A variety of filler materials can be used to significantly improve the quality of the joint created by soldering. The most popular category is solders. Their distinctive feature is that their composition is selected directly for a specific metal or alloy. This leads to a large number of different models of solders present on the market. If you take into account the characteristics of the material you are working with and choose the right consumables, you can achieve a connection of the highest possible quality. This article will examine the PIC model solder inside and out. 90.

Specifications

The main element in the chemical composition of this filler material model is tin. However, despite this, the temperature point at which the solder begins to undergo the melting process is at an average level. Also, to obtain the unique properties of solder, various additional chemical elements can be added to its basic composition.

It is worth noting that the consumable material of this model has a fairly high level of fluidity in the molten state, which allows it to penetrate even the smallest cracks during operation, which undoubtedly increases the quality of the final joint result. You can also highlight the property of wettability.

Due to the fact that it is quite high, working with filler material of this model does not cause difficulties. The production of POS 90 solder and all its modifications in our country is carried out in strict accordance with state standards.

Solder POS90/Evek

Designation

| Name | Meaning |

| Designation GOST Cyrillic | POS90 |

| GOST Latin designation | POC90 |

| Transliteration | POS90 |

| By chemical elements | PSNPb90 |

Description

POS90 solder is used : for the production of ingots, round wire, round rods with flux tubes, powder for tinning and soldering internal seams of food utensils and medical equipment.

Note

Tin-lead solder without antimony.

Standards

| Name | Code | Standards |

| Non-ferrous metals, including rare ones, and their alloys | B51 | GOST 21930-76, GOST 21931-76, GOST 28873-90 |

Chemical composition

| Standard | S | Ni | Fe | Cu | How | Al | Zn | Sn | Sat | Pb | Bi |

| GOST 21930-76 | ≤0.02 | ≤0,02 | ≤0,02 | ≤0,05 | ≤0,01 | ≤0,002 | ≤0,002 | 89-91 | ≤0,1 | Rest | ≤0,1 |

Sn is the base.

Mechanical properties

| σ U, MPa | d | KCU, kJ/m2 | HB, MPa |

| Pig in delivery condition | |||

| ≥48.07 | ≥40 | ≥411,6 | ≥15.4 |

Description of mechanical signs

| Name | Description |

| σ U | Short-term headcount limit |

| G | Elongation after break |

| KCU | Strength |

| HB | Brinell hardness number |

physical characteristics

| Temperature | r, kg/m3 | l, W/(m °C) | R, g. M |

| 20 | 7600 | 5443 | 120 |

Description of physical symbols

| Name | Description |

| l | Coefficient of thermal conductivity |

| WITH | Specific heat |

.

Application

Solder POS 90 is a universal substance. It can be used both at home with conventional equipment and in factories with specialized equipment. A few words can be said about the wide range of applications. Solder can be used when soldering copper, brass, zinc, etc. products, which significantly expands the scope of its application.

Due to the fact that with the help of soldering using solder, this model can create a completely sealed connection, it is used when working with products whose working activity takes place in constant contact with water and other liquids, as well as gases.

The absence of any difficulties with the proper skill determines the high level of popularity of this model of filler material intended for soldering. Separately, we can highlight the ability to conduct electric current. This opens up the possibility of using solder of this model for working with microcircuits, radio components, etc. The low temperature point at which the material begins to melt allows the use of solder for working with thin metal. One significant drawback can be noted - a product soldered with POS 90 solder cannot operate at high temperatures, since the joints simply begin to melt.

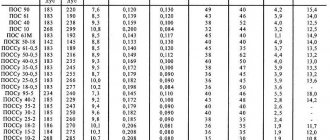

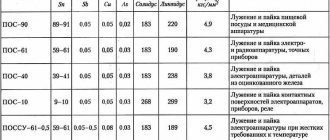

What brands of POS are there and where are they used?

POS-90 - this solder with a high tin content is used for soldering the following metals: brass, copper, bronze, steel, as well as some others. In terms of its chemical composition, POS-90 consists of almost 100% pure tin, and only 10-11% of its content is lead.

Thanks to this composition, POS-90 has high impact strength, and soldering using this solder has good tensile strength. POS-90 is characterized by plasticity and high thermal conductivity. The resulting connection with this solder is distinguished by its quality and durability.

POS-63 and POS-61 - the first POS brand was widely used in soldering printed circuit boards and microcircuits. POS-61 is especially indispensable in radio electronics. Solder is excellent for soldering radio components and measuring equipment, given its special composition.

Possessing low density and high ductility, as well as a low melting point, POS-63 has good corrosion resistance. Due to the presence of bismuth in the composition, POS-63 shows decent characteristics.

As for the POS-61 brand, it is universal in its kind. This brand of tin-lead solder is used for soldering a variety of products made of non-ferrous metals. The melting point of POS-61, like POS-63, starts at 180 degrees.

Modifications of POS 90 solder

The filler material for soldering model POS 90 is available in several different variations, which may differ from each other in chemical composition, mechanical properties and shape. You can purchase POS 90 in specialized stores in the following forms.

