plan. 2.3.2. All necessary mechanisms, machines, and tools must be delivered to the construction site before the start of work.

2.3.3. Soil for compacting trenches and pits must be delivered from reserves or from dumps located directly at the construction site before the start of work.

2.3.4. The facility must be provided with the necessary electricity and water.

2.3.5. Temporary roads must be built at the construction site to provide vehicle access to the pit and trench.

2.3.6. The construction site must be illuminated at night, including signal lighting.

2.3.7. Before backfilling the trench with soil, you must:

completely complete the laying of pipelines (collectors);

complete and check the waterproofing of pipelines (collectors);

remove all auxiliary materials, equipment and mechanisms from the trench;

draw up reports for hidden work and obtain customer permission for backfilling.

2.3.8. Before you begin adding soil under the floors, you must:

completely complete the installation of foundations;

complete and check the waterproofing of foundations;

remove all auxiliary materials, equipment and mechanisms from the pit;

make exits into the pit;

draw up reports for hidden work and obtain customer permission for backfilling.

Tips for use

There are no difficulties in operating manual rammers if they do not use a motor. It’s another matter when the tool is a vibrating plate, through which crushed stone, sand or other surface is compacted.

Basic tips for working with vibrating plate tampers for compacting concrete.

Before starting work, it is recommended to conduct a thorough inspection of the stove for any faults.

Particular attention should be paid to the belt drive casing, as it protects the engine from dust. The area to be compacted should be cleared of debris and well leveled. It is not recommended to use a vibrating tamper on a wet or dry surface, as the tool can quickly fail. The operator of the device must stand behind the tool and guide it

You cannot bend over the device or try to speed up the operation of the tool yourself. To control the vibrating tamper, you should take a special handle, due to which you will be able to turn the tool in the right direction in time.

It is also worth noting that during the operation of the device, consumables should be regularly replaced: oil, linings, casings and other elements.

How to compact soil with your own hands - Metals, equipment, instructions

You look with slight envy at the neat lawns of your neighbors or TV series characters and think: “I wish I had such beauty.” Why not? Let's see how you can create an even carpet of emerald grass in your yard yourself. And in this article we will devote a special place to the process of preparing a site for sowing a lawn.

Preparing the soil for a lawn is a specific set of work that should be started a month before sowing the seeds. Preparing the foundation for a lawn is similar to preparing the foundation for a building - it has the same importance and the work process is somewhat similar.

Of course, if you are the happy owner of a suburban area with fertile soil, then work on preparing the area for the lawn comes down to only removing debris and leveling the surface.

But if you are as “lucky” as most summer residents/owners of private houses, then you will need to work a little more.

Soil preparation

We remove garbage

To get a beautiful and well-groomed lawn, it is important that the soil for the lawn is initially completely cleared of all debris. It could be small debris - leaves, paper, small stones; and large - stumps, trees.

It is important to pick out all the garbage from the site, but under no circumstances bury it, because over time it will begin to interfere with the growing root system, and inconvenience may arise when using lawn equipment.

You will, of course, have more work if the selected area has not been cultivated before, but regardless of whether you plan to sow or lay rolls of lawn, the work on preparing the soil for the lawn will be the same.

Remove debris and level the area

Also, a special place in cleaning the area for the future lawn should be given to the destruction of weeds.

This can be done by removing the layer of soil with a shovel (this, by the way, is the most environmentally friendly way), or you can take advantage of the achievements of the modern chemical industry and treat the soil with herbicides, which, penetrating directly to the root system, will destroy all the weed. And although the newest chemicals do not accumulate in the soil, we would advise sowing the area with seeds only after 1.5 months.

Digging

As we wrote at the beginning of the article, there are lucky people who do not need to worry about the quality of the soil on the site. But this does not mean that you can avoid digging up the soil before planting.

You can call for help with heavy equipment (a cultivator), or you can get by with a shovel (which will be even better). By the way, digging is another opportunity to remove weeds from the soil that were not killed by chemicals.

Dig dry soil 25 cm deep. This is the so-called single-tier digging.

Is there a two-tier dig? Yes. This digging is used for areas of land that have not been cultivated for a long time. A furrow is dug across the lawn area to a depth of 25 cm (the bayonet of a shovel), and the layer of soil is loosened with a pick. In the next furrow you need to select loosened soil and cover it with soil from the previous furrow.

