There are a wide variety of types and types of welding. But they all have one thing in common - the need to use an electric arc, without which the formation of a seam is impossible. And among the wide variety, MIG/MAG welding using gas is one of the most popular.

This type of welding is simple and easy to use, it is suitable for both a novice welder and an experienced welder. Using instant welding, you can easily weld different types of metals, with different thicknesses and any complexity of seams. In this article we will tell you what MIG is and what are the features of shielded gas welding.

Definition

MIG/MAG welding (also known as electric arc welding in a gas environment, arc welding in a shielding gas environment, also known as magic and mig welding, GMAW) is semi-automatic, manual and automatic welding in a shielding gas environment using the fusion method (GMAW stands for “Gas metal” Arc welding").

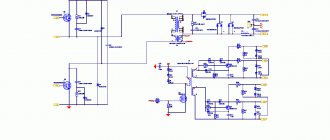

Below is a schematic diagram of TIG (tig welding) and MIG/MAG welding. You can compare them and understand what the differences are.

MIG/MAG welding is only possible with direct current, but the polarity can be either direct or reverse. You may have noticed that in addition to MIG, we also use the abbreviation MAG in this article. MAG is also semi-automatic welding, only using carbon dioxide.

With magic welding everything is the same as with mig. Only instead of, say, argon, carbon dioxide is used. It's much cheaper. But with the help of such welding, only parts made of alloy and low-alloy steels can be connected. This is a limitation. So choose professional semi-automatic machines that can work in both MAG and MIG modes. Such devices give you more possibilities; you can use filler wire of any diameter in your work.

Now that we know what mig is, it's time to find out what equipment will be optimal for this method.

Pros and cons of semi-automatic welding

The advantages of semi-automatic welding are obvious, and first of all, it is the high speed of welding work. The length of the welding wire is large, and the volume of gas in the cylinder is also large. Thanks to the automatic supply of wire to the welding site, the speed and scale of welding work increases significantly.

The second plus is associated with a very neat and smooth weld seam. It is impossible to obtain such a seam using manual arc welding, just as it is impossible to effectively weld very thin metal. Semi-automatic welding is the best way to weld thin-walled workpieces, the thickness of which does not exceed 0.5 mm.

The only disadvantage of semi-automatic welding is the need to have shielding gas in a cylinder on hand. It goes without saying that the cylinder needs to be refilled and transported to the welding site, which is not very convenient or simple.

In addition, in some places it is not possible to deliver the cylinder at all. Then semi-automatic welding is carried out using flux-cored wire.

Equipment and components

So, for work we need a standard semi-automatic machine. A set of welding equipment consists of a semi-automatic machine, a transformer (generating current), gas (a reducer must be attached to the cylinder to regulate the pressure), various hoses and cables, a gas torch equipped with an additional filler wire supply system and a feed mechanism.

MIG welding is essentially the same as gas shielded consumable electrode welding. Only instead of an electrode, a filler wire is used here. Most often the wire is made of aluminum. We recommend choosing wire made from the same material that you are going to weld.

The wire is wound onto a drum and automatically fed into the welding zone. The feed speed depends on the wire diameter and the current setting you set. All you have to do is point the torch at the welding zone and press the button.

The wire will begin to feed into the welding zone immediately after the arc is ignited. At the same time, the gas will begin to blow over the weld pool, preventing metal oxidation and the formation of defects. Drawing analogies with other types of welding, in our case the gas plays the role of a coated electrode, as in standard MMA welding. Only here the gas is supplied from the outside, and in MMA welding it is formed when the electrode melts.

What is semi-automatic MIG/MAG welding?

Unlike a conventional MMA inverter, which welds exclusively with a coated consumable electrode, the operating principle of semi-automatic welding is somewhat different. The main consumables here are shielding gas and wire, which is wound on a reel and fed automatically when the semi-automatic machine is operating.

During welding, the wire passes through a gas gun. At the moment the arc appears, it melts and fills the weld pool with molten metal. The gas, which is also supplied along with the wire, protects the molten metal from the negative effects of the environment.

Due to the fact that the entire welding process is practically automated, this welding received such a consonant name - semi-automatic. Unlike manual arc welding, there is no need to change the electrode every time. There are also no many other operations, without which the process of welding parts with an electrode cannot take place.

