Five thousand years ago, minters from Egypt discovered a new type of joining metals using the soldering method. The essence of the method is to create a connection between different metals by filling the seams with solder, which is a molten material with a melting point lower than that of the parts of the product being connected. Unlike steel, it is more expedient to connect copper parts by soldering rather than welding. This is especially important if you have to work with thin-walled copper pipes, which are widely used in heating, plumbing, gas and refrigeration systems. Even a beginner can handle this kind of work.

Preparation for soldering copper with aluminum, brass, stainless steel, iron

The preparatory period, which includes the acquisition of the necessary devices, materials, personal protective equipment, and the soldering procedure itself.

There are two ways to solder copper to copper: high and low temperature. The first involves heating the metal to 900°C, and is used for pipelines with high pressure or temperature load. For high-temperature soldering, materials intended for this are used: hard solder in the form of rods (the melting point of such solder is about 900°C) and hard-melting flux.

In order to solder copper using the low-temperature method, it is sufficient to heat the metal to 600°C (usually 300–380°C), which is achievable in domestic conditions. For the procedure, soft solder is used for soldering copper and brass in the form of a wire or rod with a cross-section of up to 3 mm and a more fusible flux. Solder is an alloy of tin, which is more than 97%, with other metals: copper, selenium, silver, antimony.

Why do you need flux? Correctly soldering copper pipes can only be done with flux - a special paste-like composition (with zinc chloride), which is applied to the surface of the connected sections of the pipe in a wide strip. It performs several functions:

- prevents the process of metal oxidation by removing oxygen;

- improves the adhesion of solder to copper;

- is an indicator of sufficient heating of the metal, signals when to apply solder and solder the copper;

- promotes uniform spreading of solder along the joint.

Safety precautions. Despite the simplicity of the process, soldering copper pipes must comply with safety rules. The danger of burns is posed not only by the burner flame itself, but also by the heated metal. Copper conducts heat well, so during operation, not only the area on which solder is placed and welding is carried out, but also the entire pipe becomes very hot, and it cools down slowly. If you need to solder copper tubing that is not already built into the piping system, preparation involves placing it on non-flammable supports where it can take a long time to cool. Before touching the welded metal from its place, you should wait until it cools completely.

The immediate danger is the open flame of the burner, so you need to purchase a tool that is convenient to work with: preferably with a movable nozzle on a long hose

Classification of copper products

Copper pipes in Europe are mainly metric; 6, 8, 10, 12, 15, 22, 28, 42 and 48 mm are also found in larger diameters, but they can also be inch:

| inches | mm |

| 1/4 | 6.35 x 0.8 |

| 3/8 | 9.52 x 0.8 |

| 1/2 | 12.7 x 0.8 |

| 5/8 | 15.9 x 0.8 |

| 3/4 | 19.1 x 0.8-0.9 |

Copper marking in Russian marks: the letter “M” is used to denote copper. Next are numbers showing the degree of purity in% (00 - highly pure, 0 - pure, 1, 2, 3 - technically pure). The last element of the marking is a letter indicating the method of copper production: (k - cathode, y - cathode remelted, b - oxygen-free, p - deoxidized, f - deoxidized with phosphorus).

| Copper grade | M00 | M0 | M1 | M2 | M3 |

| Purity | 99,99 | 99,95 | 99,90 | 99,70 | 99,50 |

Copper grades M1p, M2p and M3p, with a total impurity content identical to copper grades M, M2 and M3, differ from them in that they are more completely deoxidized and the oxygen content in them is reduced from 0.05 - 0.08% to 0. 01%. Therefore, they additionally contain from 0.002% to 0.012% phosphorus. The M1f copper grade differs from M1r in an even greater amount of phosphorus from 0.012% to 0.04%, for greater deoxidation and, accordingly, a complete absence of oxygen.