By digging up the ground, you solve several problems at once: remove the remaining weeds and fertilize the soil

But if the soil for sowing a lawn leaves much to be desired, then you need to think carefully about how to prepare the soil for the lawn. There is an option to replace the existing soil with fertile one. This is a complex process. You need to remove 20 cm of soil and fill another one.

You ask: “where can I get the right soil for a lawn?” This is done like this: mix part of the manure + 2 parts of peat + part of loam. Here is the answer to the question of how to prepare fertile soil for a lawn. The second option is not so labor-intensive, because it only involves enriching infertile soil.

To do this, add peat, manure, sand and loam to the existing soil and dig up everything with the old soil.

What soil is best for lawn grasses? Experts say that this is loam with a neutral pH level.

As a rule, digging is accompanied by laying a drainage system. Before sowing seeds, you need to install communications and drainage. If the groundwater is deep, then construct surface drainage.

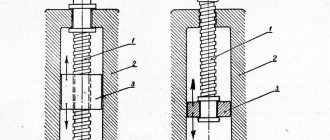

Surface drainage serves only to remove excess moisture after precipitation. In other words, it prevents puddles from accumulating. If groundwater comes close to the ground, then deep drainage is needed.

Please note that creating deep drainage even requires consultation with a specialist.

Alignment

Preparing an area for a lawn involves carefully leveling this area, so that later, when mowing, it does not turn out that on the hills you cut it bald, but in the pits, on the contrary, you left it too long. Uneven surfaces can also damage the sharp blades of your lawnmower.

To level the ground, we select a rake as a tool and walk it lengthwise and crosswise along the dug up ground. Always level the area, looking at it from the side. Transfer the soil where there is more of it into the holes for uniformity. After leveling, watering is needed to allow the soil to settle.

When it dries, the unevenness will appear again, and you will need to repeat everything.

After leveling the area, leave it for a while so that the soil shrinks.

Tamping

Lawn preparation includes tamping. For future sowing of seeds, the soil must be compacted. Compact the dug up and leveled soil with a hand roller weighing approximately one hundredweight. Although you can use a simple board.

No one should be allowed to roll the earth after or during rain. Walking on compacted and compacted soil is not allowed.

Carefully compacted soil will allow the seeds to lie evenly in the ground, and this in turn will help them swell and sprout.

It is better to do tamping in dry weather.

We have figured out how to compact the soil under the lawn, now let's move on to the next final stage.

Work immediately before sowing seeds

After the work has been done, we can say that the area for planting a lawn is almost ready. Only small nuances remain. Immediately before sowing, you need to sprinkle complex fertilizer on the soil and rake it . You will also use a rake to remove any unevenness and debris that has arisen again. The area for the lawn should have a grainy surface with a dense middle.

If you can wait a little (a month or two), then the area prepared for planting can be allowed to stand fallow. This will make it possible to prepare the area for sowing even better, because after fallowing the soil shrinks even more, and this, in turn, reveals new defects that can now be eliminated.

Preparing the ground for a lawn involves a lot of work and it will be a shame if it turns out that you did not clear the ground of weeds very well, and fallowing the ground will help cope with this problem, because

two months after resting, weeds that you missed will certainly appear on the ground, and they can still be removed before sowing.

Now all that remains is to loosen the soil again with a rake and sow the seeds

Step by step guide

In order not to miss the sequence of how to properly prepare the site, we offer the following list of works:

- Experts in the field of landscape design advise not to create areas with sharp corners and complex kinks in lines;

- Start cleaning the area in mid-spring, because by then it will already be warm and still quite humid;

- If there is a concrete path along the path of the future lawn area, then it must be destroyed right down to the foundation;

- When leveling the ground, bumps and convex irregularities can be removed with a hoe;

- Add sand to heavy soil, clay to light soil, improve poor soil with compost;

- Now is the time to install irrigation systems and lawn screens;

- It is advisable to make a very slight slope so that water can flow behind the lawn area;

- If necessary, adjust the soil pH using dolomite flour, chalk and lime;

- To effectively control weeds with chemicals, leave the soil cleared of debris and leveled for at least a couple of weeks for all the weeds to germinate;

