Why do you need such a procedure as tightening the shock absorber springs with your own hands? Due to the current circumstances and because of our vaunted domestic roads, it happens that shock absorber units in a car, even an almost new one, fail. And if they are old enough, they wear out from time of use.

Any car enthusiast can carry out these repairs; you just need to have certain skills and an aptitude for using tools. But first we will need a shock absorber spiral tie, and, therefore, a puller to make this work easier.

DIY shock absorber spring tensioner

Quite simply done in a garage. Each shock absorber system includes coil elements called springs. They help withstand the loads during vehicle operation, maintain the proper level of the body above the road surface, and, first of all, in the case of constant increased loads, are subject to wear.

If the shock absorber is in order, but the spring element has failed, worn out, or lost its rigidity, it must be urgently replaced. This operation can be done with a special puller (or in the opposite situation, when the shock absorber needs to be repaired, but the spring seems to be in order).

There are many options for this device. A fairly common one is rack and pinion. It consists of two slats made of metal with threads. There are hooks on both sides that go towards each other when turning. The hooks cling to the spring and produce a tie when the rack rotates. It must be scrolled, and the spiral contracts, freeing up space for inspection.

Alternatively, you can use a belt puller. It requires a pair of “frog” fastenings, they are tucked into fairly strong fabric belts. The belts themselves are threaded into the lower and upper coils of the spring. The “frogs” are squeezed one by one. The belts are tensioned and the spring is compressed.

Without these devices (or their other options, homemade or purchased at a car store), this procedure becomes difficult to complete.

To perform the work, it will be necessary to remove the stands with the device. Place the car, jacking it up and fixing the position (you can put it on special stands made from a block or welded ones - for greater stability of the car).

- Having freed the shock absorber, we proceed to tighten the springs using the puller described above. Regardless of its type and design, we attach it to the lower and upper coils of the spring and begin working with our hands;

- We scroll or work with “frogs” until the part is noticeably compressed. It should be noted that it is not recommended to fully compress the spring. This may increase the risk of failure of either the fixture or the part itself. You need to do everything as carefully as possible, simply releasing the element from the pressure in order to make repairs or change a shock absorber fragment.

Thus, the device itself - the puller - is designed to make life easier for the auto mechanic. After all, without using a puller, the stand would have to be secured in a vice and a lot of force would have to be applied to compress the spring.

It is also necessary that the part be additionally held while you work on the shock-absorbing unit. And with the use of a spring remover, these problems go away, and even one person can carry out the repair in a garage or box. In addition, using this procedure will protect the technician from possible spring failure, practically eliminating it.

Of course, the easiest way is to replace the entire assembly at once. Or, if you have enough free funds, turn to the specialists at the service station so that they can do everything efficiently and on time. But you will have to pay a pretty good price for carrying out repair work of this level. In addition, some car enthusiasts prefer to do any available work exclusively on their own.

These types include various repairs of struts, the main part of which is the shock absorber. And tightening the shock absorber springs with your own hands is a priority task that needs to be solved in such cases.

It can be solved quite simply using a device called a puller. It not only compresses the shock absorber spring, opening access to the necessary repair work. This is also a safe way to tighten the spring without any problems or risk of failure, allowing you to carry out repairs yourself in a garage.

How to make a simple and reliable shock absorber spring remover

We tell you how to make a simple but reliable homemade puller

, with which you can easily and quickly remove springs from shock absorber struts (

compress

and decompress them). Let's look at two different designs that every craftsman can make.

But first, let's look at the main types of these devices. If we talk specifically about factory pullers, there are several types:

Factory models of pullers can always be purchased in the store, but there is not always a reason for this.

For example, if you need to replace a shock absorber strut

or

a spring

1-2 times, it is cheaper to make a homemade design.

You will learn how and what to make a stationary puller for compressing springs

. Thanks to its compact size, it can be installed both on the floor and on a desktop (workbench).

In terms of safety and reliability, a stationary puller is the optimal solution for performing repair work in a garage.

Also in this article we will tell you how to make another simple and inexpensive design - the so-called shock absorber spring tie with your own hands

.

In terms of safety, the screed is inferior to a stationary puller, but if everything is done correctly and normal material is used, then this is also a completely working option.

It’s up to you to decide which device you prefer. Blueprints

in this case they will not be required, since everything is already clear.

