Metal pipes have many advantages, but during their operation everyone can face one problem - corrosion. Corrosion of pipes leads to a reduction in their service life and waste of a huge amount of metal, especially when it comes to steel pipes. In connection with it, accidents and water leaks occur on water supply lines; because of it, the roughness of the inner surface of the pipes increases, which is accompanied by the appearance of additional resistance, a drop in water pressure and, ultimately, an increase in the cost of its supply. In other words, metal corrosion creates the need for additional construction and operating costs in water supply systems. That is why special attention is paid to the fight against corrosion in plumbing practice.

Causes of corrosion from outside and inside pipes

Both the internal and external surfaces of pipe walls suffer from metal corrosion. Corrosion from outside pipes occurs due to metal contact with soil, which is why it is sometimes called soil corrosion. Solutions of salts contained in the soil are liquid electrolytes, and therefore they destroy the structure of the metal during prolonged interaction with it. As a special characteristic of soil, its corrosive activity is distinguished, which is inversely proportional to the electrical resistance of the soil, that is, the higher the electrical resistance, the lower the corrosive activity of the soil, and vice versa - the lower the electrical resistance of the soil, the higher its corrosive activity. Thanks to the fact that this dependence is known, specialists can determine the corrosive activity of soils by measuring only the level of their electrical resistance. Corrosion inside pipes occurs from the corrosive properties of the water itself. Water with a low pH value and a high content of oxygen, sulfates, chlorides and dissolved carbon dioxide quickly leads to corrosion of the inner surface of the walls of metal pipes.

Causes

Corrosion of steel underground pipes is a phenomenon, the main reason for which can be called the reaction of electrochemical oxidation of metals from their constant interaction with moisture. As a result of such reactions, the composition of the metal changes at the ionic level, becomes covered with rust, disintegrates and simply disappears from the surface.

We recommend: Vacuum impregnation of wooden surfaces

The oxidation process may be influenced by the nature of the liquid that flows through the underground heating pipeline or the properties of the environment in which it is located. It is for this reason that when choosing suitable means to combat rust, it is necessary to take into account all the features that preceded its occurrence. Otherwise, repairs by welding are inevitable.

External insulation

The first and most important way is external insulation. In addition to anti-corrosion functions, it reduces heat loss and provides mechanical protection. Different materials can be used to create insulation; we will briefly consider the possible options. 1. Bitumen insulation.

It consists of a layer of polyethylene, which is protected by a bitumen coating.

Sometimes there may be fiberglass wrapped around the pipes. Can be used for pipelines located in clay, sandy and rocky soils. 2. Polyethylene anti-corrosion insulation.

It consists of a multi-layer coating, specially designed to protect pipelines from corrosion.

3. Polyurethane foam insulation.

There are two types. The first is the use of polyurethane foam shells, used for above-ground and underground pipelines for channel and non-channel pipe installation. The second is the creation of a polyurethane foam shell by injecting liquid polyurethane foam between the pipe and pre-created polyethylene insulation, after which the polyurethane foam hardens and turns into a complete shell.

There is also insulation with glass wool and mineral wool, however, these options are initially designed to reduce heat loss and prevent the creation of condensation, and not to protect against corrosion, which is why they are used primarily for insulating pipelines of heating networks. The thickness of the insulating layer can vary. In each specific case, the thickness is calculated depending on the functional load on the pipeline, the importance of the water line and the corrosive activity of the soil in which it is located - the higher this activity, the thicker the insulating layer should be.

Chemistry on guard

Protection of pipelines from corrosion according to SNiP includes many different comprehensive measures, but I want to give some specific methods that great science so graciously “gives” to us, and which I was able to put into practice:

Gift #1: External insulation

We figured out above that most troubles occur due to chemical reactions that occur as a result of long-term contact of metal with the ground. Therefore, the simplest and surest step is to eliminate it completely. Moreover, in this case, it is also easy to protect pipes from freezing, that is, “killing two birds with one stone.”

I will describe to you the option that I used myself, as well as alternative methods of insulating the pipeline being laid:

- Petroleum bitumen . It was this material that I took as the basis for protecting metal from rust in underground conditions. Its price fluctuates around 18-22 rubles per kg, which is quite favorable to the family budget. The working process:

- First of all, I cleaned the surface of the pipeline until it was shiny with a steel brush;

To do this, I recommend using a grinder with an appropriate attachment. This way the task will be completed much faster and with better quality.