- A layer of coarse sand and gravel will provide excellent drainage;

- Digging the soil should be carried out in autumn or spring and do not miss large blocks of earth;

- Leveling the soil with a roller does not allow excess moisture to penetrate to the roots or, conversely, to stagnate on the surface;

- An alternative to a roller can be a flat log or an empty gas cylinder;

- On a small lawn area, a large heavy roller can be replaced with a board attached to the legs;

- Nowadays, specialized companies are ready to quickly and efficiently do all the preparatory work for you;

- Remember that preparing the land is like laying a foundation; mistakes will be almost impossible to correct in the future.

As you can see, there is quite a lot of work involved in laying out a lawn with your own hands, but this work is very interesting, and its results will please you for a very long time.

Preparing the soil and seeding the lawn (video)

Floors on the ground in a private house. Part 2

In the first part, I talked about the design of floors on the ground, now I will move on to the practical part of implementing floors on the ground in a private house.

Relative compaction coefficient

This is the ratio of the density of particles after storage or extraction to the density characteristic of the raw material that was brought to the final consumer. Knowing the rate specified by the manufacturer, you can calculate the final coefficient without organizing additional research.

At the time of production

The density of raw materials here depends on the depth of the deposits being developed, the type of pit, and the climatic zone. The bases indicated in the table make it possible to calculate the final parameters of the material, taking into account the accompanying impact on the soil.

Relative compaction coefficient at the time of production

During the process of compaction and secondary backfilling

Backfilling (or secondary backfilling) is the procedure for filling an already dug pit after work has been completed or construction has been completed. As a rule, soil is used to fill the pit; quartz sand also has optimal characteristics for this purpose. A related action is tamping, which is necessary to enhance the strength of the coating. Vibrating plates and vibrating stamps, which differ in performance and weight, are used to compact the filled raw materials.

Relative compaction coefficient during compaction and secondary backfilling

The table above illustrates the proportional relationship between compaction and compaction method. All types of mechanical impact affect primarily the upper layers. When sand is extracted, the structure of the quarry becomes looser, so the density of the raw material may decrease; laboratory tests are regularly organized to monitor changes.

During transportation

Moving bulk materials presents a number of challenges, as the density of resources changes during the transportation of large quantities. As a rule, delivery is carried out by road or rail, and is accompanied by intense shaking of the cargo (transportation by ship, in turn, has a gentle effect). In such conditions, the density will also be affected by precipitation, temperature changes, and increased pressure on the lower layers.

In laboratory conditions

For the study, 30 g of raw material from the analytical stock is used, it is sifted and thoroughly dried to obtain a constant weight value. The material brought to room temperature is mixed and divided into 2 parts.

The samples are weighed, combined with distilled water, boiled to remove air, and cooled. All operations are accompanied by measurements; based on the data obtained, the relative compaction coefficient is calculated.

Regardless of the conditions for changing the characteristics of raw materials, a number of circumstances are taken into account during testing:

- initial properties of sand - size of fractions, compressive strength, caking ability;

- bulk density - density characteristic of the natural environment of origin;

- weather conditions accompanying transportation;

- the maximum possible density detected in laboratory conditions;

- type of transport used - road, rail, sea, river.

All data related to the relative compaction coefficient is recorded in the design and technical documentation. This method of comparing material qualities implies the use of regular deliveries: the information will be correct only when ordering sand from one manufacturer; changes in variables are not allowed here

It is important that transportation is carried out in the same way, the technical characteristics of the quarry are preserved, and at least approximately the same duration of storage of raw materials in the warehouse is practiced

The compaction coefficient must be determined and taken into account not only in narrowly focused areas of construction. Professionals and ordinary workers performing standard procedures for using sand are constantly faced with the need to determine the coefficient.

The compaction coefficient is actively used to determine the volume of bulk materials, in particular sand, but also applies to gravel and soil. The most accurate method for determining compaction is the weight method.

It has not found wide practical application due to the inaccessibility of equipment for weighing large volumes of material or the lack of sufficiently accurate indicators. An alternative option for deriving the coefficient is volumetric accounting.

