Gas pipes are installed regularly. It is prohibited to weld gas pipes yourself. Such work can only be done by a specialist with extensive experience. The most common material for gas pipes is steel. The connection of pipeline components is carried out using plasma, argon arc technology or electric welding. Any types of welding work must be carried out in specially equipped places.

Welding of metal pipes for a gas pipeline is carried out in several ways

Features of gas pipeline welding

The choice of welding technology for gas pipes depends on the material they are made of. The gas industry uses metal and polymer pipes; their welding can be:

- electric arc;

- gas (plasma);

- argon arc;

- diffusion

The welding method depends on specific conditions, for example, pipe wall thickness, type of plastic or steel, outer diameter, etc. The most common method is to weld gas pipes using electric welding. Before starting work, the edges of the pipes are cleaned of corrosion and contamination. If the pipe wall thickness is more than 4 mm, then the edges are beveled, which affects the quality of heating of the metal.

Welding can occur from left to right and vice versa. The first option is used for pipe thicknesses of more than 5 mm. The flame is directed to a section of the pipe that has already been welded. The filler wire moves behind the torch.

Note! This method saves gas consumption and increases productivity.

When the burner moves from right to left, it passes through parts of the products that have not yet been welded. The consumable electrode is located in front of the burner. This method is suitable for connecting thin-walled pipes. Welding seams when working with gas pipes are classified into vertical, horizontal, ceiling and bottom.

Which welding method to use depends on the type of pipe and its location

How to weld a gas pipe using electric welding

There is an opinion that welding pipes is a fairly simple technological operation that even a beginner can handle.

Indeed, it would seem that there is nothing complicated here. The parts are quite large, the connecting surfaces are well adjusted to each other and processed, the material is of high quality. At first glance, there is everything necessary to form an aesthetic and durable seam!

In practice, however, it turns out completely differently. This process is quite difficult, especially when it comes to the formation of a full-fledged pipeline operating under pressure. The best specialists are attracted to work with its segments.

Why is this happening? How to perform high-quality welding without significant experience? What tips and tricks should you follow?

Core Technology

The most common and popular technique is electric arc welding.

Yes, it has alternatives in the form of gas welding, but its undeniable advantages lie in simplicity, a minimal set of equipment and a result that meets the most stringent standards.

Even when designing main pipelines, this method is used. To achieve high quality, you must treat your work with full responsibility.

Selecting Electrodes

The connection of steel pipeline segments must be carried out using high-quality consumables, otherwise it is unlikely that a good result will be achieved.

For example, when it comes to choosing electrodes, the following models are considered the best:

- ANO-21, ANO-24 and MR-3 . They operate on alternating currents. Work is allowed even with wet coating. The cost of the products is low, which explains their demand in everyday life; they are ideal for connecting structural elements of gates, greenhouses and other light-weight structures that do not experience high loads. Work with pipelines in which the medium is transported under significant pressure is not permitted.

- SSSI . The quality of the cores deserves flattering reviews even from professional welders, but they have a disadvantage - work cannot be carried out at high speed. It is necessary to constantly monitor the stability of the arc; the weld is deposited gradually, so the worker must have some experience in interacting with classic ANO and MR electrodes.

- LB-52U electrodes are excellent for metal pipes . This is a Japanese development. It is the one that is preferred when implementing large projects. They form an even and stable arc, the resulting seam combines strength and aesthetics. The downside is the rather high cost, but they are suitable for both specialists and beginners.

Watch a video on the topic of which electrodes to use for welding pipes:

Basic methods

The connection can be made in one of the following ways:

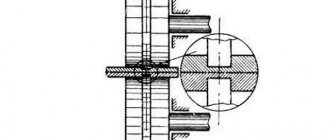

- Butt joint, when the pipes to be connected are placed opposite each other. The most common option, characterized by relative ease of implementation. However, it is also characterized by certain difficulties. The first point is that it is better to work from below. The second point is that it is necessary to thoroughly weld the metal so that the depth of penetration corresponds to the thickness of the wall.