What you need to know when dismantling

Tightening car springs is a rather dangerous process. If you make a low-quality puller, it may come off. The high pressure puts you at risk of injury. That is why it is necessary to be extremely careful when performing such work.

To prevent anything from happening, you can make a stationary screed. Its design does not differ from that described above. The only change is the rigid attachment to the tabletop. This will ensure that the shock absorber spring tie is securely fixed, which will significantly reduce the risk of injury. Now let's look at another popular and extremely effective design.

DIY shock absorber spring remover

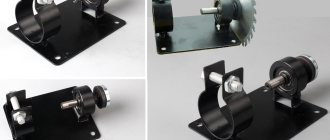

The first option is a stationary structure, which you can make yourself using a mechanical jack

(can be found on ferrous metal - there are a dime a dozen of them there).

Structurally, a homemade device for tightening shock absorber springs

consists of 4 main elements:

- mechanical jack with extended stand;

- base;

- upper (fixed) fork;

- lower (movable) fork.

In order to be able to use a car jack to disassemble shock absorbers, it will be necessary to lengthen its stand

.

To do this, select a profile pipe of the appropriate size, cut a piece of the required length and weld it to the jack stand. The base of the jack will need to be cut off before doing this.

After extending the stand

— we clean the welded seams with a grinder. We weld the base of the mechanical jack, which was cut off earlier, to the lower part.

Then we weld our entire structure to a more powerful and reliable base, which is the flywheel.

Using a grinder, we cut off the original jack hook, and weld the lower fork in its place. It can be made from pieces of profile pipe.

To make the upper fork we will use a metal plate 7 mm thick. You need to cut a semicircular hole in it to fix the spring

shock absorber

In principle, the lower fork of the puller can also (and even should!) be made from sheet metal to make it more reliable.

At the last stage, all that remains is to clean the welds with a flap wheel and paint the metal. Homemade device

to remove

springs with your own hands

!

We install the shock absorber between the two forks. Unscrew the nut at the top of the shock absorber and remove the support cup.

Then we open the spring with a jack and remove the shock absorber strut.

The detailed process of making the puller, as well as the principle of its operation, can be seen in the video below. The idea of this homemade product belongs to the author of the YouTube channel Glavnyiy Mehanik.

What are the advantages of this design?

The most important advantage is low cost. All the necessary components can be purchased for pennies at a metal receiving station.

Also, the design itself is universal - you can disassemble shock absorbers of different sizes.

Replacing struts and shock absorbers

Now that you know the difference between the shock and strut assembly and their functionality, it's time to replace them.

- Park the car on a level surface and open the hood. Place the transmission in the park position (in an automatic transmission) or in gear (in a manual transmission) and additionally put it on the handbrake.

- If your vehicle is equipped with Automatic Ride Control (ARC), turn off the air suspension before raising the vehicle.

- Loosen the wheel nuts on the side.

- Jack up the tire and secure it securely.

- Remove the wheels.

A) Replacing the rack

- Working from the engine compartment, remove the three top mounting nuts holding the strut to the body assembly.

- On some vehicle models, it is necessary to disconnect the tie rod end from the bottom of the steering knuckle.

- To do this, you may need a puller to disconnect the tie rod from the steering knuckle.

- On some other models, you may need to remove the brake caliper, brake rotor, and even the hub assembly before removing the strut assembly.

- Also, if your car has an ARC system, you will need to disconnect the electrical connectors, air pipes and sensors.

- When rust does not allow you to turn the mounting bolts, apply penetrating oil to the threads or use WD40 - a lubricant with very high fluidity and permeability, even in micro crevices.

NOTE. On some models, you must first compress the coil spring before you begin to loosen the strut mounting bolts. To do this, you will need a spring remover; you can buy it in a store or order a homemade one from a car mechanic who deals with similar things.

- Begin loosening the nuts on the two lower mounting bolts that secure the strut to the steering knuckle.

- Using a hammer, carefully push out the mounting bolts, remove the nuts from the mounting bolts, and finish removing the bolts.

- Carefully remove the strut flange assembly from the steering knuckle.

- If you have difficulty separating the strut mounting flange from the steering knuckle, use a rubber mallet or wood block to tap the strut mounting flange to help separate the strut from it.

- On other models, you may have to spread the knuckle and strut mount apart, using a pry bar to separate the components.

