Nowadays, using a welding machine in everyday life has become quite common. Previously, welding even for the simplest household purposes was the work of professionals. Now the level of development of welding machine technology is high enough that all work can be done at home. Special education to master the art of welding is also not necessary, since to successfully perform simple welds, it is enough to familiarize yourself with a small amount of information and master some practical welding skills.

One of the best solutions for household welding would be to purchase an inverter-type welding machine Foxweld Master 202. We will show and explain below how to use it correctly and what the welder itself is like.

foxweld master 202 price.

Welding current wires

This device belongs to the middle budget class. On average, the price ranges from 17,100-1,800 rubles in the online store. Read the short description below and also watch the video review.

Forced cooling fan

foxweld master 202 reviews

Having read the experience of people who have used this device, they recommend it as a good long-lasting inverter. But nevertheless, there are also disadvantages: a short cable that becomes dull at low temperatures and bursts, an inconvenient holder. The device could withstand operation at -25 °C. Workers prefer this device to Resante, as it works better and is softer. Master 202 is one of the most popular inverters in Russia. In the first days of operation, users are satisfied with the performance of the device, characterizing it as a fairly high-quality Chinese product that is worth the money. Works well with three and four millimeter electrodes. Some people complain about the short arc of the device, but this can be attributed to the inexperience of users. Typically, workers use the device for years and it serves them well in their summer cottages and in the development of small businesses. The Foxweld 202 inverter belongs to the Italian Foxweld, but all parts and equipment are assembled in China, undergoing three-stage testing. In Russia, the equipment has all the necessary certificates.

Inverter appearance

How to properly connect an inverter

Before you start using the device , you must check all included components for integrity. Using an external inspection, check the integrity of the power cables and the grounding cable. Make sure that the cables are securely connected to the device. Inspect the fan; there should be no blockages or unnecessary objects in it. If work takes place indoors, it is necessary to ensure a constant flow of fresh air.

After switching on, under no circumstances should you cover the device with any materials, especially those with a dense structure. There may be cases when, for some reason, the power wires fail, wear out, or disappear altogether. To make new ones, you will definitely need to select the cross-section of the conductive parts of the wire. If the length of the wires is less than 5 meters, the cross-section must be at least 16 squares. If you want to increase the length of the power wires, choose a cross-section of 25 squares.

Do not reverse the polarity of the rods before connecting (the polarity is indicated in the instructions for them). The grounding clamp is marked “minus”, and the electrical holder clamp is marked “plus”. The grounding clamp should be located as close as possible to the work site.

Be sure to check the mains voltage , whether it is coming to the inverter and what value it is. There is an indication on the welder panel, and the power indicator indicates the device is ready for operation.

After all the necessary checks, we switch the switch to arc welding mode (MMA toggle switch). Afterwards, you need to select the amount of current necessary and sufficient to carry out welding work under the given conditions and requirements.

Upon completion of welding work, be sure to turn off the device and remove the working rod from the clamps.

The master 202 welding machine is capable of operating in DC argon arc welding mode or so-called TIG welding. This requires special tungsten electrodes and a number of actions:

- Attach the grounding wire to the part to be worked on.

- Attach the cable from the burner to the negative contact.

- Connect the hose to an argon cylinder through a reducer to regulate the gas supply pressure.

For different currents of work, it is necessary to select a certain diameter of tungsten rods. Moreover, the greater the current, the larger the cross-section of the rod should be. At currents from 10 to 200 A, the diameter of the rod should be 2 mm, 60-150 A - 1.6 mm, and up to 80 A - 1 mm.

The ignition of the arc occurs after the rod comes into contact with the part and is gradually withdrawn from the part. Next comes the actual welding. The work is stopped by increasing the distance between the torch and the workpiece, while the gas supply is turned off 5-6 seconds after welding is completed.

foxweld master 202: inverter made in China.

The foxweld master 202 inverter weighs about 8 kg. The device is used for surfacing and stick electrode welding using direct current. Like similar models, foxweld master is distinguished by high efficiency, economical energy consumption, and stable arc burning. Can be used both outdoors and indoors while maintaining safety rules.

The foxweld master 202 welding inverter has several operating modes, which will allow you to perform any type of work from minor repairs to professional needs.

The foxweld master 202 welding machine also has a set of additional accessories.

Popular inverter models

The Foxweld brand has a fairly large assortment, but we will highlight the most popular models from this manufacturer: welding inverter Foxweld Master 162, welding inverter Foxweld Master 202, welding inverter Foxweld Master 162, welding inverter Foxweld Master 202M, semi-automatic welding machine Foxweld Invermig 185.

Let's talk in more detail about the Foxweld Master 202 welding machine, since it is one of the most popular among the entire range of the Foxweld brand.

The Master 202 inverter from Foxweld is designed for manual arc welding and produces up to 200 Amps of welding current. The device is capable of working up to 60% of the welding cycle without interruption, which is not so much, but this is enough for a beginner.

