Greetings to dear readers! In this material I tried to collect all the data about PIC solder. This Tin-Lead Solder is the most popular solder for mounting radio components and is used more often than others in radio engineering. I will try to explain why this is so and tell you about the types and technical characteristics of POS series solders. I’ll also tell you a terrible secret about POS-60 and POS-62 solders. Go!

Types of POS solders

First, let's remember what types of solders are made from alloys of the tin-lead group. The most popular are antimony-free solders POS-10, POS-40, POS-61 and POS-90. POS solder containing antimony is called POSSU. Antimony in the solder adds several percent to its strength.

When we talk about melting a mixture of tin and lead, we need to remember the definitions of solidus and liquidus . When any mixture of two or more metals is heated, the melting (transformation from solid to liquid phase) of the lightest particles occurs first. This temperature mark is called the solidus of the alloy.

With a further increase in temperature, more refractory components begin to melt. As soon as they melt, the liquidus . The PIC solder is now completely melted. This process is explained in more detail by a picture taken from a presentation on the topic of alloys.

Between these two points is a state of increased ductility of the solder . In this state, the solder can be pulled and deformed without losing integrity.

There are eutectic alloys - solders, in which the solidus and liquidus points coincide. This is very convenient when soldering and indicates the high quality of the solder.

Types of tin solders, properties and characteristics

According to the chemical composition of the alloy, antimony solders, solders with a small amount of antimony (low-antimony), and alloys without antimony (antimony-free) are distinguished. All of the above types of solders are produced in accordance with GOST 21931-76 (in products), GOST 21930-76 (ingots).

There is another option for classifying tin solders. According to it, alloys are divided into:

— tin-lead (abbreviated POS);

- antimony (abbreviated POSSu);

— tin-lead-cadmium (abbreviated POSC);

- lead-free.

The latter are alloyed with copper, silver, zinc, aluminum, and cadmium.

POS tin solders (tin-lead alloys), having a tin percentage of 10% to 90%, are classified as soft solders.

They begin to melt at 183°C (the melting temperature of the tin-lead pair) and complete melting at different temperatures. This is determined by the chemical composition of the alloy. Namely:

POS-15 (tin 15%) - 280 °C.

POS-25 (25%) - 260 °C.

POS-35 (33%) - 247 °C.

POS-61, POS 63 (tin 61% and 63%) - 183 °C

POS-90 (tin 90%) - 220 °C

Due to the fact that the composition of the POS-61 and POS-63 alloys is almost identical to the composition of the tin + lead eutectic, they melt at a constant temperature of 183 °C.

Soft tin solders also include:

— POSSu – used for soldering products made of zinc, galvanized metal, with high requirements for solder joints (antimony solders);

— OTs — for joining aluminum products (tin-zinc solders);

— POSK — for connecting products that react to overheating, piezoceramics, capacitor leads (tin-lead-cadmium);

- lead-free solders, which in addition to tin include silver, copper, bismuth and other metals.

Solder is an alloy consisting of low-melting metals. For example, tin. But soldering with tin alone is quite expensive. They work with pure tin only when it is necessary to obtain a junction that is absolutely harmless to humans: when soldering utensils for food consumption or medical equipment. In other cases, to reduce the cost of solder, cheaper but harmful lead is added to tin.

For reference: the surface of the solder is darker, the more lead it contains. A rod made of pure tin, when bent or compressed, produces a characteristic crunch.

The positive properties of tin solders include:

— strength combined with ductility;

— high thermal conductivity coefficient;

- corrosion resistance.

Tin solders are used to join parts made of almost all metals, and the more pure tin in the solder, the better the quality of the resulting connection. The advantage of PIC is its versatility. Soft solders are used in the form of sticks (rods); less often, wire or paste (a mixture of solder with a fluxing agent) is used. The more tin in the alloy, the stronger the connection between the parts when soldering.

This type of rolled tin is not used for soldering aluminum. Other metals, including copper and iron, lend themselves well to PIC soldering. The junction is the most vulnerable point of the metal-solder-metal connection. The strength of the solder depends on the chemical composition of the solder used. The tensile strength of the soldering area is 6-8 kg/mm2, increasing in proportion to the increase in the amount of tin.

Let's look at some features of using zinc and antimony as additives to solder when soldering certain metals. The addition of zinc when working with aluminum and alloys of this metal increases the corrosion resistance of the solder. Such CO solders, containing from 10% to 40% zinc, are used for ultrasonic or abrasive soldering and tinning.

