Corrugated sheets are profiled sheets of galvanized steel that have a universal purpose. It can be used as wall cladding, for making fences or various enclosures, as well as for covering flat and pitched roofs. MP 20 corrugated sheeting is one of the most popular, popular brands of this material, mainly used in roofing work. In this article we will talk about its technical characteristics, varieties, and possibilities of application in construction.

Description of material

Profiled sheet MP-20 optimally combines good load-bearing capacity, low weight, and aesthetic appearance.

Profiled sheet with the designation MP 20 is the same as C 20. In the first case, the coating is produced by the Metal Profile company in Lobnya, and the second combination is used by other manufacturers, which also produce MP20 profiled sheet. The variety of rental options and low cost allow it to be used in various areas.

The properties of the profile depend on the base metal. Galvanized corrugated sheet C20 is a material made up of several layers, the number of which varies from 3 to 10. The qualities of the profile depend on the structure of the films and their thickness.

Film coating technology is regulated by the following documents:

- TU 141.46.95 – 1989, GOST 149.18 – 1980, which sets out standards for the production of cold-rolled steel with galvanized oxide film;

- TU 141.47.92 - contains recommendations regarding galvanized metal with a polymer layer;

- TU 141.12.47 – 1988 – technology for applying aluminum-zinc film;

- GOST 24.045 – 94 - composition and requirements for paint and varnish coatings;

- TU 11.220.01.525 -2003 - quality indicators for powder painting.

Profiled sheet MP 20 contains galvanized metal with an oxide film on both sides. Increasing the number of other layers leads to increased useful properties and extended service life. The outer covering differs in texture and color. The surface has the appearance of natural stone, brickwork, wood, and can be matte or glossy.

Manufacturing and painting technology

The metal profile is made from rolled steel, which is given a corrugated structure using special rollers.

The MP 20 metal profile is made from rolled steel, which already has a color coating. The protection is applied on technological conveyors, and attention is paid to the quality of workmanship, since the film may be destroyed during the stamping process. Paint is rarely applied to a finished profiled surface due to the complexity of the shape.

Manufacturing includes the following steps:

- galvanizing of ferrous metal to increase resistance to moisture;

- creation of an oxide film on the surface;

- primer treatment to increase adhesion with subsequent layers;

- polymerization with compounds, varnishing;

- protective coating with a special film.

Galvanizing is done by passivation using anodes or cathodes in an electrolyte solution. Here, zinc reacts with various melts, resulting in an oxide film. The barrier protects the metal from rust and destruction.

Decorative polymer coating can be 25 - 200 microns thick; in a thick layer, relief embossing is done to match the texture of wood and stone. The back of the profile is coated with durable varnish. Paint and varnish layers are applied by continuous rolling of a galvanized roll on an automatic line. After this, the painted steel is transferred to stamping, chopping, and stretching conveyors.

Requirements for a protective polymer barrier:

- fast hardening, resistance to contamination;

- good adhesion to the galvanized layer;

- flexibility, elasticity, scratch and abrasion resistance.

Automation reduces material costs by 25–40%. On mechanized lines, paint can be applied on both sides or only on the face.

Positive and negative properties

Metal profiles are available in a wide choice of colors.

The dimensions of MP 20 corrugated sheets allow you to install sheets without the use of special lifting equipment. Profiled products weigh little. To install the panels into the mounting position, a few assistants are enough.

Other useful features

- A reinforced frame is not made for the sheets, since wall finishing made from C 20 corrugated sheets does not load the wall too much. They also do not care about strengthening the foundation, and they put cladding on old buildings.

- You can order any length of corrugated sheet strips, so the roof is covered along the length of the slope without joints. This method avoids leaks at connections and speeds up the work.

- Flexible material is used for complex structures. The profiled sheet will last from 25 to 50 years, depending on the type of polymer barrier on the surface of the sheet. Corrugated sheeting will not rust, will retain its color and shade for a certain time, and will not deform.