Grinder with a steel brush attachment

- Then I diluted part of the purchased bitumen with gasoline to obtain a bitumen primer in the following proportions:

| Substance | Component |

| Bitumen | 1 |

| Petrol | 3 |

Mixing bitumen primer

- Carefully treated the metal surface of the water main with the resulting solution;

I do not recommend neglecting this stage, since it significantly increases the level of adhesion of iron to the oil substance.

- Next, I prepared bitumen mastic over the fire with the addition of crushed asbestos to enhance the strength characteristics of future insulation. Cement and kaolin are also suitable for this purpose;

Making bitumen mastic with your own hands

- I applied the first layer of hot mixture, after which I wrapped the pipeline with waterproofing . I used a model with the following characteristics:

| Parameter | Description |

| Base | Fiberglass |

| Weight of one square meter | 2500 g |

| Daily moisture absorption | No more than 1.2% |

| Absolutely waterproof | Three days of constant exposure |

| Price | 43.5 rubles per 1 m2 |

Waterproofing rolls in stock

- Then he repeated the procedure two more times. For your region, you may need less or, conversely, more layers of bitumen with waterproofing, depending on the corrosive activity of the soil, which is affected by its moisture level, chemical composition, acidity and structure;

Protecting a gas pipe with bitumen waterproofing

- Polyethylene . It is worth noting two completely different situations:

- The first includes the personal execution of the plan. This method can be called the easiest to implement, since you just need to wrap the pipe in several layers with polyethylene cloth and secure it with mounting tape. But this material itself has low strength characteristics, so I would be careful not to use it to protect long sections of the highway;

- In the second, we are talking about the factory application of reinforced extruded polyethylene. That is, you buy metal pipes that have a special protective layer. Of course, such products will cost more, but they will provide quite effective protection against corrosion;

Factory application of extruded polyethylene to a steel pipe

- Polyurethane foam . Here you can also take two roads, but in any case it is worth immediately noting the very high thermal insulation qualities of the finished anti-corrosion protection:

- Use special polyurethane foam shells . They are two halves of a cylinder, which are put on the pipeline on both sides and are joined to each other, creating a tight connection;

Ready-made casings for water and gas pipelines

- Injection of liquid polyurethane foam between the pipe body and a pre-installed sheath of extruded polyethylene or other suitable insulating material. After the substance hardens, the seams are completely absent, which, of course, significantly improves the quality of the insulation, although the process itself is more labor-intensive to implement.

Graphic representation of a pipeline, the waterproofing of which is created by pouring liquid polyurethane foam

External insulation is not limited to the above options; here you can use many more moisture-resistant materials that can take a cylindrical shape. Therefore, in any case, also be guided by the current offers of a specialized store located near you.

Gift #2: Internal Insulation

Steel pipes with internal sand-cement insulation

As I noted above, liquid transported through pipes can also provoke the occurrence of corrosive processes, and here things are somewhat more complicated. The fact is that without special equipment at home, high-quality internal insulation is impossible. Then all that remains is to order the appropriate services from specialists or immediately buy already protected products.

The most common option today is to apply a cement-sand mixture to the inner walls of the pipeline and then crimp it using a special pulled device. The result is a smooth, non-corrosive coating.

Inside view of a protected pipe

When I ordered this type of service, I was offered the following prices:

| Pipeline cross-section, mm | Cost of internal waterproofing per linear meter, rub. |

| 159 | 401,5 |

| 219 | 460,7 |

| 273 | 519,3 |

| 325 | 591 |

It is noteworthy that the instructions allow processing of both new metal pipes and old ones.

petroleum bitumen can also be . In this case, products with a large cross-section are dipped into a liquid solution, and the joints are then processed manually. And samples with a small diameter are coated after welding, by passing a mixture with a hollow copper cylinder through them under the influence of a direct electric current. Due to the influence of electricity, bitumen particles adhere tightly to the iron, creating a thin, reliable film.

Pipe with internal bitumen insulation

Gift #3: Active Insulation

This includes electrical protection methods, which I was quite able to implement on my own. Here is their description:

- Cathodic protection:

- We apply a negative potential to the pipeline, transferring it to the cathode zone;

- Next to the pipes we bury iron pipes , pieces of rails or other ferrous metal products that will take on the role of an anode;

A steel rail is quite suitable as an anode.

