Protect your eyes | 09/10/2015

Many people know this type of welding as electric arc and gas. They are widely used both in production and in construction. But thermite welding is not known to many people. Therefore, we will talk about her. Thanks to the use of thermite welding, the results are no worse in terms of joint quality than with electric or gas welding, and no power source or gas cylinders are required.

Household use

For this use, a pencil is used with a combustion temperature of at least 1300 0C; if the technological nuances are observed, a fairly strong connection of large parts is obtained.

A variety of thermal mixtures will allow the home craftsman to achieve high quality and strength during repairs. When performing work, you must strictly observe safety measures:

- face and hand protection is required;

- When thermite burns, it releases a lot of heat energy and bright light, so dark glasses are needed.

K.I. Mamonov, education: vocational school, specialty: 6th category welder, work experience since 1999: “You should not risk your health and prepare thermite mixture yourself in the garage or at home - the consequences can be quite disastrous.”

Technology

When connecting parts, a special powder mixture is used as a consumable material, which includes elements such as aluminum, magnesium and iron oxides. These powders are called termites. When they burn, energy is released. This energy is enough to transform the edges of the parts being joined into a semi-liquid state. The metal is mixed with the mixture material and subsequent crystallization occurs.

To carry out the welding process, at the initial stage it is necessary to ignite the mixture. Its combustion temperature reaches 1350°C degrees. Several effective methods of arson have been developed. The specified temperature can be achieved by receiving an electric discharge, exploding a squib, or burning a special cord.

When thermite burns, the temperature inside the mixture rises to 2400-2700°C degrees. Most metals have a melting point below this value.

What is noteworthy about this technology is that combustion does not require the supply of atmospheric oxygen. There is enough oxidizing agent inside the mixture itself. If necessary, thermite welding can be carried out in an inert gas environment.

Technological features

Thermite or powder welding GOST 2601-84 is a type of welding work in which thermites serve as a heat source; it is used to connect rails, electrochemical protection, etc. Thermite is a powdered mixture of various metal materials, in particular aluminum and magnesium and iron scale.

There are the following types of thermite welding:

- Crucible (aluminium-thermic);

- Muffle.

The crucible is used to create grounding loops and when connecting small-diameter electrical cables. The technology involves the use of a thermite mixture in the ratio of aluminum / iron in proportions 23/70. When thermite is completely burned, iron is released, which is used to connect the joints together. The combustion process itself depends on the grain size of the thermite powder. When working with copper or other compounds, compounds of other metals are sometimes added to the powder to increase the strength of the weld.

Photo - working on rails

Aluminum is used when it is necessary to create a surfacing on the surface of a certain structure, for repairing tram rails or when working with fragile materials. One of the key advantages of this technology is the possibility of welding cast iron using a weldless method.

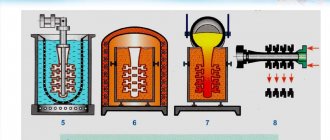

Photo - schematic diagram

At the same time, crucible welding cannot be used to join aluminum, so muffle welding is used here. The peculiarity of muffle work is such that, upon direct contact, the high melting temperatures of thermites cause certain areas of the aluminum compounds to evaporate. Therefore, to create such fastenings it is necessary to use linings or thermite cartridges. These sockets make working with single-core and stranded wires much easier. They are a tip equipped with a metal mold. The difference between the muffle type and the crucible type is that liquid welding products do not appear during operation. When exposed to high temperatures, magnesium does not spread over the surface to be joined, but is absorbed into it, forming a seamless connection.

Photo - seam

For aluminum cables, exposure to flux is required before performing thermite welding. It will dissolve the oxide film that prevents the welding of individual parts of aluminum, but can cause rusting of the wires. Therefore, professionals rarely use this technique. To connect this type of cable, molds or filler rods are used, into which the ends of the wires are inserted and heated to the required temperature.

Photo - types of thermal effects

Welding with thermite, which contains magnesium, is used for processing small-section wires (telephone, Internet cables), various electrical connections, etc. To create thermite, about 20% magnesium or aluminum in the mixture and 80% iron (its scale) are required ). At the same time, the main source of oxygen in the process is iron oxide, and heat is generated by pure metal.