CHEMICAL COMPOSITION OF COPPER ACCORDING TO GOST 859 (%)

| Copper grade | Cu+Ag (%) | Impurities, no more (%) | ||||||||||

| Bi | Sb | As | Fe | Ni | Pb | Sn | S | Zn | O | P | ||

| M1f | 99,90 | 0,001 | 0,002 | 0,002 | 0,005 | 0,002 | 0,005 | 0,002 | 0,005 | 0,005 | — | 0,04 |

| M1r | 99,90 | 0,001 | 0,002 | 0,002 | 0,005 | 0,002 | 0,005 | 0,002 | 0,005 | 0,005 | 0,01 | 0,012 |

| M1 | 99,90 | 0,001 | 0,002 | 0,002 | 0,005 | 0,002 | 0,005 | 0,002 | 0,004 | 0,004 | 0,05 | — |

| M2 | 99,70 | 0,002 | 0,005 | 0,01 | 0,05 | 0,2 | 0,01 | 0,05 | 0,01 | — | 0,07 | — |

| M3 | 99,50 | 0,003 | 0,05 | 0,01 | 0,05 | 0,02 | 0,05 | 0,05 | 0,01 | — | 0,08 | — |

The use of various grades of copper in plumbing products is determined by GOST 52318, and in Europe - EN 1057. In construction products: GOST 495-92, in Europe - EN 1172. Typically, water pipes contain 99.90 copper and are excellent for home brewing purposes.

Safety precautions when soldering copper

It should be taken into account that the heat conductivity of copper is very high, as a result of which it is not recommended to solder parts while holding them in your hands without protection; this will most likely result in burns. Parts shorter than 30 cm are handled exclusively with pliers or in protective gloves. If during the soldering process flux drips onto exposed parts of the body, you need to immediately wash it off with soap and water, since, in addition to thermal burns, you can get a chemical burn.

For any work with open fire and hot metal, as well as flux that contains acid, synthetic clothing is undesirable, since such fabric ignites and melts much faster than others. Be sure to ventilate when working; smoke from burnt flux is harmful.

If you have absolutely no soldering skills, it is advisable to practice on scraps of pipes or wires before performing important work. There are few difficulties in this work, and 2-3 times, as a rule, are enough to master all the basic techniques. If the plumbing system is being assembled, it is recommended to pre-assemble it on the floor before installing everything in place. After assembly and soldering, the system should be thoroughly rinsed with hot, clean water to remove any flux and solder from the inside of the pipes.

Plumbing or heating systems made from copper pipes are expensive, but they are strong and durable. Since copper has a high thermal conductivity coefficient, good anti-corrosion and antibacterial properties, pipelines made from it are efficient and durable. Soldering copper at home is not difficult: a socket-coupling is put on the pipes, and then the seam is sealed. Instead of using a flare, sometimes they widen the end of one pipe and insert another into it. This connection is convenient because it does not require fittings, and the service life is equal to the life of the pipes themselves.

Basic information about metal soldering

The main advantage of copper is that this metal is ideal for soldering. This is explained by the fact that the surface of such pipes is easy to clean from oxides and contaminants using improvised means. Again, there is a wide range of different alloys that can be used as solder.

The process of soldering copper pipes involves the capillary effect, due to which the molecules of the solid and liquid (molten solder) interact with each other. As a result, at the interface between solid and liquid media, attraction between molecules of the base metal and molecules of the molten metal occurs.

Difference in using hard and soft solder

| Solder grade | Melting temperature | phosphorus | zinc | silver | cadmium |

| L-Ag45Sn | 480-640 | — | — | 44-46% | — |

| L-Ag34Sn | 630-730 | — | 1,5-2,5% | 33-35% | — |

| S30F-SH1 | 600-690 | — | — | 29-31% | 19-23% |

| S15L-Ag15P | 650-810 | 4,7-5,3% | — | 14-16% | — |

| S3L-Ag5P | 650-810 | 5,7-6,3% | — | 4-6% | — |

| S2L-Ag2P | 650-810 | 5,9-6,5% | — | 1,5-2,5% | — |

| Rolot S94 | 710-880 | 5,9-6,5% | — | — | — |

Table with brands and characteristics of hard solder

How does brazing copper pipes with hard solder differ from a similar operation using soft solder?