When joining copper, adding antimony to the composition increases the strength of the joint. When soldering brass, antimony does not affect the strength of the joint. And iron reduces the strength of the joint.

Sometimes you can find a rod or wire for soldering without markings. The approximate chemical composition of such a product can be determined using the following parameters:

- a rod with a tin content above 60% shines brightly (perhaps it is POS-90, POS-61);

- material containing a lot of lead - dark gray, matte;

— a rod with a significant lead content is plastic (up to 60%), it is easy to deform (POS-40, POS-30);

- a rod with a lot of tin, strong and hard. It cannot be bent by hand;

— PIC of various brands melts at temperatures from 183 °C to 265 °C.

About the composition of solder

The name of the solder of the tin-lead group indicates the tin content in it. For example, POS-40 contains 40% tin, and POS-61 contains almost 61% tin. The rest consists of lead and additional impurities. By appearance, you can estimate the composition . If the PIC solder is more matte and dark, then it contains more lead. If it is lighter and shiny, then there is more tin. This is best understood by comparison. Look at the photo to see what a sheet of tin and a sheet of lead look like.

The strength of solder depends not only on the alloy alloy, but also on the metal being soldered. For example, to solder copper or zinc, several percent of copper or zinc are added to the POS solder, respectively. This reduces chemical erosion of the metal and increases the surface strength of the joint.

Solder alloying

To improve performance characteristics, alloying of solder with the following substances is used:

- adhesion is improved by the addition of copper, cadmium, antimony, aluminum, silver and zinc;

- ductility and resistance to thermal cycling are improved by the addition of indium, silver, manganese, bismuth, and lithium;

- Nickel, cobalt, zinc, silicon, boron, iron add strength

- The corrosion resistance of solder is increased by nickel and copper;

- Heat resistance is increased by silicon, zirconium, tungsten, vanadium, cobalt, niobium, hafnium.

Basic properties

Wettability

Melting temperature

Regardless of the type of solder, the melting point of any type should not be higher than the temperature of the parts being soldered. However, it must be higher than the operating temperatures of the materials so that the solder does not melt during operation of the soldered device.

There are two temperature thresholds in this matter. The first is the temperature at which the melting of the most fusible components of the solder just begins, and the second is when all the solder has turned into liquid. The interval between these two values is called the solder solidification interval.

If the place connected by soldering is at a crystallization temperature, then the soldering place can quickly collapse, even from a small load, since the connection will have increased electrical resistance and fragility. When soldering, you need to know that until the solder has completely hardened, you cannot apply any loads to it.

Properties of solders

Any solder composition should not contain substances that have toxic properties to humans beyond the norm. Solders for soldering must have the properties of thermal stability and electrical stability. When choosing a solder, the thermal conductivity of the solder and its thermal expansion are taken into account. They must be level with the soldered parts.

Types of solders

All solders for soldering are divided into hard and soft. The melting point of hard solders is more than 450 degrees, and soft solders - up to this value.

Soft solders for soldering

The most popular of them are alloys of tin and lead with different percentages. To impart special properties to the solder, auxiliary components can be added to it. Cadmium and bismuth are used to reduce the melting point. Antimony increases soldering strength.

Tin and lead solders have a low melting point and low strength. It is better not to use such solder for critical parts. If you have to soft solder parts that are subject to heavy loads, it is recommended to increase the soldering area of the parts.

POS-40 is used for non-critical parts that do not require special precision. The soldering area can be heated to a high temperature. POS-30 goes well with brass and copper, as well as steel alloys.

Brazing alloys for soldering

Among hard solders with a high melting point there are two groups: alloys of copper and silver. Copper types of solders include solders based on zinc and copper, which are well combined for connections intended for static loads. These alloys are brittle, so they should not be used for soldering materials subject to shock or vibration.

Other types of solder

There are other types of solder that are rarely used. They are necessary for soldering rare metals, or for special special conditions. There are nickel-based solders used for parts operating at high temperatures or made of stainless steel. Gold solders are used for vacuum tubes. Magnesium solders are also available.

Expert opinion

It-Technology, Electrical power and electronics specialist

Ask questions to the “Specialist for modernization of energy generation systems”

Solders for soldering. Types and properties. Composition and fluxes. Melting The most optimal solder option for stainless steel is pure tin solder, especially if the soldering will come into contact with food products. Ask, I'm in touch!