Advantages:

- Simplicity. This technology for joining joints of steel, aluminum, cast iron and other metals can be used even by beginners in welding. The work does not take much time and is carried out with compact equipment that is convenient to store at home;

- Termites provide excellent quality joints. The joints are strong and durable. When working with aluminum, VAMI type fluxes are used to reduce corrosion processes;

- Availability. Thermite welding equipment does not require a large amount of electrical energy.

Photo - thermite mixture

But this type of welding work also has certain disadvantages:

- To carry out this type of welding, auxiliary and preparatory processing of metal structures and cables will be required;

- The welding process cannot be tracked, so only professionals with NAKS certification will be able to work with seamless technology.

Electric contact method

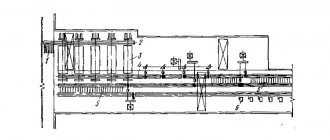

The electric contact approach to connecting rail joints is based on their strong heating and subsequent melting through an electric arc, which is formed by a significant low-voltage current.

To implement the method, special machine complexes are used that operate in automatic mode (MSGR-500, MS-5002 or K-190, for example).

Before welding, the rails to be processed are laid either directly on the tracks, or with a slight offset inside the branch or outside the track (at a distance of about 260 centimeters from its axis).

In this case, the welding mechanism itself moves along the restored thread, that is, it is a self-propelled rail welding station.

During its operation, replaceable contact heads of various types are used, providing the necessary welding modes (continuous reflow or intermittent heating of contacts).

Weldability properties

The correct choice of electrodes allows you to solve the problem described above, that is, to ensure high quality joints with relatively little time and effort. Good options (from those that are constantly on sale and are relatively inexpensive) are SSSI from the 13/45 and 13/55 series, which are suitable even for critical facilities or reinforced structures.

Although it is even more important to choose the right method and, in the process of its implementation, adhere to the norms and requirements prescribed in the interstate standard 103-76. This will simplify work that is already being carried out with not the most favorable initial data.

Features of aluminothermic welding

Aluminothermic welding is not as common as contact welding. However, this method of welding has a number of significant advantages. These include the following.

- Requires minimal labor. To perform welding work using the aluminothermic method, a minimum number of workers is required. A team of 3 people can cope with this work.

- Aluminothermic welding does not require complex equipment to perform. And the weight used is up to 400 kg.

- This method of welding is much faster compared to the contact welding method. The welding time for one rail joint takes less than an hour.

- To carry out aluminite welding, a powdered combination of aluminum, iron scale and magnesium is used, which is packaged in a certain way. Elements that require heating are molded with a material that is resistant to high temperatures. These parts are then heated. Using an electric arc or fuse, the thermite is ignited and heated to a liquid state. Molten metal is poured into the area that needs welding.

- Welding work using thermite is carried out using autonomous power sources.

As a result of correctly carried out aluminothermic welding, a fairly reliable connection is obtained. This type of welding is used to connect steel and cast iron products.

The essence of the aluminothermic method

Thermite welding of rails is one of the most balanced methods of joining joints. It meets modern requirements for the quality of seams in this important area. The technology for connecting rails in this way involves the use of a special mixture. The thermite mixture contains 77% iron oxide, and the remaining 23% is aluminum chips. Slight deviations in percentage composition are possible.

The presence of the word “thermitic” in the name of the method indicates that heating is required during welding. Strong heating will contribute to the formation of a strong, reliable seam. In order to bring the composition of the mixture closer to the parameters of the material being welded, steel particles and alloying elements are added to it.

The essence of this technology is that under the influence of aluminum oxides, iron is reduced from the oxides. This reaction is accompanied by a significant release of heat, the amount of which will be sufficient for the metal rails to begin to melt.

After heating the metal to a temperature of 2000 degrees, it is poured into a special mold, which is then installed at the joint.

The following options for thermite welding exist:

- Butt connection.

- Intermediate casting.

- Combined view.

- Duplex.

