Hardening of aluminum profiles on a press

The cooling rate of aluminum profiles - hardening - immediately after exiting the press must be fast enough to retain magnesium and silicon in solid solution.

This ensures the achievement of maximum mechanical properties of the profile material due to their release during subsequent hardening by aging. The required cooling rate of a solid solution of alloying elements - magnesium and silicon in aluminum - to ensure the hardening effect depends on the cross-sectional dimensions of the aluminum profile and the methods of its cooling:

- calm air,

- fans,

- water mist,

- water spray cooling or

- in a stream of water.

The figure and table show the minimum permissible cooling rates of aluminum profiles for various alloys of the 6xxx series. For 6060 alloy aluminum profiles (AD31 aluminum alloy), still air or fan cooling is usually sufficient, while for 6061 alloy profiles, spray water cooling or water flow cooling is required.

Heat treatment of aluminum profiles

Heat treatment of aluminum alloys

Heat treatment of aluminum profiles is used to modify the properties of the aluminum alloys from which they are made by changing their microstructure. The main strengthening mechanisms in aluminum alloys are strengthening due to solid solution alloying and strengthening due to precipitation of secondary phases. As a rule, one of these mechanisms is dominant in the alloy.

Solid solution of aluminum alloys

A solid solution is obtained by heating an aluminum alloy, during which all phases present in it dissolve to form one homogeneous phase - aluminum with alloying elements dissolved in it. With increasing temperature, the solubility of elements increases, and with decreasing temperature, it decreases. The mechanism of hardening is that when the aluminum alloy is cooled quickly enough, the dissolved elements remain in the atomic lattice of aluminum and distort and elastically deform it. This distorted atomic lattice hinders the movement of dislocations and, consequently, plastic deformation of the alloy and thereby increases its mechanical strength.

Aging of aluminum alloys

Aluminum alloys that are hardened by age contain a certain amount of soluble alloying elements, such as some combinations of copper, magnesium, silicon, manganese and zinc. When subjected to appropriate heat treatment, these dissolved atoms combine into very small particles that are released within the grains of the aluminum alloy. This process is called aging, as it occurs “by itself” at room temperature. To speed up and achieve greater efficiency in strengthening the aluminum alloy, aging is carried out at elevated temperatures, say 200 °C.

Hardening of aluminum profiles on a press

Press hardening is a very cost-effective technology for heat treatment of aluminum profiles compared to hardening with separate heating. When hardening in a press, aluminum profiles are cooled based on the temperature at which they leave the matrix. A necessary condition for hardening on a press is that the heating temperature range of the aluminum alloy for hardening must coincide with the temperature range of aluminum profiles at the outlet of the press. This, in principle, is carried out only for “soft” and “semi-hard” aluminum alloys - technical aluminum, aluminum alloys of the 3xxx and 6xxx series, as well as low-alloy alloys of the 5xxx series (with magnesium up to 3%) and some aluminum alloys of the 7xxx series without copper alloying (7020, 7005 (our 1915), 7003). The hardening effect for 3xxx and 5xxx aluminum alloys is very small and, as a rule, is not taken into account. The final mechanical properties of aluminum alloys 3xxx and 5xxx are obtained not as a result of thermal hardening, but during subsequent cold hardening, which may include heat treatment operations: one or more annealing. The strengthening phase for alloys of the 6xxx series is the Mg2Si compound. For more details, see Hardening aluminum profiles on a press

Press hardening of alloys AD31, 6060 and 6063

All aluminum alloys of the 6xxx series can be hardened directly on the press. To fix the dissolved phases in the aluminum solid solution, it is necessary to cool the aluminum profiles at the outlet of the press at a speed not lower than a certain critical speed. This speed depends on the chemical composition of the aluminum alloy. Typically, enhanced cooling by fans is sufficient for most aluminum profiles, but sometimes it is necessary to cool them with water or a mixture of air and water. Successful hardening of 6xxx series aluminum alloys depends on the thickness of the profile, as well as the type of alloy and its chemical composition. In the case of overly massive aluminum profiles, for example, from alloy AD33 (6061) and a relatively slow pressing speed, the material exiting the matrix may not reach the temperature range required for hardening and some of the Mg2Si particles will remain undissolved. Therefore, with subsequent air, or even water, cooling of the profiles, their complete hardening will not be possible. In such cases, separate heating is used for hardening in special furnaces - usually vertical, followed by cooling in vertical tanks with water. After hardening, aluminum profiles are stretched by 1.5 - 3% to straighten and relieve residual stresses.

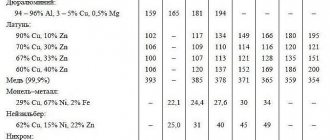

Aging of aluminum profiles: artificial and natural

The final operation of heat treatment of aluminum profiles is aging, natural or artificial. Natural aging occurs naturally over a period of time, which varies for different aluminum alloys - from several weeks to several months. Artificial aging is carried out in special aging ovens. Typical heat treatment conditions for some 6xxx aluminum alloys are given in Table 1.

Table 1

Heat treatment of aluminum alloys Al-Zn-Mg

Aluminum alloys Al-Zn-Mg without copper alloying (7020, 7005 (1915), 7003) are also classified as “semi-hard” alloys. They are successfully used in the manufacture of car bodies, load-bearing structures, including welded ones. These aluminum alloys are successfully hardened by aging if the temperature of the profiles at the exit from the press is at least 400 °C. Most often they are used without forced cooling at all due to their tendency to stress corrosion. At the same time, for example, aluminum alloy 1915 provides a tensile strength of more than 315 MPa even in a hot-pressed state with natural aging of 30 to 35 days.