Device description: FoxWeld Master 202 front panel

Front panel with display and switch off switch

- Reliability of equipment, possibility of autonomous use;

- slight metal spattering;

- forced cooling system;

- there is an anti-stick function for the electrode so that it does not stick to the base metal;

- there is a “Hot Start” option for quickly obtaining an arc;

- “ARC FORCE” function for stable arc burning;

- resistance to high humidity;

On the front side of the device there is a special a yellow lamp that lights up when the voltage in the network changes; if the protection is triggered, the device will be turned off for a while.

Is it worth buying?

In our opinion, Foxweld devices are quite typical Chinese inverters. They are foldingly made, the manufacturer saves almost no money on components. The assembly is decent for their price, and the functionality is also sufficient. The same welding inverter Master model 202, which we talked about above, is very popular among welders.

But you must understand that when buying an inexpensive Chinese device, miracles will not happen. It will not become number one, it will not be able to cook in the same way as devices from European manufacturers, and with frequent use it will be prone to breakdowns. Foxweld devices and others like them are, in fact, just copies of other Chinese devices, only under different names. It's not bad, and it's not good. Just a fact to consider.

Can I buy Foxweld inverters? Can. Beginners especially like such devices because they are inexpensive and at the same time quite functional. But you should not rely on the excellent quality of the seams and the devices themselves from this manufacturer.

Specifications:

Idle speed is 59 volts, welding current is adjustable over wide intervals (from 20 to 200 amperes).

To operate, you need a mains voltage of 210-255V, minimum value 180V. This device received excellent arc ignition, a good appearance of the weld, a uniform droplet shape, and good current characteristics. This is achieved thanks to the operation of power modules at a purity of more than 80 kilohertz, where the response value does not exceed 500 milliseconds. Without emergency on. Foxweld Master 202 at the maximum welding current (200 amperes) is 60%.

Advantages of foxweld master 202, Italy:

Equipped with forced ventilation of all components

- there is thermal protection

- electronic scoreboard

- slots for hot air are made

- There is a 140 mm fan in the rear.

- robust housing

- rubberized plastic handle

- smooth adjustment of welding current, easily adjusted by switch

- budget solution

- The device is turned off with the front toggle switch

- the display does not change its readings, as for example on Resant (the values remain unchanged during the process)

Minuses:

- heavy weight -8 kg.

- uncomfortable grip;

- a short cable that breaks at sub-zero temperatures;

External device of the welding inverter:

The standard rectangular inverter shape is limited to a metal casing with air openings. On the front side there is a panel for regulating the welding process, and there are also all the necessary indicators. It is convenient to carry the device thanks to a special rubberized handle.

Master Problems 202

If you notice any changes in the operation of the device, for example, the light does not light up, you should stop working immediately.

- if the circuit breaker fuse is turned off, the automatic plugs on the electrical panel should be replaced with a value of 25-35 amperes;

- if the foxweld master 202 inverter begins to emit a burning smell, it should be turned off immediately and taken for repair;

- if your electrode often sticks, you should increase the current;

- If the arc does not light up, but the fan and green signal are working, you should check the welding current regulator (position OA).

You should beware of various fakes foxweld master 202

since this can lead to bad consequences. Always use original equipment, not counterfeits. This will save you money and health

Common problems and their solutions

Here are examples of simple problems ; in more complex cases, it is better to immediately send the device to a repair service. For example, if the ready-to-work light stops lighting or mild electric shocks occur. If there is a burning smell from the inverter and, moreover, smoke appears from the device, the best solution would be to contact a specialist.

- Often, when a circuit breaker is turned off, it is enough to simply change the plugs.

- The arc does not light up, but the cooling fan is running and the welder's readiness indicator shows that everything is in order with the device. Most likely, the current is not set, look at the current adjustment, it is probably in the 0 A position.

- The electrode began to “stick”; in most cases, the situation will be corrected either by increasing the current or by changing the welding angle from strictly vertical to an angle of 45 degrees to the part.

- The yellow indicator lights up, indicating that the device is overheating - just stop working and wait until the device cools down and the yellow signal goes off. This will mean that the device is ready for use again.

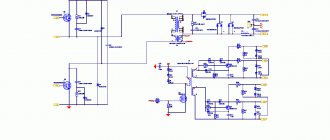

Electrical diagram foxweld master202

PSU circuit foxweld master202

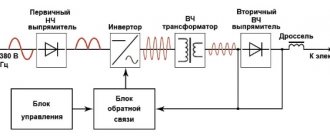

Block diagram foxweld master 202

General electrical diagram foxweld master202

Advantages and disadvantages of the device

Among the advantages are its low cost, ease of use, and the ability to support argon welding. In addition, the welder is quite easy to repair. All electronics are located on one board; its simple replacement will solve any, even the most complex, problem with electronics.

The disadvantages include power cables; they are of little use for our climatic conditions. At low temperatures they quickly become tanned, become completely inflexible and inconvenient to work with. Many users note that the carrying holder is inconvenient. The device is quite popular in Russia, so very often it may turn out that your Foxweld Master 202 is a fake. Beware of fakes of foxweld master 202.