Lifting operations pose a great danger to the lives of personnel and people in the work area. Therefore, the first condition for working with lifting equipment and devices is to ensure their safety.

The “Inter-industry rules for labor protection during loading and unloading operations and placement of goods” POT RM-007-98 and other regulatory documents have developed standards and recommendations for the inspection and rejection of all types of removable lifting devices. In this article we will talk about the norms and rules for rejecting chain, rope and textile slings.

Inspection and rejection of slings is carried out by engineering and technical personnel responsible for the serviceability of the equipment and the safety of the work performed. To identify faults, slings undergo external, instrumental and internal inspection, during which the compliance of the slings with their characteristics reflected in the product passport is assessed. The assessment results are reflected in the inspection log, which is drawn up in the prescribed form. The log should also reflect information about the elimination of defects and damage and contain the signatures of the responsible persons.

Norms for rejecting slings

Steel rope slings

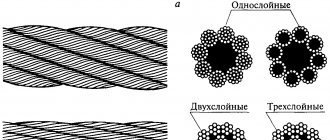

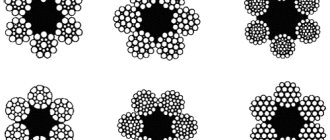

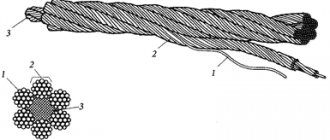

Rope slings are produced in accordance with GOST 25573-82 and RF-10-33-93. They must undergo all 3 stages of inspection: external, instrumental and internal. If non-compliance with safety requirements is detected, as well as if damage exceeds the established standards, rope slings should not be allowed to work.

When inspecting rope slings, the main focus is on the following aspects:

- compliance of the sling and the data on the tag with the passport data of the product;

- loops at the end of the rope and their serviceability;

- defects and damage along the length of the rope and their acceptable level;

- condition of the internal strands and core.

In what cases are rope slings subject to rejection?

- Rope slings are subject to rejection if there is no tag or marking on it.

- Wear of outer wires should not exceed 40% of their diameter

- The rope should not be used if the core is torn or squeezed out.

- A rope is subject to rejection if the diameter has decreased by 7% or more with corrosive wear, by 3% or more with a non-rotating rope, and by 10% or more with internal wear and rupture of the core.

- Also in case of deformation, cracks or wear of thimbles with a decrease in thickness by more than 15% and bushings with a decrease in thickness by more than 10%, with damage to braids and other protective elements.

- When there are signs of displacement of the rope in the braid, bushings and clamps.

- If there are protruding ends of the wire in the braided areas by more than half the diameter of the rope.

- The sling is subject to rejection for waviness, if the diameter of the spiral, coinciding with the direction of lay, is 1.08 times greater than the diameter of the rope, and if the diameter of the spiral does not coincide with the direction of lay, then 1.33 times.

- The rope should also not be allowed to work with defects resulting from exposure to temperature or electric arc discharge.

- The number of breaks should not exceed the following standards:

| Number of breaks | Rope length |

| 4 | 3 x rope diameter |

| 6 | 6 x rope diameter |

| 16 | 30 x rope diameter |

Important!

In cases where the wear of the outer wires reaches 30% of the diameter of the rope or, as a result of wear, the diameter of the rope decreases by 5% or more, the above figures are halved.

Chain slings

Chain slings are produced in accordance with PB-10-382-00 and TU3150-001-52466920-2005. Among all slings, chain models have the longest service life - 18 months. Regular inspection of chain slings includes visual and instrumental stages, during which the following are studied:

- tags and markings, as well as their compliance with the product passport;

- serviceability of the connecting elements at the end of the sling;

- diameter and length of chain links and deviations from the original dimensions.

Chain slings are subject to rejection

in the following cases:

- When there is no tag or marking on it.

- For any cracks, ruptures, deformations and delaminations of the metal.

- When the link is lengthened by more than 3%

. - When it decreases by more than 10%

due to mechanical wear and corrosion. - For damage due to gas cutting, welding, electric arc cutting or temperature exposure.

Textile slings

To assess serviceability, textile slings must undergo a visual inspection for compliance of the markings with the passport, serviceability of seams and loops, connecting elements and grips. They must also undergo an instrumental inspection to determine dimensions and defects. If the following deficiencies are identified, textile slings should not be allowed to work.

- If there is no tag or marking.

- If there are knots or transverse breaks on the supporting tapes of the sling, despite their size.

- The length of longitudinal cuts or tears should not exceed 50 mm, and the total length should not exceed 10% of the length of the sling branch.

- In case of local delamination of the tape by more than 0.5 m with a break in three or more lines. And also in case of delamination on the sealing edges of more than 0.2 m and deviations of the edge of the loop with a length of more than 10% of the stitching length.

- In case of surface breaks of the belt, damage from chemicals, as well as single damage measuring more than 10% of the width of the belt.

- With through holes from sharp objects or burns with a diameter of more than 10% of the width of the tape. It is also not allowed to have three or more holes with a distance of less than 10% of the width of the tape.

- When more than 50% of the sling length is contaminated with cement, soil, paints, petroleum products, and so on.

The above points apply to tape

textile slings.

to the rejection standards for round-strand

slings: rupture of the cover, breaks of 6 or more wires, breaks of threads in the stitching unit by 10 percent or more of its length and through holes in the cover.