- Harmful microorganisms, mold, and moss do not develop on the panels.

- Large selection of colors and textures to match various natural materials, attractive appearance.

The disadvantage of a metal profile is that it conducts sound well. Therefore, raindrops and birds produce a “drum effect”. They combat this phenomenon with sound insulation, which is installed together with the coating.

Galvanized corrugated sheeting MP 20 1100 0.7 can only be used on slopes with a large slope, since on other roofs it will not withstand the additional load from snow.

When cutting, the seams are immediately painted with special compounds from a spray bottle so that corrosion processes do not begin. For the same purpose, welds to the supporting frame are additionally protected from moisture by painting. For welding, sheets with a thickness of at least 0.8 mm are used.

Production Features

Galvanized steel is used to make profiled decking. Its thickness, depending on the purpose of the final product, varies from 0.36 to 0.8 millimeters.

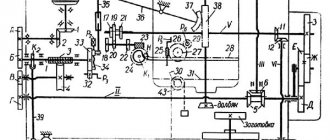

For production, the cold rolling method is used: the rolled web is unwound by special machines and fed to the rolling table. Next, it is passed through roller machines, where the material acquires the corrugated shape necessary for its operation. Then the sheets are cut according to the specified parameters, and only then they are sent for final processing.

The final coating can be paint, polymer coating or galvanization. The most resistant against all environmental troubles is, of course, a polymer coating: it does not crack in the sun, and in addition, it is not afraid of moisture and does not rust.

Scope of use

Metal profiles are used for the manufacture of fences and fences.

Unlike other brands, which are used in any form for facades and roofs, MP20 corrugated sheeting is produced in three versions. Each is designed for its own area of use.

Modifications of the MP 20 brand:

- Type A and B. Designed for the manufacture of fences, they are placed as filling between pillars of brick, stone, steel, and concrete. This type is always used on the profile surface by default. Trapezoidal corrugations are located at equal intervals of 137.5 mm. The ridge is 35 mm wide at the top, with a lower section of 67 mm between them.

- Type R. Used for roofing work. The comb is 67.5 mm wide, the pitch between waves is 35 mm. It has greater strength compared to markings A and B.

Decorative profile options are used for the facade. Often the base is made with corrugated sheets with a masonry pattern; a brick pattern is also used for the lower part of the building. Such a pedestal at home inspires a sense of solidity of the structure. For walls above the base, a pattern of wood, brick, or leather is used. Plain sheets with various colors according to the RAl catalog are placed on the roof.

Universal flooring

It is more convenient and cheaper to use universal flooring. These are sheets of the NS, NPC, MP20 series. Broad-spectrum materials are more in demand than highly specialized ones. Because they can be purchased in large quantities, which is much more economical, and used on different objects (say, a fence and a roof of the same color).

NS combines the properties of both types of sheet coating. It is light and flexible, like roofing, but at the same time quite durable, like wall covering. In addition, almost every plant produces flooring with stiffeners and painted either with special paint under pressure or using electrolysis. In addition, it is considered a variable material, if desired, change the roof at least every year once a month.

Using universal profiled sheets, it is much easier to carry out the process of covering a roof or fence. This is explained by the fact that self-tapping screws, rivets and screws can be used as mounting parts (it is best to use threaded options, as the fastening is stronger and more reliable, and it is also not necessary to buy a special tool). Its marking looks like this - NS45-1200-0.8:

- 1200 – sheet length;

- 0.8 its thickness;

- NS 45 – brand type.

Sometimes it is marked as follows: MP45-1000-0.8. Why MP? This is a designation according to specifications; most likely the marker is simply using old instructions.

The only requirement for the installation of such profile sheets is the need to install drain grooves. Despite all the positive qualities, universal corrugated sheeting does not tolerate standing water very well. Moisture must be removed from the roof, for example, otherwise the sheets will begin to rust.