Hardening of aluminum profiles with separate heating

Aluminum alloys Al-Cu-Mg and Al-Zn-Mg-Cu, as well as alloys of the Al-Mg series with a magnesium content of more than 3% are classified as difficult to press. Aluminum-magnesium alloys are not subject to thermal hardening, and the process of thermal hardening of aluminum alloys Al-Cu-Mg and Al-Zn-Mg-Cu (2xxx and 7xxx) differs significantly from the heat treatment of 6xxx alloys, which are always hardened in a press. Hardening of these alloys, for example, alloys 7075 and 2024 (D16), is carried out only with separate heating, most often in vertical furnaces, followed by rapid hardening in vertical baths-tanks with water. The final heat treatment operation - the aging operation - is carried out either at room temperature (natural aging) or at a given elevated temperature for the required time (artificial aging).

Hardening of hard aluminum alloys

Table 2 presents the strengthening phases of thermally hardenable hard alloys. When heated in a furnace for quenching, they dissolve in a solid solution. The heating process involves holding at a given temperature to achieve a nearly homogeneous solid solution. The cooling rate of aluminum profiles from the quenching temperature must exceed a certain critical rate, which is different for different aluminum alloys, in order to obtain maximum strength properties and intergranular resistance in the aged state. For example, for alloy 7075 the cooling rate must be no less than 300 °C/s in the temperature range from 400 to 280 °C. In the quenched state, age-hardened aluminum alloys are unstable. When aluminum alloys age, submicroscopic particles of the secondary phase are released, which form an irregular dislocation structure. Due to the formation of this structure, the alloy is strengthened. The size and distribution of these precipitates determines the optimal mechanical properties of the aluminum alloy. Typical heat treatment modes for some hard aluminum alloys are given in Table 3. The heating duration depends on the thickness of the aluminum profiles.

table 2

Table 3

Sources: 1. Saha P. 2. Aluminum and Aluminum Alloys: ASM, 1993

Source: aluminum-guide.ru

Aging of aluminum alloys

Aging of 6xxx series alloys is carried out to improve the mechanical properties of aluminum profiles. The extent of this increase in properties depends on the type of alloy and aging conditions. These conditions vary for:

- natural aging, which occurs “by itself” at room temperature, and

- artificial aging, which is carried out at elevated temperatures, about 160-200 ºС.

The strength of 6xxx series alloys is directly related to their ability to resist the movement of dislocations during deformation. When stress is applied to a material, dislocations form and move within it. As stress increases, the number and density of dislocations moving in the material increases until the material finally fails.

The movement of dislocations is inhibited due to the presence of Mg 2 Si particles and therefore the strength of the aged aluminum alloy increases. The size and density of these particles are controlled by aging parameters. A small number of small particles of β"- Mg 2 Si can do little to stop dislocations moving through a material, but when there are many of them they impede the movement of dislocations and this increases the strength of the material.

If the particles grow too large (β'-Mg 2 Si and β-Mg 2 Si), there are too few of them due to the limited content of Mg and Si in aluminum. In this case, dislocations easily bypass these particles and the strength of the material decreases.

This is demonstrated by the schematic graph of typical artificial aging in the figure below.

The peak strength properties are achieved with a large number of small particles β”-Mg 2 Si. For 6xxx alloys, typical artificial aging parameters are a temperature of 170 ºС for 8 hours or 185 ºС for 6 hours.

T-states of aluminum alloys

Different options for aging parameters correspond to different designations of the state of aluminum alloys:

- T1 – cooled after pressing to room temperature and naturally aged;

- T4 – after pressing, hardened with separate heating and naturally aged;

- T5 – cooled after pressing to room temperature and artificially aged to maximum strength properties;

- T6 - after pressing, hardened with separate heating and artificially aged to maximum strength properties.

To refer to other aging treatments that are specifically designed to produce mechanical properties that differ from the maximum strength properties. For example, states T52 and T591 are used for aluminum profiles that are subject to bending, and state T7 is used for profiles that are used at elevated temperatures.

Stretching and curing profiles

The usual practice for the manufacture of extruded aluminum profiles includes stretching them from 0.5% to 3% and then curing them with a delay of a day of artificial aging for profiles made of low-alloy 6xxx alloys (no more than 0.9% Mg 2 Si), for example, aluminum alloys AD31, 6060 and 6063. This helps to achieve optimal mechanical properties of the profiles after aging.

However, such a delay for higher strength aluminum alloys (Mg 2 Si content more than 0.9%), for example, 6061, can lead to reduced mechanical properties of the aluminum profile material. These alloys contain copper in an amount of at least 0.1%, which counteracts the effect of delayed artificial aging on the final mechanical properties of thermally strengthened aluminum profiles.

Source: aluminum-guide.ru

Aging of aluminum alloys

Aluminum alloys gain hardness when there is controlled precipitation of the alloy elements (due to the decomposition of the supersaturation of the solution necessary for effective solidification), and the resulting sediment is cohesive (cohesive) or partially connected to the lattice microstructure of the base metal.

The kinetics of precipitation of a supersaturated solid solution is a function, i.e. chemical composition. For example, for alloy 2024, aging is achieved naturally, while for alloy 7075 the kinetics of precipitation in a solid solution occurs only at +100 - 200 ° C. Alloys that undergo natural aging can be aged artificially.

But the best resistance to intergranular corrosion is achieved artificially. Natural aging favors durability characteristics and greater resistance to fatigue crack propagation.

With different aging parameters, the same results can be achieved. For example, alloy 6060, the same conditions are achieved for 5 hours at 185 °C and for 11 hours at 170 °C.

In insufficiently aged parts, a decrease in the level of mechanical properties may be observed during subsequent processing.

Overaging can occur due to plastic deformation performed after quenching to aging (by rolling, forming, rolling, rolling, etc.)

These operations accelerate the kinetics of sedimentation, proportional to the degree of deformation, in cases of homogeneous processing (such as stretching, compression, rolling, rolling).

In general, the combinations are such as to bring the alloy to maximum hardness T6.T7 - greater aging, rather overaging, with a partial decrease in mechanical characteristics. With such processing, it is possible to increase the dimensional stability of the product, which allows the product to be used for operation at high temperatures. Greater resistance to surface corrosion or exfoliative corrosion (flaking) can also be developed.