Multi-leg slings are subject to rejection if there is a difference in the branches due to their elongation. The table shows the minimum permissible residual elongation of the branches of different slings:

| Cable cars | Chain | Textile |

| 3% | 1% | 6% |

Features of instrumental and visual control

Safety regulations and building codes require checking the serviceability of the sling immediately before starting work, as well as at intervals of 10 and 30 days. Products with a high degree of wear and obvious defects are tested out of turn.

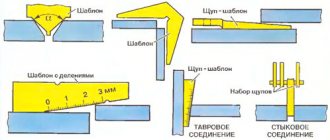

When checking monthly, it is necessary to use the most effective control equipment options; for routine checks, a caliper or micrometer is required.

It is strictly prohibited to use products that have not passed the full cycle of tests and do not have a tag indicating the load capacity, date of manufacture and other mandatory data.

2.1. General requirements

2.1.1. Load slings must be manufactured in accordance with the requirements of this RD, Rules for the design and safe operation of load-lifting cranes,

as well as design documentation approved in accordance with the established procedure.

The design and manufacture of cargo slings must be carried out in organizations and enterprises that have a permit (license) from the Gosgortekhnadzor of Russia and have qualified specialists and technical means to ensure the design and manufacture of slings in full compliance with the requirements of this regulatory document.

To obtain a permit (license) for the production of slings, the manufacturer must submit to the territorial bodies of Gosgortekhnadzor the documents specified in clause 2.1 of the Regulations on the procedure for issuing special permits (licenses) for activities associated with increased danger of industrial production (facilities) and work, as well as ensuring safety during the use of subsoil, approved by Resolution of the Gosgortekhnadzor of Russia dated 07/03/93 No. 20.

The application of the sling manufacturer must be accompanied by other documents confirming the possibility and readiness of high-quality production of slings, including:

technical specifications for manufacturing, approved in accordance with the established procedure;

working drawings of slings;

description of the technological process for manufacturing slings (technological maps);

certificates for ropes and chains;

certificate of availability of certified specialists (if welding work is required).

A permit (license) for the manufacture of slings is issued by the territorial bodies of the Gosgortekhnadzor of Russia based on the results of an inspection of the manufacturer and consideration of the documentation submitted by it. Slings manufactured for third-party organizations must be provided with a passport (the form of the Sling Passport is given in).

2.1.2. Calculation of ropes and chains of slings used both for direct tying of cargo and for capturing the latter using end links is carried out in tension.

2.1.3. Determination of forces in ropes and chains of two-, three- and four-branch slings in the absence of additional requirements is carried out based on the condition that the angles between the branches do not exceed 90° ().

Rice. 1.

Slinging a load of two ( a)

), three- (

b

) and four-legged (

c

) slings

2.1.4. Calculation of three- and four-leg slings in the absence of a guarantee of uniform distribution of loads between the branches is carried out based on the condition that the load is held by only two branches.

2.1.5. When calculating under the action of a rated load, the safety factor for ropes and chains in relation to the breaking load specified in their certificate must be at least 6.0 and 5.0, respectively.

2.1.6. When checking the cross-sectional strength of the working part of the sling hook and taking into account the curvature of the latter, the safety margin in relation to the yield strength of the material is taken to be no less than 1.2, and for the cross-section of the branches of the hook head with an eye when calculating tensile strength - no less than 1.5.

2.1.7. When calculating loops of all types, their straight sections are calculated for tension; The safety margin relative to the tensile strength of the material must be at least 5.0. For curved sections, when calculating taking into account their curvature, the safety factor for the inner side of the section should be at least 1.1 in relation to the yield strength of the material, and on the outer side - at least 1.3 in relation to the strength of the material.

2.1.8. The load capacity of chain slings intended for moving cargo with a temperature above 300 °C, but not more than 500 °C, is reduced by 25%, and above 500 °C - by 50%.

2.1.9. Rope slings, the branches of which are made of ropes with an organic core, may be used for transporting goods with a temperature not exceeding 100 ° C, and slings, the branches of which are made of ropes with a metal core, with the ends of the rope sealed by crimping aluminum bushings - not higher than 150 °C.

The load capacity of slings with branches made of rope with a steel core when moving loads having a temperature of 250 to 400 ° C is reduced by 25%; movement of cargo with a temperature above 400 °C is not allowed.

2.1.10. The deviation in the length of the branches used to complete one sling should not exceed 1% of the length of the branch.

How to assess the condition of the cable core (its property)

Service life of workwear: standards

Based on the standards for rejecting steel ropes, they can be considered faulty even in the absence of external damage. This happens if flaw detection reveals damage to the core. The rope is considered unsuitable for use if the inspection reveals more than 18% loss of wires of the internal part.

Note! Not every enterprise has such equipment, as well as specialists to service it. And this is normal, because there is no need to constantly check the sealed parameters of the core. These tests are only required for products that must meet very high safety requirements.

In production

Repair

5.1. Restoration repairs involving welding of load-handling devices, containers and their elements must be carried out in specialized organizations that have technical means and qualified specialists.

5.2. Routine repair of elements of lifting devices and containers without the use of welding (straightening parts, sealing ends of ropes, replacing fasteners, etc.) must be performed by mechanics for the repair and maintenance of hydraulic lifting equipment, in accordance with the repair documentation and under the guidance of a specialist responsible for the maintenance of lifting structures in working condition

5.3. Information about the quality of individual repair work must be entered in the repair log. When accepting a lifting device or container from repair, it is necessary to inspect and test it in order to determine the degree of reliability.