- Once you have removed the knuckle spacer, use a piece of wire to secure the knuckle to the suspension to prevent the knuckle from turning and sagging.

- Remove the strut assembly from the vehicle.

B) Replacing the shock absorber

- Working from the engine compartment, loosen the top mounting nut holding the shock absorber to the body. On some models, you can access the top mount bolt from underneath the vehicle after the vehicle is jacked up and securely secured.

- If the rod turns when you try to remove the top mounting nut, try holding the rod in place with pliers from under the car.

- Support the bottom of the shock absorber with a jack.

- Apply penetrating oil to the bolts to make it easier to remove if necessary.

- Loosen and remove the lower mounting bolt that holds the shock absorber in place.

- Remove the top mounting bolt and slowly lower the jack a few centimeters. Leave the jack in place to support the axle or control arm.

CAUTION: Removing the shock absorber

In some cases, it is necessary to support the axle (usually with a jack) to which the shock absorber is connected before actually removing the mounting bolt. This will prevent downward shock (shock absorber expansion) after removing the mounting bolt, which could cause serious damage to the vehicle.

After removal, leave the jack supporting the control arm or axle in place.

DIY shock absorber spring ties

If it is not possible to make a stationary puller, you can make ordinary ties with your own hands.

For this we will need the following materials:

- threaded rod;

- extended couplings;

- round pipe;

- regular hex nuts;

- clamps for fastening ventilation ducts.

The clamps will act as hooks. To make two ties you will need four clamps.

We weld extended couplings to two clamps, and pieces of round metal pipe to the remaining ones.

Cut two pieces of threaded rod to the appropriate length. We screw two nuts onto the end of the studs, and put on bushings made of a round pipe with clamps welded to them.

We screw extended couplings with clamps welded to them onto the top of the studs. As a result, we ended up with a pair of zip ties for disassembling the shock absorbers.

We install the couplers on the spring parallel to each other. After this, we gradually begin to tighten the spring.

Of course, unlike a stationary puller, homemade zip ties take much longer to complete the task. But, as they say: patience and work will grind everything down.

It is important to tighten the ties evenly to avoid distortions. Otherwise, the spring may “shoot”.

In terms of convenience and speed, a stationary puller definitely wins. However, if it is not possible to get a jack, then you can use zip ties.

You can watch the detailed process of making homemade shock absorber spring ties below in the author’s video. The author of the YouTube channel “Samodelkin Uman” shared his experience.

Source

A few more points

So we have figured out that making a screed with your own hands is not so difficult. For this, apart from desire, a small amount of tools and time, you don’t need anything. If there is no tie, but the spring needs to be removed, then it is better not to risk your own health and not to experiment, but to contact a service station.

It will not be possible to tighten the shock absorber spring without zip ties; this has already been said. This does not apply to cases where the product has lost its elasticity and has cracks. Such a spring can no longer be called working. You can find a huge number of options for making homemade zip ties, the most popular of which we have just reviewed.

A homemade shock absorber spring tie is quick and easy to make. The main thing is that the structure is durable and fulfills its main task. Don't forget that if the tie comes off the spring, you can get seriously injured from the impact, so always try to keep the spring away from your face and securely fasten it if possible.

We cook the screeds ourselves

In general, it makes sense to make shock absorber spring ties yourself. How to do this is discussed further.

Four nuts and two threaded rods

The metal products listed below are easy to find in almost any supermarket. For example, you can buy two M16 threaded rods. You will also need four extended nuts, as well as a steel plumbing pipe. Its internal diameter is 16-16.5 mm.

The end result is what is shown in the pictures. You will also need a steel rod, which is used to make reinforcement. Let's look at how screeds are made:

- Two identical cylinders are cut from the pipe, the length of which is 80-120 mm;

- Threaded rods can be shortened if necessary;

- 8 rods approximately 30 cm long are made from reinforcement;

- Using any bending equipment, the rods are bent to obtain hooks;

- Four rods are welded to two nuts, another four - to pipe sections;

- The set of components is completely ready for use at this stage.

It is easier to weld by placing the workpieces on a plane. The essence of these words is illustrated by the picture:

How to weld hook rods

Actually, what follows is a film where the technology is shown “inside and out”. The author even solved the problem with the lack of a bending machine: to bend one rod, you need two similar rods welded to a steel profile.