First of all, the temperature regimes for heating the metal differ. This is due to the different melting temperatures of the material.

Soft solder (heating temperature up to +450 °C) is made from low-melting alloys of tin and lead. Hard solder (heating temperature not less than +700 °C) is made of copper with the addition of phosphorus, tin and silver.

A bar of braze requires more heat to liquefy, but the finished joint is stronger, more durable, and more heat resistant than a joint made with tin.

Table with types of fluxes suitable for high-temperature soldering

The listed soldering methods are selected in accordance with the subsequent scope of application of the pipes. Domestic piping uses soft-soldered joints, while refrigeration equipment uses hard solder.

By the way, the price of tin and the cost of soldering made with its use are much more affordable than the cost of a connection made with hard solder.

Necessary materials and equipment: tin and others

The following tools are required for working with copper pipes:

- pipe cutter, hacksaw or grinder with a thin disk;

- chamfer;

- pipe expander (expander);

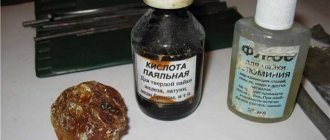

- soldering flux;

- solder;

- soldering iron for copper, for example, a propane torch for soldering copper pipes;

- rubberized gloves;

- paper napkins.

Pipe cutters of various sizes are used to cut pipes. Larger samples have a large turning radius and are inconvenient to use in hard-to-reach places, so if there is a need to cut off a section of a finished installed water supply, use a small pipe cutter. You can cut the pipe with a hacksaw or a grinder with a thin disk, but a better cut can only be achieved using a pipe cutter.

After the pipe is cut, the burrs are removed. This is necessary to ensure that there is no turbulence in the fluid flow in the system. When there are no obstacles, the water supply does not experience stress and works like a clock.

Before welding the copper, the ends of the pipe are polished with fine-grained sandpaper, which can be purchased at hardware stores. They clean both surfaces that are preparing for soldering. Sometimes small brushes with a diameter of Ø 22 mm are used for these purposes; they are suitable for almost all pipes. For cleaning, the stem of the brush is inserted into a screwdriver or drill, with the help of which the process is carried out faster and with better quality.

Flux is applied to the cleaned, smoothed outer surface - a composition that prevents the oxidation process of copper.

Rubberized gloves are used to protect hands, since when cutting copper and burrs, many small metal elements are formed that dig into the skin like splinters. In addition, when cleaning the surface with a drill, the rotating brush chews on rag gloves.

To solder copper correctly, you need to take into account that from the moment of stripping and applying flux to soldering, no more than half an hour should pass, otherwise the stripping must be repeated again. If the flux is applied with a brush, there should be no bristles or hairs from it left on the surface - otherwise the connection will not be tight and the pipeline will leak after water is supplied.

After inserting the pipe into the socket, the remaining flux is not completely removed with a napkin, it remains on the connection in the form of an edge of 1–2 mm, and when soldering, the solder is drawn inward - the capillary effect is triggered. First, the joint is heated with a burner, and the moisture between the walls is evaporated. Then the burner is brought up a second time, the copper gradually heats up, and the flux takes on a tin appearance. At this moment, solder is placed on the front side, soldering occurs, and the molten alloy flows down to the back side, solidifying as it moves. The excess metal overhangs that form below are separated on their own. Soldering copper can be done in different ways.

Preparation for soldering copper with aluminum, brass, stainless steel, iron

The preparatory period, which includes the acquisition of the necessary devices, materials, personal protective equipment, and the soldering procedure itself.