- In the form of a wire. The most common type of solder in the form of wire is a model with a diameter of three millimeters. It can also take values in the range from 0.5 to 8 millimeters. It is worth noting that solder in this form is the most common among both amateurs and professionals.

- In the form of a ribbon. The main purpose of solder of this form is its use when working with metal sheets of large size but small thickness. The dimensions of the tape can take on various values.

- In paste form. This is the rarest variety. Its distinctive features are that the substance does not require pre-melting before use.

- In the shape of a tube. The peculiarity of this version of the POS 90 filler material is that there is some additional material in the structure of the material (in the empty space of the tube). Most often it is rosin or flux; therefore, soldering with solder of this modification does not require any additional materials.

Technical characteristics of tin-lead solder brand POS 90

In order for metal to be soldered to a higher level of quality, a variety of solders are used, the properties of which are selected for a specific type of metal, for which alloys are created from several elements in appropriate proportions. One such example is POS 90 solder. This product is based on a special material that is created on the basis of tin and lead. Moreover, in this case it is one of the most unique in the series, which includes POS 61 solder and others. It has the highest tin content, but the melting point is not the lowest, as expected, but is at an average level. Moreover, they can be either tin-lead solders without antimony, or contain this element in their composition. The physical properties of the material provide sufficiently high fluidity, resulting in better bonding. The molten solder penetrates into all irregularities, filling them with itself, after which it solidifies over the widest possible joint area. There is also good wettability, thanks to which the soldering process itself is much more comfortable, since there are no problems with the distribution of the material on the surface of the base metal. Solder POS 90 is manufactured in accordance with GOST 21931-76.

Solder POS 90

The properties of the material are excellent for both home use, using standard tools, and professional use in industry. The ability to interact with almost all basic materials, such as copper, brass, zinc, etc. also plays a role here. Thus, it can be used to solder copper pipes, connect wires, solder contacts in radio components, and so on. Taking into account the fact that the melting point of the solder here is less than 450 degrees Celsius, it is classified as low-melting and can be used not only as a material for creating a seam, but also for tinning. Due to the ability to create hermetic connections, the material is actively used for sealing cracks in pipes and other containers. In other words, POS 90 solder can be used for all common situations.

Solder POS 90 GOST 21931-76

The alloy has become widespread due to the absence of defects during soldering. After hardening, a dense layer is obtained that is attached to the base material. This also includes good conductivity properties, which help create high-quality contacts whose resistance will not interfere with the correct operation of the device. The main thing is to correctly determine the temperature regime and the thickness of the wire. The low melting point helps avoid burning the base metal. But there is also another feature that does not allow finished products to be used at high temperatures. This can lead to the joint melting and the solder simply draining away.

Varieties

Propoy POS 90 is available in several different versions, which differ in their appearance and structure. Among the main ones are the following:

- Wire. This is an alloy supplied in coils, where the wire thickness can range from 0.5 to 8 mm. The most common solder is POS 90 3 mm. Wire is the most convenient and affordable option.

Solder POS 90 in the form of wire

- Ribbon. Long, fairly wide strips of varying thicknesses that are well suited for soldering sheet material. It is also a convenient method that can be used for various procedures.

- Paste. The material is very easy to use, as it does not require preliminary melting to apply it to the surface. After application, you can already solder the material directly on the workpiece.

- A tube. The main feature here is the rosin content inside. This makes the process more convenient and simpler, since all materials are already selected and fastened together.

Solder POS 90 with rosin

Chemical composition

| Composition element name | Approximate content in solder,% |

| Tin | 90 |

| Lead | 9-10 |

| Antimony | 0,5 |

Physical properties

| Property name | Meaning |

| Melting point | 220 degrees Celsius |

| Full melt temperature | 183 degrees Celsius |

| Material Density | 7.9 kg/cubic meter |

| Alloy elongation | 58% |

| Temporary resistance to mechanical stress at break | 47 MPa (or 4.9 kgf/mm square) |

| Crystallization interval | 37 degrees |

Range and sizes

| Wire diameter, mm | Possible error, mm |

| 0,5 | 0,05 |

| 0,6 | 0,06 |

| 0,8 | 0,08 |

| 1 | 0,1 |

| 1,2 | 0,09 |

| 1,5 | 0,1 |

| 1,8 | 0,1 |

| 2 | 0,1 |

| 2,5 | 0,12 |

| 3 | 0,15 |

| 3,5 | 0,17 |

| 4 | 0,17 |

| 5 | 0,17 |

| 6 | 0,18 |

| 7 | 0,2 |

| 8 | 0,2 |

Examples of decoding markings

The marking of this solder shows what elements are included in its composition, as well as which group it belongs to:

- POS – tin-lead solder. It is part of a large group of soldering materials. It presents several different options that differ in the ratio of the elements included in it.

- 90 – percentage of tin. The rest of the space is occupied by lead, as well as other elements that are presented in much smaller proportions, but still affect the properties of the solder.

Manufacturers

This filler material is produced by the following companies:

- UkrInterstal;

- Ukr-Spetssplav;

- "Technological Lines";

- Vadis-M;

- Arsenal;

- Technoscrap;

- KievColorMet.