Video: how to choose the right corrugated sheet

The main features of universal corrugated sheeting:

- installed on any surface (but again, take into account either the presence or absence of stiffeners);

- used for covering greenhouses, roofs, fences and much more;

- Corrosion-resistant paints are used to cover it.

Appearance of the material

The roofing corrugated sheet is equipped with a capillary trench.

MP 20 corrugated sheeting is produced with a profile height of 20 mm. The size of the trapezoids on both sides is different due to the inclination of the side walls. Some manufacturers produce products with a corrugation height of 18 mm, despite the stated marking.

Type of corrugation:

- For wall use, sheets are made with a wave without a roofing groove on the crest and the painting will be on both sides.

- A roofing metal profile marked with the letter R is produced with a gutter on the crest of the wave for water drainage, and polymer protection is made only on one side.

- Options with semicircular waves, with a pair of rectangular protrusions stamped between them; this profile has an original appearance.

- The corrugated sheeting for the roof is equipped with a capillary groove, pressed along the side border of the sheet at the point of overlap with another element on the roof to drain condensate during the operation of the coating.

The main colors for the MP 20 brand are: 9003 signal white, 6005 moss green, 8017 brown chocolate, 3005 red wine, 8019 brown-gray, 7024 graphite gray, 1015 light ivory.

Tips to help the buyer

Detailed familiarization with the nuances of material selection and its labeling is only part of the story. Practical recommendations from experienced roofers will help the future owner not to make a mistake in purchasing:

- Buy material for work from one supplier . Immediately calculate the consumption to purchase from one batch. So that you don’t have to search long and painfully for one sheet of corrugated tin of a similar tone and thickness.

- Purchase additional elements and fasteners together with the roofing . You can, of course, later in another store, but the shade may differ. If this was not included in the design, the effect may be completely unexpected.

- Pay attention to the integrity of the packaging . There shouldn't be any damage. It is possible that under the rupture there is already a microcrack in the polymer shell. This means that there is a possibility of a rust outbreak.

- Consider the sheets and additions . If you find the smallest scratches or abrasions, feel free to contact the seller for a replacement.

- Buy repair paint to match the corrugated coating . It will be useful during installation and after, if damage left by branches or vandals is detected. Do not buy spray paints.

It’s worth following the tips listed above if you don’t want to waste your money. If, of course, you have excess savings that you can easily part with, then you can ignore the recommendations presented.

Corrugated steel does not require any special maintenance techniques. Dust is washed off from its surface without delay during rains. The snow coming off the slopes does not leave scratches or streaks.

If persistent contamination is detected, it is recommended to wash the corrugated sheet with soapy water and wipe with a soft cloth.

Specifications and Dimensions

Wall metal profiles are produced with a thickness of 0.35 - 0.5 mm, and material for roofs is produced with a thickness of 0.55 - 0.8 mm. A profile with a thickness of up to 0.4 mm is classified as an economy category; more often, walls are lined with a profile of 0.4 - 0.5 mm. The division by metal thickness is conditional, since roofing is also used for cladding facades and fences.

The roofing option marked R is most popular in a thickness of 0.5, which provides an optimal ratio of cost and quality.

Performance characteristics:

- total width from edge to edge - 1150 mm, working width taking into account overlap - 1100 mm, lock takes 50 mm;

- the length can be ordered from five to twelve meters, but builders do not recommend using sheets longer than 4 - 5 meters for ease of installation.

The thickness of the zinc layer on the surface of the sheet plays a role. There is a material with thin galvanization, which is characterized by a weight of less than 100 g/m². This metal profile is used for temporary structures, since it is the zinc oxide film that protects against rust.

The recommended zinc layer on the metal plane should be in the range of 140 – 275 g/m². Accordingly, the types of metal have a difference in price, so before purchasing they are determined for the purpose of use.