There are two ways to solder copper to copper: high and low temperature. The first involves heating the metal to 900°C, and is used for pipelines with high pressure or temperature load. For high-temperature soldering, materials intended for this are used: hard solder in the form of rods (the melting point of such solder is about 900°C) and hard-melting flux.

In order to solder copper using the low-temperature method, it is sufficient to heat the metal to 600°C (usually 300–380°C), which is achievable in domestic conditions. For the procedure, soft solder is used for soldering copper and brass in the form of a wire or rod with a cross-section of up to 3 mm and a more fusible flux. Solder is an alloy of tin, which is more than 97%, with other metals: copper, selenium, silver, antimony.

Why do you need flux? Correctly soldering copper pipes can only be done with flux - a special paste-like composition (with zinc chloride), which is applied to the surface of the connected sections of the pipe in a wide strip. It performs several functions:

- prevents the process of metal oxidation by removing oxygen;

- improves the adhesion of solder to copper;

- is an indicator of sufficient heating of the metal, signals when to apply solder and solder the copper;

- promotes uniform spreading of solder along the joint.

Safety precautions. Despite the simplicity of the process, soldering copper pipes must comply with safety rules. The danger of burns is posed not only by the burner flame itself, but also by the heated metal. Copper conducts heat well, so during operation, not only the area on which solder is placed and welding is carried out, but also the entire pipe becomes very hot, and it cools down slowly. If you need to solder copper tubing that is not already built into the piping system, preparation involves placing it on non-flammable supports where it can take a long time to cool. Before touching the welded metal from its place, you should wait until it cools completely.

The immediate danger is the open flame of the burner, so you need to purchase a tool that is convenient to work with: preferably with a movable nozzle on a long hose

Existing connection technologies

During installation, individual elements can be connected in two ways: soldering and crimping . In both cases, special connecting elements - fittings - are used.

Soldering of copper can be performed in different temperature conditions:

- Low temperature . The connection is performed at a temperature of 250-300 Cº. This method is considered optimal for installing home heating systems operating at temperatures up to 110 Cº. Soft solder is used as a consumable material.

- High temperature . Used when installing systems operating at high temperatures under pressure. Soldering requires hard grades of solder for professional equipment, so the method is used primarily for industrial purposes.

When connecting by crimping, fittings of a special design are used, with a rubber sealing ring inside. For installation, special pliers are required that fix the pipe with the coupling. In practice, this method is used extremely rarely, since soldering is considered a more reliable technology.

What is needed for soldering copper pipes

Soldering copper pipes, which is not difficult to do with your own hands, does not require expensive equipment or any special materials. In order to carry it out correctly, you will need the following equipment.

A burner that will heat the solder and the section of pipes where they will be connected. Such a burner is usually supplied with propane gas, the pressure of which is regulated using a welding reducer. Special device for cutting copper pipes. Since products made from this metal are very soft, they should be cut gently enough so as not to crush the walls. The modern market offers pipe cutters of various models, differing in both their functionality and technical capabilities.

The design of individual models of such devices, which is important, allows them to be used even for working in hard-to-reach places. A pipe expander is a device that allows you to expand the diameter of a copper pipe, which is necessary in order to perform soldering better. Various systems mounted from copper pipes use elements of the same cross-section, and in order to connect them efficiently, it is necessary to slightly increase the diameter of one of the elements being connected

This is precisely the problem that a device such as a pipe expander solves.

Copper pipe flaring kit

A device for chamfering the ends of copper pipes. After trimming, burrs remain on the ends of the parts, which can interfere with obtaining a high-quality and reliable connection. To remove them and give the ends of the pipes the required configuration, a bevel remover is used before soldering. There are two main types of chamfering devices on the market today: those placed in a round body and those made in the form of a pencil. More convenient to use, but also more expensive, are round devices that can process soft copper pipes with a diameter of no more than 36 mm. To properly prepare copper pipes for soldering, it is necessary to remove all contaminants and oxides from their surface. For these purposes, brushes and brushes are used, the bristles of which are made of steel wire. Typically, brazing of copper pipes is performed with hard solder, which can be high- or low-temperature. High-temperature solder is copper wire containing about 6% phosphorus. Such wire melts at a temperature of 700 degrees, while for its low-temperature type (tin wire) 350 degrees is sufficient. The technology for soldering copper pipes involves the use of special fluxes and pastes that perform a protective function. Such fluxes not only protect the seam being formed from the formation of air bubbles in it, but also significantly improve the adhesion of the solder to the pipe material.