The simplest and most accessible method is the method with intermediate casting:

- a special metal structure in the shape of a container is installed above the joint;

- a mixture of aluminum and iron oxide crumbs is placed inside the container;

- at the junction of the rails to be connected, a casting mold is installed, the configuration of which must match the shape of the rail profile;

- with the help of an igniter, the container is heated to a temperature of 1000 degrees;

- an aluminothermic reaction occurs, accompanied by the release of heat, as a result of which the mixture is heated to a temperature of 2000 degrees;

- the resulting melt is poured into a pouring mold;

- the ends of the rails become very hot and melt;

- with gradual cooling, even greater compaction occurs, in which the slag is squeezed out.

At the finishing stage, it is necessary to beat off the slag with a hammer and finish the seam using an angle grinder or grinder.

Aluminothermic welding has undeniable advantages:

- High speed of the process. The duration of welding one rail joint is no more than half an hour. Within an hour, one team can complete more than a dozen connections.

- There is no connection to stationary current sources. Mobile units are small in size and weigh less than a kilogram. They work autonomously.

- There are no increased requirements for the experience and qualifications of performers. It is sufficient to follow the instructions of the technological process.

- When using equipment that is in good condition and following the rules for welding work, the degree of safety can be called high.

- The effectiveness of the method, both when laying new tracks for various purposes, and when repairing existing ones.

- Excellent seam characteristics for further use.

- High performance.

- Low cost.

Care must be taken to ensure that no water gets into the container. Welding rail joints using the aluminothermic method guarantees the safe movement of vehicles.

Features of welding rail joints

We have already found out that profiles for rutting are made of particularly strong metal, namely high-carbon steel. This is a material that has its own specific heat treatment: exceeding the exposure temperature will result in internal stresses, the appearance of cracks and other minor defects that can cause an accident.

To ensure sufficient quality of the seam and at the same time minimize the likelihood of microdamage, when connecting two VSP elements, the following rules must be observed:

Use professional equipment as the most accurate, productive and safe in its class. Take a responsible approach to purchasing consumables (we have already mentioned the importance of the same electrodes). Be sure to use fluxes (where they are needed) and other solder auxiliaries. Adhere to the optimal operating mode selected earlier (we will look at the features of each later). Pay attention to the post-processing of the seam, and then check it with appropriate instruments for integrity.

During the operation of the rut, welded strands must be periodically inspected for microdamage in order to promptly prevent more significant damage.

Features of welding rails

Railway profiles are made from high-carbon steels characterized by poor weldability. During heat treatment, cracks form on the metal and internal stresses arise. When welding rail strands, this is unacceptable; defects in the rail material can cause an accident.

To work you need:

- professional equipment;

- high-quality consumables;

- control devices that check the integrity of the seam.

To form a strong connection, thick-walled beams must be welded to their entire depth. After welding the joint, it is necessary to level the surface so that the seam does not collapse.

Possibility of using this method

This method of connecting various metal parts is most widespread on the railway. Thermite welding, also called aluminetermite welding, is used for joining rails.

Thermite welding process for railway rails

Typically, teams consisting of two or three people are used to carry out work. Thermite welding of rails on the railway involves the use of special equipment, the weight of which varies between 350-400 kilograms. To carry out the work in question, autonomous sources of electrical energy are required.

In addition, it is actively used in welding cast iron. It is in demand for processing telephone and electrical communications. Using this method, you can work with pipes and individual parts of power units.

Thermite welding of wires is used for terminating and connecting cores of sections of different diameters. We are talking about wires made of aluminum. This connection method is suitable for copper conductors up to 10 mm2.

Areas of application

Thermite welding today is used for welding cast iron, electrical and telephone communications, pipes, engine parts, and so on. Thermite is especially often used for welding railway rails. The connections are quite reliable. The repair site can be on any section of the road, even several hundred kilometers from a populated area.

Advantages and disadvantages

Thermite welding has a number of advantages over the electric arc method, namely:

- speed of work;

- affordable components that are sold freely in specialized stores;

- ease of connection, which does not require extensive prior training of the worker;

- no need for electricity or bulky gas cylinders;

- strong seam, resistant to breaking and tearing forces.

Despite these advantages, the thermite welding method also has several negative factors that are important to consider when carrying out work.