Its only drawback is the need to determine compaction at different stages. This is how the coefficient is calculated immediately after production, during warehousing, during transportation (relevant for road deliveries) and directly at the end consumer.

Electric vibrating plates and compactors from Wacker Neuson

Wacker Neuson has offered three new plate vibratory models powered by universal lithium-ion batteries. The batteries, in two versions, have been specially designed for heavy construction work. The battery capacity is enough to keep one machine running throughout the working day. Operators can replace dead batteries with new ones within seconds thanks to the modular design. Since compaction with electric vibrating plates does not produce harmful emissions, new areas of application are opening up for such equipment: trenches, construction sites located in tunnels and inside buildings, environmental areas. Wacker Neuson has also recently expanded its range of tampers in a new fashion. The AS60e is battery-powered, delivering up to 55% energy savings compared to petrol equivalents. In addition, the electric motor does not require maintenance.

Light equipment BOMAG

Light, medium and heavy BOMAG compactors (BT 60, BT 65, BT 80) are suitable for long-term work in confined spaces. All the main advantages of BOMAG rammers are already available in the basic version. These include an increased impact force of 17 kN thanks to the powerful Honda GXR 120 engine (model BT 65), a low vibration handle, an hour meter, an automatic oil level check in the crankcase and uninterrupted oil supply even at an angle, an air filter with a self-cleaning function, an engine switch and fuel supply, engine protection made of especially durable plastic that can even withstand falling from a truck platform. For trench work, BOMAG offers special gas-powered models. These are the BT 60 G and BT 65 G tampers with low CO emissions. These rammers are equipped with a 4-stroke engine that runs on regular propane. Two cylinders can be refilled safely on the job site. A full charge is enough for 2 hours of operation. All BOMAG reversible vibratory plates weighing over 500 kg and BMP 8500 trench rollers also have the ECONOMIZER compaction control system as standard. It does not require calibration and turns on automatically when the machine starts operating. The system displays compaction results in real time, helping to identify missed areas and weak spots, and significantly saves labor time and fuel.

How to properly compact crushed stone with a vibrating plate

The main difficulty when working with crushed stone is that it is usually represented by different factions. The maximum thickness of the poured layer is determined immediately before the operation of the vibrating plate. As a rule, 3-5 passes are enough for compaction, after which fairly high-quality compaction occurs. Further compaction makes no sense.

When working with crushed limestone, builders have to deal with the clinking effect, when the top layer of stones, under the influence of vibrations emanating from the vibrating plate, adheres tightly. In this case, the underlying stones are not compacted. To combat this effect, it is necessary to use heavier equipment. For example, when using a vibrating plate weighing 100 kg, it is possible to efficiently compact limestone crushed stone of a fraction of 10...20 mm.

At the service of the client

Direct support from the manufacturer after the initial sale of any equipment protects the contractor's investment and extends the life of the machines. Operator training at the dealership or manufacturing plant increases productivity and also reduces the risk of premature equipment failure. Some manufacturers offer on-site training. In this case, the crew receives the necessary skills and learns how to operate and maintain the equipment in real conditions. It is good practice to publish machine operating instructions on the Internet. This allows contractors, operators and mechanics to access them 24/7 to resolve issues that may arise at any time during operation or maintenance.

The advantage of a manufacturer that offers a wide range of products is that it simplifies the task of completing the equipment fleet. In one “window” it is more convenient to order both spare parts and consumables, for example, hydraulic oil. Some manufacturers offer special financing programs to make ownership of various new machines more affordable for different categories of customers.

Choosing the right compaction equipment may seem like a no-brainer given the number of options on the market. But taking the time to learn how each feature of a particular machine affects the overall outcome of a job can be very rewarding in the long run. It is the key functions of the machines that provide the contractor with a competitive advantage, reduce work completion time and, most importantly, increase profitability.

Which sand is best to use?

As we have already found out, sand (both quarry and river) can be divided into several different fractions. The smallest of them is not used at all when performing work such as laying a foundation. Even if you are making a non-recessed version of the base for a light veranda or gazebo. This is due to the fact that the fine material will quickly settle, causing the pillow to lose its shape in a short time, causing the finished structure to warp.

Accordingly, in order for the foundation cushion to last as long as possible, it is better to use coarser sand.

