05.21.2019 Author: VT-METALL

Issues discussed in the material:

- What are the features of welding non-ferrous metals and alloys

- How copper and its alloys are welded

- How to weld aluminum

- What to consider when welding bronze and brass

- What are the features of titanium welding

At first glance, it may seem that welding non-ferrous metals and their alloys is not a difficult task, since melting them will not be difficult. But the fact is that when non-ferrous metals come into contact with oxygen, they exhibit increased chemical activity. In addition, their surface is covered with an oxide film, which prevents the reliable connection of parts of the structure. Normal heating in air leads to an increase in chemical activity, which is why you will not get the expected smooth seam, but only a melted area covered with a dense layer of oxide.

Features of welding non-ferrous metals

During the phase transition process, light components evaporate and burn out, which has a detrimental effect on the condition of the seam. It's cracking. Refractory oxides are another problem. Sometimes it is necessary to increase the operating current to break through the oxide. When welding non-ferrous metals and alloys, the melt often becomes too fluid; it is necessary to isolate the melt pool. For some alloys, it is necessary to limit not only contact with oxygen, but also other components of the air. Nitrogen is not suitable as a protective atmosphere for some alloys.

Aluminum

Aluminum in its pure form is in second place after iron, but its alloys are no less popular. The most common of them are silumin, duralumin and avial.

In addition to cleaning and degreasing the edges, preparing aluminum workpieces for welding includes the need to etch the parts for a couple of minutes in a solution of sodium fluoride (50/50 proportions), dip them in nitric acid for a couple of minutes and rinse with hot and cold water. The same algorithm allows you to prepare an additive.

Under no circumstances should abrasive materials be used for cleaning.

Due to its properties, both manual and automatic welding technologies are suitable for bonding aluminum. With the manual method, it is necessary to control the angle of inclination when feeding the filler wire, and perform the weld slowly from right to left. The automatic option is a little easier to perform and allows you to achieve a higher quality seam.

When processing thick aluminum workpieces, the optimal solution is to first make spot tack welds, and carry out thorough welding after these manipulations.

Non-ferrous metal welding technology

The preparatory stage consists of removing grease stains and cleaning parts from dirt. The oxides are cleaned to a shine, the surfaces to be welded are etched before work. Edges are formed on thick parts. Welding of non-ferrous metals and their alloys is carried out in the lower position; some melts resemble mercury in fluidity. The choice of electrodes and operating mode depends on the chemical composition of the alloy. When choosing a welding machine, it is necessary to correctly assess the weldability of the alloy, take into account the melting point, and the thickness of the workpiece.

Distinctive features

The welding process (type of connection and technology) of non-ferrous materials depends on their properties, namely:

- density;

- melting point;

- chemical activity;

- mechanical indicators;

- boiling point;

- thermal conductivity.

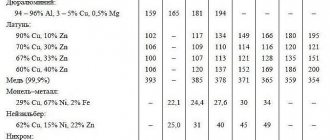

Some features of the behavior of non-ferrous metals and alloys during welding are reflected in the table.

| Properties | Possible manifestations and actions | Materials |

| Low melting and boiling points |

| Zirconium, brass, titanium, aluminum, bronze |

| Easy oxidation with the formation of refractory oxides |

| |

| Increased susceptibility of the molten alloy or metal to gas absorption | Weld Porosity | Everything, especially molybdenum, titanium, niobium, zirconium, tantalum |

| High thermal conductivity and specific heat capacity | Rapid cooling of the welding zone, which leads to the need for preheating of the object before welding and an increase in the thermal conditions of welding | Magnesium, copper, aluminum |

| High coefficient of linear expansion | Appearance:

| |

| Sudden decrease in mechanical properties during heating | Easy destruction of metal upon impact | |

| Collapse of the weld pool due to its own weight | Aluminum and bronze |

Aluminum alloys

Duralumin, silumin, avmel and other aluminum-based alloys vary greatly in weldability. Aluminum is welded with an electric arc using consumable and non-consumable electrodes, using equipment that generates direct current. The contacts are connected in reverse polarity. It is recommended to preheat the workpieces:

- thickness up to 8 mm – up to 200°C;

- over 8 mm – up to 400°C.

They weld aluminum at currents up to 200 A with sheet thickness up to 4 mm without preliminary cutting of edges. For workpieces over 4 mm, the edges are ground at an angle and cooked at currents 35-40 times greater than the thickness of the workpiece (up to 160 A). A high-quality gas environment is used so that the cloud does not move from the working area during the formation and hardening of the seam. The distance between the tacks is made taking into account the thickness of the workpiece:

| Workpiece thickness, mm | Interval between tacks, mm |

| 1,5 | up to 30 |

| 3 | up to 50 |

| 5 | 5 — 80 |

| 10 | 10 — 120 |

| 20 | 25 — 200 |

The refractory or carbon electrode that ignites the electric arc is held at right angles to the additive to prevent lack of penetration of the weld root.