Products that will operate at high temperatures, for example, motor parts, can only achieve good dimensional stability with artificial aging; in T5 processing, it is very rare in these cases to use material aged by natural aging. (T1).

Low alloy alloys such as 6060 should be aged to a maximum hardness of T6.

For products requiring greater precision (dimensions), various processing cycles are used. Within 1-2 hours at 175-200C after pre-treatment (grinding), after machine processing and during intermediate phases.

At the first stage of isothermal aging cycles. For example, 6 hours at a temperature of 100°C, up to 3 hours at a temperature of 120°C. At the second stage, temperature and time must be controlled, because may cause changes in the physical properties of the part. The temperature in the oven should be uniform.

Undesirable effects of overaging parts can be caused by a long process caused by low heating rates caused by overloading the furnace.

The time between hardening (cooling) and aging does not affect the aging of the profile. But, it must be remembered that in some 6060 series alloys the mechanical properties will be slightly higher if aging is performed immediately after quenching. While other alloys require exposure to ambient temperature before aging for better mechanical properties.

The maximum interval allowed between the dissolution of substances and quenching (quenching delay).

Source: vseokraskah.net

Aluminum Heat Affected Zone

When welding pure aluminum and alloys that are not hardened by heat treatment, in the heat-affected zone only grain growth and some softening are observed, caused by the removal of cold-working (if the alloy was welded in a cold-worked state). The intensity of grain growth and softening of the cold-worked alloy during welding can vary depending on the welding method, modes and magnitude of the previous cold-working. Practice shows that even under gas welding conditions, which are characterized by the longest heating of the metal, welded joints made from these alloys are not inferior in strength to the strength of the base metal in the annealed state.

Thermal weldability of aluminum-magnesium alloys with a high magnesium content (AMg5V and AMg6), which also belong to the group of alloys that are not thermally hardened, is complicated by their increased sensitivity to heat and their tendency to swell in areas of the base metal immediately adjacent to the weld. The tendency to swell in heat-affected zones increases with increasing magnesium content in the alloys and the duration of heating during welding. Therefore, swelling of the metal in heat-affected zones is observed primarily when welding them with a gas flame and to a lesser extent during arc welding.

Most authors of works devoted to the study of this phenomenon come to the conclusion that the main cause of swelling and the formation of discontinuities may be the reaction of magnesium with water vapor, the accumulation of hydrogen in discontinuities and an increase in pressure in them.

It has now been established that swelling in heat-affected zones is observed only when welding metal of certain semi-finished products and melts. Swelling of the metal when heated is caused by molecular hydrogen, which fills micro-discontinuities formed during the deformation and compression of small gas bubbles that arise during the crystallization of the ingot based on dispersed oxide inclusions present in the insufficiently refined metal. In areas of the metal that are heated to a temperature close to the melting point, due to its softening, an increase in the volume of rolled bubbles and swelling of the metal occurs.

The concentration of dissolved hydrogen in the metal of industrial ingots cast by continuous casting does not exceed 0.15–0.3 cm3/100 g, which coincides with the calculated data on the solubility of hydrogen in the alloy at temperatures of the lower limit of the effective crystallization range. In this regard, to control the quality of the metal being welded, it is necessary first of all to determine the molecular hydrogen content in it.

The MATI thermal test is intended for these purposes. A cylindrical sample with a diameter of 15 mm, a length of 25 mm, made of a controlled metal, is heated in an oven at a temperature of 580 + 5 ° C for 15 minutes. After cooling, a thin section is made from the sample. The presence of macro-discontinuities and delaminations in the metal of the sample indicates an insufficiently high quality of the metal and an increased content of molecular hydrogen.

When welding alloys that are strengthened by heat treatment, changes occur in the areas near the weld that significantly reduce the properties of the metal being welded. Hardness measurements and the study of the metal structure in the heat-affected zone of welded joints made of alloys strengthened by heat treatment make it possible to detect in it areas of metal with varying degrees of decomposition of the solid solution and coagulation of the hardener.

The most dangerous change, which in most cases causes a sharp decrease in the properties of the metal and the formation of cracks, is the melting of grain boundaries. The appearance of liquid layers between the grains leads to a decrease in the mechanical properties of the metal in a heated state and often to the formation of cracks. After welding in areas of fusion, the metal becomes brittle and its strength decreases. The study of structural changes occurring in heat-affected zones during welding of industrial alloys of complex alloying is associated with certain difficulties due to the presence of a large number of phases of complex composition in the alloys.

The simplest model for studying the processes occurring in heat-affected zones during welding may be a double aluminum-copper alloy containing 4% Cu.

When an alloy containing 4% Cu is slowly cooled from a temperature above the eutectic, the copper concentration decreases in accordance with the solubility curve (Fig. 9.5). Copper, which was in solid solution, is released in the form of the CuAl2 phase (θ-phase). At normal temperature, the alloy cooled in this way consists of grains of a solution of copper in aluminum with a concentration of 0.1-0.2% Cu and particles of the CuAl2 phase distributed throughout the grain volume and along the grain boundaries.

Rice. 9.5. Aluminum corner phase diagram of Al-Cu system

By rapidly cooling the same alloy from the α-solid solution region to normal temperature, the precipitation of the CuA12 phase can be delayed and copper can be fixed in the solution. If we do not take into account that the alloy contains insoluble phases formed by impurities, then after rapid cooling the alloy should be a homogeneous solution of copper in aluminum containing 4% Cu.

A supersaturated solution of copper in aluminum is unstable. Even at normal temperatures, processes occur in it that lead to an increase in its strength and a decrease in ductility—the aging of the alloy occurs.

During natural aging, there is no separation of the second phase, and the supersaturated solution of copper in aluminum remains. The increase in the strength of the metal is explained by the movement of copper atoms over short distances, accompanied by its collection on the planes of the cube (100) lattice into two-dimensional plate-like formations called Guinier-Preston zones. This uneven distribution of copper atoms leads to lattice distortions, increasing the strength and hardness of the alloy.