- Overlapping. This method is focused on connecting elements that initially differ in diameter, or segments, one of which is flared, that is, its diameter is intentionally increased by mechanical action.

- The T-joint is made at a 90-degree angle.

- A corner connection assumes that the angle between the connected segments is less than 90 degrees.

Useful tips

Before electric welding pipes, it is worth remembering a number of tips, following which will simplify the process and also improve the quality of the final result:

- If the connection is made using the butt or tee method, then electrodes whose diameter varies from 2 to 3 millimeters perform best.

- The recommended amperage is from 80 to 100 amperes, with the exception of overlap welding, when it is recommended to increase it to 120 amperes.

- When filling a welding seam, you need to ensure that the rise of the metal above the plane of the element reaches 2-3 millimeters.

- If the cross-section of the pipe is not the usual ovals or circles, but profiles, that is, rectangles and squares, then a point method of connecting it is used.

Its essence is that initially you need to weld a small area on one of the sides. Next - a similar section on the opposite side, then - on the remaining two planes. Only after this the pipe is finally welded.

This approach makes it possible to eliminate the possibility of warping of the product when the temperature rises; its geometry remains stable.

Preparatory operations

The final quality of the joint depends not only on the professionalism of the welder and the use of the “correct” electrodes, but also on how well the preliminary preparation is done.

It consists of the following operations:

- Checking the compliance of the geometry of the connected elements with the selected technology. It must be remembered that the wall thickness must be identical, otherwise it will not be possible to fully weld a thick-walled pipe, and in the case of working with a thin-walled product, on the contrary, the risk of burn-through increases.

- The presence of defects on the welded products, be it cracks, creases or deformations, is not allowed. During the process of thermal expansion, they can turn into areas of complete destruction of the structure.

- Geometric deviations of the cut are not allowed. Its angle must be 90 degrees, otherwise the welding seam will not be strong enough and problems will arise with its formation, which will pose a threat of destruction of the entire structure.

- The edges of the connected pipes must be cleaned until a shiny metal surface appears, for which coarse sandpaper or a special brush is used. The minimum length of the area to be cleaned is a centimeter from the edge.

- Grease and other contaminants, traces of paint and corrosion are removed. The most effective removal agent is a chemical solvent.

This video shows how to prepare the edges of a pipe for clearance using a grinder:

Process Features

Pipe welding technology requires following the following rules:

- The seam must be continuous, that is, end at the point of its beginning. Tearing of the electrode from the surface is not allowed. It is impossible to follow the rule if the pipe diameter is too large. In such a situation, multilayer welding is used. The number of layers must be correlated with the thickness of the walls.

Performing argon arc welding

A special feature of TIG (Tungsten Insert Gas) argon arc welding is the use of refractory electrodes. They do not burn out during the formation of the weld. An arc occurs between the metal surface and the electrode after current is applied. Gas (most often argon) enters the working area through a nozzle, which blocks the access of oxygen. The seam is formed in one of the following ways:

- due to the melting of metal edges under the action of an arc;

- through the use of filler wire.

This type of welding of gas pipes allows you to get a good seam on thin metal products. Equipment for this connection technology is represented by rectifiers and argon inverters. A TIG rectifier converts AC to DC. The TIG inverter produces DC power with ideal characteristics. Some models of devices produce alternating current. When working with such equipment, it is possible to control the arc and obtain a high-quality seam.

The main characteristics of machines for argon pipe welding include the type of current and its maximum value. The higher the maximum current value, the thicker the electrodes can be used.

For argon welding you will need a DC machine

Welding of steel pipes is carried out using equipment using direct current (DC). Different argon arc installations have their own maximum welding current values, which range from 150 to 500 A.

Arc welding

This is one of the simplest and most reliable types of welding used to connect gas pipes. It is simple and reliable. True, provided that the work is done by a professional or a person who simply knows how to hold an electrode correctly in his hands.

The operating principle of this method is to connect parts using a fusible electrode. Under the influence of electric current, the moment the electrode touches the pipe, an electric arc occurs. Under the influence of electric current, the rod begins to melt, and the flux coating releases gas, which displaces atmospheric air. Thus, a weld pool is formed in which the metal of both the electrode and the parts melts into a single whole.