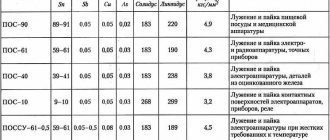

Technical characteristics of POS and POSSu solders

In order not to describe all the technical characteristics of solders of the tin-lead group, I will simply provide a table of parameters. It can be used to determine the melting point, density, electrical resistivity, thermal conductivity, tensile strength, elongation, impact strength and Brinell hardness of solders.

An analysis of the table shows that the most fusible among the list is cadmium with a melting point characteristic of 145 degrees Celsius. The strongest solder is POSSu 4-6 solder with a tensile strength of 6.5 kgf/sq.m. mm.

Technical characteristics of POS-10 solder

POS 10 solder has a distinctive chemical composition. It contains 9-10% tin, about 89% lead, 0.2% bismuth, 0.1% antimony and other impurities in small quantities. POS-10 solder is used for soldering and tinning contact surfaces of electronics. For example, they solder relays and fill control plugs in radio electronics housings.

The POS-10 soldering temperature is 299 degrees Celsius. The solidus point is 268 degrees.

Advantages of POS-10 solder:

- high melting point is useful when soldering equipment cases.

Disadvantages of POS-10 solder:

- low strength and tensile strength of about 3.2 kgf/sq.mm.;

- high resistivity - 0.2 Ohm x sq.mm./m;

- high content of lead, which is hazardous to health.

Melting temperature

To solder thick wires, use solder with a higher melting point than for soldering thin wires. In some cases, the conductivity of the solder must also be taken into account (reminder: the resistivity of tin is 0.115 ohm x mm2/m, and that of lead is 0.21 ohm x mm2/m).

More homemade products: How to make a paper pyramid with your own hands - steps with photos

For soldering transistors, you can use the so-called Wood's alloy with a melting point of 75 ° C, which contains: tin - 13%, lead - 27%, bismuth - 50%, cadmium - 10%. Wood's alloy can be prepared according to the specified recipe yourself or purchased at a pharmacy. Soldering is carried out with a weakly heated soldering iron. Rosin is used as a flux.

Nowadays a large number of different so-called “no-clean” fluxes are produced, both liquid and in the form of a semi-liquid gel. Their peculiarity is that they do not contain components that cause oxidation and corrosion of the parts being connected, do not conduct electric current and do not require washing the board after soldering. Although it is still better to remove all flux residues from the soldered parts after completing soldering.

For soldering copper parts, both soft and hard solders are used. For repairing radio components, the former are more suitable; for soldering cores and fittings on pipes, both light alloy (1S and Rosol 3) and carbide (Rolot 2) can be used. Silver alloys are of high quality and are used to make compounds when working with copper, brass or silver. They are used when electricity must pass through the seam.

When choosing an alloy for soldering, one is guided by its melting point, the type of materials being joined, the size of the parts, the required characteristics (strength, corrosion resistance, etc.), the joining method and its complexity. When soldering aluminum, alloys based on silver, tin, zinc, copper and silicon are used (TsOP-40, POS, 34A, AVIA-1, AVIA-2, VPT-4, 34-A, P250A, P300B, etc.) .

Compared to refractory solders, the mechanical strength of low-melting solders is low. Despite this, they are often used for electrical and radio installation work. They melt already at a temperature of 183–280°C. Soft solders are made on the basis of tin and lead in various proportions with the addition of cadmium, bismuth, antimony, zinc, thallium and other metals.

More homemade products: How to remove a dent on a car with your own hands - ideas with photos

Technical characteristics of POS-30 solder

Solder for soldering of the POS 30 brand is an intermediate link between POS 10 and POS 40. The composition of POS 30 solder is as follows: 30% tin and 69.5% lead. The rest is impurities and doping. Solder POS 30 can be easily replaced with POS 40, which is described below. The melting point (liquidus) is 238 degrees, and the plasticity temperature (solidus) is 183 degrees Celsius. According to the technical characteristics, POS 30 solder is most often used for soldering and tinning of zinc sheets and radiators.

Advantages of POS-30 solder:

- good adhesion;

- high strength.

Disadvantages of POS 30 brand solder:

- high lead content;

- often produced in rods.