If the reader thinks that using welding is difficult, then it is better not to take risks. Welded joints can withstand significant loads, but only if they are performed according to all the rules. Spring ties can be made without welding. A suitable drawing is given below.

Two ties in 10 minutes (video)

How should the spring be tightened?

Let's list the steps involved in tightening the shock absorber springs yourself. Everything looks simple:

- When the body is supported by a jack, two ties are brought to the spring from opposite sides;

- By rotating the nuts with your hands, you achieve confident engagement of the hooks and springs;

- Using a wrench, the nuts on different rods are rotated in turn;

- It is better to play it safe and secure the compressed spring with straps or wire.

Video of spring tensioners on shock absorber

No explanation required here. The result is shown in the photo.

When using homemade and even purchased equipment, follow these simple tips:

- Before using ties, threaded connections are lubricated with cyatim or grease;

- The ties cannot be removed from the compressed spring, even if it is additionally fixed;

- When carrying out work, exercise maximum caution. It is better to sacrifice body parts than your own health.

Features of the suspension of Lifan cars are discussed in these articles:

Some practical tips

When working with a factory product or a homemade device, you must:

- Threaded connections must be lubricated with grease or cyatim. Ciatim-201 lubricant is not cheap. Therefore, in order to save money, it is mixed with machine oil. The proportion is 50/50.

- When compressing the working structure, it is prohibited to remove the screed, even if additional fixation measures have been taken.

- While working, you must be constantly alert and careful. It is better to sacrifice body parts than your own health or even life.

At home, working with your hands, you can use various devices to compress springs. For example, clamping the work material in a vice. All methods to achieve the final result are good. The main thing is to follow safety precautions and not join the ranks of injured “home spill” specialists!

How does a spring remover work, and what types are they?

What is a puller used for? It overcomes the straightening force of the springs. The applied force on the puller brackets is commensurate with the weight of the car, but this does not mean that its design is too expensive and high-tech.

There are many options, but they are divided into only two types: mechanical and hydraulic drive.

Mechanical spring remover

Most often it has a threaded drive mechanism.

With a sufficient diameter of the pin (providing a good gear ratio on the thread), and a long handle of the key, you can compress the springs manually without excessive effort.

The technology is as follows: two pullers are symmetrically put on the rack. By turning the threaded rod, you bring the claws to the middle of the spring directly on the shock absorber, compressing it to the required size.

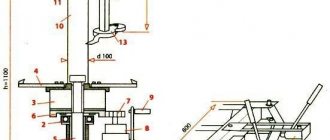

Drawings of universal threaded ties

Let's return to the question of how to make a device for tightening shock absorber springs yourself. Below is the appearance of the finished devices:

Factory-made threaded ties

On one side of the rod there is a left-hand thread, on the other - a right-hand thread. The standard thread pitch is M18. But buying threaded rods is not enough here. And to cut the thread yourself, you will need special equipment.

Drawings of the components that make up the entire structure are shown here:

Threaded tie (3 parts)

To make parts, you need a lathe, drilling and, probably, milling machine. It may be easier to contact a workshop. Print the drawing by downloading it from the website.

Most likely, there are no other drawings of universal ties on the Internet. And what is shown above is taken from a book on repairing domestic cars. You can use it.

Let's say the ties were made according to the drawings and all the parts fit together. But even then the advice about using lubricant remains valid. You need to take solid oil or cyatim and apply this material to the threads of the nuts.

Cyatim-201 lubricant is a rather expensive material. You can reduce consumption by mixing it with machine oil in a 50/50 ratio. Good luck.

Why do you need such a procedure as tightening the shock absorber springs with your own hands? Due to the current circumstances and because of our vaunted domestic roads, it happens that shock absorber units in a car, even an almost new one, fail. And if they are old enough, they wear out from time of use.

Universal and branded

Despite the fact that the design of the screed is extremely simple, they come in several types.

For example, dealers of some companies use branded tools that are suitable only for a certain brand of car. This also applies to screeds, although in most cases such scrupulousness is not required. Universal screeds, as the name suggests, are suitable for everything. A spring is a spring everywhere, and the device for working with it is suitable for any make of car. As for the craftsmen who repair cars in their garage, they need a screed. Let's see how to assemble such a tool with your own hands.