Firstly, the mixture is highly flammable, which requires caution during transportation or preparatory processes. It will no longer be possible to extinguish an accidentally lit container of powder, and the instantly rising temperature can create a fire if it ends up on flammable materials.

It will no longer be possible to extinguish an accidentally lit container of powder, and the instantly rising temperature can create a fire if it ends up on flammable materials.

Secondly, water or other liquids should not be allowed to come into contact with the burning thermite mixture. If a certain volume of water spills into the melting zone of the powder, this can lead to an explosion and splashing of the composition

It is important to have training and follow safety instructions before using the welding method.

Equipment

To implement the thermite welding method, certain equipment is required:

- casting mold that helps fill the space between the rails;

- ceramic crucible and plug made of melting material for filling the container and draining the molten product;

- press for sealing the connection;

- crucible stand;

- coating paste;

- grinder with grinding wheels;

- hammer;

- spatula for removing slag from pockets.

To protect the worker from high temperatures, a suit made of thick fabric is required.

Due to its autonomy and speed of execution, thermite welding is widely used in emergency and scheduled repairs of railway tracks. By applying the above recommendations, you can create a high-quality connection for domestic purposes.

Rail welding methods

The rails are made of high-carbon steels, which have poor weldability. When choosing a method for connecting rails, it is necessary to take into account the chemical composition of the alloys from which the rails are made, their fluidity and ductility. You must choose from the following available technologies:

- electric arc;

- electrical contact;

- aluminothermic;

- gas press

Each technology has its own advantages.

The most common is the electric arc method. Welding rail joints with electrodes is used as follows:

- The ends of the rails to be connected are laid with a small gap of several millimeters between them.

- Their ends are welded with electrodes that are melted by the temperature of the welding electric arc.

- The melt will gradually begin to fill the entire joint.

- After the cooling of the weld pool is completely completed, the resulting joint is cleaned, scale is removed, and the surface of the rail at the joint is leveled.

To obtain current, alternating or direct, a mobile welding station is used. Transformers, rectifiers and inverters are used as equipment.

First you need to decide what electrodes to use to weld the rails. Their diameter should be approximately 5-6 millimeters. Electrodes that have the main type of coating are used. Among the electrodes produced in our country, we can recommend UONI 13/45 and UONI 13/55, and among imported electrodes, LB 52U. Before butt welding the rail with electrodes, it is necessary to calcinate them.

A type of arc method that can be called successful is rail welding. It consists in the fact that the ends of the rails are cut off in advance. Then they are laid with a small gap clearly along the length of the tracks, but with a slight rise. An electrode is inserted between the pieces of rails laid in this way and a current of approximately 300-350 Amperes is passed.

The resulting hot mass begins to spread along the gap until it fills it completely. This happens gradually and evenly. To prevent drainage from starting to occur outside, the gap is protected with blockers. A high-quality connection of rails is also obtained by contact welding.

Welding is carried out automatically. The rails are placed close to their permanent location. The microstructure of the butt resistance weld of the rails should, as far as possible, correspond to the base composition. The disadvantages of resistance welding include the need for several welders to participate in this process, the difficulty of delivering equipment, the duration of the process, and the high cost of equipment.

The gas pressing method is based on connecting rail joints at lower temperatures, but at high pressure. It is necessary to carry out preparatory operations, which consist in carefully processing the welded ends of the rails in order to ensure the necessary tightness.

During the process, the rails are compressed with a hydraulic press with considerable force and heated with a burner to a temperature of 1200 degrees. The advantages of this method include the uniformity of the resulting seam and its strength, but the disadvantages are not very high productivity. It makes sense to use gas pressure welding for the repair of railway tracks, where the load on the rails is of great importance.

Electric arc option

At this time, electric arc welding of rails is the most common among the technologies used. The reason is that this type of processing combines:

- simple and affordable equipment;

- ease of execution;

- high quality seams.

These characteristics make it possible to weld both rail joints and damaged areas.

Before starting work, preliminary cleaning and grinding of the edges of the products being welded is necessary - this will improve the final quality of the joint. Laying with a gap between the parts is required - this will make it easier to weld the joints.