Preparation for welding

Parts made of non-ferrous metal are welded after cleaning from the oxide film and cutting the edges.

The preparation is done as follows:

- Clean surfaces from grease stains using a solvent. Clean the edges with sandpaper or a wire brush until they have a metallic shine.

- Install the parts at a distance of 2-3 mm from each other. It is recommended to work in the lower position, since molten materials are characterized by high fluidity.

- Prepare a gas cylinder with a reducer. Argon or nitrogen is most often used.

- Purchase tungsten or graphite electrodes.

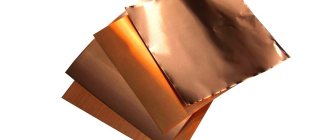

Copper and its alloys

Copper alloys, brass, and bronze are welded in several ways:

- electric arc welding in a nitrogen atmosphere;

- manual, semi-automatic, automatic argon;

- electron beam, creating high temperature in a limited area.

When welding non-ferrous metals up to 2 mm thick, a direct current of reverse polarity is required. As an additive, surfacing wire with a high content of deoxidizing agents is used. The thickness is selected according to the size of the workpieces being welded. The minimum diameter of the additive is 1.5 mm, the maximum is 8 mm. Welding of copper and non-ferrous alloys with high copper content is carried out:

- using a manual electric arc method using direct polarity current, the metal is welded with a short arc, 35 to 40 mm long, to reduce metal splashing (it is recommended to avoid transverse movements with the electrode);

- in an argon atmosphere with a current of reverse polarity; if the alloy melts up to 400°C, bronze wire is laid into the joint at high speed so that the workpieces do not overheat.

Borax or a mixture of borax with boric acid, table salt, and methyl borate is used as a flux.

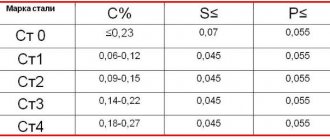

Welding carbon and alloy steels

Low-carbon and low-alloy steels have good weldability and can be joined by most welding methods without much difficulty.

Carbon and alloy steels, with a carbon content of more than 0.3% under standard welding conditions, undergo hardening. t.v. (probability of cracks).

To ensure good weldability during arc welding of these steels, the following technological measures are recommended:

- preliminary and subsequent heating of workpieces to a temperature of 100 - 300 ° C for the purpose of slow cooling and avoiding hardening. t.v.

- calcination of electrodes, fluxes at a temperature of 400 - 450 ° C for 3 hours and drying of protective ones to prevent hydrogen from entering the metal of the welded joint;

- low or high tempering of welded joints immediately after welding is completed in order to increase the ductility of hardening structures and the release of hydrogen.

Nickel alloys

Nickel-based non-ferrous alloys are characterized by high toughness and ductility. Nickel parts melt at 700–1000°C, the process is accompanied by saturation of the alloys with gases, the weld becomes porous and fragile. Although nickel is resistant to corrosion. When argon arc welding, electrodes with niobium, silicon, and aluminum are selected. The presence of manganese and magnesium in the melt is also desirable. The weldability of the metal increases and a strong connection is formed.

To work with nickel alloys, welding machines that produce a constant operating current are needed. Welding of nickel non-ferrous workpieces is carried out using a current of reverse polarity so that the shielding gas is ionized and the electric arc becomes more stable. With reverse polarity, the workpiece heats up less than the electrode. This is especially true for workpieces of small thickness. By adjusting the current potential, the temperature of the workpiece can be reduced.

Necessary equipment

The choice of a machine for working with non-ferrous metals depends on the welding method and the type of base alloy component.

The main devices include:

- work table or accessories for assembling and fixing the structure;

- welding machine;

- source of direct or alternating current;

- additional devices depending on the welding method;

- cable;

- gas-burner;

- hand tools;

- welder protection equipment;

- fire extinguisher.

Titanium processing

Titanium in the molten state reacts violently with three components of air: oxygen, hydrogen, nitrogen. It is necessary to reduce their content in the protective atmosphere to a minimum. The gas must be of high quality if you need a reliable seam. It must cool in a protective atmosphere to prevent cracks from forming. For welding titanium on an industrial scale, sealed chambers are used. When manual welding, it is necessary to shield the working area so that the cloud of inert gas does not move from the seam; argon or helium, mixtures must be of the first or highest grade. Due to its high density, the shielding gas will displace air. Welding equipment that generates direct current is used. Welding of non-ferrous metal is carried out with a current of straight polarity. The main thermal load is concentrated on the surface of the workpiece, the root of the weld deepens, the arc is maintained stably, and the metal spatters less.