Heating the alloy above a temperature of 150 °C causes further development of the resulting formations. The copper-enriched planes occupy a certain order between the adjacent planes of aluminum atoms. The appearance of a superstructure is considered as a transitional stage to the release of the hardening agent from the solution. When heated to temperatures above 200 °C, an intermediate phase θ' is formed at the base of the superstructure; its composition corresponds to the θ phase (CuAl2), and the crystal lattice differs from the aluminum lattice and phase 6.

At temperatures above 300 °C, a stable phase θ is formed. The appearance of the metastable phase θ' leads to a significant strengthening of the alloy and a decrease in its ductility.

In accordance with the above, a distinction is made between natural aging, which occurs at normal temperatures, and artificial aging at temperatures above 150–200 °C. The first type of aging was called zone aging by I. N. Frldlyander, and the second type was called phase aging.

To understand the processes occurring in heat-affected zones during welding of alloys strengthened by heat treatment, certain features of the decomposition of supersaturated solid solutions are important. The appearance of a particle of a new phase of a different volume is accompanied by elastic distortions of the matrix lattice.

If the elastic energy concentrated around a particle of the new phase is large, then its appearance becomes more likely, first of all, at the grain boundaries, where there are lattice defects. This is also facilitated by the increased concentration at the grain boundaries of dissolved atoms having an atomic radius that differs from the atomic radius of the solvent.

In this regard, with rapid heating of a supersaturated solution to high temperatures, characteristic of welding conditions, one can expect the appearance of a second phase, primarily along the grain boundaries.

When welding an annealed alloy in the heat-affected zone, as the maximum heating temperature of the metal increases in accordance with the state diagram, processes of dissolution of the precipitated hardener occur. Particularly noticeable are the processes of dissolution of dispersed precipitates of the second phase in the grain volume in a section of the metal heated above a temperature of 350 °C. At the boundary of this area, a clearing of the background is observed due to the disappearance of smaller particles of the hardening agent released throughout the grain volume, and an increase in the hardness of the solution.

As the heating temperature increases, grain boundaries begin to be more clearly visible due to the enlargement of hardener precipitates at their boundaries. This process continues in a section of the metal heated from 500 °C to the melting point of the eutectic (548 °C). In this area, as the heating temperature increases, along with the thickening of the grain boundaries, a white stripe of the peripheral part of the grain depleted in copper, adjacent to the second phase precipitates at the grain interface, becomes more noticeable (Fig. 9.6).

Rice. 9.6. Melting of grain boundaries in the area of the heat-affected zone of a welded joint of an aluminum alloy with 4% Cu: 1 - melted grain boundary; 2 - light edge of the periphery of the grain; 3 - section of grain with normal etchability

In a section of the metal heated in the temperature range between the solidus and the melting point of the eutectic (548 °C), liquid layers appear along the grain boundaries, which, apparently, can be explained by the development of contact melting between the particles of the hardening agent - the CuAl2 phase - and the solid solution. The process of contact melting, accompanied by the appearance of liquid layers at the grain boundary, leads to depletion of copper in the peripheral sections of the grain adjacent to the melted boundary.

When welding a hardened and artificially aged alloy, a noticeable change in the etchability of grains and a more clear identification of their boundaries is observed in areas of the metal that were heated during the welding process to temperatures above 500 °C. Apparently, this is due to partial coagulation of the hardening agent released in the grain volume and along the grain boundaries. However, according to the equilibrium state diagram of the Al-Cu system (see Fig. 9.5), at a temperature of 500 °C, instead of coagulation of the released hardener, its additional dissolution should occur.

The reason for the apparent discrepancy between the detected structural changes and the equilibrium state diagram is as follows. The decomposition of the solution at high temperatures begins with the appearance of stable nuclei of the second phase at the grain boundaries, their development due to the influx of copper atoms from the grain boundary areas and then the release of the hardening agent in the grain volume.

Thermal effects during welding are characterized by rapid heating of the metal to maximum temperatures and slower subsequent cooling.

When welding an artificially aged alloy during a period of rapid heating to a temperature of 500 °C, coagulation of the hardener does not have time to occur. On the contrary, starting from a temperature of 500 °C and above, even partial dissolution of dispersed precipitates of the second phase in the bulk of the grain is possible. During subsequent cooling, starting from a temperature of 500 °C and below, the high-temperature decomposition of the solid solution continues, accompanied by the formation of hardener nuclei, primarily along the grain boundaries, and their development due to the influx of copper atoms from the adjacent peripheral areas of the grains, which leads to the appearance light rims along their boundaries and increased etchability of the main part of the grain due to coagulation of dispersed precipitates of the second phase in the bulk of the grain.

As the temperature of maximum heating increases, the time of existence of the metal in the temperature range of 500–300 °C increases and conditions are created for more complete decomposition of the solution and coagulation of the precipitated hardener. Therefore, as you approach the weld, the hardness of the metal gradually decreases, the grain boundaries thicken, and light edges at the grain boundaries, which are a solution of aluminum depleted in copper, are more clearly visible.

In the temperature range between the solidus and the melting point of the eutectic, melting of the grain boundaries is observed. Melting of the boundaries in this case also causes contact melting that develops between particles of the CuAl2 phase, precipitated along the grain boundaries, and the solid solution of copper and aluminum.

The mechanism of grain boundary melting discussed above is characteristic of most heat-treatable alloys that can undergo aging. In contrast to the binary aluminum-copper alloy, considered as a model for welding complex alloy alloys, the composition of the strengthening phases and eutectics formed as a result of contact melting changes.

The above point of view on the causes and mechanism of grain boundary melting during welding of alloys strengthened by heat treatment is not the only and generally accepted one. There is also an opinion that the main reason for the melting of grain boundaries is associated with the presence in the alloy of an equilibrium eutectic at a high degree of alloy alloying or a nonequilibrium eutectic formed during crystallization of the ingot under conditions far from equilibrium.