Arc welding

The advantage of this type of connection of parts is obvious - accessibility and simplicity. Both welding machines and welding electrodes are available in any quantity. But as for the disadvantages, it requires training and dexterity; those who do not know how to work in two days will not learn how to make the correct seam.

Welding with MIG/MAG technology

According to the degree of mechanization, connecting pipes by electric welding is divided into manual, automatic and semi-automatic. The technology for connecting gas pipes MIG/MAG (Metal Inert/Active Gas) is based on arc welding using a metal consumable electrode (wire) in the presence of an inert/active gas. The filler wire is fed automatically.

This method is implemented by the following devices:

- inverter semi-automatic welding equipment;

- semi-automatic welding machine;

- a set of a consumable electrode supply mechanism and an arc welding source.

MIG/MAG welding is performed by feeding a metal wire with a gun into the joint area and melting it in an arc. It is located between the product and the consumable electrode. The molten wire and edges form a weld pool. The crystallizing seam, arc, weld pool metal and wire are protected by gas from environmental influences.

MIG/MAG welding involves the use of special wire

Often this method is also called semi-automatic, since the welder must manually move the torch along the seam. The wire is both a filler material and a conductive electrode.

Important! It is better to regulate the gas supply using reducers with flow meters.

The MIG/MAG method can be used to weld low and high alloy steels. The quality of an electric welded joint depends on the arc voltage, the feed rate of the consumable electrode, the gas feed rate and welding.

Additional tools and materials

But the above equipment alone is not enough to carry out gas welding work. In addition to the gas welding machine, it is necessary to prepare additional tools:

- Retainers . Necessary to facilitate gas welding work and improve the quality of the joint created. If the part is securely fixed in a static position, then working with it is much easier.

- Lift . When it becomes necessary to connect bulky parts that are difficult to transfer to the table manually.

- Installation tool. Includes a set of wrenches or wrenches used to securely secure key elements of the welding station.

- Related tool . This list should include hacksaws, sledgehammers, pliers, hammers and other devices.

- Hood . Welding, which involves joining metals using gas, necessarily requires effective ventilation.

One of the principles of gas welding technology is the use of filler wire, which fills the weld pool. The wire for welding must be selected taking into account the composition of the surfaces that need to be welded. It must have a uniform and smooth structure. In addition, fluxes are used when welding with gas. We are talking about special compositions, produced in the form of a paste or powder, which are applied to the additive and edges to protect the melt from oxides.

Advantages and disadvantages of welding methods

Advantages of argon welding:

- high quality weld seam, reliable pipe connection;

- long service life;

- Possibility of welding stainless steel and titanium.

Disadvantages include special training and the lack of ability of some devices to operate in DC and AC/DC modes.

The advantages of MIG/MAG welding are high productivity, low smoke, ease of automation of the welding process and absence of slag. This method has limitations for outdoor use and the inconvenience of having a gas cylinder.

Semi-automatic welding of gas pipes can provide high quality connections on metals of different thicknesses, the ability to weld in many spatial positions, and low cost of work when using active shielding gases.

Each welding method has its own disadvantages and advantages

Butt welding of polyethylene gas pipes is quite common and provides low cost, high speed and ease of installation, as well as the ability to connect pipes with diameters of 50-1200 mm.

Equipment Specifications

Gas cylinders

Welding, which is carried out using portable equipment, involves the use of gases stored in special hermetically sealed vessels - cylinders. Each gas must be stored in a container suitable for it, which must have a special shape, dimensions and valve.

- Oxygen cylinders. For their production, alloy or carbon steels are used. Sometimes oxygen cylinders are made from seamless pipes, but they can only store gas for which the permissible pressure is no more than 30 kgf/cm². If it is necessary to maintain a lower pressure in the cylinder, then it should be made only of welded structures. In the latter case, it is recommended to use types 150 and 150JL with a maximum volume of 40 l. Moreover, it is important that during the manufacture of structures the requirements of GOST 949–73 are met.