Welding of high-alloy corrosion-resistant steels

The corrosion resistance of steel is ensured by the content of more than 12% Cr, and the content of 8% Ni stabilizes the austenitic structure and preserves it at normal temperatures (steel 10Х18Н9Т, etc.). When welding these steels in conditions that cause the metal to remain in the temperature range of 500–800°C for a long time, the metal may lose its corrosion resistance. t.v. The reason for this is the formation of chromium carbides at grain boundaries and the depletion of border areas of grains in chromium. As a result, the metal of the welded joint becomes prone to so-called intergranular corrosion (Fig. 1.

Rice. 1. Intergranular corrosion of steel

When arc welding, to prevent intergranular corrosion of welded joints, it is recommended:

- welding at low heat input (q/v, J/cm) using heat-removing copper pads;

- heat treatment after welding - heating to T = 1100°C and quenching in water.

When heated, carbides dissolve, and hardening fixes a purely austenitic structure.

When arc welding austenitic steels, hot cracks may form in the welds. To prevent them, it is recommended to introduce into welding materials (electrodes, wire) alloying elements Si, Al, Mo, Mn and others that contribute to grain refinement, and reduce the content of harmful impurities. Austenitic steels can be welded by resistance welding.

To ensure the tightness of tees, which were previously made from two pipes with shaped cutouts and butt welding, a new technology was introduced into production - cold drawing of the edge of the shaped hole of the main tee pipe. A side pipe is welded to the cylindrical flange formed after drawing using a resistance welding machine. Thus, a product was obtained using a fundamentally new technology with a sealed weld (Fig. 2).

Rice. 2. Resistance welding of stainless steel

Works with magnesium

For magnesium parts, the entire edge is boiled. To work with workpieces thicker than 10 mm, you need powerful welding equipment operating from a three-phase network with a power of 380 V, generating alternating high-frequency current. During periods of reverse polarity, the arc breaks through the oxide film and it melts. When working, it is recommended to use pads with low thermal conductivity.

Welding of magnesium and non-ferrous metals based on it is carried out under the atmospheric protection of helium or argon; it protects the melt from saturation with nitrogen, the weld does not bubble, and scale does not form on it. The supply of gas to the working area begins before the arc is ignited, and is stopped 20 seconds after extinction, when the upper part of the seam has set.

Precautionary measures

When working with non-ferrous metal, observe the following rules:

- Wear a work suit, welding mask and gloves. In production conditions, in the absence of protective equipment, a permit is not signed.

- The room is well ventilated. It is advisable to provide forced ventilation. Volatile compounds released during welding are dangerous to humans.

- Due to the high thermal conductivity of materials, workpieces are heated before welding. For this purpose, special ovens with sensors that control the heating temperature are used.

Welding of dissimilar non-ferrous metals

The complexity of the process lies in the limited mutual solubility. When welding non-ferrous metals and alloys together, several technologies are used to ensure reliable connections:

- the seam is formed by exposing the parts to a pulsed electron beam, the rate of heating of the workpieces increases, and at high temperatures the parts set;

- when pressure welding, non-ferrous metal is heated due to the energy released during plastic deformation of the structural lattice, concentrated thermal energy accumulates in the contact zone, the parts do not need to be additionally heated;

- for welding non-ferrous dissimilar non-ferrous metals, an intermediate layer is used that adheres to the workpieces, the risk of weld embrittlement is reduced;

- In an argon environment, automatic, manual and semi-automatic welding of dissimilar non-ferrous metals is carried out; the electrode is held perpendicular to the parts so that the weld is of high quality.

The shielding gas reduces the degree of oxidation and saturation of the non-ferrous metal with nitrogen and hydrogen. High temperature internal technologies increase welding speed. Due to the fluidity of non-ferrous metals, the voids are filled and the joint is welded through. When selecting a buffer layer, the component composition of the workpieces and the melting temperature of the alloys are taken into account.

Having an argon welding machine, you can repair parts made of non-ferrous metals yourself. In industrial settings, advanced technologies are used that do not allow the molten metal to react with air.

Lead Welding

The main reasons for the difficulty of welding lead are its low melting point and the formation of refractory oxides with a high melting point. Applicable welding types:

- Gas acetylene-oxygen . Fluxes and filler lead wire or strips of sheet lead are used.

- Manual arc with a carbon electrode in a protective gas environment with non-consumable and consumable electrodes . Produced with a short arc. Current is constant, polarity is straight.