How to determine quality

First of all, an external inspection. The quality of application of paint, polymer or galvanization is the first indicator. There should be no sagging, drips or bald spots. GOST allows for abrasions and small scratches that do not damage the integrity of the protective layer. That is, if the scratch does not reach the metal, this is normal. This happens all the time during transportation. The main thing is that the coating is intact.

One of the indirect indicators of the quality of corrugated sheets is its weight. Reference values are indicated in GOST (available in the table). If the weight varies significantly downwards, this means that a thinner sheet or less dense (and cheaper) metal was used.

Direct evidence of the manufacturer’s reliability is the thickness of the sheet. If the declared thickness matches the actual one, this is a good sign. How to measure the thickness of a profiled sheet? Using an electronic caliper. Not such an expensive tool, but easier to use. If you have a regular one, you can take measurements using it. But keep in mind that the actual thickness - with a layer of paint or polymer - should be at least a little (several micrometers) greater than declared. This difference will be shown by an electronic device. A mechanical one will not cope with such a task.

Classification of MP 20 profiled sheets by type of coating

Several types of film are used for polymerization. The layers differ in thickness and chemical composition. Corrugated sheeting also includes profiled polycarbonate MP 20 and metal tiles with a figured wave.

Types of polymer coatings:

- Acrylic. The coating works for a long time, but after a few years it fades and fades. The layer thickness is 25 microns, the film is easy to damage. Such sheets are installed on temporary buildings.

- Polyester. The second budget option with a similar thickness of 25 microns. Additives increase sun resistance, so it fades less. The strength is low, it is easily scratched and erased.

- Plastisol. Contains polyvinyl chloride and modifiers. The thickness of 200 microns allows for surface embossing. Durable coating, used in chemically contaminated conditions.

- Pural. During production, polyamide is combined with polyurethane, resulting in a reliable and durable material. It is not destroyed in conditions of heat and frost, and is used on the seashore in conditions of increased insolation.

The most reliable of all layers is considered to be a polydifluorionade coating. The effective coating does not react to harmful chemicals, alkalis, and acids in the atmosphere. It differs from other coatings in its high cost.

Brands of corrugated sheets

Typically, corrugated sheets are made of sheet steel with zinc and aluminum-zinc coating. If they use an aluminum-zinc coating, they put AC in the marking, if they use zinc, they don’t put anything. If zinc is applied electrolytically, then EOTS is installed. The sheet can also be coated with a layer of aluminum (letters AL in the marking) or aluminum-silicon (AK). These coatings provide better protection, but are expensive.

Profiled steel sheet with a protective coating - this is corrugated sheeting

In addition to various “primary” coatings, rolled steel sheets are used in various thicknesses. In combination with different profiles, it has different load-bearing capacities, accordingly, it has different purposes and areas of application. According to their purpose, profiles are divided into types (GOST 24045-2016):

- N - for load-bearing covering decks that support the weight of the roof with insulation and the load of climatic influences;

- NS - for flooring and wall fences;

- C - for wall fences that perform load-bearing and enclosing functions.

Sometimes there is such a decoding of the designations of corrugated sheets, where type H is load-bearing (for load-bearing covering decks that bear the weight of the roof with insulation and the load of climatic influences). He is the heaviest, the toughest. Roofs with high snow and wind loads are made from this corrugated sheeting.

Brands of corrugated sheets and their purpose

NS - load-bearing wall. Another name is universal. Less “hardy”, but can be used on the roof with low loads on it. It is also possible to build load-bearing walls from it (with sufficient thickness and depth of the relief). He is often “allowed” onto fences that do not have crossbars between the posts.

C - wall profiled sheet. Used for cladding frame walls. It is used in the construction of garages from corrugated sheets and utility rooms. The same type, but of sufficient thickness, can be attached to the fence if there are crossbars between the posts. This material is not recommended for roofing. Unless there is almost no snow and wind. And then, the sheathing should be frequent, with small gaps.