The sucker rod line in this diagram is represented by a solid black line in the center of the well.

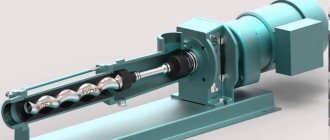

A sucker rod

This is a steel rod, usually 25 to 30 feet (7 to 9 meters) in length, and threaded at both ends, used in the oil industry to connect the surface and well components of a piston pump installed in an oil well. B, the pumping station is a visible surface drive for a downhole pump, which is connected to the downhole pump at the bottom of the well through a series of interconnected sucker rods. Fiberglass sucker rods are also widely available in 37 1/2 foot lengths and 3/4, 7/8, 1 and 1 1/4 inch diameters. They terminate in metal threaded ends that are female at one end and male at the other.

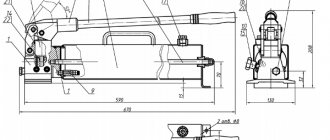

The surface unit transfers energy to pump the well from the prime mover to the sucker rod string. In doing so, he must change the rotational motion of the prime mover to the reciprocating motion of the sucker rod. And it must reduce the prime mover speed to a suitable pumping speed. Speed reduction is achieved using a gear reducer, and the rotational motion of the crankshaft is converted into oscillatory motion using a balancer. The connecting rod is connected to the balance beam using a connecting rod. The walking beam is supported by a Samson post and saddle support. The horse's head and bridle are used to pull on the rod string vertically at all times, so that no bearing movement is applied to that portion of the sucker rod column above the box filling. A combination of polished rod and oil seal is used to maintain a good seal of the fluid to the surface.