Some researchers are also inclined to think that the melting of grain boundaries occurs in a section of the metal in the heat-affected zone, which is heated during the welding process above the solidus temperature—the high-temperature region. A zone depleted of strengthener and melted eutectic appear during the subsequent nonequilibrium crystallization of the melted grain boundary.

Experience in welding alloys of the duralumin type (D1 and D16) shows that, regardless of the welding method and the initial state of the metal, in all cases a zone of grain boundary melting is observed in the immediate vicinity of the weld. The width of this zone varies depending on the welding method and modes. The widest zone appears with gas welding and a narrower zone with automatic arc welding.

The nature of the eutectic distribution in this zone varies depending on the initial state of the alloy. In welded joints obtained by arc welding of a hardened alloy, the eutectic is located in the form of a continuous layer around the grains of the solid solution, while in joints made of annealed metal, discontinuities appear in the occurrence of the eutectic.

When gas welding D16 duralumin in a hardened state, it is difficult to obtain a joint without cracks. When arc welding in argon and flux, the strength of hardened alloy joints ranges from 290-320 MPa, and when welding in an annealed state it is about 220 MPa.

Due to the presence of a continuous mesh of fused eutectic, welded joints made of hardened metal have low ductility and are easily destroyed under slight deformation and vibration or dynamic loads. When welding rigid assemblies made of hardened metal, cracks often occur along the fusion boundary. Subsequent heat treatment fails to restore the properties of the metal in this zone. When welding samples from aluminum alloys such as duralumin using very sharp cooling, it was possible to significantly reduce the width of the zone with melted grain boundaries and increase the properties of the welded joints. However, the use of such cooling rates in production conditions is difficult to implement.

The problem of welding high-strength aluminum alloys that are strengthened by heat treatment can be solved by creating special weldable alloys of this group. Much attention is paid to the creation of weldable high-strength alloys that are strengthened by heat treatment. In our country, a number of alloys of this group have been developed that have better heat weldability: VAD1, M40, etc. Self-hardening alloys based on the Al-Zn-Mg ternary system (V92Ts, ACM, 1915, etc.) are promising, as well as alloys based on A1-Cu-Mn systems (type 1201) and alloys based on the Al-Mg-Li system (type 1420).

Aging of hardened aluminum alloys

After hardening of the aluminum alloy, aging follows, when the alloy is kept at room temperature for several days (natural aging) or for 10–24 hours at elevated temperatures (artificial aging).

During the aging process, the supersaturated solid solution decomposes, which is accompanied by strengthening of the alloy. The decomposition of a supersaturated solid solution, in the lattice of which copper atoms are distributed statistically evenly, occurs in several stages depending on the temperature and duration of aging. During natural (at 20°C) or low-temperature artificial aging (below 100 - 150°C), no decomposition of the solid solution with the release of excess phase is observed; at these temperatures, copper atoms move only within the crystal lattice of the α-solid solution over very short distances and are collected along planes into plate-like formations or disks - Guinier-Preston zones (GP-1). GP-1 zones in Al-Cu alloys with a length of 1–10 nm and a thickness of 0.5–1 nm are more or less evenly distributed within each crystal. The copper concentration in the zones of GP-1 is less than in CuAl2 (54%).

Heat treatment of aluminum alloys

Introduction

To harden aluminum alloys, hardening and aging are used. To eliminate nonequilibrium structures and deformation structural defects that reduce the plasticity of the alloy, annealing is used.

Hardening of aluminum alloys

Quenching consists of heating the alloys to a temperature at which excess intermetallic phases are completely or mostly dissolved in aluminum, holding at this temperature and rapidly cooling to room temperature to obtain a supersaturated solid solution. For example, the hardening temperature of alloys of the Al–Cu system (Fig. 1) is determined by the line abc

, passing above the limiting solubility line for alloys containing less than 5.7% Cu, and below the eutectic line (548 ° C) for alloys containing more Cu.

When alloys containing up to ~ 5% Cu are heated for quenching, the excess CuA12 phase completely dissolves, and upon subsequent rapid cooling, only a supersaturated α-solid solution is fixed, containing as much copper as is present in the alloy (Fig. 2c). With a content of more than 5% Cu in the structure of the alloys after quenching there will be a supersaturated α-solid solution of the composition corresponding to point b

, and crystals of the CuAl2 compound that are not dissolved during heating. The holding time at the quenching temperature required to dissolve the intermegallide phases depends on the structural state of the alloy, the type of furnace and the thickness of the product. Sheets, plates, rods, strips with a thickness of 0.5–150 mm can withstand heating in saltpeter baths for 10–80 minutes, and in electric furnaces with forced air circulation, the most widely used for this purpose, for 30–210 minutes. The holding of shaped castings at the hardening temperature is longer (2–15 hours). During this time, coarse precipitates of intermetallic phases dissolve (Fig. 2a). During hardening, deformed alloys are cooled in cold water, and shaped castings are cooled in heated water (50–100 °C) to avoid warping and cracking. After hardening, the alloys have a relatively low strength σв, σ0.2 and high ductility (delta;, ψ).

| Fig.1. Al–Cu phase diagram |

|

Aging of hardened alloys

After hardening, aging follows, during which the alloy is kept at normal temperature for several days (natural aging) or for 10–24 hours at elevated temperature (artificial aging). During the aging process, the supersaturated solid solution decomposes, which is accompanied by strengthening of the alloy. The decomposition of a supersaturated solid solution occurs in several stages depending on the temperature and duration of aging. During natural (at 20 °C) or low-temperature artificial aging (below 100–150 °C), no decomposition of the solid solution with the release of excess phase is observed; at these temperatures, copper atoms move only inside the crystal lattice of the α-solid solution over very short distances and are collected along the (100) planes into two-dimensional plate formations (Fig. 3a) or disks - Guinier-Preston zones (GP-1). These GP–1 zones, several tens of angstroms long (30–60 Å) and 5–10 Å thick, are more or less evenly distributed within each crystal. The copper concentration in the GP-1 zones is lower than in CuAl2 (54%).