As for quarry sand, its use is, in principle, also quite acceptable. But in its qualitative characteristics it differs significantly from river water. Therefore, many people prefer to act on the principle: why buy low-quality material if you can buy a higher quality one for not much more.

When choosing sand in order to install a cushion under the foundation, you should pay attention to the following points:

- if the material has a large number of clay inclusions, the solution made from such sand will not be strong enough;

- you need to choose one that is not too loose, but not too wet;

- Before use, the sand must be additionally sifted.

Criterias of choice

First of all, before purchasing, you must clearly understand which pneumatic rammer is best suited for the job at hand. Determining the type of equipment is the most important part of selecting a tool, since the difference in price is significant

Next, pay attention to the characteristics. They are a consequence of many factors, but ultimately these are the indicators you should rely on

Don't forget about dimensions and weight. If you need to compact the soil at your dacha or suburban area, then the issue of transportation is important. Of course, here you need to understand the relationship between the performance of the tool and its size, so the choice of model should be made consciously, and not based on one or more criteria.

It’s worth mentioning the material you’ll be working with.

It is very important to take into account its density, degree of humidity, as well as how the pneumatic rammer you choose can work with this component. For example, the selection of models for concrete, sand or paving slabs varies significantly

An incorrectly chosen technique can, for example, easily damage paving slabs.

Of course, after determining the appropriate type of tamper, start based not only on the technical characteristics, but also on reviews. Studying them is very useful due to the experience of real people who have already tried the technique and can tell about all the advantages and disadvantages of the model. Sharing such experience will allow you to avoid mistakes when choosing a tool. As for the price, the range in this component is as wide as the scope of application of the pneumatic rammer.

The manufacturer of the equipment also matters. If you are already positively familiar with the equipment of one of the companies offering tampers, then you should not doubt the quality of the chosen model.

Types of vibrating plates and prices

Manufacturers offer several modifications of vibrating plates, which differ in characteristics and design.

Electrical

They operate from the mains, are lightweight, the power is not very high, and are suitable for the simplest jobs. They practically do not need to be maintained, as is the case with an internal combustion engine, which has certain operating requirements, this is a big advantage. Electric motors operate from generators and electrical networks of 220 or 380 Volts. But there is also equipment that requires a supply voltage below 42 V. This equipment is connected through a step-down transformer.

Cost from 20 thousand rubles.

Gasoline

The most common models are gasoline, this is a very light and lightweight class. The design of the petrol vibrating plate is distinguished by a 4-stroke engine. A special centrifugal clutch has been added to reduce the load. The cost varies depending on the manufacturer, you can purchase from 25 thousand rubles.

Diesel

Significant disadvantage: not used at sub-zero temperatures. But they are the most powerful, most often presented as professional equipment.

Comprises:

- strong foundation;

- shaft bearings that can withstand maximum loads;

- air-cooled cylinder engine.

Significantly more expensive and most often it is industrial and heavy equipment. Price from 160 thousand rubles.

Self-propelled

Produced in two variations:

- forward or non-reversible, can only move forward, can often be seen on sale, quite popular;

- Reversible ones have a reverse motion, which makes work convenient, and is the best type.

The cost starts from one hundred thousand rubles, while the first variation is cheaper.

Rechargeable

This type is new. Alternative for weight category up to 150 kg. Advantage: ability to work in any climatic conditions, both indoors and outdoors. The only drawback is that the price starts from 200 thousand rubles. But, soon this modification will replace other types, completely displacing them from the market.

Methods for laying soil in embankments and foundations

Laying and compaction of soil is carried out during planning work, construction of various embankments, backfilling of trenches and foundation cavities, etc.

For the stability of the embankment, it is necessary to prevent the formation of slip planes. For this purpose, homogeneous waterproof soils with natural or artificial compaction are used. If the soils are heterogeneous, then it is necessary to ensure the drainage of atmospheric water entering the embankment.

The surface of layers of less draining soils located under more draining ones must have a slope from the axis of the embankment to the edges of at least 0.04. The surface of layers of more draining soils covered with less draining ones must be horizontal .

It is not allowed to cover embankment slopes with soils that drain less than the main embankment soil (with the exception of covering sandy slopes in order to protect the embankment body from blowing out soil).