In addition to flux, solder and other basic elements, to solder copper pipes you will also need additional tools, which can be found in every workshop or garage. To solder or cook copper products, additionally prepare:

- regular marker;

- roulette;

- building level;

- a small brush with stiff bristles;

- hammer.

Before starting work, it is also important to decide how to solder copper pipes. There can be two main options: soldering copper with hard solder (used less frequently) and using soft solder

When addressing this issue, it is important to assume that there are requirements for the use of one or another type of solder. Thus, hard solders are used for soldering elements of refrigeration units and air conditioners. In all other cases (water supply systems, heating systems, etc.) tin wire can be used. But no matter what technology is chosen, it should be remembered that flux is necessary in any case.

Cleaners for cleaning the inner surface of a copper pipe before soldering

Pipe types

Despite their high performance characteristics, copper pipes are not the most popular product on the domestic market. The limiting factor is high cost , although if the connection technology is followed, the service life will be much longer than that of similar materials.

There are two types of copper pipes.

- Otozhenennye . After manufacturing, the pipes are subjected to heat treatment at a temperature of 650-700 Cº. The procedure imparts plasticity to the product, with some loss of strength. In addition, the cost of production increases.

- Unannealed . They are characterized by high strength. The only drawback is low elasticity. When installing a pipeline, bends are made using couplings, since such pipes are almost impossible to bend.

Regardless of the type of product, there are special requirements for the purity of the material. According to GOST 859-2001, the mass fraction of copper should not be lower than 99%.

Copper soldering rules

If you need to solder a copper product or a product containing copper components, it is impossible to give a definite answer as to how and what is the best way to do this. The choice of method and tools depends on many factors, such as the size and weight of the parts, their composition. The load to which already soldered products must be subjected is also taken into account. There are several soldering methods, and it is better to know them all so that, if necessary, choose the most suitable one.

Soldering large parts

Scheme of capillary soldering of copper.

If you need to solder massive or large parts that cannot be heated to the required temperature with a soldering iron, a torch and copper solder are used. The flux in this case is borax. The strength of copper-phosphorus solder is higher than that of standard tin.

A thin layer of flux is applied to the mechanically stripped pipe or wire. After this, a fitting is put on the pipe, also mechanically cleaned. Using a gas torch, the joint is heated until the flux-coated copper changes color. The flux should become silver in color, after which you can add solder. The solder melts instantly and penetrates into the gap between the pipe and the fitting. When drops of solder begin to remain on the surface of the pipes, the solder is removed.

The pipes should not be overheated, as this will not promote a greater capillary effect. On the contrary, copper heated to blackness is less amenable to soldering. If the metal begins to turn black, heating should be stopped.

Soldering wires or wires

To solder thin copper wires, do not use zinc chloride solder as it will destroy the copper. If there is no flux available, you can dissolve an aspirin tablet in 10-20 ml of water.

Scheme of copper welding in an inert gas environment.

Copper wire or parts made of wire of various sections can be easily heated to the desired temperature using a soldering iron. The temperature regime should be the one at which the solder, tin or lead-tin, melts, and this is what soldering is done with. Fluxes must contain rosin or be made on its basis; solder oil or even rosin itself can be used.