The distance between the ends of the rails is welded layer by layer (filled) with the metal of the electrodes, which is melted using the high temperature of the arc formed during operation. The semi-automatic device operates from a direct or alternating current source.

"Bathroom" method

The “bathtub” method of arc welding is also known for its effectiveness. In this case, a special “bath” is mounted on the track, and the ends of the rail braids are cut off perpendicular to the main axis and placed in the “bath”. The gap between the rail joints should not exceed 16 mm. Surface roughness of 3-5 mm is acceptable, but no more. The space between the joints is welded with a fusible electrode, through which an electric current of 300-350 amperes is passed.

To prevent molten metal from flowing out of the “bath” during welding, special barriers are installed. At the end of the process, the seams are checked for quality and sanded around the entire perimeter.

Technological process SKS (welding of crane rails)

The SKS process is intended for welding steel crane rails of special profiles such as KR70, KR80, KR100, KR120 and KR140, manufactured in accordance with GOST 4121, as well as foreign-made profiles of types A45 to A150, manufactured in accordance with DIN 536, or types MRS and CR, and used for the construction of crane tracks. The profile of crane rails differs significantly from railway and other rails, in comparison with which crane rails have a massive head and neck (especially in width) with comparable dimensions of the sole (width and thickness), as well as a smaller ratio of the height of the rail to the width of the sole. These fundamental differences are due to the peculiarities of the operation of crane rails and the nature of the loads acting on it, as well as the design features of various types of crane tracks. All these factors influence the physical welding processes and technical parameters of the seams, therefore, for high-quality welding of crane rails, a special SKS process

Crane rail welds produced using the SKS thermite welding process are significantly superior in quality and strength to welds produced using the traditional electric arc welding method. At the same time, welding of rails using the SKS process occurs more than 2.5 times faster, and the thermite weld metal does not contain defects such as pores, slag inclusions and lack of fusion. Thermite seam after welding and grinding along the perimeter of the rail head on top and side does not require any additional maintenance, and its service life is equal to the service life of the rail.

What is aluminothermic welding?

The method is as follows: a special powder is placed in a special metal structure, which is located above the junction of two sections of the fabric being welded, and then this powder melts. The purpose of the powder is that it reliably and firmly connects the base material and thus the microstructure of the seam becomes very viscous. Such joints are made very quickly and over time they do not sag, which indicates their high quality.

The powder, which acts as a binder in thermite welding of rails, consists of 23% aluminum chips and 77% iron oxide. The powder structure is finely dispersed, granule size is 0.5 mm. The technology is based on the ability of the metal to be reduced in aluminum oxides. However, as already noted, this can only happen at high temperatures, which is why an igniter is used, through which the mixture is ignited. It is this process that turns iron oxide into pure metal.

A casting mold is used at the site, thanks to which the alloy is directed to the joint.

If, after completing the work, you find some gaps and cracks, then you need to get rid of them; for this, heat-resistant coating is used. Due to its liquid consistency, it flows into the butt joint area and fills the free space. As a result, slag forms on the surface.

The process of creating a rail weld must be carried out with the obligatory sealing of the joint when it is still hot. To do this you need to get presses. Upon completion of the work, the slag must be beaten off with a hammer, and the seam itself must be sanded with a special machine and grinder.

History and essence of welding

The invention of thermite welding was facilitated by the need to develop a method of joining metals without the use of bulky equipment. At the same time, the heating temperature of the sides must be high enough to melt the thick sides of the materials and form a strong connection.

Beketov N.N. discovered a phenomenon called aluminothermy. This is a process in which metal is reduced thanks to aluminum oxides. To do this, aluminum shavings are mixed with iron oxide. The resulting mixture is brought to a temperature of 3000 degrees, as a result of which steel and slag are formed.

The scientist Goldschmidt was the first to be able to put this idea into practice in welding. He used two metal bars, filling the gap between them with burning thermite powder. A monolithic seam of acceptable quality was formed, and the slag floated to the surface and spread to the sides. At the same time, his department was quite free.