Technical characteristics of POS-40 solder

The chemical composition consists of 39-41% tin, 59% lead. The remaining impurities are in the same ratio as in POS-10. Soldering solder POS-40 is often used for soldering and tinning radio equipment casings made of galvanized iron with galvanized seams.

The soldering temperature of the solder is 238 degrees Celsius, and the solidus is 183 degrees.

Advantages of POS-40 solder:

- good ratio of ductility and melting point;

- because of this, it tolerates thermal cycling better than POS-61.

Disadvantages of POS-40 solder:

- high lead content, which is harmful to health;

- elevated liquidus temperature.

How POS stands for

Let's consider the main brands of tin-lead and tin solders, which are widely used today in soldering. To mark all solders containing lead and tin, a special abbreviation is used, consisting of Russian letters and numbers.

The letter “P” means solder, the letter “O” means tin solder, and the letter “C” means lead solder. The number at the end of the abbreviation POS means one thing - the percentage of tin content. For example, POS-61 or the so-called “Tretnik” contains 61% Sn, that is, tin.

The terrible secret of POS-60 solder

Now the time has come for the terrible secret of POS 60 solder . According to GOST 21930-76 entitled “Tin-lead solders in ingots. Technical specifications" and GOST 21930-76 "Tin-lead solders in products. Technical specifications", solder such as POS-60 simply does not exist. GOST 21930-76 itself can. Here is the complete table from this GOST.

So “ POS-60 ” is jargon or a popular designation for “the solder that everyone solders with.” It seems to me that this is due to confusion in the designation of POS-61. Because when the tin content in the solder according to GOST is from 59 to 61%, it is more logical to call it POS-60 rather than POS-61.

Among the solders produced according to international standards there is Sn60Pb40 solder . This is a solder solder containing 60% tin and 40% lead. It could be called POS-60, if at least specifications for it were developed. According to international data describing the characteristics, the melting point of 60/40 solder is 191 degrees Celsius.

The same story with POS-62 type solder . Such lead solder according to GOST has not yet been invented. So, if they ask me “what is the melting temperature of POS-62 solder,” I know that the answer with the figure 184 degrees Celsius must be looked for in the imported solder catalog. For example, you can use the Kester solder catalog.

Types of solders

Solder is not always necessary to purchase. You can use an old radio component and assemble it from the board tracks using a soldering iron tip. This option is perfect for those who live far from the city, where it is not possible to purchase the material in a store.

Standard lead solders.

However, they are different and differ in their properties and characteristics. In this regard, every experienced master should understand this issue. To solder parts, it is necessary to use special alloys - solders.

The latter have a lower melting point than individual parts of the products.

Such alloys are divided into two main categories depending on their melting point: soft and hard. The first type is widely used in radio electronics, both by amateurs and professionals.

Low-melting solders include solders with a melting point of less than 450°C. They are made from: gallium, indium, tin, bismuth, lead and cadmium. High-temperature ones melt when heated above 450°C. In any case, it is usually an alloy consisting of several metals and impurities.

The most common option is a tin-lead alloy called PIC. The numbers after the abbreviation indicate the percentage of tin.

You can distinguish one alloy from another without knowing the brand. For example, with a higher tin content, a characteristic metallic luster appears, and with a higher lead concentration, the color becomes dark gray.

In addition, the melting point of POS does not exceed 265°C. Another distinctive feature of alloys with a higher proportion of lead is their ductility and the ability to be easily bent by hand.

Classification of alloys is carried out in accordance with GOST standards.

Physico-mechanical properties of solders.

The most common are:

- solder POS 90;

- POS 61;

- POS 40;

- POS 30.

In fact, there are significantly more markings. There are several dozen of them. Each is written in such a way that the composition of the alloy becomes clear from its name; all are manufactured in accordance with GOST 21930-76 tin-lead solder.

It is worth noting that the alloys differ from each other not only in their chemical composition. Depending on the form of release, they come in ingots, wire, a tube with rosin, or in a rod.

For example, POS 61 solder can be sold in rods or in the form of wire of various diameters. It is important to understand that the ratio of lead to tin affects the melting point. This parameter largely determines the choice of the required alloy.

In addition, the alloy can be produced with a flux, for example, with FRK525-2-T1, a low-activity halogen-free rosin flux.

This flux contains no halogens. Thanks to this fact, it has significantly less harm to the health of masters.