Chemical composition and physical and mechanical properties of POS 90 solder

The chemical composition of the material includes three elements that are present in the composition of the material in the following percentage ratio:

- Sn – 90;

- Pb – from 9 to 10;

- Sb – 0.5.

This set of chemical elements based on the composition of the filler material provides it with the following physical and mechanical properties:

- the temperature mark at which the material begins to undergo a melting process is 220 degrees Celsius;

- the density of the material is 7.9 kilograms per square meter of working surface;

- the material is capable of increasing relative to its original size by about sixty percent;

- tensile strength is 47 MPa.

Chemical composition

| Composition element name | Approximate content in solder,% |

| Tin | 90 |

| Lead | 9-10 |

| Antimony | 0,5 |

Physical properties

| Property name | Meaning |

| Melting point | 220 degrees Celsius |

| Full melt temperature | 183 degrees Celsius |

| Material Density | 7.9 kg/cubic meter |

| Alloy elongation | 58% |

| Temporary resistance to mechanical stress at break | 47 MPa (or 4.9 kgf/mm square) |

| Crystallization interval | 37 degrees |

Range and sizes

| Wire diameter, mm | Possible error, mm |

| 0,5 | 0,05 |

| 0,6 | 0,06 |

| 0,8 | 0,08 |

| 1 | 0,1 |

| 1,2 | 0,09 |

| 1,5 | 0,1 |

| 1,8 | 0,1 |

| 2 | 0,1 |

| 2,5 | 0,12 |

| 3 | 0,15 |

| 3,5 | 0,17 |

| 4 | 0,17 |

| 5 | 0,17 |

| 6 | 0,18 |

| 7 | 0,2 |

| 8 | 0,2 |

Examples of decoding markings

The marking of this solder shows what elements are included in its composition, as well as which group it belongs to:

- POS – tin-lead solder. It is part of a large group of soldering materials. It presents several different options that differ in the ratio of the elements included in it.

- 90 – percentage of tin. The rest of the space is occupied by lead, as well as other elements that are presented in much smaller proportions, but still affect the properties of the solder.

Nomenclature and marking

The filler material for soldering model POS 90 is available in a fairly diverse range of sizes. In specialized stores you can purchase solder, the diameter of which is equal to the following values:

- 0.5 and 0.6 mm;

- from 0.8 to 1.2 mm in increments of two tenths of a millimeter;

- 1.5 and 1.8 mm;

- from 2 to 4 mm in increments of five tenths of a millimeter;

- from 5 to 8 in steps of one millimeter.

The marking of the filler material allows you to find out the category to which it belongs and the percentage of the dominant chemical element in the composition. In this case, the abbreviation POS tells us that solder belongs to the group of tin-lead materials, where the dominant element in the composition is tin. Accordingly, the number indicates the percentage of tin.

The production of solder for soldering the POS 90 model is carried out by a fairly large number of different companies, including Vadis-M, Tekhnoskrap, KievTsvetMet and others.

Solder POS90 / Auremo

Designations

| Name | Meaning |

| Designation GOST Cyrillic | POS90 |

| Designation GOST Latin | POC90 |

| Translit | POS90 |

| By chemical elements | PSnPb90 |

Description

POS90 solder is used : for the production of ingots, round wire, round rods, flux-filled tubes, powder used for tinning and soldering internal seams of food utensils and medical equipment.

Note

Antimony-free tin-lead solder.

Standards

| Name | Code | Standards |

| Non-ferrous metals, including rare ones, and their alloys | B51 | GOST 21930-76, GOST 21931-76, GOST 28873-90 |

Chemical composition

| Standard | S | Ni | Fe | Cu | As | Al | Zn | Sn | Sb | Pb | Bi |

| GOST 21930-76 | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.05 | ≤0.01 | ≤0.002 | ≤0.002 | 89-91 | ≤0.1 | Remainder | ≤0.1 |

Sn is the base.

Mechanical characteristics

| σB, MPa | d10 | kJ/m2, kJ/m2 | Brinell hardness, MPa |

| Pig in delivery condition | |||

| ≥48.07 | ≥40 | ≥411.6 | ≥15.4 |

Description of mechanical symbols

| Name | Description |

| σB | Short-term strength limit |

| d10 | Elongation after break |

| kJ/m2 | Impact strength |

physical characteristics

| Temperature | r, kg/m3 | l, W/(m °С) | R, NOM m |

| 20 | 7600 | 5443 | 120 |

Description of physical symbols

| Name | Description |

| l | Coefficient of thermal conductivity |

| WITH | Specific heat |

Low tin solders

All solders that contain 50% tin or less are characterized by high melting points and tensile strength. They, just like tin-lead solders with a high tin content, have found worthy application in a variety of fields.

For example, POS-40 has received widespread use, both in large factories and in everyday life. POS-35 is especially popular in mechanical engineering and for soldering electrical equipment. But POS-30 and POS-20 are refractory solders that are used for soldering radiators and wires.