The surface of the wire is cleaned of dirt and oxide film, after which the parts are tinned. This process involves applying a thin layer of flux or rosin to heated copper, and then solder, which is distributed over the surface as evenly as possible using a soldering iron. The parts requiring connection are connected and heated again with a soldering iron until the already solidified solder begins to melt again. When this happens, the soldering iron is removed and the connection cools.

The parts can be clamped in a vice so that the distance between them is 1-2 mm. Flux is applied to the parts and heated. Solder is brought to the gap between the hot parts, which will melt and fill the gap. The melting point of solder for soldering using this method must be lower than the melting point of copper so that the parts do not become deformed. The part cools, then it is washed with water and, if necessary, sanded with sandpaper until smooth and uniform.

Soldering utensils or soldering holes in copper

When soldering dishes, they use pure tin, the melting point of which is higher than that of tin or lead-containing solder. Sometimes, to solder large parts, hammer soldering irons are used, heated over an open fire with a gas burner or blowtorch. In the future, everything happens according to the standard scheme: stripping, flux and tinning, joining parts and heating with a soldering iron. It is for this soldering iron that pure tin solder is convenient.

On the inside, the fitting usually has a border that prevents it from being threaded through the pipe. It can be removed using a coarse file if the fitting needs to be pushed onto the pipe further than intended and thus soldering an unnecessary hole.

Types of fittings used

On sale you can find many types of fittings for making various connections. The most common are:

- Clutch. Intermediate element between two pipes.

- Corner. Necessary for changing the direction of the highway.

- Tee. To divide one highway into several channels.

If you use pipes after heat treatment, you can reduce the number of fittings to a minimum . This material is particularly flexible, so you can use a regular expander to connect two elements. In this case, it is necessary to remember about the gap for introducing solder into the heating zone. The amount of overlap depends on the diameter of the pipe. As a rule, this figure should not be less than 5 mm. If necessary, you can bend the pipe with a small rounding radius to save corners.

Features of soldering with soft and hard solders

The connection of copper pipes has a number of characteristic features. They are especially pronounced when using different materials.

Soldering of links with low-melting solder is carried out at a temperature of 175–315ᵒC. Soldering with solid compounds is carried out by heating the joint to a temperature of 650–815ᵒC.

Soft alloy soldering is used for soldering copper pipes with an internal diameter of up to 22 mm, and hard alloy soldering with a diameter of 22 mm or more.

Soft and hard solders - description

When sufficiently heated, the applied flux layer boils. When soft solder melts, a molten drop is formed, which plays an important role in creating a strong pipe connection. Boiling flux pushes the molten composition out of the joint space. Under the action of capillary forces, the solder alloy is drawn into the joint as it cools.

When butt brazing, a thin spacer of soft metal is inserted between the elements being soldered. The parts to be connected are securely and firmly fixed with a guide gasket.

A simple technique for soldering copper pipes and the availability of all materials allows you to do this work yourself at home.

Related video: Soldering copper pipes “my experience”

Selection of questions

- Mikhail, Lipetsk — What discs should I use for cutting metal?

- Ivan, Moscow - What is the GOST for rolled sheet steel?

- Maxim, Tver - Which racks for storing rolled metal products are better?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals without the use of abrasives mean?

- Valery, Moscow - How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

How to choose solder

Despite the fact that soft solders are considered not strong enough, using capillary welding you can obtain a high-quality plumbing structure. Low-melting solders are used for joining copper pipe products with a diameter of 6–180 millimeters. They are preferred because they operate at low temperatures. The fact is that copper can lose strength at high temperatures.

All solders belonging to the medium and high melting point are of the hard type. For high-temperature soldering of copper products, solders based on copper, silver and other metals are used. Thanks to their use, a seam is obtained that is durable and resistant to high pressure and high temperatures.

The most popular among them are:

- copper-phosphorus;

- copper-silver-phosphorus;

- silver

In the latter case, not only solder is required, but also flux paste for soldering copper pipes.