Manufacturing instructions

There are many ways to make such a device. Their main idea is to save money and use unnecessary scrap materials to make an instrument. In any automotive market you will be able to find a hydraulic device that is easily used for repairs, but its cost is high for a small device. If you dig around in your garage, you will definitely be able to find things there that seem unnecessary at first glance. Analyze whether they can partially recreate the design you saw on the market. It is unlikely that it will be possible to recreate hydraulic couplers for a shock absorber, but replacing them with a mechanical device is quite possible.

Let's look at a brief instruction on how to make ties for shock absorber springs with your own hands.

- We remove the front wheel shock absorber and measure the size of the large spring that prevents replacement. We start measuring from the first large turn and end with the last one. We write down all the data on a piece of paper, preferably in one unit of measurement (centimeters or millimeters), which is more convenient for you. It is recommended to make clamps specifically for the front wheels, since these shock absorbers most often break and require repair.

- We find a strong metal pipe with a diameter of 2 centimeters in the garage and cut it into 4 pieces 10-15 centimeters long.

- Next, we find a standard rod with a diameter of 0.7-1 centimeters and cut it into pieces 20-30 centimeters long. You should have 8 such short strong rods.

- We find a threaded rod or buy a pipe with a diameter of 1.5-1.7 centimeters and cut it into 2 pieces, the length equal to the measurement obtained in the 1st point, which can be extended to 5 centimeters. If the selected tubes do not have threads, we cut them using a special tool from all edges of each piece over 10-15 centimeters.

- We process all the edges of the tubes and rods in such a way as to get rid of metal burrs; the edges should be even and smooth.

- We bend the metal rods equally so that they form a hook on one side. Please note that such rods are very strong and difficult to bend, so you can use additional tools.

- Using mobile welding, we connect the rods and short tubes so that the hooks are evenly located on both sides of the tube. We cut off the excess edges of the rods so that they are flush with the tube. We get 4 small products from rods and pipes.

- We put the resulting parts on long tubes and tighten large nuts at the ends. The hook is put on so that its smooth side faces the edge of the bar.

- That's all the work, the shock absorber tie is ready. It will fit both the front wheel and the rear (if you added a few extra centimeters to the bar). Test it on one of the shock absorbers and correct any shortcomings if any appear.

This technique allows you to quickly build a mechanical device that can compress or slightly expand the shock absorber spring to repair, replace or check it. The only disadvantage of this method is that the master must be able to use mobile welding. If such a device is not available or you do not want to use it, then you can build a similar device without using a complex mechanism. The method of producing shock absorber ties based on an old strong jack is considered very good .

If you remember, such devices were included with old Soviet-era car models. Its operation scheme is clear; all that remains is to make sure that one part of the jack can be attached to the upper coil of the shock absorber spring, and the other branch to the lower one. This can be done through various means - look at what is present in your garage among the parts and be sure to find something suitable. Keep in mind that the above methods for producing screeds are not the only ones of their kind; they can be changed or supplemented depending on the type of car, its model, skills and desires of the car owner. It’s worth using your imagination to make this mechanism simple and uncomplicated.

Why do you need a puller?

Each car shock absorber has an external spring that is very firmly attached to the edges of the part. It also takes over the functions of protection against large particles and provides a small shock-absorbing effect. Without strong springs, installing a shock absorber makes no sense, since it will be damaged very quickly. So the question is how to install and remove them.

The shock absorber remover helps the repairman easily get rid of the springs and move on to repairing the main part or replacing its protection. It can be either hydraulic (such a device can be sold in specialized stores) or mechanical (it can be made at home with your own hands).

The type of puller indicates how it works and the time it takes to work with it. In other words, a mechanical puller will perform tasks more slowly and with the use of physical force, but does this really matter when we are talking about significant financial savings on maintenance, replacement of shock absorbers and the purchase of a hydraulic type.