For filling embankments, it is allowed to use: pre-loosened rocky, coarse-grained and sandy soils containing clay particles larger than 0.25 mm, more than 50% and with a diameter less than 0.005 mm, no more than 6%; heavy and silty sandy loams containing particles larger than 0.25 mm less than 50%, as well as loams in a hard and highly plastic state. Heterogeneous soils consisting of sand, loam and gravel can only be used in the form of a natural quarry mixture.

Do not use silty sands and light sandy loams, fatty clays, chalk, talc, tripolite soils, peat, silt, sand mixed with silt, silty loams and saline soils containing more than 8% of readily soluble salts in chloride and sulfate-chloride salinity, as well as more than 5% of such salts with sulfate, chloride-sulfate and soda salinity.

To ensure the stability of embankments, soil compaction is of great importance. Embankments filled without artificial compaction are built with reserves, since over time they give rise to settlement, the amount of which depends on the type of soil, construction methods and embankment height. If there is a reliable foundation the margin for settlement of embankments erected without artificial compaction from rocky soils is taken to be up to 6%, from non-rocky soils - up to 9%; in case of unreliable grounds, the draft reserve is taken according to the design. The settlement of artificially compacted soils is about 1% and is practically not taken into account.

The filling of soil layers is carried out from the edges of the embankment to the middle , and on waterlogged weak foundations and in swamps - from the middle of the embankment to the edges until a height of 3 m is reached, and then from the edges to the middle (Fig. 1).

Rice. 1 - Methods for filling embankments (dimensions in m): a) filling the embankment in horizontal layers; b) the same, with waterlogged and weak foundations and in swamps; c) fan method; d) overpass method; e) method of filling “from the head”

There are the following methods of filling soil in an embankment:

- longitudinal (horizontal, inclined layers) - fig. 2, fig. 3;

- transverse (“from the head”) Fig. 4.

When constructing embankments, soil is dumped layer by layer with leveling and compaction. In Fig. Figure 5 shows a technological diagram for filling the site.

Rice. 2 - Scheme of filling the embankment in horizontal layers

Rice. 3 - Scheme of filling the embankment with inclined layers transversely (“from the head”)

Rice. 4 — Scheme of filling the embankment “from the head”

Rice. 5 — Technological scheme for filling the site

In some cases, earthworks have to be erected in unfavorable conditions - slopes with weak soils, karst rocks, inclined layers, alternation of waterproof and permeable rocks or the presence of aquifers, soils that are strongly deformed by pressure when moisture enters. Therefore, to prevent such phenomena as collapses of semi-liquid masses, landslides of parts of embankments and excavations, special measures are required that must be carried out both during the preparatory period and during the main work.

On slopes made of non-draining soils covered with vegetation with a slope of 1:5 to 1:3 at the base of the embankment, ledges no narrower than 1 m are cut (depending on the width of the undercarriage of the machine developing them), which are given a slope of 0.01 …0.02. When the cross slope of the slope is from 1:10 to 1:5 and the height of the embankment is up to 1 m, the turf is cut off; at a higher height of the embankment, poured from clay soils, the base is plowed. If embankments up to 2 m high from clay soils are erected on waterlogged foundations, it is necessary to divert surface water or remove a layer of weak soil before filling, or fill the bottom layer of the embankment from draining soils.

Embankments are often constructed from soils mined in lateral reserves and in excavations or special reserves (quarries), from which the soil is moved in the longitudinal direction.

In the first case, depending on the height of the embankment and the distance of soil movement, the following machines should be used: grader elevators and motor graders - for laying soil in the lower layers of the embankment, moved from a distance of 8...15 m; bulldozers – with an embankment height of up to 1 m and a movement range of up to 50 m; scrapers - with a height of up to 1...2 m and a delivery range from 50 to 100 m; dragline excavators – for laying soil in embankments 2.5...3 m high.

In the second case, depending on the movement distance, the following are used: up to 100 m, powerful bulldozers; from 100 to 300 m – scrapers with a capacity of 6...8 m3; over 300 m - self-propelled scrapers with a capacity of 9...15 m3, single-bucket and multi-bucket excavators with loading soil into dump trucks, dump trailers and broad and narrow gauge railway trains.