|

If the alloy after natural aging is briefly (several seconds or minutes) heated to 230–270 °C and then quickly cooled, then the hardening is completely removed, and the properties of the alloy will correspond to the freshly quenched state. This phenomenon is called return

. The softening upon return is due to the fact that the GP-1 zones at these temperatures turn out to be unstable and therefore dissolve in the solid solution, and the copper atoms are again more or less evenly distributed within the volume of each crystal of the solid solution, as after quenching. During subsequent aging of the alloy at room temperature, the formation of GP-1 zones and strengthening of the alloy again occur. However, after the return and subsequent aging, the corrosion properties of the alloy deteriorate, making the use of the return difficult for practical purposes. Long-term exposure at 100 °C or several hours at 150 °C leads to the formation of larger HP-2 zones (thickness 10–40 Å and diameter 200–300 Å) with an ordered structure different from the α-solid solution (Fig. 3b) . The concentration of copper in them corresponds to its content in CuAl2. With increasing aging temperature, diffusion processes, and therefore the processes of structural transformations and self-strengthening, proceed faster. Holding for several hours at 150–200 °C leads to the formation in places where the GP-2 zones were located, dispersed (thin-plate-like) particles of the intermediate θ′-phase, which does not differ in chemical composition from the stable phase θ (CuAl2), but has excellent crystal lattice; The θ′ phase is coherently associated with the solid solution (Fig. 3c). An increase in temperature to 200–250 °C leads to coagulation of the metastable phase and the formation of a stable θ-phase (Fig. 3d).

Thus, during natural aging, only GP-1 zones are formed. During artificial aging, the sequence of structural changes can be represented as the following scheme: HP–1 → HP–2 → θ′ → θ (СuAl2).

This general scheme for the decomposition of a supersaturated solid solution in Al–Cu alloys is also valid for other alloys. The difference boils down only to the fact that in different alloys the composition and structure of the zones, as well as the resulting phases, are not the same.

For aging aluminum alloys of different compositions, there are also their own temperature-time regions of zone (formation of GP-1 and GP-2) and phase (θ′- and θ-phases) aging.

After zone aging, alloys often have an increased yield strength and a relatively low ratio σ0.2/σв ≤ 0.6÷0.7, increased ductility, good corrosion resistance and low sensitivity to brittle fracture.

After phase aging, the ratio σ0.2/σв increases to 0.9–0.95, and ductility, toughness, resistance to brittle fracture and stress corrosion decrease.

Structural strengthening

The recrystallization temperature of some aluminum alloys with manganese, chromium, nickel, zirconium, titanium and other transition metals exceeds the usually assigned heating temperature for deformation or hardening, therefore, after hardening and aging of such alloys, they retain a recrystallized (polygonized) structure with a high dislocation density, which increases its strength compared to the recrystallized structure. This phenomenon is called structural hardening

.

As a result of structural strengthening, the values of σв, σ0.2 increase to 30–40%. Structural hardening is most pronounced in pressed semi-finished products (rods, profiles, pipes), therefore this phenomenon in relation to them is called the press effect

.

Homogenization annealing

Ingots are subjected to this type of annealing before pressure treatment to eliminate dendritic segregation, which leads to the formation of an inhomogeneous solid solution and the precipitation of brittle nonequilibrium eutectic inclusions CuAl2, Al2CuMg (S-phase), Mg2Si, Al3Mg2Zn2 (T) along the grain boundaries and between the branches of dendrites -phase, etc.). During the homogenization process, the composition of solid solution crystallites is leveled, and intermetallic compounds are dissolved. During subsequent cooling, intermetallic compounds are released in the form of evenly distributed small secondary inclusions. As a result, the ductility of the cast alloy increases, which makes it possible to increase the degree of compression during hot forming, the pressing speed and reduce technological waste. Homogenization promotes a fine grain structure in the annealed sheets and reduces the susceptibility to stress corrosion. The homogenization temperature is in the range of 450–520 °C, and the holding time is from 4 to 40 hours. Cooling is carried out in air or together with a furnace.

Recrystallization annealing

Such annealing consists of heating the deformed alloy to temperatures above the temperature at which the primary recrystallization ends; used to remove hardening and obtain fine grains. The temperature of recrystallization annealing, depending on the composition of the alloy, ranges from 350 to 500 °C, holding time is 0.5–2.0 hours. After recrystallization annealing of alloys that cannot be strengthened by heat treatment, the cooling rate is chosen arbitrarily. For alloys strengthened by heat treatment, the cooling rate to 200–250 °C should be ≤ 30 °C/h. Annealing is used as an intermediate operation during cold deformation or between hot and cold deformation.

Annealing for softening of alloys that have undergone hardening and aging

This type of annealing is carried out at 350–450 °C with a holding time of 1–2 hours. At these temperatures, complete decomposition of the supersaturated solid solution and coagulation of strengthening phases occurs. The cooling rate should not exceed 30 °C/h. After annealing, the alloy has low tensile strength, satisfactory ductility and high resistance to stress corrosion.

Press effect

The recrystallization temperature of some aluminum alloys with manganese, chromium, nickel, zirconium, titanium and other transition metals, subjected to certain hot and, in some cases, cold pressure treatment modes, exceeds the usually assigned heating temperature for deformation or hardening. Therefore, after quenching and aging of such alloys, they retain a non-recrystallized (polygonized) structure with a high dislocation density, which significantly increases strength compared to a recrystallized structure. This phenomenon is called structural hardening . Structural hardening is essentially a high-temperature thermo-mechanical treatment.

As a result of structural strengthening, the values of σ0.2 and σв increase to 30 - 40%. Structural hardening is most pronounced in pressed semi-finished products (rods, profiles, pipes), therefore this phenomenon in relation to them is called the press effect.

Source: www.metmk.com.ua

Heat treatment of aluminum alloys

Heat treatment of aluminum alloys is designed to adjust the characteristics of the material by exposure to high temperatures. A wide variety of structures and properties can be achieved by various processing methods.