Advantages and disadvantages

The MIG welder is often criticized for being bulky. You can’t just hang it on your shoulder; you’ll have to carry a huge gas cylinder and other components with you. You will not be able to quickly move from one point to another unless you install the entire set of equipment on a special cart.

But, despite this, instant welding has many advantages that more than offset the disadvantages. For example, during operation no dangerous fumes are emitted, the arc is quite easy to ignite (beginners will appreciate this plus), the wire is consumed very economically, and it is possible to weld almost any metal of any thickness.

Welding technology

Set the voltage to no more than 30V. The optimal value is from 18 to 30V, selected individually depending on your welding machine. Also note that in most cases, your semi-automatic welding machine will not have the function of manually adjusting the wire feed speed. This is not a breakdown or a defect, it is necessary to stabilize the arc.

For professionals, the inability to manually adjust the wire feed can be a problem, but believe me, it is very convenient. The feed mechanism is complex and technologically advanced; it relieves the welder of unnecessary manipulations and allows him to concentrate on work.

For example, the wire feed mechanism in a semi-automatic machine for MIG/MAG welding itself determines at what moments it is necessary to slow down or, conversely, speed up the feed so that the arc is more stable. The mechanism also protects the wire from melting into the burner. With this mechanism, the wire will never stick to the torch or to the connection when first fed. Also, thanks to the automatic feed mechanism, pulse welding can be performed.

In most cases, MAG/MIG welding will be done using reverse polarity and constant current, as these settings are most optimal. But if you have enough experience and are willing to experiment, you can install straight polarity and alternating current.

Also, more or less advanced machines have several operating modes. Let's look at them in more detail:

- "Short Arc" mode. Suitable for thin metal applications where current less than 200 amps is used.

- Spray Arc mode. This is the most universal mode, used when working with wire with diameters greater than 1 millimeter.

- Pulse Arc mode. Used when working with large diameter wire. Ideal for welding steel and aluminum.

- Pulse on Pulse Arc mode. Suitable for creating extremely aesthetic seams.

Peculiarities

Semi-automatic MIG MAG welding is effective only if all rules are followed and all features are taken into account. We will talk about some of them further.

Selecting a device

First, a little about the equipment. MIG MAG welding machines perform specific tasks, so you need to choose a welder with special attention. First of all, pay attention to what current the device operates on: direct or alternating. We recommend purchasing a DC device and installing reverse polarity when performing work.

A semi-automatic welding machine using alternating current or direct current and straight polarity is not capable of generating a stable welding arc. Under such conditions, it is difficult to form a weld because the filler wire melts too quickly and the metal spatters.

Also pay attention to additional functionality. Many MIG/MAG welding machines can also perform MMA or MMA and TIG welding. Such welders are universal and significantly increase your capabilities when carrying out work. You don't need to have several different devices when all the functions are in one.

Selecting consumables

Now about consumables. First about the wire. Its diameter is selected based on the thickness of the metal you are going to weld. The composition of the wire must be identical to the composition of the base metal. Copper wire cannot be used for welding stainless steel. This is a grave mistake.

As for the shielding gas, everything is not as complicated as it might seem at first glance. You can use inert, active gas or gas mixtures. We will give several recommendations regarding the choice of shielding gas when welding various metals.

For welding non-ferrous metal and its alloys, as well as non-ferrous metal-based materials, it is best to use inert gas. This can be helium, argon or gas mixtures of argon and helium in various proportions. If you are boiling copper and cobalt, use nitrogen gas. When working with various types, it has become better to use carbon dioxide (carbon dioxide). But keep in mind that in this case the wire must contain an increased amount of silicon and manganese.

Experienced welders also use mixtures of inert and active gases to improve arc stability and reduce metal spatter. This is a very specific topic that comes with experience. So in this article we will not touch on the topic of a mixture of inert and active gas.

Seam formation

When MIG/MAG welding, it's not just the welding machine and consumables that are important, but also how you form the weld. As we already wrote above, with this welding method, the seam is formed thanks to molten metal and molten wire. Therefore, the shape of the finished weld bead depends on how you transfer the molten wire into the weld pool.