The use of alloys of various grades is determined by the scope of their application. POS thirty and forty are considered soft. Their melting point does not exceed 300°C. Used in joining galvanized products, tinning, repairing electrical appliances, etc.

Technical characteristics of POS-61 solder

The designation of solder, as we found out, is quite controversial, but you can’t argue against GOST. POS-61 is used for soldering and tinning of electronic components and printed circuit boards of precision instruments with highly hermetic seams, for which overheating is not allowed.

Composition of POS-61 solder

The chemical composition of POS-61 solder is as follows:

- Tin 59 - 61%;

- Antimony - no more than 0.1%;

- Copper - no more than 0.05%;

- Bismuth - no more than 0.02%;

- Arsenic - no more than 0.02%;

- Iron - no more than 0.02%;

- Nickel - no more than 0.02%;

- Sulfur - no more than 0.02%;

- Zinc - no more than 0.002%;

- Aluminum - no more than 0.002%;

- Lead - everything else - about 38.7 - 40.7%.

The soldering temperature of POS-61 solder is 220 degrees Celsius. Solidus is 183 degrees. I even shot a slow motion video of this solder melting on my Olympus Tough TG-860 at 240fps.

Solder POS 61 GOST 21931-76 has the following technical characteristics:

- Density determines weight and is equal to 8.5 g/cu. cm.;

- The electrical resistivity is 0.139 Ohm x mm2/m;

- Thermal conductivity is 0.12 kcal/cm x s x deg;

- Temporary tensile strength is 4.3 kgf/sq.mm.;

- The relative elongation is 46%.

Advantages of POS-61 brand solder:

- the best ratio of melting temperature and strength;

- good adhesion to metal surfaces;

- universal solder for soldering and most radio installation work;

- accessibility and prevalence;

- low cost;

- often produced in the form of wire, for example POS 61 T2A solder.

Disadvantages of POS-61 type solder:

- versatility reduces performance in special cases, for example when soldering zinc;

- melting temperature is not suitable for all devices;

- solder fumes (lead in it) are harmful to health.

Low temperature solders

Chemical composition of different types of solders.

Low-temperature alloys are used for soldering radio components that are sensitive to high temperatures. These include: POS 40 solder and POS 30 solder. They are widely used in industry, but they are also taken for private use.

POS 30 is excellent for soldering copper and non-copper based alloys. It is used both as a filler material and for tinning parts. A special feature of this brand is the absence of antimony in its composition.

POS 30 makes it possible to obtain reliable sealed connections, which has led to the active use of the material for pipeline systems. In addition, it is characterized by good conductivity and low resistance, which allows it to be used for making small contacts.

The low melting point allows you to avoid overheating of radio components during soldering. At the same time, after hardening, it reliably fixes parts of the product.

From a technical point of view, soldering with this alloy is quite easy. However, it should be borne in mind that if it is used, the parts should not operate at high temperatures.

POS 30 is produced in the form of wire of various diameters from 0.5 to 8 mm. The thickness is chosen based on the problems that need to be solved. To connect small wires and parts, the smallest option is perfect. But repairing cases and soldering large products is easier to do with 8 mm wire.

POS 40 solder has similar technical characteristics to POS 30. It also does not contain antimony. It belongs to the low temperature class. The densities of the noted alloys and the onset of melting temperature are also the same.

They differ from each other, of course, in composition. This is evidenced by the numbers at the end of their markings.

Types of lead-free solders.

POS 40 allows you to obtain high-quality and reliable connections. When working with it, no cracks appear, and there are no unsoldered areas or other defects. Low resistance and good conductivity make it possible to use PIC for soldering electronics.

As noted above, this solder has a low melting point. This also imposes restrictions on the use of products soldered using it.

The most common form of alloy production is wire. Its diameter varies from 0.5 to 7 mm. However, it also exists in the form of rods, foil strips, and small tubes.

Another low-temperature solder is POS 61. However, it contains antimony. The alloy has fairly good ductility. Most widely used for soldering semiconductor equipment. The resistivity of POS 61 solder is 0.139 Ohm*mm2/m.

It is produced in the form of metal ingots weighing about 25 kg, rods with a cross-section from 8 to 15 mm, and wire with a diameter from 0.5 to 6 mm. There are also form factors such as tapes, anodes and tubes.