- We connect a source with negative direct current to the pipeline;

- We connect a source with positive direct current to a rail or other product that you used as an anode;

- This creates a closed circuit of electric current , which flows from the positive pole to the anode grounding, spreads over the ground, hits the pipe and then to the negative pole;

Scheme for implementing cathodic protection of a water supply main

- Since current comes out of the rails in the form of positive metal ions, it is the rail itself that is gradually destroyed, and not the pipe . So much for chemistry;

- Tread protection. It is much easier to implement, since it does not require an external power source . This is the option I prefer to use:

- We place a rod of metal next to the water supply, which has a negative chemical potential , which exceeds that of steel. This may be a product made of zinc, magnesium or aluminum;

- We connect it to the protected structure using a cable;

I also recommend filling the protector with a special mixture of salts, which facilitates the process of its corrosion and thereby increases the performance of its protective functions.

The diagram shows the tread protection of pipelines

| Symbol | Element |

| 1 | Priming |

| 2 | Protected pipeline |

| 3 | Metal protector with high negative chemical potential |

| 4 | Salt mixture |

- The entire impact will fall on the anode protector, excluding pipe corrosion;

- Once the zinc or magnesium rod is completely destroyed, it must be replaced;

- Drainage. With its help, pipelines are protected from stray currents:

- We connect the pipe with a cable to the nearest electrified source , through which the currents that enter it are returned;

- Metal ions stop going into the soil, due to which corrosion processes stop.

Thus, all active methods of protection come down to preventing the loss of metal ions due to “sacrifice” or getting rid of stray currents.

I recommend using an integrated approach to waterproofing your pipeline. That is, combine external, internal and active protection. This will give the most effective result, allowing you to extend the operational life of the highway for decades.

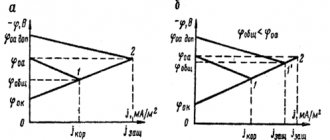

Cathodic protection

Cathodic protection is another method of protecting metal pipelines from corrosion, fundamentally different from those discussed above. It is based on the electrochemical theory of corrosion, according to which corrosion is associated with galvanic vapors that are formed in the area of contact of metals with the soil environment, and the destruction of metals occurs in places where current flows out of it into the environment. Consequently, if you connect an external source of direct current and direct the current into the ground through old iron pipes, rails and other metal objects previously buried near the pipeline, then the surface of the pipeline will turn into a cathode, which will protect it from the destructive influence of galvanic couples. And the current must be diverted from the pipeline through a special wire to the negative pole of an external source. The disadvantage of this method is that it requires energy, so it is often used as an additional, but not the main method.

Application of anti-corrosion coating

The method of applying anti-corrosion coating depends on the selected coating material and requires an individual approach. However, there are uniform rules that apply in any case:

- The surface is prepared: cleaned of scale, rust, old protective coating, paint;

- Clean the cleaned surface;

- The surface is degreased using special compounds;

- Clean using a sand or shot blasting machine with fine sand;

- Treated with detergents to clean the deep layers of the product;

- Rinse the surface;

- Dry the surface before applying the main protective coating;

- Each layer of protective coating applied is thoroughly dried.

Anti-corrosion painting of pipes is most often used, since this material is widespread, affordable in price, easy to apply (spray or roller applied) and durable.

Equipment used for anti-corrosion treatment of pipes

Depending on the type of protective coating, special equipment is used, for example, an electric arc metallization installation (allows the application of metal coatings), plasma spraying installations, cold galvanizing installations for steel products (for paint and varnish products), spraying installations (primers and paints and varnishes) ), roller.

It is mandatory to comply with safety precautions when performing work. The specialists performing the processing must wear special protective uniforms.

Removing water pipes from electric transport routes

Corrosion of metal pipes can be facilitated by the influence of stray currents, which are especially exposed to pipes laid near the tracks of intra-factory or urban electric transport. This can be avoided in two ways - by removing water pipes from electric transport tracks and adhering to the well-known rules for constructing rail roads for electric transport.

The listed methods for protecting water pipes from corrosion are usually used in combination. These methods summarize the experience of many years of practice and various technical studies, so their effectiveness is not only proven, but also tested by life.

Protecting pipelines from corrosion will extend their service life

All pipeline protection methods have a large number of advantages. They are:

- increasing the strength level of pipes,

- increasing the level of resistance to the influence of an aggressive environment,

- extending the service life of pipelines of various types,

- increasing the hardness of the pipe surface both inside and outside.

Thanks to all protection methods, it is possible to ensure a long service life of all pipelines. They give them the opportunity to serve for at least ten years.