The embankment, constructed from soils delivered by road trains, is divided by width and length into sections - maps - length

100 m , on one the soil is unloaded, on the other it is leveled with bulldozers and compacted. Earth hauling tracks for railway trains are built on pioneer embankments up to 3 m high within the profile of the embankment being built, first at one of the embankment bases, then along the slopes and finally along the axis of the embankment, sequentially laying the upper track structure on them. The unloaded soil is leveled with bulldozers across the entire width of the embankment in layers of 30...40 cm.

Features of working with vibration compactors

Following simple recommendations ensures operator safety, efficient operation and long equipment life.

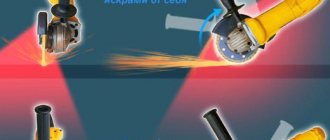

Safety regulations:

When working with a vibratory plate or vibratory roller, the operator must always be behind the unit; Particular care should be taken when turning equipment. Do not leave equipment unattended with the engine running. The electric vibratory soil compactor must be disconnected from the network during each break in operation. It is imperative to use personal protective equipment (shoes with reinforced metal toes, glasses, comfortable work clothes without decorations or protruding parts)

To protect your hands, wear vibration-proof gloves or choose equipment with vibration-compensated handles. Diesel machine operators should wear noise protection

It is advisable to take a break every 10–15 minutes of work. The equipment must be used exclusively for its intended purpose.

Russian line

The Russian line includes medium mod. DM-614 weighing 14 tons, a heavy machine DM-617 weighing 16 tons and two promising models of heavy rollers weighing 21 and 25 tons. Soil rollers are designed primarily for large-scale work. Among the features of the machines, we can note the Carraro rear axle with a differential lock, which ensures stable operation on slopes and high traction force, a reliable Cummins engine with a sufficient power reserve, a fully lifting hood, which provides convenient access for service, and good ergonomics of the operator’s workplace.

BOMAG products

BOMAG soil compaction rollers with weights from 3 to 26 tons are suitable for all types of work. For compacting granular or cohesive soil in cramped conditions, the lightweight BW 124 model weighing 3300 kg with the ability to overcome slopes of up to 55% is suitable. The BOMAG ECONOMIZER soil compaction control system with all-round display requires no calibration and starts automatically when the vibrator is turned on. The easy-to-learn system saves working time and fuel, identifies weak areas and allows you to be confident in the quality of the work performed. The BOMAG Ecomode system controls engine speed and improves fuel efficiency. If idling for an unreasonably long time, the engine is automatically switched off by Ecostop. BOMAG currently offers two series of soil compactors: the D-40 – proven, simple and fuel-efficient machines with a Tier-2 engine, as well as the modern generation D-5, which combines all of BOMAG’s innovative developments in the field of intelligent soil compaction and the highest operator comfort thanks to the new layout of the operator's workplace and a spacious cab with increased glass area.

Rating of the best: 5 proven models

We selected five models of modern vibrating plates from trusted manufacturers.

CHAMPION PC9045F

The linear vibratory plate is equipped with a 6.5 liter four-stroke gasoline engine. With. Impact force - 15 kN.

Refers to professional construction equipment.

Used for the following tasks:

- Road surface repair.

- Laying asphalt.

Compacting crushed stone and sand.

Key Features:

- The engine is equipped with a critical oil level sensor. The sensor monitors the oil level in the engine crankcase; if there is not enough oil, the vibrating plate will not start.

- Recoil starter for starting.

- The compact design allows you to work in hard-to-reach places - near poles, in a trench, next to a curb or wall, etc.

- The vibrating plate is equipped with a 3.6 liter fuel tank.

- The maximum compacted area is 416 m2/h.

What users say:

- Excellent for working in confined spaces - where a roller cannot pass, a vibrating plate can pass freely;

- Starts great in cold weather;

- Easily moved by hand (does not require much effort);

- The handle is equipped with a mechanism that reduces the transmission of vibration to the operator's hands.

DDE VP160-HK

Reversible vibrating plate with Honda GX200 petrol engine. Impact force - 30.5 kN.

Key Features:

- High-performance vibrating plate equipped with a 6 hp motor.

- The powerful engine allows you to compact soil to a depth of up to 50 centimeters in 1 pass.