Alloys that contain impurities in the amount of 15-18% have the form of a solid solution. Copper, magnesium, zinc, silicon and other substances are used as additional components, different combinations of which and their percentage directly affect the properties of the material.

In their normal state, aluminum alloys are not very strong, but are quite ductile. The most unstable alloys include a large number of alloying components that affect the equilibrium structure.

Heat treatment methods are used to strengthen aluminum alloys. By uniform heating, which is regulated by technical conditions, the appropriate structure necessary for the initial stage of decomposition of the solid solution is obtained.

Heat treatment can produce many types of material structures that meet production requirements. Heat treatment allows you to create a structure that has no analogues.

To date, many methods have been developed for heat treatment of aluminum products, among which three have gained the most popularity: annealing, hardening, and aging.

Main types

The purpose of this article is to consider possible options for using equipment for various types of heat treatment of products made of aluminum alloys.

This article does not cover equipment for producing castings and gas-fueled furnaces. Heat treatment of aluminum alloys is carried out to obtain the required structure and, accordingly, mechanical properties, both at the blank stage and in finished products.

For heat treatment, there are five main types of manipulations with their own heating and cooling methods. To obtain the desired physical properties, one or another heating method is used.

Annealing of the first kind

Designed to relieve casting or thermal residual stresses, eliminate work hardening; with such heating, phase transformations do not occur in the metal structure.

Annealing of the second kind

Designed to change the structure of a material through recrystallization. The workpieces are heated above critical temperatures and cooled slowly. As a result, the grain size, their shape, and the distribution of particles of the second phases change.

Hardening of aluminum alloys

designed to consolidate nonequilibrium (metastable) structural states. A freshly hardened product is soft, like after annealing steel, it can be deformed. But after 4-6 days the metal self-strengthens.

| Initial structure before hardening | Structure after hardening |

Scheme of changes in the structure of an aluminum alloy containing 4% Cu (after quenching)

Vacation (aging)

designed to impart the desired properties to products. Depending on the temperature, hardening or softening occurs.

Features of heat treatment of aluminum alloys

Aluminum and its alloys require a special approach to heat treatment to achieve a certain strength and structure of the material. Several heat treatment methods are often used. Typically, aging follows after hardening. But some types of materials can be aged without hardening.

This opportunity appears after casting, when the components, at an increased cooling rate, can give the metal the necessary structure and strength. This occurs during casting at a temperature of about 180 degrees. At this temperature, the level of strength and hardness increases, and the degree of ductility decreases.

Each heat treatment method has some features that should be taken into account when processing aluminum products.

Annealing is necessary to impart a uniform structure to the aluminum alloy. Using this method, the composition becomes more homogeneous, the diffusion process is activated and the size of the base particles is equalized. It is also possible to achieve a reduction in the voltage of the crystal lattice. The processing temperature is selected individually, based on the characteristics of the alloy, the required final characteristics and the structure of the material.

Composition and properties of aluminum alloys strengthened by heat treatment

An important step in annealing is cooling, which can be done in several ways. Cooling is usually carried out in an oven or in the open air. Step-by-step combined cooling is also used, first in an oven and then in air.

The characteristics of the finished material directly depend on the rate of temperature decrease. Rapid cooling promotes the formation of supersaturation of the solid solution, and slow cooling promotes a significant level of decomposition of the solid solution.

Quenching is required to strengthen the material by supersaturating the solid solution. This method is based on heating products to temperatures and rapid cooling. This contributes to the complete dissolution of the constituent elements in aluminum. Used for processing wrought aluminum alloys.

Annealing methods for aluminum sheets

Annealing of aluminum alloys is not mandatory. But in some cases, without this heat treatment method it is impossible to achieve the desired characteristics of the material.

The reason for the use of annealing may be the special state of the alloy, which can be expressed in a decrease in the ductility of the material.

The use of annealing is recommended when observing three types of conditions:

- The non-equilibrium state characteristic of cast products is associated with the difference in temperature conditions. The cooling rate of cast products significantly exceeds the recommended one, at which the effect of equilibrium crystallization is achieved.

- Plastic deformation. This condition may be caused by technological requirements for the characteristics and shape of the finished product.

- Heterogeneous structure of the material caused by other heat treatment methods, including hardening and aging. In this case, one of the alloying components separates into the intermetallic phase, accompanied by supersaturation of the components.

The above problems can be eliminated by annealing. Normalization of the structure and condition of the aluminum alloy is accompanied by an increase in ductility. Depending on the type of nonequilibrium state, various annealing methods are selected.

Today there are three annealing modes:

- Homogenization. Designed for processing cast ingots. During the heat treatment of ingots at high temperatures, a uniform structure is achieved. This simplifies the rental process while reducing production costs. In some cases it can be used to improve the quality of deformed products. The annealing temperature is maintained within 500 degrees, followed by holding. Cooling can be done in several ways.

- Recrystallization. Used to restore deformed parts. This requires pre-treatment with a press. The annealing temperature varies in the range from 350 to 500 degrees. The holding time does not exceed 2 hours. The speed and method of cooling has no special limits.

- Heterogenization. Additional annealing after other heat treatment methods. This method is necessary for softening aluminum alloys. This processing method makes it possible to reduce the degree of strength while simultaneously increasing the level of ductility. Annealing is carried out at approximately 400 degrees Celsius. Exposure is usually 1-2 hours. This type of annealing significantly improves the performance characteristics of the metal and increases the degree of corrosion resistance.

General information about stoves

Distinctive features of aluminum alloys, such as significantly higher heat capacity, heating accuracy within ±3°C, thermal conductivity, structure, melting point, alloying concentrations, do not always allow the use of electric furnaces for heat treatment of steels. These features must be taken into account when choosing equipment for heat treatment of aluminum-based alloys. Low-temperature furnaces are used for heat treatment, a characteristic feature of which is the transfer of most of the heat to heated products by enhanced convection

Therefore, powerful

fans

to mix the gas in the working chamber and a distributed scheme for directing convection flows. Depending on the type of production, electric furnaces can be periodic (cage type) or continuous (pass-through).