- Acetylene cylinders. During their production, the requirements of GOST 5948–60 must be met. Most often, in order to ensure maximum safety, such containers are made in the form of two-chamber cylinders, which make it possible to more effectively equalize the pressure inside them. But at the same time, it is important to comply with the main condition - the internal pressure in the acetylene cylinder should not exceed 19 kgf/cm² at 20ºC.

- Cylinders for propane-butane mixture. Their production must be carried out in accordance with the requirements of GOST 15860–70. Such cylinders are made in volumes of 40 and 50 liters. The internal pressure in them should not exceed 16 kgf/m², and they should weigh no more than 24 kg.

Particular care must be taken when handling gas cylinders, as they belong to a high explosion hazard category. As a result, during their use, particularly stringent requirements for their operation must be observed. To be able to transport or carry them, a specialist must undergo special training and obtain a permit.

Cutters

In order to be able to change the pressure of flammable gas on welding equipment, each cylinder must be equipped with a reducer. When choosing a gearbox, first of all you need to pay attention to its throughput. It should be selected based on the type of work being done and the cutters used. Gearboxes come in two types, depending on the design: single-stage and two-stage. The latter are more accurate.

When the gases from the cylinder reach the cutter, they mix. The main part of the cutter is most often made of carbon steel and is equipped with various functional elements - shut-off valves, injectors, a mouthpiece, which are repairable. The cutter itself is necessary to control the welding process and mixing gases.

Cutters may differ from each other in power, which implies their throughput. Based on this, we can conclude that for each cutter it is necessary to select the appropriate burner, which must be of a certain type and size. All cutters have removable parts, so they are universal and can be used for welding with any type of gas.

Gas welding of steel pipes

Gas welding is based on heating the edges of pipes with an oxygen gas flame and filling the resulting gap with molten metal. Gas welding produces a connection with worse mechanical properties than electric welding, but it allows you to join small-diameter pipes with a wall thickness of up to 3.5 mm. To carry out the work you will need a gas burner and a cutter.

The welding process involves two gases – oxygen and acetylene. Oxygen supports the combustion of acetylene. It is located in special cylinders under high pressure, which is reduced during welding by using a reducer. The combustion temperature of acetylene can be 3 thousand degrees. Another flammable gas can be used instead.

Important! When burning gas, the flame temperature should be 2 times higher than the melting point of the metal being welded.

Welding wire is selected based on the identity of its chemical and physical characteristics with the same parameters of the parts being welded. The use of fluxes helps prevent metal oxidation. Gas welding allows you to obtain a strong connection between thin-walled pipes without burning through the metal.

