It is possible to ensure high-quality connection of aluminum parts only by TIG welding. A regular electrode can weld aluminum alloy for strength, but it will require longer post-processing. Welding aluminum with argon allows you to work with material of different thicknesses, creating neat seams with good sealing properties. This is especially in demand when repairing cars, boats or various containers. But how to cook this specific material for the first time? How to set up equipment when welding aluminum? A short guide from the article and video lesson will help you master this complex matter.

What must be considered when argon welding aluminum?

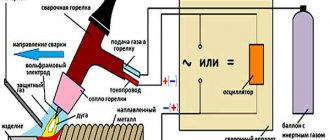

Argon welding is quite universal, which allows you to join different thicknesses of materials using this method and work with alloys that are considered difficult to weld. The basis is an electric arc burning between a tungsten electrode and the product. Its appearance is ensured by direct or alternating current supplied to the torch and the mass attached to the parts being welded. The inert gas acts as a protection for the weld pool. But aluminum and its alloys have a number of specific features that need to be known and taken into account when welding.

One of the difficulties is the oxide film that forms on the surface of the material. It appears when metal interacts with oxygen. The film melts at a temperature of 2000 degrees. But aluminum itself begins to take on a liquid form after 500 degrees. Therefore, by choosing too high a current and melting the oxide, it is impossible to weld. By setting small parameters on the device, it is not possible to begin the process of creating a weld pool at all. Therefore, argon arc welding of aluminum involves preliminary cleaning of the metal surface from oxide. This is achieved with a special brush or solvent, after which it is necessary to immediately begin the welding process.

An additional difficulty is the hygroscopicity of the material. When the ambient humidity is high, aluminum absorbs some of the water from the air. When the product begins to be heated by an electric arc, the material being welded releases moisture to the surface. This may affect the quality of seam formation, the density of contact with the product, and low-voltage pinching of the welder in contact with wet areas. Although you can cook with argon immediately, it is recommended to slightly heat the material with a gas burner at a temperature of 150 degrees. This will allow excess moisture to evaporate and improve the welding process.

Argon welding of aluminum also requires good protection of the molten metal from external air. To do this, you need to set the correct gas flow. Insufficient supply of the latter will lead to foaming of the metal and burning of tungsten. Excessive argon purging will interfere with weld formation and will make the process more expensive.

Another difficulty for novice welders is the formation of a funnel at the end of the seam. If the arc is abruptly interrupted, a crater appears. Holding the torch in one place for a long time leads to unnecessary heating and expansion of the weld pool. Therefore, argon-arc welding of aluminum alloys requires additional settings for the arc attenuation mode, which gradually reduces the current strength. Taking into account these characteristics of the material, you can correctly set the voltage parameters and make a high-quality seam with your own hands.

Preparation of base and filler metal for welding

Preparation of weld edges

Before welding, aluminum edges must be cleaned of the oxide film on the surface of the Al2O3 metal, which has great hardness and a high melting point. This film does not melt in liquid aluminum, since its melting point exceeds not only the melting point of aluminum, but also its boiling point. The film can be removed mechanically or chemically, but this must be done immediately before welding, because the film again very quickly forms on the surface after cleaning.

The quality of welded joints largely depends on the choice of structural elements for cutting edges. According to GOST 23949, depending on the thickness to be welded, the following edge groove shapes and seam sizes are recommended:

When the metal thickness is less than 5 mm, butt welding is performed without cutting on pads (diagram a) in the figure).

When butt welding sheets with a thickness of 5-15mm, a cup-shaped cutting with an opening angle of 30-40° on each side and a radius of 6mm is recommended (diagram b) in the figure). It is recommended to make the weld seam from the reverse side.

If you are welding sheets with a thickness of 5-20mm, then a double-sided cutting with an opening angle of 20-30° on each side and a blunting radius of 6mm is recommended (diagram c) in the figure.

When welding large metal thicknesses, more than 20 mm, a double-sided cup-shaped groove with an opening angle of 25-30° on each side and blunting of the edges is recommended. The amount of blunting is 6 mm (diagram c) in the figure.