Technical characteristics of POS-63 solder

Solder POS 63 is described in GOST and in the industry standard OCT 4G 0.033.200. POS-63 solder is understood as an alloy that consists of 63% tin and 37% lead. This is a kind of modernization of POS-61 solder, adjusted to the international standard J-STD 006B. Most are also labeled Sn63Pb37 . These are eutectic alloys with a melting point of 183 degrees Celsius.

POS-63 is used for soldering and tinning the leads of microcircuits and packaged radio components, printed circuit boards, wires and cables. In general, of modern solders, this is the most common. The technical characteristics of POS 63 solder are approximately the same as those of POS-61. But I haven’t found the exact values yet.

Advantages of POS-63 solder:

- the most common POS series solder;

- relatively low melting point;

- coincidence of solidus and liquidus points;

- low cost;

- supplied in the form of wire filled with flux.

Disadvantages of POS-63 solder:

- often counterfeited, especially by the Chinese;

- contains lead, which increases the cost of recycling electronic equipment in accordance with modern safety standards.

Composition and characteristics

Chemical components

It was previously mentioned that PIC solder consists of an alloy of tin and lead. Tin has a lower melting point than lead, so by varying the percentage of these two components, you can select certain temperature characteristics. POS 60 has the following chemical compounds in its composition:

- Tin. The share is 59–60.5% of the total mass.

- Lead. The percentage content ranges from 39 to 40.5% by weight of POS.

- Impurities. They are represented by various elements such as copper, iron, antimony, nickel, zinc and others. Their mass fraction is no more than 0.3% of the total mass of the alloy.

Chemical composition of POS61 solder

The addition of copper or germanium significantly increases the wettability, as well as the strength of the solder joint; such an alloy is labeled POS-60M.

Other metals also influence the technical properties of the solder alloy.

Physical properties

The large amount of tin contained in this brand of solder directly affects its temperature characteristics and physical properties. Thus, POS 60 has the following properties:

- Melting point 183-190 degrees Celsius.

- Density 8.5 grams per cubic centimeter.

- The resistivity is 0.137 ohms per meter, which is 9–15% of the conductivity of copper.

- The tensile strength corresponds to the limit for soft solders and is equal to 50–70 MPa.

- The Brinell hardness is 14.9 PV.

- Thermal conductivity is 0.117 W/(m×k). Tensile strength is 4.3 kg/mm.

Physical properties of POS 60 and other solders

It is worth noting that tin and lead are identical in both softness and viscosity. Both of these metals have a characteristic of 1.5 on the Moss scale, so their percentage does not affect the physical properties of the solder.

Technical characteristics of solder POSSu-61-0.5

Solder marking POSSu-61-0.5 indicates a type of antimony solder containing 61% tin, up to 0.5% antimony and about 38% lead. This solder is used for soldering and tinning of printed circuit boards and galvanized radio components under increased operating temperature requirements. But its melting point is 189 degrees.

Advantages of POSSu-61-0.5 solder:

- increased adhesion to the metal surface due to the antimony content;

- technical characteristics are almost the same as POS-61.

Disadvantages of POSSu-61-0.5 solder:

- difficult to find on sale;

- increased cost.

Dimensions

Depending on the scope of application, wire or tube with flux are produced with a diameter of 0.5 to 5 millimeters. As mentioned above, the intended purpose of this form of solder is radio electronics. POS rods are available in four diameters: 8, 10, 12 and 15 mm. They are used when soldering metal structures, for example when installing copper heating pipes, where thin wire will have a high consumption. Tinning tapes also have a certain thickness, depending on the width of the tape. With a width of up to 10 mm, the tape has a thickness of up to 1 mm, and a tape with a width of 10 to 15 mm can have a thickness of up to 5 mm.

Solder POS60 with a diameter of 1 mm

Technical characteristics of POS-90 solder

POS-90 brand solder consists of 90% tin and 10% lead. It also contains about 0.1% antimony and 0.05% copper. It is mainly used for soldering and tinning internal seams of food utensils and medical equipment. Yes, 10% lead can already be put into food products - surprisingly, everything is in accordance with GOST 1976. According to the technical characteristics, the melting temperature of solder type POS 90 is 220 degrees.

Advantages of POS-90 solder:

- low lead content;

- rarely counterfeited;

- low resistance;

- high strength.

Disadvantages of POS-90 brand solder:

- high cost (higher than pos-61);

- low plasticity.