Oxy-acetylene welding is suitable for joining thin-walled pipes

Equipment for gas welding and cutting

ACETYLENE AND PROPANE CUTTERS

| P1, Donmet-147A (plug-in) | |

| P1, Donmet-149 A, up to 100 mm, 6/6 or 9/9 | |

| P1, Donmet-142 A (RGR-100A), up to 100 mm, 6/6 or 9/9 | |

| R3, Donmet-300 A (RGR-300A), up to 300 mm, 9/9 | |

| P3, Donmet-337 A (MAYAK type), up to 300 mm, 9/9 | |

| R3-Promin-344 A (lever), three-pipe, up to 300 mm, 9/9 | |

| R3-Promin-347 A (valve), three-pipe, up to 300 mm, 9/9 | |

| "NORD", propane or acetate, three-pipe, increased reliability |

ACETYLENE AND PROPANE WELDING TORCHES

| G2-Mini DM 273 (tips No. 0,1,2,3), 6/6 | |

| G2-Mini DM 273 (tips No. 2,3 solid-drawn copper) | |

| G2-Malyatko (tips No. 0,1,2,3), 6/6 | |

| G2-Malyatko (tips No. 2,3 solid-drawn copper), 6/6 | |

| G2-Donmet 225 (No. 2.3 or No. 3.4), 6/6 | |

| G2-Donmet 225 (No. 2,3 or No. 3,4), 9/9 | |

| G3-Donmet 251 (No. 3,4,5), 9/9 | |

| GZU-Donmet 247 (No. 2,3), 6/6 or 9/9 (propane-oxygen) | |

| GZU-Donmet 249 (No. 5), heating and surfacing, 9/9 (propane-oxygen) |

PROPANE AIR BURNERS

| GV-231 (L=850 mm), wooden handle, valve, 9 mm | |

| GV-250 (L=850 mm), aluminum handle, valve and lever, 9 mm | |

| GV-252 (L=850 mm), 2-flare, valve and lever, 9 mm | |

| GVP-229 for soldering cables and copper pipes, aluminum handle | |

| GVP-246 for soldering cables and copper pipes, wooden handle, | |

| GV-231 (L=400 mm) for household purposes, wooden handle, 9 mm | |

| GV-254 set with nozzles of 3 sizes |

ACCESSORIES FOR CUTTERS AND BURNERS

| fitting 6.3mm / 9mm | |

| 6.3mm fitting for M16 nut | |

| nut M12 / M16 | |

| connecting adapter 6.3/6.3; 6.3/9; 9/9 | |

| universal connecting adapter 6+9/9+6 | |

| acetylene and propane mouthpieces for internal cutters P1 and P3 from No. 0 to No. 5 | |

| acetylene and propane mouthpieces for external cutters P1 and P3 No. 1 and No. 2 | |

| mouthpieces for three-pipe cutters of the “Promin” type, propane, with slotted grooves from No. 0 to No. 6 | |

| mouthpieces for three-pipe cutters of the “Promin” type, acetylene monoblock from No. 0 to No. 6 | |

| Tips for burners G2, G3 and “Malyutka” from No. 0 to No. 5, including solid-drawn copper, |

REDUCERS AND GAS FLOW REGULATORS manufactured by BAMZ or DONMET

| oxygen BKO-50-4 | |

| oxygen BKO-50-MG small-sized | |

| oxygen BKO-50 mini | |

| acetylene BAO-5-4 | |

| acetylene BAO-5-MG small-sized | |

| acetylene BAO-5 mini | |

| propane BPO-5-4 | |

| propane BPO-5-MG small-sized | |

| propane BPO-5 mini | |

| propane RDSG household (“frog”) | |

| carbon dioxide U-30-2 | |

| carbon dioxide UR-6 DM | |

| carbon dioxide U-30P-2 with heater | |

| argon AR-10-2, R-40-2 | |

| argon AR-40 DM | |

| argon regulator AR-40-6 | |

| nitrogen flow regulator A-30-2 | |

| universal AR-40/U-30 with rotameter | |

| pass-through heater PU-70 |

SAFETY VALVES

| check valve OBK - oxygen, M12, M16 | |

| check valve OBG - acetylene, propane, methane, M12, M16 | |

| fire-preventing valve KOK - oxygen M12, M16 | |

| fire-preventing valve KOG - acetylene, propane, methane, M12, M16 |

GAS WELDING RUBBER SLEEVE (price per 1 m)

| BLACK SLEEVE (coils 40 m): | |

| diameter 6.3 mm (3 cells) | |

| diameter 6.3 mm (3 cells) frost-resistant | |

| diameter 9.0 mm (3 cells) | |

| diameter 9.0 mm (3 cells) frost-resistant | |

| COLOR SLEEVE (coils of 30 and 40 m): | |

| diameter 6.3 mm (1 cl. red) | |

| diameter 6.3 mm (3 cl. blue) | |

| diameter 9.0 mm (1 cl. red) | |

| diameter 9.0 mm (3 cl. blue) |

PROPANE CYLINDERS (empty, new, with valve)

| 5 l. | 12 l. | 27 l. | 50 l. |

CYLINDERS FOR OTHER GASES (new or recertified)