Preparing wire and rods for welding

Particular attention should be paid to cleaning the welding wire from the oxide film. The best method is electrolytic polishing. But after processing, the film immediately begins to oxidize again. To prevent this, it is packaged in polyethylene. And it is in this form, according to state standards, that wire for aluminum welding is supplied. Rods for manual argon-arc welding of aluminum after processing are stored in sealed cases.

Welding technology for beginners

The process of argon welding of aluminum is performed not with direct current, but with alternating current. This way you can achieve better results. It is better to start your first seam on the training surface:

- It is necessary to set the plates in a comfortable position. Edge cutting is performed according to the same parameters as other types of metals.

- It is advisable to heat the material to 150 degrees to remove moisture.

- The top refractory layer is removed with a brush. As an alternative, you can use a solvent.

- The burner is brought to the product so that there is 3 mm between the electrode and the surface. The button is pressed and the arc is ignited. The fluidity of aluminum depends on the impurities in the composition.

- If a small puddle of molten metal (weld pool) occurs, an additive can be supplied to the welding zone.

- The burner must be directed evenly, from right to left. Oscillatory movements will be needed in the case of a wide seam. On alternating current, a characteristic welding noise will be heard.

- When the seam is completed, the button is pressed and the arc fades out smoothly. The torch is held above the welding zone until gas flow has completely stopped.

Necessary equipment for welding

We will not talk about the essence of the TIG welding method here; we will only note that tig welding of aluminum is feasible if you have:

- welding machine;

- tungsten electrode;

- protective gas (argon);

- filler wire.

Welding power source

When argon welding aluminum with a tungsten electrode in a shielding gas, alternating current (AC) is used. It serves to create a better quality seam. Let's see how it works:

- When crossing the mark, an arc is lit;

- With a positive half-cycle, the oxide film of both the base metal and the filler rod is destroyed;

- During the negative cycle, the arc acts on the aluminum itself, heating it. The tungsten electrode cools;

- Polarity changes occur up to 100 times per second at a frequency of 50 Hz.

On modern argon-arc machines for aluminum welding, at least two adjustment functions are provided:

- frequency adjustment

- change AC balance

We recommend! Methods for monitoring welds and joints

For performing tig welding at home, welding machines such as Brima TIG or Svarog TECH TIG are quite suitable. These are universal power sources that can be used for other welding operations, for example, for processing ferrous metals. They are unpretentious and easy to use. They allow you to carry out welding work even in an apartment, of course, subject to safety measures.

Tungsten Electrodes for Aluminum

To join aluminum under such conditions, it is necessary to use non-consumable tungsten electrodes, which are made using alloying additives.

Electrodes are distinguished by the type of additives added to their composition. This determines the brand of the electrode to distinguish them from each other; their ends are painted in different colors. There are several types of electrodes that are necessary for aluminum welding:

- WC 20 (gray);

- WT 20 (red);

- WL 15 (yellow)

Usually, the electrode is sharpened before welding to easily excite the arc, and during operation it takes on the shape of a ball.

Shielding gases

Used to protect the weld pool from the harmful effects of atmospheric oxygen. The most common is the inert gas argon (Ar), hence the name of the process. Its use is due to its low cost and prevalence.

Better penetration and increased welding speed are achieved by using helium or a mixture of these two gases (He). Read on to learn how to cook aluminum with argon.

Device setup and modes

TIG welding of aluminum is possible only where the machines support operation not only with direct current, but also with alternating current. Despite the frequency of voltage fluctuations, the best seam is obtained with the last setting. Polarity can be either direct or reverse. Voltage parameters can be set based on the thickness of the material:

| Plate thickness, mm | Current strength, A | Diameter of tungsten electrode, mm |

| 1 | 30 — 40 | 1.6 |

| 1.5 | 45 — 60 | 2.3 |

| 2 | 70 — 80 | 2.3 |

| 3 | 90 — 120 | 3.2 |

It is important to install the current supply in a stepwise manner, with a smooth ignition, an ascending value during the welding process, and a gradual attenuation when combustion is completed. This will avoid creating a crater at the end of the connection.