- Efficient transmission or selection of torque from the engine to the eccentric (carried out using a powerful 3-jaw clutch).

- The vibrator rotor is equipped with reinforced steel bushings, and the motor is mounted on a durable mount. The vibrating plate serves for a long time and reliably.

- There are transport wheels for easy movement.

What users say:

- The engine has a long service life.

- High quality materials from which the device is made.

- Convenient to use.

RedVerg RD-29155

Straight-line vibrating plate with a four-stroke gasoline engine. Engine power - 6.5 hp, impact force - 13 kN.

Key Features:

- The RedVerg Vibrating Plate has a durable base made from thick sheet of stamped steel.

- The protective cover prevents foreign objects from entering the drive belts.

- Equipped with a soft handle that dampens vibrations.

- The package includes a polyurethane pad - it allows you to carefully lay paving stones or paving stones.

- There is an irrigation system - an additional water tank, with which you can moisten the surface under the slab when laying asphalt.

What users say:

- Easy to manage.

- The best option in terms of price/quality ratio.

Elitech PVT 60 BVL

Petrol vibrating plate with a reliable four-stroke engine. Power - 6.5 hp, centrifugal force - 10.5 kN.

Key Features:

- The vibrating plate engine of this model is installed on a reinforced frame.

- Works without interruption in extreme heat, as well as in frost. The full temperature range is from -10 to +40 °C.

- The device is equipped with an impact-resistant casing to protect the belt transmission.

- The vibrating plate is equipped with an anti-vibration system. Reduces the negative impact of vibration on the engine and extends its service life.

- There is an irrigation system with a 10 liter tank.

- Ergonomic control handle. Conveniently folds for storage or transportation.

- The set includes transport wheels for easy movement around the site.

What users say:

- Easy to start.

- Good build quality.

- One of the disadvantages is that vibration can cause the bolts of the transport wheels to come loose.

CHAMPION PC5431F

Compact petrol vibrating plate of linear type. Equipped with a four-stroke engine, power - 2.3 hp, impact force - 8.2 kN.

Key Features:

- Vibration frequency - 5140 beats per minute, compaction depth - 200 millimeters.

- The body is made of impact-resistant plastic. Provides reliable protection of the actuators of the device from impacts of crushed stone and small stones, as well as from dust.

- The vibrating plate is equipped with a special shock absorption system that absorbs vibrations well. Thanks to this system, engine parts wear less and last longer.

- There is an engine oil level sensor.

- Comfortable handle. It can be adjusted in height; all device controls are located on the handle.

What users say:

- Compact and lightweight vibrating plate, easy to use and transport.

- Does its job perfectly.

General information

What is it for?

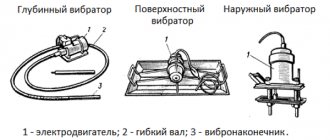

Tamping, i.e. The vibrating plate consists of five main elements. This is an engine , which can be gasoline, electric or diesel, and drives all the parts of the tool. The belt drive helps transfer torque from the engine to the eccentric . This, in turn, helps create vibration vibrations in order to perform compaction.

The impact on the surface being processed is created using the base plate, and everything can be controlled using the operator’s handle. The vibrating plate has a heavy and powerful base, which, together with vibration at high frequencies, allows for compaction of the surface. The efficiency of the work done will depend on the power of the device and the size of its electric or gasoline engine. In most models, the devices are quite maneuverable, and this makes it possible to perform tasks even on inconvenient and sometimes curved surface areas.

Application area

The pneumatic soil compactor was created to compact bulk materials using an oscillating motion. After the materials are poured onto the surface, their particles will not be located close enough to each other. To ensure that they fit as tightly as possible to each other, you should use a tamper. This will help change the load-bearing properties of some of the materials so that construction work can be carried out on this surface in the future. Compacting with a vibrating plate is used for a large number of construction areas.

It is especially often used for such cases:

Road construction.- Laying lawns.

- Creation of a bulk cushion for the foundation in a large number of buildings, as well as on the floors of tall buildings.

- Construction of car parks and sports grounds.

- Laying asphalt.

- Seals for trenches and pits, laying utilities.

In special cases, compaction is used to lay paving slabs and paving stones. This makes it possible to complete work several times faster.