Soldering process

It consists of performing sequential operations:

- the pipe is cut into pieces of the required sizes, which are marked for convenience - supply or return;

- a chamfer is removed from the edge;

- the edges are cleaned by 2 cm: the outer ones on the pipe, as well as the inner ones in the socket;

- Flux is applied in a strip along the cleaned surfaces (external and internal);

- the connection is assembled: the pipe is inserted into the socket;

- excess flux is removed with a paper napkin, but not completely - an edge of 1–2 mm is left;

- the burner is ignited, the flame is brought to the junction;

- the surface is heated for 10–15 seconds to a certain temperature - the flux should acquire a tin color;

- Solder is placed on top of the joint; when heated, it will be drawn into the joint and spread along the seam, filling it.

If the connection joint has not been cleared of bristles or dust, and as a result the soldered seam of the copper water pipe leaks, then the tightness can be restored using one of two methods:

Using a soldering iron

- the surface is cleaned, treated with phosphoric acid, heated with a soldering iron, and tin is applied;

- using a torch: flux is applied to the cleaned surface, heated, solder is applied, and melted.

How to properly solder copper with a gas torch

You can solder a copper tube as follows:

- Clean the soldering area with a fine file, sandpaper or wire brush.

- Grind rosin and sprinkle the soldering area.

- Heat the tube over a gas flame until the rosin melts.

- Place POS-30 or 40 solder and melt it with a soldering iron, spreading it over the surface.

In everyday life, copper processing is encountered not only when it is necessary to solder copper heating or water pipes, but also in car repair if a crack or leak appears on the car radiator. In this case, you do the soldering of the copper radiator yourself. Instead of a gas torch, car enthusiasts use a powerful 250 W electric soldering iron for copper pipes. To strip copper, use sandpaper or a metal brush, and for soldering tin, rosin or orthophosphoric acid is used as soldering acid.

Soldering with a soldering iron at home

Soldering copper with a soldering iron is easier than using a torch. The procedure looks like this:

- The surface of the radiator is cleaned with fine-grained sandpaper or a brush.

- A few drops of acid are evenly applied to the edges of the damaged area.

- The crack is heated with an electric soldering iron and solder is applied. Having melted, the tin fills the hole.

Independent soldering of copper heating or water supply pipes, repairing cracks in radiators is a simple technology process that can be done at home with a small set of tools.

WATCH THE VIDEO

Soldering copper at home is something every man can do.

Installation stages

Preparatory procedures

Novice craftsmen often neglect the procedure for preparing materials, which negatively affects the quality of installation . For cutting, use a pipe bender or a hand saw with a metal blade. A professional tool for deburring – a chamfer. Alternatively, you can use sandpaper.

Particular attention should be paid to cleaning the area that is inserted into the fitting and the inner surface of the connecting element.

Flux application

The next step is applying a special flux for soldering copper pipes. Each type of solder has its own type of flux. For example, for durum varieties it is recommended to use borax. The procedure is no different from the preparation of aluminum or other metals: the composition is evenly distributed over the working surface.

Low temperature soldering

To work in low-temperature mode, you can use a regular disposable gas torch or an electric soldering iron.

The main difficulty lies in maintaining the temperature regime , since overheating negatively affects the quality of the connection.

When heating the joint area, it is necessary to move the burner smoothly to uniformly heat the entire surface. Once operating temperature is reached, solder begins to be added. If it starts to melt, you should remove the flame - then the solder will fill the mounting gap.

Upon completion of work, you should wait for the metal to cool under natural conditions . Hot joints have low strength, so any contact with the seam should be avoided until it crystallizes.

Nuances of high temperature

As the name suggests, this technology has a high operating temperature, so acetylene or a mixture of propane and oxygen is used as a flammable component. A characteristic feature is the short duration of the temperature effect , in order to avoid overheating of the pipes. The operating temperature varies between 750-900 Cº, depending on the selected solder.

After completing the work, it is necessary to wait until the seam crystallizes, and then remove any remaining flux from the surface.