The argon consumption during welding is set on the pressure gauge closest to the gas hose. Russian models need to be installed in the range from 6 to 11 liters. This is the error of the measuring device, which is brought to the optimal value only by practical means. If the pressure gauge is imported (German, Czech), then you can immediately supply 8 liters.

In the device settings, it is important to set the subsequent gas purging time after the arc stops burning. The duration of argon supply is set to five seconds, which gives enough time for the bath to solidify and cool the electrode.

Application of pulsed arc welding

Pulse-arc welding allows you to increase the productivity of welding work; thanks to this technique, a directed jet transfer of metal is created, its spatter is reduced, and the stability of the electric arc also increases.

The use of pulsed arc welding is very promising for welding aluminum structures. Due to the high energy concentration in the pulse, with optimal timing of pulses and pauses, it is possible to ensure stable penetration and correct formation of the weld root, as well as significantly reduce welding deformations.

When welding metal 6 mm thick with a consumable electrode with a diameter of 1.6 mm, the following modes are recommended: pulse repetition rate 100 pulses/s. Current strength I=160-180A, operating voltage U=18-21V, welding speed v=18-25m/h. Welding is done in one pass.

When welding thick metal, it is recommended to use electrodes with a diameter of more than 2 mm. For example, using wire with a diameter of 4 mm, you can weld aluminum alloys (type AMg-61) with a thickness of 90 mm using an X-shaped groove in 5 passes under the following welding modes: I = 450-500 A, U = 22-25 V, v = 21-24 m /h.

Welding large thicknesses due to the high thermal conductivity of the metal requires preliminary and concomitant heating to a temperature of 150°.

Selection of filler material

Since aluminum melts relatively quickly, if you choose the wrong diameter of the filler wire, you may not have time to feed it into the welding zone and form a seam. Therefore, the thickness of the solder should be the same as the thickness of the plates being welded. It is also necessary to be careful when choosing the chemical composition of the filler material. For example, a product made of duralumin cannot be welded with a rod for food-grade aluminum. A table with filler wire numbers and its purpose can help:

| Additive marking, no. | Purpose |

| 1070/1100 | AD1, AMts. |

| 5754 | For welding aluminum with magnesium admixture. |

| 1450 | For alloys used in aircraft construction. The additive is equipped with a titanium inclusion that strengthens the seam. |

| 5183 | For food containers and shipbuilding. |

| 5554 | For wheel rims and containers in the chemical industry. |

| 4043 | For alloys with silumin used in construction. |

Electrode selection

The technology of welding aluminum with argon also requires the correct choice of a tungsten electrode, the diameter of which should be as close as possible to the thickness of the parts being welded. Sharpening is done in the classic way, but without a sharp tip, as is the case with stainless steel welding. During the first seconds of combustion, the electrode will take the shape of a drop at the end and the seam will have to be made this way. The projection from the nozzle is required to be 3-5 mm to avoid overheating of the tungsten. When welding, small spatters of aluminum will stick to the electrode, requiring re-sharpening.

Learning to weld aluminum is not easy. But knowing the above principles and watching videos with lessons from experts, you can confidently try your hand at practice.

Selecting a welding method depending on the thickness of the aluminum being welded

Welding of aluminum in argon can be done with consumable and non-consumable electrodes. The non-consumable electrode can be used for manual, semi-automatic and automatic welding. To improve arc stability, it is recommended to use oscillators or pulse exciters. In this way it is advisable to weld metal up to 10-12mm thick. For large thicknesses, it is economically unacceptable due to low productivity, as well as due to the strong overheating of the heat-affected zone, therefore, consumable electrode welding is used.

To weld metal with a thickness of 0.5-2.0 mm, as a rule, single-pass welding without filler metal on removable or remaining backings is used. In this case, it is not recommended to bring the end of the filler rod outside the gas protection to avoid its oxidation. The arc length should not exceed 2.5mm.

Welding of metal 6-8 mm thick is carried out using the “left method” to reduce overheating of the metal being welded.

For welding metal with a thickness of 8-12 mm, it is already recommended to use consumable electrodes. But if welding with consumable electrodes is not possible, then the “right” welding method is used to facilitate observation of the process.