What thermite welding actually is is easy to understand after watching the video. Currently, 23% aluminum chips and 77% iron oxide are used. The granulation of the composition does not exceed half a millimeter in diameter. Ignition is carried out with a special fuse. Combustion causes a chemical reaction that releases large amounts of heat. In this case, iron oxide is converted into pure metal, and the second component forms oxides and makes up slag.

Advantages and disadvantages

This method is used quite often. This is because it has advantages that welders appreciate. Among them are the following:

- Fast operating speed. All stages take no more than half an hour. With a lot of experience, up to ten seams can be processed in 60 minutes.

- Do not use stationary electrical power. This allows you to move the device from place to place.

- All parts of the structure can be found in one place. They are sold in specialized stores.

- To obtain an even connection, you do not need to have a professional education. You need to try your hand at welding several times.

- If you do not forget about the rules of work and adhere to all technologies, you can get a lasting final result.

- The entire process does not pose a danger to workers if high-quality equipment and materials are used.

- Welding work can be carried out both at home, in workshops, and in the open field.

The use of aluminothermic welding involves some difficulties. They can be like this:

The powder can easily catch fire, so you need to be extremely careful with it. Preparatory work is carried out carefully and in detail so as not to miss important nuances. The equipment you will work with must be in working order. Check its serviceability before starting welding. If drops of liquid get into a hot pan, then the entire mixture will splash

Don't let this happen.

Pros and cons of thermite welding

The advantages include the availability of materials, the ease of performing most operations and low energy consumption during the work process. In other words, this option is suitable for both large-scale welding of massive building structures and minor household operations. As for the disadvantages, thermite welding causes many difficulties in working with seamless joints. The fact is that directly during the operation, the master cannot fully monitor the quality of the formation of the gap and connection. As a result, in most cases one cannot count on smooth and clean joining of parts of structures without significant deformations. But in terms of strength and durability, thermite compounds are considered one of the best.

General information

Despite the fact that connecting rail joints by welding has been known for a long time, the problem of making work easier and faster is still relevant. One of the reasons was that the rails are made from high-strength metal that is difficult to weld. Any attempt at additional hardening or heat treatment increases the risk of deterioration in the quality of the joint joint.

Therefore, it is important to follow the welding technology, follow the established rules and GOST 103-76

There are many ways to weld rails, but the main ones are:

- electrical contact;

- aluminothermic;

- electric arc;

- gas press

Each method has its own execution technique and depends on various factors, so it is worth considering them separately.

Aluminothermic rail welding process

Before starting work, you need to make sure that there is enough thermite to completely fill the joint, otherwise you will have to redo everything. The technology of aluminothermic welding of railway joints is carried out in stages in a strict sequence.

Preparatory work

On sections of rails located near the joint, the fastenings to the sleepers are removed, and the distant ones are loosened. This is necessary so that they do not interfere with installation and to relieve metal tension. The areas near the joint are heated with a burner and cleaned of rust. Then the rails are set so that there is a distance of 25 mm between the ends.

Rail alignment

Next, the gaskets are removed from all fastenings, replacing them with wedges on both sides. In order for the connection to withstand the load from passing trains without deformation, the rails must be straight horizontally and vertically. Pre-installation is done by eye. Then, knocking out the wedges with a hammer, achieve the required position. For control, a meter-long metal ruler is applied to the surfaces of the rails.

Installing forms

Using the meter as a guide, install the clamping device at the required distance from the joint. Place the mold and cover the remaining cracks with heat-resistant paste. A stand with a funnel is installed on top, above which a barrel with thermite is placed. When using a loose mixture, a crucible will be required. The burner is mounted in the center of the connection just above the axis of the rails.

Heating and welding

To preheat the connection point, propane is supplied to the burner at a pressure of 1.5 Bar and oxygen at 0.5 Bar. After 1.5 - 2 minutes, the burner is extinguished and removed. If there are no increased requirements for the quality of the seam, this procedure can be skipped. After igniting the thermite mixture with a special fuse, the molten metal begins to flow into the mold. During this time (20 - 30 sec) the position of the crucible cannot be changed. After emptying, it is removed, as well as the covers and slag trays. The mold is disassembled after 4 minutes, when crystallization of the metal is complete.

https://youtube.com/watch?v=kuydZx-ckTs

Sanding and quality control

After completion of aluminothermic welding, the joint is processed from the sides and top so that the rail surface is smooth. The joint is heated with a burner for 10 minutes, after which the sagging is removed with a chisel or grinder. The final grinding is carried out with abrasive tools after cooling, controlling the process with a feeler gauge and ruler. The quality of the connection is checked by static bending along the base or head of the rail. The progress of the tests is monitored using measuring instruments.