Communities › Garage Equipment and Tools › Blog › DIY spring ties

Hi all. I'm twisting the suspension in places. And you have to change the springs, but this is a rather unsafe task, it can fly into your head and leave you without a finger. But it needs to be done)). And in order to make my work easier, I decided to sculpt a machine for compressing and releasing springs from a Volgov jack (I spotted it on the internet). But after half a day of welding, I realized that mostly in YouTube they compress small springs, which I can easily compress with ordinary ties. Yes, and the plates must be even, otherwise everything will compress awry, and to add to this, my jack was already rickety and did not want to work as expected. What do I mean by all this? And to the fact that after I went PSYCHANIC, I cut up the entire halabuda, and made excellent couplers from the screws of the worthless jacks that would not let me down. And I also rebuilt the factory ones and now they are quite reliable and convenient. What actually happened: Here is a tie from an old non-working jack for Renault 19. The jack is bent, but the screw is reliable. But I made one very necessary upgrade to this device. I added a support bearing to it (the red one in the photo) that was in the jack. That is, if earlier (tested) when you twist the nut, it could bite due to friction, the tie could be pulled to the side and it would naturally fly off, THEN now the support bearing will not allow this to happen, everything will spin like clockwork and the tie will stand dead. The grips are made from a thick chain link, they will never straighten out)))

Spring tightening process

Let's start with the fact that the pullers described above are not the only ones of their kind; there are several other configurations of this device; you can also make it yourself or simply buy it. However, without it, the screed will be a complete nightmare and an almost impossible task.

When starting to perform this operation, it is necessary, first of all, to remove the strut with the shock absorber, having first placed the car on a jack and securely fixed it.

Next, the puller is attached to the upper and lower coils of the springs, and manual work begins. Depending on the operating principle of your puller, you will either rotate some element of it, or, as in the case of the “frog,” alternately work with two pedals.

At this point, the tie can be considered complete; the main thing to remember is that you should not compress the spring completely, increasing the risk of breakage of both the spring itself and the compression device. It is enough to simply release the element you need from the pressure and repair or replace the shock-absorbing mechanism.

As for the use of a puller, it is designed to facilitate the entire repair process, because without it you would not only have to fix the stand with a vice, but also make enormous efforts to compress the springs; someone would need to hold them while you work on the entire mechanism etc.

In addition, by using this device, you make the repair process safe for yourself, practically eliminating the chance of spring failure.

What is a puller

A puller is a special device that allows compression of shock absorber springs so that repair work can be continued in the future. There are many variations of this device, but the most common puller for springs is two metal slats with threads cut along their entire length and hooks attached to both sides, which move towards each other when turned. Those. when you need to compress the springs, you just need to turn the rack, and the fixed hooks will tighten the spring.

There is an even more simplified puller method - a belt puller. In this case, two “frogs” are used with durable fabric belts tucked into them. The belts are thrown onto the upper and lower coils of the springs, then the car owner begins to work with “frogs”, pressing each one in turn. Subsequently, these actions tighten the belts, and the “spiral” begins to tighten, after which repair work can be carried out.

How to make a shock absorber spring remover with your own hands

Dear visitors to the “ Samadekin Friend ” website, today we will look at one of the options for making a homemade shock absorber spring puller with our own hands, as well as look at step-by-step photos of assembling the spring puller and a video. Every car enthusiast who has ever repaired the suspension of a passenger car knows perfectly well how difficult it is The shock absorber springs are removed and to perform this operation without a special tool you will have to get pretty clever. But if you think a little and use ingenuity, then a simple shock-absorbing spring remover can be made independently and at minimal cost, so to speak, a simple and budget version of a tool that makes life easier for a motorist.

The design and principle of operation of the presented puller is actually quite simple and understandable; it is based on the compressive force of the spring's screw tie, namely, there are 2 metal hooks installed on the pin that hook onto the spring and, under the influence of tightening the nut, the spring is compressed and then removed from the rack.

So, let's look at what exactly is needed to assemble the puller.

- metal pipe 16-20 mm

- hairpin M-14

- corner

- nut 2 pcs

- solid oil

Tools

- welding inverter

- drill

- vice

- hammer

- wrench

- Angle grinder (grinder)

Step-by-step instructions for creating a shock absorber spring remover with your own hands.

How does a shock absorber work?

A mandatory component of every shock absorber is a spring. There are now all sorts of progressive types of this mechanism, such as oil or pneumatic, but the design of each of them includes the same spiral element, which helps to maintain a given level of the car above the ground, and also facilitates work when there is a load on the shock-absorbing device itself.

Quite often it happens that the shock absorber is in perfect order, while the spring element has worn out, lost the necessary rigidity, or has completely burst. In this case, it needs urgent replacement, which can be done with your own hands only if you have a puller.