Chamber electric furnaces with a fixed hearth are used for annealing, hardening, and aging of small and medium-sized parts in small and medium-scale production. The advantage of such furnaces is their availability and reliability. The disadvantage is the lack of mechanization.

Chamber electric furnaces with a bogie bottom are used for heat treatment of large-sized castings, profiles, forgings, mainly for annealing, tempering or aging, etc. Advantages in the ability to load large batches of workpieces. The disadvantage of such structures is the large occupied areas. When using such furnaces, it is difficult to carry out the hardening operation due to the cooling of the workpieces during rolling out of the hearth and unloading.

Shaft electric furnaces are widely used for heat treatment of shaped castings. They occupy minimal workshop space and have relatively higher productivity than chamber ones.

Conveyor electric furnaces are widely used for heat treatment. Push-type or roller-type furnaces. Here, the workpieces are loaded into a container, which is pushed along guides or rolled through the entire thermal chamber. The advantage of pass-through designs is that they are easily connected by other installations into units and lines. These furnaces are usually used in large-scale production.

Features of the design of annealing installations

After initial heating, for some types of annealing, a fixed cooling rate is required, less than in air. To do this, the housing must have holes that are closed during heating and holding. During cooling of parts with a furnace, these holes open slightly and air blown by a fan flows through them.

Design features of thermal equipment for hardening aluminum alloys

Heating for hardening of parts is a responsible operation, and its successful implementation depends mainly on the uniform distribution of temperature in the heating chamber and the ability to regulate it within limited limits (±3℃)

.

The temperature range for hardening is 500-550 ℃

. If the metal is overheated, a liquid phase forms around the perimeter of the grains, shrinkage occurs, and microporosity appears, with a significant decrease in strength and ductility. Heaters must be placed in flow-forming channels. The temperature-controlling device “Thermoregulator” must have a mechanism for reducing the temperature (fine adjustment) in the range of 480-530℃, which will ensure the necessary heating accuracy for hardening (±3℃).

Features of heat treatment techniques

After heating and holding, the workpieces must be moved from the chamber to the quenching tank as quickly as possible, no longer than 5-7 seconds. Cooling should be carried out as intensively as possible. Cooling must begin at the holding temperature. This means that the time for transferring parts from the chamber to the quenching tank (water) should be minimal; this can be achieved by mechanizing the movement of the charge into the quenching tank. The quenching tank must have a powerful water mixing system and a large cooling heat exchanger power.

Hardening of aluminum castings

Hardening is not suitable for all types of aluminum alloys. For a successful structural change, the alloy must contain components such as copper, magnesium, zinc, silicon or lithium. It is these substances that are able to completely dissolve in the composition of aluminum, creating a structure that has properties different from aluminum.

This type of heat treatment is carried out under intense heating, allowing the constituent elements to dissolve in the alloy, with further intensive cooling to their normal state.

Thermal transformations in alloys 6060, 6063, AD31

When choosing a temperature regime, you should focus on the amount of copper. Also, you need to take into account the properties of cast products.

In industrial conditions, the heating temperature for hardening ranges from 450 to 560 degrees. Holding products at this temperature ensures the melting of the components in the composition. The holding time depends on the type of product; for deformed ones it usually does not exceed more than an hour, and for cast ones - from several hours to two days.

The cooling rate during hardening must be selected so that the composition of the aluminum alloy is not subject to decomposition. In industrial production, cooling is carried out using water. However, this method is not always optimal, since when thick products are cooled, an uneven temperature decrease occurs in the center and along the edges of the product. Therefore, for large and complex products, other cooling methods are used, which are selected individually.

Aging of aluminum alloys

Aging is carried out to improve the strength characteristics of the product. This type of heat treatment involves exposure to normal temperature conditions.

An increase in strength is achieved by decomposition of the solid solution, which is necessary after hardening, since hardening leads to saturation of the metal.

There are two ways of aging aluminum alloys: natural and artificial.

Natural aging occurs without preheating at normal temperatures. This can happen in an ordinary warehouse or industrial premises, where the air temperature does not exceed 30 degrees.

Natural aging is possible due to a special property of aluminum called the “freshly quenched state.” The properties of products differ significantly immediately after hardening and after some time in storage.

Artificial aging is carried out by heating products to a temperature of 200 degrees. This activates the diffusion process, which promotes improved dissolution of the constituent elements. Exposure ranges from several hours to several days.

It should be noted that artificially aged alloys can be returned to their original state. To do this, you need to heat the product to 250 degrees and hold for up to one minute. Exposure must be carried out in a saltpeter bath at a strictly defined time, accurate to within a few seconds.

Moreover, such a return can be performed several times, without losing the strength of the material, but with a slight change in properties. The return of aged metal is usually carried out in order to restore the ductility necessary to change the shape of the product.

Any type of heat treatment is widely used in industry. Thanks to this, manufacturers have the opportunity to obtain materials that fully meet production requirements. Moreover, such processing of alloys can significantly improve the properties of aluminum and obtain a material that has no analogues.

The main condition for heat treatment is compliance with the requirements and recommendations for the processing temperature and holding time. The slightest deviations can lead to irreversible changes in the properties of the material.

If you find an error, please select a piece of text and press Ctrl+Enter.

Source: stankiexpert.ru

Aluminum alloys

These materials can be subjected to hardening - it increases strength and makes it possible to strengthen the workpiece by aging in the future.

(Picture 1)

Hardening leads to the formation of a supersaturated solution of alloying substances in a matrix solution of the base metal with a nonequilibrium structure. The hardening technology is as follows:

- The aluminum alloy is heated to the temperature of complete or partial dissolution of excess intermetallic phases in aluminum.

- Maintained at this temperature.

- Quickly cools to a temperature of 18-20 degrees.

The greater the degree of supersaturation with alloying elements, the higher the strength of the alloy.

Through artificial or natural aging, an unstable state is transferred to a stable one, and strength increases while the level of ductility decreases.