Despite the high temperatures that arise when making aluminothermic rail joints, the technology is not considered dangerous. An experienced worker should do the actual welding. All team members must be provided with protective clothing made of non-flammable fabric, safety glasses, and signal vests.

Source

The process in practice

The technology for welding railway rails is as follows:

- The two ends of the rails are aligned equally vertically and horizontally with their ends opposite each other. A gap of 25 mm is left between them for filling. To do this, a special plate of appropriate thickness is inserted.

- Both sides are clamped with small grips or clamps.

- The junction is lined with fireproof plates to direct the hot flow exactly between the rails. Small gaps between the mold and the metal are covered with paste.

- A crucible is installed on the mold - a small container with thermite powder. Or a funnel-like watering can is placed on top of which a store-bought barrel with the mixture is placed.

- The thermite is ignited with a ignition pencil through the top hole in the barrel or crucible.

- Burning lasts about 30 seconds. The increasing temperature melts the bottom plug and the mixture flows into the mold. The latter is filled in and a connection is created. High temperature promotes good fusion of iron and base metal. The slag flows onto the ground or into special pockets of the device.

- After the end of combustion, the pockets, crucible and mold are removed.

- The connection is crimped with a press to ensure complete formation. The product remains in this state for about 5 minutes.

- The slag deposits are broken off by tapping with a hammer.

- The seam on the rails is sanded on the working sides so that there are no protrusions in the area. The surface not touched by the train wheels is left without sanding.

https://www.youtube.com/watch?v=kuydZx-ckTs

Types of thermite welding

Depending on the material and application conditions, crucible or muffle welding is used. The first is better known as aluminothermic welding. It is used when installing grounding loops and metal structures. Thermite is prepared from a mixture of iron oxide and aluminum powder in a ratio of 70:23. When it burns, the joints of the parts are connected by molten iron reduced from scale.

The aluminothermic variety is also used for repairing damaged surfaces using the surfacing method. Its main advantage is the ability to weld cast iron parts without joints. However, seams on aluminum products are not possible using this technology. To connect them, muffle welding is used.

Since aluminum evaporates under high temperature, muffle welding is performed using magnesium-based thermite. Due to its high melting point, it does not spread over the surface, but is absorbed into it, creating a joint without a seam. When joining aluminum workpieces, a special flux is used to remove the oxide film from the joint.

Thermite welding is carried out in four ways:

- Butt joints require preliminary preparation. The surfaces to be welded are thoroughly cleaned. To prevent thermal deformation, the joined parts are wrapped in thermal film. After burning the thermite, the resulting liquid metal from the crucible is poured into the joint gap. Then the parts are pressed against each other.

- The intermediate casting technique is used to connect workpieces fixed in the required position. It is considered the simplest, since the melt prepared from the thermite mixture in a crucible is immediately poured into the gap between the parts.

- The combined method combines two techniques. Used for connecting rails. After cleaning the ends, a steel plate is inserted between them. Melt is poured into the gap and the rails are compressed. After cooling, the joint around the perimeter is scalded again.

- Duplex is also crucible welding, but the joint is additionally compressed.

What is included in the thermite mixture?

The most commonly used is iron-aluminum thermite welding: Fe2O3 = 75%; Al = 25% (this mixture contains either calcined scale or iron ore). This composition is used mainly for welding rails and many large parts. This mixture ignites at a temperature of approximately 1300 °C, and the slag and iron that are formed are heated to 2400 °C. Quite often, iron cutting, alloying additives and fluxes are added to the iron-aluminum mixture. This process takes place in a magnesite crucible.