| oxygen 5 l. | oxygen 10 l | |

| acetylene 5 l. | acetylene 10 l. | |

| argon 10 l. | carbon dioxide 12 l. |

GAS WELDING ACCESSORIES

| Pressure gauges for 4, 6, 25, 40 and 250 atm. | |

| Oxygen valve VK-94 | |

| Propane valve VB-2 | |

| Trolley for two 10 l cylinders. | |

| Universal wrench, cylinder | |

| Acetylene cylinder wrench | |

| Adapter for non-standard valve ½ - ¾ | |

| Welding mirror with regular handle | |

| Welding mirror with magnetic handle | |

| Replacement mirror unit | |

| Cylinder refilling device | |

| Gaskets for all cylinders in stock |

GAS WELDING TECHNOLOGY

Butt welding of polyethylene gas pipes

Welding of gas pipes made of polyethylene can be performed using mechanically or hydraulically driven devices, as well as program-controlled devices. Special tables available in the instructions for the devices regulate, depending on the wall thickness and diameter of the pipe, the values of welding parameters - temperature, heating time, etc.

The stages of butt welding of gas polyethylene pipes are as follows:

- The parts of the pipes to be welded are installed in the welding machine.

- A heated plate is placed between the parts to be joined.

- The ends of the pipes are pressed against the plate with some force.

- After some time, the polyethylene melts.

- After the pressure on the pipes is reduced, the ends heat up.

- The hot plate is removed.

- The parts are immediately connected under some pressure.

After complete cooling, the pipeline is ready for use. The seam is very durable and high quality. It is able to withstand pressure up to 4.5 MPa.

Special welding machines are used for installation of polymer gas pipes

Features of welding work in an apartment

For safety reasons, before starting welding work, the gas in the apartment is turned off. Household gas is highly flammable, so if the pipes are not shut off in time, it can lead to a fire. Welding of small diameter pipes can be carried out by one person.

Note! To connect pipes with different diameters, special adapters are used, which will reduce the likelihood of gas leakage.

Gas pipes in an apartment are often welded end-to-end. In this case, the arc must be conducted so that the edges of the product have time to melt a little, and the required amount of filler material is deposited on them. This will ensure the quality and aesthetics of all seams.

It is often necessary to digest a gas pipe in an apartment when moving it. After shutting off the gas, the process proceeds in the following sequence:

- The gas pipeline is purged to remove remaining gases.

- The unnecessary pipe is cut off, and the resulting hole is welded.

- A hole is drilled in the required location and the metal pipe outlet is welded to the gas pipeline.

- A tap is mounted to the outlet and a connection is made to the slab.

The presence of a leak is determined using special tests. If it is detected, re-installation is carried out. Upon completion of the work, gas is turned on and the functioning of the pipes is checked.

Before you begin installing the gas pipeline in the apartment, you need to turn off the gas supply valve

Safety precautions when welding gas pipes

If you need to move or digest gas pipes in your apartment, you should contact the gas service. In an apartment building, it is prohibited to carry out such work yourself; if necessary, they are performed by specialists from specialized organizations.

During the welding process, particles appear in the air from the oxidation of metal vapors. There is a danger of explosion due to improper handling of the acetylene generator and burner due to backfire. In addition, oxygen reducer valves may ignite or if the cylinder is opened suddenly. The most dangerous is the explosion of an oxygen cylinder, which is under high pressure.

Gas welding is harmful to vision due to the action of visible and infrared rays. It is prohibited to carry out welding work close to flammable and flammable materials. The room where gas pipes are welded must be well ventilated.

Before supplying gas to the pipes after welding, all connections must be checked for leaks. Only a specialist can weld gas pipes efficiently and safely.

Safety precautions

Work with electrical equipment and explosive gas must be carried out after the gas has been turned off. The gas pipeline must be cleared of gas residues, and the room must be ventilated. When working, you need to constantly ventilate the room from combustion products and gases formed during the metal smelting process.

It is recommended to have a carbon dioxide or powder fire extinguisher in the room where work is taking place. If a fire occurs, it can be easily localized and extinguished using fire extinguishers.

The insertion into the main pipe must be made by a qualified welder with the appropriate permit. It is not allowed to work with a gas pipeline under pressure.

When working, it is recommended to use an asbestos blanket or a screen made of non-flammable material to protect the decorative coating from exposure to flame and temperature.