There is a flip side to the coin, when everything is fine with the spring, but you need to carry out repair work on the shock absorber itself, in which case a puller will be indispensable.

Manufacturing a shock absorber spring remover

Many car enthusiasts use a regular chain: they wind a few turns around the coils of the spring and tighten the chain. After lifting the car with a jack, the shock absorber strut is stretched, but the spring remains compressed. This is a dangerous method: if the chain slips, the spring may spring back and cause serious injury.

How to make a simple puller similar to an industrial one

A mechanical semi-stationary “machine” can be created from a “Volgovsky” jack.

- old jack from Volga-24, Moskvich 412 or other Soviet passenger car = 0 rub.

- old connecting rod from any engine = 0 rub.

- steel corner from a landfill 1 meter = 0 rub.

- a pair of rods from broken shock absorbers = 0 rub.

- a handful of bolts and nuts M12 - M14 = conditionally free.

Making a tie for shock absorber springs with your own hands

Using a grinder, we cut two meter-long pieces from a pre-prepared pipe. We adjust the threaded rods to the required length. Next, we take the reinforcement and mark eight 30 cm sections. We saw it using a grinder and using any bending equipment we try to make hooks from the rod.

Please note that you will also need a welding machine. If you don’t have your own, you can borrow it from a neighbor for a while. We weld 4 pre-cut rods to the nuts, the remaining 4 to the pipe. In principle, we made ties for the shock absorber springs with our own hands and can use them. Let's look at a few more interesting options that are popular among car enthusiasts.

How to compress a spring in the field

Some craftsmen use seat belts in the absence of ties. To work you need 2 seat belts, 2 levers (fittings, strong sticks, pipes).

Spring compression procedure

1. Thread the straps on both sides of the spring and tie with a secure knot.

2. We take the above materials as levers.

3. The spring is placed on its side.

4. We insert the lever under each belt and tighten it. We fix it with wire.

5. We begin to alternately twist the levers to compress the spring.

6. The spring is compressed, continue the following procedures.

Homemade spring removers from car struts - video

Homemade portable stand

Bottom line: The cost of homemade spring pullers tends to zero, since they are literally assembled from trash. And without them, it is not possible to service the car’s suspension.

- DIY shock absorber spring tensioner

- Spring tensioning equipment

- How to make a screed device yourself

- Necessary tool

- Manufacturing process

- How to tighten a spring correctly

If you need to repair shock absorber struts or car suspension, the question arises of how to tighten the shock absorber spring. To achieve this goal, spring ties are used. They are necessary in order to compress and remove any type of spring.

Spring tensioning equipment

Spring ties can be of two types, depending on the basic principle of operation:

• Mechanical – based on mechanical action on a spring. Their price is low, and they are often used by car enthusiasts.

•Hydraulic – the action on the spring is created using a hydraulic pump. Used in large car repair shops. The price is much higher.

Auto repair shops usually buy compressors with a wide range of possible sizes, since they are used on different cars. If you have not given up the idea of repairing your vehicle yourself, then you need to pay attention to the fact that some models of couplers are offered by the manufacturer specifically for certain types of suspensions. But they can also be universal.

How to make a screed device yourself

If you calculate the price of the components of a spring puller, it will be significantly lower than the price of a finished puller. Therefore, the question arises: how to make a spring puller with your own hands. It is possible to make spring ties yourself. But at the same time you need to have a welding machine and the ability to make something with your own hands.

It is clear that the principle of their operation will be based on the mechanical effect on the spring. For one spring, two ties are required, secured on opposite sides for uniform compression. Their design is standard: a threaded rod with hooks and nuts. By turning the rod or nuts with a wrench, we can easily compress the spring. Since the design is simple, it does not require special skills in manufacturing. But you should remember that the device you make must be reliable, since now you are responsible for your own health.

Replacing the front spring without a puller or zip ties.

Published on August 28, 2016

Replacing the front spring without a puller or zip ties.

where are the tuning levers from the package?

Replacing the front spring without a puller or zip ties.

Hello Roman, in your case, when replacing the lever, you could not bother yourself with this work, unscrew the wheel, put a beam under the lever and lower the car with all your weight. Then take a thick wire and tie the springs on both sides. And then take everything apart. A lot I did this once, but then I had to get the ties anyway. I think this method is suitable for anyone who is replacing the springs with new ones)) good luck to everyone in the repairs.

Tough.