Aluminum is not the only metal that is used. The following combinations are also used:

- Mg (31%) + Fe2O3 (69%)

- Ca (43%) + Fe2O3 (57%)

- Ti (31%) + Fe2O3 (69%)

- Si (21%) + Fe2O3 (79%)

Thermite incendiary compositions:

- Ba(NO3)2 (26%) + Fe3O4 (50%) + Al (24%)

- Ba(NO3)2 (37.5%) + Al (26.5%) + coal (3%) + shellac type binders (23%)

- Fe2O3 (21%) + Al (13%) + Ba(NO3)2 (44%) + Ba(NO3)2 (6%) + Mg or Fe (12%) + binders (4%)

Thermal welding is used for various purposes and for each of them a specific mixture composition is selected. The most common types among them are the following:

- Elementary mixture: iron scale combined with aluminum powder in strict chemical proportions;

- Thermite mixture for joining joints in rails: this procedure is more complex. Aluminothermic welding of rails involves introducing steel filler into the charge. This filler consists of ferromanganese, graphite (in the form of shavings) and small parts of low-carbon twig or shavings of the same material;

- Composition for joining alloy steels. This mixture is characterized by the use of additives in the form of ferrotitanium, ferrovanadium and other similar materials;

- Thermite welding used for welding cast iron parts: Silicon is usually used in large quantities as an additive. Using this solution, you can obtain a very high-quality connection (subject to the rules of the processes), this is justified by the release of graphite, both in welding and transition zones. This reaction occurs due to the high silicon content in thermite metal. The main requirement is the complete exclusion of the use of manganese;

- Composition for joining high-manganese steels: the content of this mixture is quite simple. It is necessary to introduce ferromanganese (carbon and a large amount of manganese), as well as cast iron shavings in a stoichiometric ratio;

- Special (special) thermites - used for all other needs (re-crushing minerals), such mixtures are called pyrotechnic.

We recommend! How to cook cast iron using electric welding. Welding with inverter

Profession of thermite welder

This working profession is not only in demand, but also well paid. During the training process, a person studies thermite mixtures, the features of working with them, as well as safety precautions during welding work.

A thermite welder must know:

- purpose and components included in existing thermite compositions;

- welding methods and features of the use of each of them;

- equipment design and features of working with it;

- sequence of work in accordance with the developed operational and technological maps;

- techniques for safe use of thermite matches;

- fire safety and labor protection rules.

Thermite welding is a modern way of joining parts. If you follow the rules and technology of its application, then even in field conditions you will be able to obtain a durable, high-quality and aesthetic seam.

How to make thermite yourself

To make your own thermite mixture, you will need rust and aluminum powder. You can get rust at home; if it is wet, you should dry it using a stove. Then you should turn your rust into powder and heat it in a metal vessel. Making thermite yourself requires little effort and expense. Aluminum powder (you can buy it or extract it yourself using a file from a whole piece of aluminum) must be added to the iron oxide. The proportion of rust to aluminum will be 8 to 3.

What advantages of such technology should be highlighted?

If we talk about the main advantages of the process under consideration, they include:

- High speed of work completion. It should be noted that this is one of the fastest methods of joining metal products. For example, joining railway rails takes an average of about 50 minutes. Moreover, if several teams work simultaneously, the efficiency of such work will only increase (in just 2 hours, three teams can weld up to 12 joints).

- Good quality seams. The joints between parts are highly resistant to mechanical loads and chemicals. In addition, such seams look aesthetically attractive.

- Ease of completing the task. This technology does not require special skills and knowledge, since any specialist can cope with it, subject to short training. The number of workers involved is also small.

- Availability of materials. The powder mixtures and additional materials required for this can be purchased in specialized stores, and their price will not be high.

- No need to use expensive equipment. Unlike methods of resistance welding of metal elements, when using thermite mixtures it is not necessary to use expensive welding equipment. This is especially true for working at remote sites, when it is not possible to find a source of electric current or transport bulky gas cylinders.

However, there are some disadvantages, which include the need to comply with strict safety rules

Firstly, thermite itself is a highly flammable substance, so special care should be taken when transporting and storing it. Secondly, while performing the task, care must be taken to ensure that water or any other liquids do not get into the burning mixture, as this may cause an explosion